Abstract

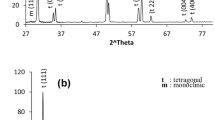

Locally found Egyptian dolomite, commercial zirconia, and alumina were used to fabricate calcium zirconate-based refractory with improved thermal shock damage resistance. CaZrO3/MgO (CZM) and CaZrO3/MgAl2O4 (CZS) green compacts were obtained by mixing dolomite, commercial zirconia, and alumina with molar ratios of 1:1.23:0 and 1:1.23:0.59, respectively, and then ball milled for 1 h and uniaxially pressed at 150 MPa. The obtained green compacts were sintered at 1200, 1300, 1500, and 1650 °C for 2 h with a heating rate of 5 °C/min. The phase composition, microstructure, densification parameters, and thermal shock damage resistance of the prepared refractory were investigated. The results showed that CaZrO3 was present as the predominant phase and c-ZrO2 as a secondary phase due to the solubility of calcium and magnesium ions in the zirconia lattice structure. CZM1500 and CZS1500 showed a bulk density of 4.05 and 3.8 g/cm3 respectively. Thermal shock damage resistance of CZM samples was greatly improved with the in situ spinel synthesis where CZS1500 was able to withstand 16 cycles before fracturing compared to 10 cycles recorded for CZM1500.

Similar content being viewed by others

References

Taib, M.: 2014 Minerals Yearbook: Egypt. U.S, Geological Surv (2017) https://minerals.usgs.gov/minerals/pubs/country/2014/myb3-2014-eg.pdf

El-Gameel, A.-A.M.K., Abouzeid, A.-Z.M., El-Maaadawy, K.: Metallic commodities – carbonate ores. J. Min. World Express. 6, 29 (2017). https://doi.org/10.14355/mwe.2017.06.004

Assa, F., Sharifi, L., Mirhosseini, S.H., Ajamein, H., Etemad, A.: Effect of zirconia addition on the properties of dolomite magnesia refractories used in steel industries. 18, 33–43 (2021)

Szczerba, J., Pedzich, Z.: The effect of natural dolomite admixtures on calcium zirconate-periclase materials microstructure evolution. Ceram. Int. 36, 535–547 (2010). https://doi.org/10.1016/j.ceramint.2009.09.025

Booth, F., Stabile, F.M., Bruni, Y., Gauna, M.R., Rendtorff, N.M.: Dolomite-zirconia reaction sintered bonded coarse magnesia ceramics: effect of the bonding proportion. Ceramica. 67, 151–157 (2021). https://doi.org/10.1590/0366-69132021673823095

Chen, M., Lu, C., Yu, J.: Improvement in performance of MgO-CaO refractories by addition of nano-sized ZrO2. J. Eur. Ceram. Soc. 27, 4633–4638 (2007). https://doi.org/10.1016/j.jeurceramsoc.2007.04.001

Rodríguez, E.A., Castillo, G.A., Das, T.K., Puente-Ornelas, R., González, Y., Arato, A.M., Aguilar-Martínez, J.A.: MgAl2O4 spinel as an effective ceramic bonding in a MgO-CaZrO3 refractory. J. Eur. Ceram. Soc. 33, 2767–2774 (2013). https://doi.org/10.1016/j.jeurceramsoc.2013.04.027

Szczerba, J., Madej, D., Dul, K., Bobowska, P.: Ca7ZrAl6O18 acting as a hydraulic and ceramic bonding in the MgO-CaZrO3 dense refractory composite. Ceram. Int. 40, 7315–7320 (2014). https://doi.org/10.1016/j.ceramint.2013.12.073

Serena, S., Sainz, M.A., Caballero, A.: The system Clinker-MgO-CaZrO3 and its application to the corrosion behavior of CaZrO3/MgO refractory matrix by clinker. J. Eur. Ceram. Soc. 29, 2199–2209 (2009). https://doi.org/10.1016/j.jeurceramsoc.2009.01.015

Ewais, E.M.M., Bayoumi, I.M.I.: Fabrication of MgO-CaZrO3 refractory composites from Egyptian dolomite as a clinker to rotary cement kiln lining. Ceram. Int. 44, 9236–9246 (2018). https://doi.org/10.1016/j.ceramint.2018.02.134

Schafföner, S., Aneziris, C.G., Berek, H., Rotmann, B., Friedrich, B.: Investigating the corrosion resistance of calcium zirconate in contact with titanium alloy melts. J. Eur. Ceram. Soc. 35, 259–266 (2015). https://doi.org/10.1016/j.jeurceramsoc.2014.08.031

Zhang, H., Tang, X., Zhou, C., Zhang, H., Zhang, S.: Comparison of directional solidification of γ-TiAl alloys in conventional Al2O3 and novel Y2O3-coated Al2O3 crucibles. J. Eur. Ceram. Soc. 33, 925–934 (2013). https://doi.org/10.1016/j.jeurceramsoc.2012.11.006

Ewais, E.M.M., Bayoumi, I.M.I.: Effect of hercynite spinel on the technological properties of MCZ products used for lining cement rotary kilns. Refract. Ind. Ceram. 60(2), 192–200 (2019). https://doi.org/10.1007/s11148-019-00334-w

Szczerba, J., Śnieżek, E., Antonovič, V.: Evolution of refractory materials for rotary cement kiln sintering zone. Refract. Ind. Ceram. 58, 426–433 (2017). https://doi.org/10.1007/s11148-017-0123-y

Szczerba, J., Pedzich, Z., Madej, D.: Synthesis of spinel-calcium zirconate materials. Ceram. Mater. 63, 27–33 (2011)

Ganesh, I.: A review on magnesium aluminate (MgAl2O4) spinel: synthesis, processing and applications. Int. Mater. Rev. 58, 63–112 (2013). https://doi.org/10.1179/1743280412Y.0000000001

Sinhamahapatra, S., Tripathi, H.S., Ghosh, A.: Densification and properties of magnesia-rich magnesium-aluminate spinel derived from natural and synthetic raw materials. Ceram. Int. 42, 5148–5152 (2016). https://doi.org/10.1016/j.ceramint.2015.12.035

Moorkah, H.I., Abolarin, M.S.: Investigation of the properties of locally available dolomite for refractory applications, Niger. J. Technol. 24, 79–86 (2005)

Abdelgawad, M., Li, S., Ewais, E.M.M., El-Gamal, S.M.A., Hou, X., Zhang, X., Pan, D., El-Amir, A.A.M.: Highly-stable, nondegradable M2A-reinforced YSZ ceramic composites prepared by SPS. Int. J. Appl. Ceram. Technol. 18, 472–482 (2021). https://doi.org/10.1111/ijac.13664

Abdelgawad, M., El-Gamal, S.M.A., Ewais, E.M.M., Li, S.: Effect of magnesia rich spinel on densification and stabilization behavior of monoclinic zirconia. J. Korean Ceram. Soc. 58, 276–286 (2021). https://doi.org/10.1007/s43207-020-00095-0

Jiang, L., Guo, S., Bian, Y., Zhang, M., Ding, W.: Effect of sintering temperature on mechanical properties of magnesia partially stabilized zirconia refractory. Ceram. Int. 42, 10593–10598 (2016). https://doi.org/10.1016/j.ceramint.2016.03.136

Liddle, J., Brett, N.H.: Phase equilibria in the System CaO–MgO– Al2O3–ZrO2. Br. Ceram. Trans. 84, 128–134 (1984)

Schafföner, S., Fruhstorfer, J., Ludwig, S., Aneziris, C.G.: Cyclic cold isostatic pressing and improved particle packing of coarse grained oxide ceramics for refractory applications. Ceram. Int. 44, 9027–9036 (2018). https://doi.org/10.1016/j.ceramint.2018.02.106

Schafföner, S., Aneziris, C.G.: Pressure slip casting of coarse grain oxide ceramics. Ceram. Int. 38, 417–422 (2012). https://doi.org/10.1016/j.ceramint.2011.06.064

Funding

This work was supported by the National Foreign Experts Project of the Ministry of Science and Technology (Grant number QN2021041002L).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdelgawad, M., Li, S., El-Amir, A.A.M. et al. Calcium zirconate–based refractory with improved thermal shock damage resistance from Egyptian dolomite and zirconia through in situ spinel synthesis. J Aust Ceram Soc 60, 485–495 (2024). https://doi.org/10.1007/s41779-023-00937-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-023-00937-0