Abstract

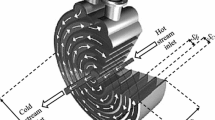

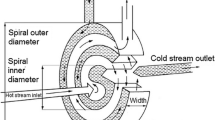

In this research, three aspects of modeling, analyzing, and optimizing spiral plate heat exchangers (SPHEs) are studied. The main objective of this work is to pave the way for comparing manufacturers’ designed SPHEs with theoretical designed SPHEs without involving designers in using computational methods. To begin, with assumption of constant overall heat transfer coefficient and specific heat capacities, a mathematical modeling of SPHE based on energy balance equations is developed to model the SPHE as a network of series-connected equivalent internal heat exchangers to determine the temperature distribution in spiral turns. This modeling can facilitate the usage of temperature-enthalpy diagram in SPHEs’ analysis and design. Furthermore, a new algorithm for thermal design optimization of SPHEs has been proposed. The proposed algorithm is based on maximizing pressure drops at channels, considering geometric proportion of SPHE and minimizing the total cost simultaneously. To show the proposed method applicability in analyzing thermal and hydraulic design parameters, a single-phase counter-current SPHE is assessed and optimized for different design cases with temperature approach variations. Results of comparing manufacturers’/standard designed SPHEs and research/theoretical designed SPHEs by defining appropriate geometric proportion ranges confirmed that temperature approach variations can improve SPHE performance to a higher extent, such as finding temperature approach ranges for optimized SPHEs with higher compactness to reduce the manufacturing cost. This fact is revealed by introducing compactness-temperature approach diagram which depicts the geometric optimization of SPHEs and the effects of temperature differences in SPHE’s optimization.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer area (m2)

- A c :

-

Free flow area (m2)

- b :

-

Channel plate spacing (m)

- c p :

-

Specific heat capacity (J/kg K)

- C :

-

Heat capacity rate ratio

- C e :

-

Energy cost (USD/KW hr)

- C i :

-

Capital cost (USD)

- C od :

-

Operational cost (USD)

- C tot :

-

Total cost (USD)

- CS :

-

Carbone steel

- D h :

-

Hydraulic diameter (m)

- D i :

-

Core or Inside diameter (m)

- D s :

-

Outer diameter of SPHE (m)

- F T :

-

Temperature difference correction factor

- GP :

-

Geometric proportion

- h :

-

Heat transfer coefficient (W/m2 K)

- H :

-

Channel plate width (m)

- Hw :

-

Work hours (hr/yr)

- HX :

-

Heat exchanger

- i :

-

Annual discount rate

- k :

-

Thermal conductivity (W/m K)

- L :

-

Plate length (m)

- M :

-

Mass flow rate (kg/s)

- M weight :

-

Molecular weight

- n :

-

Year (yr)

- N :

-

Number of spiral turns of the stream

- NTU :

-

Number of heat transfer units

- ny :

-

Equipment life year (yr)

- p :

-

Plate thickness (m)

- P :

-

Pressure (KPa)

- Pr :

-

Prandtl number

- Q :

-

Heat transfer rate (W)

- R fouling :

-

Fouling factor resistance (m2 K/W)

- Re:

-

Reynolds number

- Recr :

-

Critical Reynolds number

- s :

-

Relative density (relative to water at 20 °C)

- SPHE :

-

Spiral plate heat exchanger

- SS :

-

Stainless steel

- T :

-

Temperature (°C)

- U :

-

Overall heat transfer coefficient (W/m2 K)

- V :

-

Total volume of SPHE (m3)

- V f :

-

Fluid mean velocity (m/s)

- b :

-

Bulk fluid properties

- c :

-

Cold stream

- cr :

-

Critical

- f :

-

Fluid

- h :

-

Hot stream

- HX :

-

Heat exchanger

- i :

-

Inlet

- j :

-

Counter

- l :

-

Liquid

- max :

-

Maximum

- min :

-

Minimum

- o :

-

Outlet

- s :

-

Scale or fouling material

- w :

-

Wall plate material or at wall temperature

References

Anil M, Prasad KL, Kumar AN (2018) Performance study of spiral plate heat exchanger. Int J Res Eng Appl Manag 4(4):176–180

Bes T, Roetzel W (1991) Approximate theory of spiral heat exchanger. Design and Operation of Heat Exchangers, Proceedings of the Eurotherm Seminar No. 18, Hamburg, Germany (Edited by Roetzel W, Heggs PJ, Butterworth D (1991) springer–Verlag, Berlin: 223–232)

Bes T, Roetzel W (1992) Distribution of heat flux density in spiral heat exchangers. Int J Heat Mass Transf 35(6):1331–1347

Bes T, Roetzel W (1993) Thermal theory for spiral heat exchanger. Int J Heat Mass Transf 36(3):765–773

Bidabadi M, Sadaghiani AK, Vahdat Azad A (2013) Spiral heat exchanger optimization using genetic algorithm. Sci Iran B 20(5):1445–1454

Burmeister LC (2006) Effectiveness of a spiral-plate heat exchanger with equal capacitance rates. J Heat Transf 128(3):295–301

Chen Q, Xu YC, Guo ZY (2012) The property diagram in heat transfer and its applications. Chin Sci Bull 57(35):4646–4652

Chowdhury K, Linkmeyer H, Bassiouny MK, Martin H (1985) Analytical studies on the temperature distribution in spiral plate heat exchangers: straightforward design formulae for efficiency and mean temperature difference. Chem Eng Process 19:183–190

Dávalos LC, Luna EM, Angeles MAR, Delgado VJC (2019) Designing spiral plate heat exchangers to extend its service and enhance the thermal and hydraulic performance. IntechOpen. https://doi.org/10.5772/intechopen.85345

Devois JF, Durastanti JF, Martin B (1995) Numerical modelling of the spiral plate heat exchanger. J Therm Anal 44:305–312

Dongwu W (2003) Geometric calculations of the spiral heat exchanger. Chem Eng Technol 26(5):592–598

Energy Efficiency Office (2000) Compact heat exchangers: a training package for engineers. Energy Efficiency Office, London

Garcia MM, Moreles MA (2012) A numerical method for rating thermal performance in spiral heat exchangers. Mod Appl Sci 6(6):54–63

Guha P, Unde V (2014) Mathematical modeling of spiral heat exchanger. Int J Eng Res 3(4):226–229

Hall SG, Ahmad S, Smith R (1990) Capital cost targets for heat exchanger networks comprising mixed materials of construction, pressure ratings and exchanger types. Comput Chem Eng 14(3):319–335

Jarzębski AB (1984) Dimensioning of spiral heat exchangers to give minimum costs. J Heat Transf 106(Aug.):633–637

Kathir Kaman MD, Sathishkumar A, Balasuthagar C, Ponsankar (2017) Design and analysis of spiral plate heat exchanger for cooling applications. J Chem Pharm Sci 10(1):511–514

Khorshidi J, Heidari S (2016) Design and construction of a spiral heat exchanger. Adv Chem Engineer Sci 6:201–208

Kumar KPM, Vijayan V, Kumar BS, Vivek CM, Dinesh S (2018) Computational analysis and optimization of spiral plate heat exchanger. J Appl Fluid Mech 11:121–128

Kumar TA, Sharma N, Mohammad MN, Pradeep BT, Saichand U, Vamsi NM (2019) Optimization of spiral plate heat exchanger by gradient based optimizer. Int J Innov Technol Explor Eng 8(6):1819–1823

Kuppan T (2013) Heat exchanger design handbook, 2nd edn. CRC Press – Taylor and Francis Group, New York

Manoj V, Gopal P, Senthilkumar T (2016) Heat transfer enhancement by using nanofluid in spiral plate heat exchanger. Int J Eng Res Technol 5(6):101–105

Martin H (1992) Heat exchangers. CRC Press – Taylor and Francis Group, Washington DC

Memon S, Gadhe P, Kulkarni S (2019) Design and testing of a spiral plate heat exchanger for textile industry. Int J Sci Eng Res 10(7):149–157

Metta VR, Konijeti R, Dasore A (2018) Thermal design of spiral plate heat exchanger through numerical modeling. Int J Mech Eng Technol 9(7):736–745

Milovančević UM, Jaćimović BM, Genić SB, El-Sagier F, Otović MM, Stevanovic SM (2019) Thermoeconomic analysis of spiral heat exchanger with constant wall temperature. Therm Sci 23(1):401–410

Minton PE (1970) Designing spiral-plate heat exchangers. Chem Eng 77(May):103–112

Nguyen DK, San JY (2011) Heat transfer performance of a spiral heat exchanger. Conference: Proceedings of the 28th National Conference on Mechanical Engineering of CSME A01–008, Taiwan

Nguyen DK, San JY (2015) Effect of solid heat conduction on heat transfer performance of a spiral heat exchanger. Appl Therm Eng 76:400–409

Nguyen DK, San JY (2016a) Decrement in heat transfer effectiveness due to solid heat conduction for a counter–current spiral heat exchanger. Appl Therm Eng 103:821–831

Nguyen DK, San JY (2016b) Heat transfer and exergy analysis of a spiral heat exchanger. Heat Transf Eng 37(12):1521–0537

Picon Nunez M, Canizalez Davalos L, Morales Fuentes A (2006) Alternative design approach for spiral plate heat exchangers. Heat Transf Eng 27(6):12–21

Picon Nunez M, Canizalez Davalos L, Martinez Rodriguez G, Polley GT (2007) Shortcut design approach for spiral heat exchangers. Food Bioprod Process 85(4):322–327

Picon Nunez M, Canizalez Davalos L, Medina Flores JM (2009) Alternative sizing methodology for compact heat exchangers of the spiral type. Heat Transf Eng 30(9):744–750

Polley GT, Panjeh Shahi MH, Jegede FO (1990) Pressure drop considerations in the retrofit of heat exchanger networks. Chem Eng Res Des 68(May):211–220

Polley GT, Panjeh Shahi MH, Picon Nunez M (1991) Rapid design algorithms for shell and tube and compact heat exchanger. Trans I Chem E 69(A):435–444

Rajavel R (2014) Experimental and numerical studies of a spiral-plate heat exchanger. Therm Sci 18(4):1355–1360

Rajavel R, Saravanan K (2008a) An experimental study of spiral plate heat exchanger for electrolytes. J Univ Chem Technol Metall 43(2):225–260

Rajavel R, Saravanan K (2008b) Heat transfer studies on spiral plate heat exchanger. Therm Sci 12(3):85–90

Rosenblad CF (1935) Heat exchanger apparatus made of sheet metal. Patent No US2011201A

Rosenblad CF (1936) Heat exchanger apparatus. Patent No US2060440A

Sakariya PJ, Jhavar PM, Gujarati RD (2014) Analysis of heat transfer in spiral plate heat exchanger using experimental and CFD. Int J Sci Res Dev 2(7):446–451

Saravanan K, Rajavel R (2008a) Analysis of heat transfer enhancement in spiral plate heat exchanger. Mod Appl Sci 2(4):68–75

Saravanan K, Rajavel R (2008b) An experimental investigation of heat transfer coefficients for spiral plate heat exchanger. Mod Appl Sci 2(5):14–20

Shabiulla AM, Sivaprakasam S (2014) Optimization of process parameters for water–sea water (3%) system in a spiral plate heat exchanger (SHE) using response surface methodology (RSM). Int J Dev Res 4(5):1020–1026

Shah RK, Sekulic DP (2003) Fundamentals of heat exchanger designing. John Wiley & Sons Inc., Hoboken, New Jersey

Strelow O (2000) A general calculation method for plate heat exchangers. Int J Therm Sci 39:645–658

Tapre RW, Kaware JP (2018a) Experimental study of the effect of the Reynolds number on overall heat transfer coefficient in spiral heat exchanger for acetic acid – water system. SSRG Int J Chem Eng Res 5(2–May to Aug):1–4

Tapre RW, Kaware JP (2018b) Experimental analysis of spiral heat exchanger: evaluation of Reynolds number and Nusselt number for acetic acid – water system. Int J Sci Res Sci Technol 4(9):1–4

Tapre RW, Kaware JP (2018c) Comparison of theoretical and experimental overall heat transfer coefficient for acetic acid–water system in spiral heat exchanger. SSRG Int J Therm Eng 4(3–Sep to Dec):1–4

Vasconcelos Segundo EH, Mariani VC, dos Santos CL (2018) Design of spiral heat exchanger from economic and thermal point of view using a tuned wind-driven optimizer. J Braz Soc Mech Sci Eng 40(212):1–14

Greek Letters

β Compactness factor or surface density (m2/m3)

ΔP Pressure drop (KPa)

ΔTLM Logarithmic mean temperature difference-LMTD (K)

ΔTmax Greater terminal temperature difference (K)

ΔTmin Smaller terminal temperature difference (K)

ε Thermal effectiveness per turn

εtot Thermal effectiveness of heat exchanger

η Pumping efficiency

μ Viscosity (kg/m s)

μb Fluid bulk viscosity (kg/m s)

μw Fluid viscosity at the wall temperature (kg/m s)

ρ Density (kg/m3)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sabouri Shirazi, A.H., Jafari Nasr, M.R. & Ghodrat, M. Effects of Temperature Differences in Optimization of Spiral Plate Heat Exchangers. Process Integr Optim Sustain 4, 391–408 (2020). https://doi.org/10.1007/s41660-020-00128-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-020-00128-5