Abstract

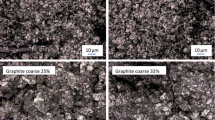

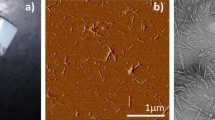

Five commercially available cut-resistant gloves were sourced from four different worldwide manufacturers which were advertised to contain graphene. A method was developed to assess the fibers composing each glove, including dissolution of the constituent fibers using sulfuric acid or liquid paraffin at elevated temperature, to extract and analyze particle additives. Scanning electron microscopy with energy-dispersive X-ray spectroscopy was applied to fibers and extracted particles for morphological and elemental analysis; Raman spectroscopy was applied to discern the composition of carbonaceous materials for the ultimate purpose of identifying any graphenic additives. Only one of the five tested products contained conclusive evidence of material in the graphene family, as graphene oxide was clearly presented as advertised. Two of the products, which were sourced from the same manufacturer, exhibited evidence most suggestive of graphite or amorphous carbon rather than graphene. The remaining two products exhibited signatures of amorphous carbon without evidence of graphitic or graphenic material. The four products that did not conclusively present evidence of advertised graphene also contained prolific alternative cut-resistant additives such as steel wire, glass fiber, or a silicon-based particle that elemental analysis suggests may be silicon carbide. Methods and techniques for the evaluation of products claiming graphene content are demonstrated for the purposes of improving market integrity and consumer confidence in product claims.

Similar content being viewed by others

References

Novoselov KS et al (2004) Electric field effect in atomically thin carbon films. Science 306(5696):666–669

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6(3):183–191

Hooker N, Simons CT, Parasidis E (2018) “Natural” food claims. Food Drug Law J 73(2):319–337

Hooker N, Simons CT, Parasidis E (2018) “Natural Food Claims" industry practices, consumer expectations, and class action lawsuits. Food and Drug Law J 73(2):319–337

Rao A, Wang E (2017) Demand for “healthy” products: false claims and FTC regulation. J Mark Res 54(6):968–989

Mayhew L, Singh AP, Li P, Perdue EM (2023) Differentiation between humic and non-humic substances using alkaline extraction and ultraviolet spectroscopy. J AOAC Int 106(3):748–759

Cooper JE, Kendig EL, Belcher SM (2011) Assessment of bisphenol a released from reusable plastic, aluminium and stainless steel water bottles. Chemosphere 85(6):943–947

Hudspeth A et al (2022) Independent sun care product screening for benzene contamination. Environ Health Perspect 130(3):037701

Kinloch IA et al (2018) Composites with carbon nanotubes and graphene: an outlook. Science 362(6414):547–553

Jang H-K et al (2014) Interfacial shear strength of reduced graphene oxide polymer composites. Carbon 77:390–397

Mannov E et al (2013) Improvement of compressive strength after impact in fibre reinforced polymer composites by matrix modification with thermally reduced graphene oxide. Compos Sci Technol 87:36–41

O’Masta MR, Russell BP, Deshpande VS (2017) An exploration of the ballistic resistance of multilayer graphene polymer composites. Extreme Mech Lett 11:49–58

Garces IT, Ayranci C (2018) A view into additive manufactured electro-active reinforced smart composite structures. Manuf Lett 16:1–5

Young RJ, Liu M (2016) The microstructure of a graphene-reinforced tennis racquet. J Mater Sci 51(8):3861–3867

Donato KZ et al (2023) Graphene oxide classification and standardization. Sci Rep 13(1):6064

Aliyev E et al (2019) Structural characterization of graphene oxide: surface functional groups and fractionated oxidative debris. Nanomaterials 9(8):1180

Childres I et al (2013) Raman spectroscopy of graphene and related materials. New Dev Photon Mater Res 1:403–418

Kaniyoor A, Ramaprabhu S (2012) A Raman spectroscopic investigation of graphite oxide derived graphene. AIP Adv 2(3):032183

Song J et al (2013) Penetration depth at various Raman excitation wavelengths and stress model for Raman spectrum in biaxially-strained Si. Sci China Phys Mech Astron 56(11):2065–2070

Hill AH, Manifold B, Fu D (2020) Tissue imaging depth limit of stimulated Raman scattering microscopy. Bimed Opt Express 11(2):762–774

Esposito R et al (2016) Depth profiles in confocal optical microscopy: a simulation approach based on the second Rayleigh-Sommerfeld diffraction integral. Opt Express 24(12):12565–12576

Paton KR et al (2023) On the use of Raman spectroscopy to characterize mass-produced graphene nanoplatelets. Beilstein J Nanotechnol 14:509–521

Backes C et al (2016) Spectroscopic metrics allow in situ measurement of mean size and thickness of liquid-exfoliated few-layer graphene nanosheets. Nanoscale 8(7):4311–4323

Acknowledgements

This work was performed in part at the Nanoscale Characterization and Fabrication Laboratory, which is supported by the Virginia Tech National Center for Earth and Environmental Nanotechnology Infrastructure (NanoEarth), a member of the National Nanotechnology Coordinated Infrastructure (NNCI), supported by NSF (ECCS 1542100 and ECCS 2025151). M. Hull acknowledges support of Virginia Tech’s Institute for Critical Technology and Applied Science (ICTAS).

Funding

A portion of the research reported in this publication was supported by the National Institute of Environmental Health Sciences of the National Institutes of Health under Award Number R44ES030650. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institutes of Health.

Author information

Authors and Affiliations

Contributions

W.C.H. designed the experimentation, interpreted results, and primarily authored the manuscript T.B. identified the research topic, provided the tested products, and contributed to discussion and edits T.A. assisted in laboratory execution including preparation of materials and analyses W.L. conducted Raman spectroscopy and provided related insights M.H. contributed to discussion and interpretation of results All authors reviewed and approve of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors do not have any financial or non-financial interests to disclose that are directly or indirectly related to the work submitted for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hill, W.C., Barkan, T., Amos, T. et al. Investigation of commercial cut-resistant gloves claiming graphene additive content. Graphene and 2D mater 9, 87–99 (2024). https://doi.org/10.1007/s41127-023-00070-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41127-023-00070-6