Abstract

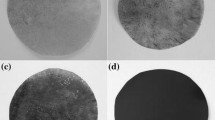

We present a novel synthetic approach to produce epoxy-graphene nanocomposites by in situ polymerization, without the need of adding/removing external solvents to improve graphene dispersion. It is based on the use of 1,4-butanediol diglycidyl ether (BDE), an epoxy monomer able to efficiently produce and disperse graphene via ultrasound-induced liquid exfoliation of graphite. Suitable values of Hansen solubility parameters, surface tension and viscosity explain its ability to disperse graphene. Yields and quality of graphene produced in BDE were found comparable to those obtained when solvents such as NMP and DMF are used. Graphene-BDE dispersions were polymerized with an aliphatic diamine to produce the epoxy-based nanocomposites. The composites showed a very good level of graphene dispersion as shown by SEM images and as reflected by shifts in the glass transition temperature, decrease in reaction enthalpy and increase in Young’s modulus with respect to the neat epoxy. This strategy opens new possibilities for obtaining epoxy-based nanocomposites with graphene of high quality in a clean, straightforward way.

Similar content being viewed by others

References

Novoselov KS, Fal’ko VI, Colombo L, Gellert PR, Schwab MG, Kim K (2012) A roadmap for graphene. Nature. https://doi.org/10.1038/nature11458

Yi M, Shen Z (2015) A review on mechanical exfoliation for the scalable production of graphene. J Mater Chem A 3(22):11700–11715. https://doi.org/10.1039/c5ta00252d

Kauling AP, Seefeldt AT, Pisoni DP, Pradeep RC, Bentini R, Oliveira RVB, Novoselov KS, Castro Neto AH (2018) The worldwide graphene flake production. Adv Mater. https://doi.org/10.1002/adma.201803784

Baig Z, Mamat O, Mustapha M, Mumtaz A, Munir KS, Sarfraz M (2017) Investigation of tip sonication effects on structural quality of graphene nanoplatelets (GNPs) for superior solvent dispersion. Ultrason Sonochem 2018(45):133–149. https://doi.org/10.1016/j.ultsonch.2018.03.007

Bøggild P (2018) The war on fake graphene. Nature. https://doi.org/10.1038/d41586-018-06939-4

Ciesielski A, Samorì P (2014) Graphene via sonication assisted liquid-phase exfoliation. Chem Soc Rev 43(1):381–398. https://doi.org/10.1039/c3cs60217f

Godoy AP, Ecorchard P, Beneš H, Tolasz J, Smržová D, Seixas L, Pedrotti JJ, de Souza EAT, El Seoud OA, Donato RK (2018) Ultrasound exfoliation of graphite in biphasic liquid systems containing ionic liquids: a study on the conditions for obtaining large few-layers graphene. Ultrason Sonochem 2019(55):279–288. https://doi.org/10.1016/j.ultsonch.2019.01.016

Muthoosamy K, Manickam S (2017) State of the art and recent advances in the ultrasound-assisted synthesis, exfoliation and functionalization of graphene derivatives. Ultrason Sonochem 39:478–493. https://doi.org/10.1016/j.ultsonch.2017.05.019

Silva LI, Mirabella DA, Pablo Tomba J, Riccardi CC (2020) Optimizing graphene production in ultrasonic devices. Ultrasonics. https://doi.org/10.1016/j.ultras.2019.105989

Tung TT, Karunagaran R, Tran DNH, Gao B, Nag-Chowdhury S, Pillin I, Castro M, Feller JF, Losic D (2016) Engineering of graphene/epoxy nanocomposites with improved distribution of graphene nanolayers for advanced piezo-resistive mechanical sensing. J Mater Chem C 4(16):3422–3430. https://doi.org/10.1039/c6tc00607h

Rohini R, Katti P, Bose S (2015) Tailoring the interface in graphene/thermoset polymer composites: a critical review. Polymer (Guildf) 70:A17–A34. https://doi.org/10.1016/j.polymer.2015.06.016

Chong HM, Hinder SJ, Taylor AC (2016) Graphene nanoplatelet-modified epoxy: effect of aspect ratio and surface functionality on mechanical properties and toughening mechanisms. J Mater Sci 51(19):8764–8790. https://doi.org/10.1007/s10853-016-0160-9

Mao HN, Wang XG (2020) Use of in-situ polymerization in the preparation of graphene/polymer nanocomposites. Xinxing Tan Cailiao/New Carbon Mater 35(4):336–343. https://doi.org/10.1016/S1872-5805(20)60493-0

Cho EC, Huang JH, Li CP, Chang-Jian CW, Lee KC, Hsiao YS, Huang JH (2016) Graphene-based thermoplastic composites and their application for LED thermal management. Carbon N Y 102:66–73. https://doi.org/10.1016/j.carbon.2016.01.097

Papageorgiou DG, Kinloch IA, Young RJ (2017) Mechanical properties of graphene and graphene-based nanocomposites. Prog Mater Sci 90:75–127. https://doi.org/10.1016/j.pmatsci.2017.07.004

Pontén A, Zimerson E, Bruze M (2004) Contact allergy to the isomers of diglycidyl ether of bisphenol F. Acta Derm Venereol 84(1):12–17. https://doi.org/10.1080/00015550310005870

Schiraldi A, Baldini P (1983) Epoxy polymers: use and misuse of non-isothermal DTA and DSC in the study of the curing process. J Thermal Anal Calorim 28(2):295–301. https://doi.org/10.1007/bf01983263

Bortz DR, Heras EG, Martin-Gullon I (2012) Impressive fatigue life and fracture toughness improvements in graphene oxide/epoxy composites. Macromolecules 45(1):238–245. https://doi.org/10.1021/ma201563k

Wan YJ, Tang LC, Gong LX, Yan D, Li YB, Wu L, Bin Jiang JX, Lai GQ (2014) Grafting of epoxy chains onto graphene oxide for epoxy composites with improved mechanical and thermal properties. Carbon NY. 69:467–480. https://doi.org/10.1016/j.carbon.2013.12.050

Zhang Y, Wang Y, Yu J, Chen L, Zhu J, Hu Z (2014) Tuning the interface of graphene platelets/epoxy composites by the covalent grafting of polybenzimidazole. Polymer (Guildf) 55(19):4990–5000. https://doi.org/10.1016/j.polymer.2014.07.045

Martucci JF, Espinosa JP, Ruseckaite RA (2015) Physicochemical properties of films based on bovine gelatin cross-linked with 1,4-butanediol diglycidyl ether. Food Bioprocess Technol 8(8):1645–1656. https://doi.org/10.1007/s11947-015-1524-x

Flores HA, Ayude MA, Riccardi CC, Fasce LA (2019) Influence of a reactive diluent on curing kinetics, internal curing process, and mechanical performance of filament wound glass fiber-reinforced epoxy composite pipes. Polym Eng Sci 59(2):344–354. https://doi.org/10.1002/pen.24911

Silva L, Tognana S, Salgueiro W (2013) Study of the water absorption and its influence on the Young’s modulus in a commercial polyamide. Polym Test. https://doi.org/10.1016/j.polymertesting.2012.10.003

Tognana S, Salgueiro W, Somoza A, Marzocca A (2010) Measurement of the Young’s modulus in particulate epoxy composites using the impulse excitation technique. Mater Sci Eng A 527(18–19):4619–4623. https://doi.org/10.1016/j.msea.2010.04.083

Ravinder D (1994) Composition dependence of the elastic moduli of mixed lithium-cadmium ferrites. J Appl Phys 75(10):6121–6123. https://doi.org/10.1063/1.355480

Terry JS, Taylor AC (2021) The properties and suitability of commercial bio-based epoxies for use in fiber-reinforced composites. J Appl Polym Sci 138(20):1–12. https://doi.org/10.1002/app.50417

Salavagione HJ, Sherwood J, De Bruyn M, Budarin VL, Ellis GJ, Clark JH, Shuttleworth PS (2017) Identification of high performance solvents for the sustainable processing of graphene. Green Chem 19(11):2550–2560. https://doi.org/10.1039/c7gc00112f

Jenkins S (2011) Hansen solubility parameters (HSP), vol 118

Van Krevelen DW, Te Nijenhuis K (2009) An illustrative example of end use properties. https://doi.org/10.1016/b978-0-08-054819-7.00027-3

Hernandez Y, Nicolosi V, Lotya M, Blighe FM, Sun Z, De S, McGovern IT, Holland B, Byrne M, Gun’ko YK, Boland JJ, Niraj P, Duesberg G, Krishnamurthy S, Goodhue R, Hutchison J, Scardaci V, Ferrari AC, Coleman JN (2008) High-yield production of graphene by liquid-phase exfoliation of graphite. Nat Nanotechnol 3(9):563–568. https://doi.org/10.1038/nnano.2008.215

Mason TJ, Lorimer JP (2002) Lorimer applied sonochemistry the uses of power ultrasound in chemistry and processing, vol 0

Quintana M, Vazquez E, Prato M (2013) Organic functionalization of graphene in dispersions. Acc Chem Res 46(1):138–148. https://doi.org/10.1021/ar300138e

Ferrari AC, Meyer JC, Scardaci V, Casiraghi C, Lazzeri M, Mauri F, Piscanec S, Jiang D, Novoselov KS, Roth S, Geim AK (2006) Raman spectrum of graphene and graphene layers. Phys Rev Lett 97(18):1–4. https://doi.org/10.1103/PhysRevLett.97.187401

Backes C, Paton KR, Hanlon D, Yuan S, Katsnelson MI, Houston J, Smith RJ, McCloskey D, Donegan JF, Coleman JN (2016) Spectroscopic metrics allow in situ measurement of mean size and thickness of liquid-exfoliated few-layer graphene nanolayers. Nanoscale 8(7):4311–4323. https://doi.org/10.1039/c5nr08047a

Coleman JN (2013) Liquid exfoliation of defect-free graphene. Acc Chem Res 46(1):14–22. https://doi.org/10.1021/ar300009f

Cançado LG, Jorio A, Ferreira EHM, Stavale F, Achete CA, Capaz RB, Moutinho MVO, Lombardo A, Kulmala TS, Ferrari AC (2011) Quantifying defects in graphene via raman spectroscopy at different excitation energies. Nano Lett 11(8):3190–3196. https://doi.org/10.1021/nl201432g

Naebe M, Wang J, Amini A, Khayyam H, Hameed N, Li LH, Chen Y, Fox B (2014) Mechanical property and structure of covalent functionalised graphene/epoxy nanocomposites. Sci Rep. https://doi.org/10.1038/srep04375

Acknowledgements

Leonel. I. Silva and J. Pablo Tomba acknowledge Agencia Nacional de Promoción Científica y Tecnológica, Fondo para la Investigación Científica y Tecnológica (PICT16‐3633 and PICT14-1919) for financial support. S. Tognana acknowledges SECAT (UNCPBA) Argentina.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Silva, L.I., Tomba, J.P., Tognana, S. et al. Ultrasound-induced exfoliation of graphene in 1,4-butanediol diglycidyl ether monomer: a promising free-solvent route to epoxy-based nanocomposites. Graphene and 2D Materials Technol 6, 49–58 (2021). https://doi.org/10.1007/s41127-021-00044-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41127-021-00044-6