Abstract

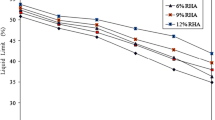

This paper presents the efficacy of industrial wastes such as molasses (5%, 10%, 15%, and 20%) and waste foundry sand (10%, 20%, 30%, and 40%) stabilized clayey soil blended with lime (3%, 6%, 9%, and 12%). The objective of the current research was to develop a composite soil subgrade material for designing the thickness for flexible pavements. Various laboratory tests such as differential free swell, consistency limits, compaction characteristics, and California bearing ratio (CBR) tests were conducted on soil incorporating waste foundry sand and molasses (with/without lime) to find their efficacy to be used as a subgrade material. The laboratory tests revealed that the differential free swell and consistency limits of clayey soil decreased and CBR values increased on adding optimum amount of molasses (10%), waste foundry sand (20%), and lime (9%) alone and in combination with each other. Based on CBR values, the thickness of flexible pavement was designed using IITPAVE software and was also assessed to meet the required criteria based on the IRC: 37-2018 recommendations. The results of the software analysis showed a reduction in the pavement thickness for various values of commercial vehicles per day (1000, 2000, and 5000) for all combinations. The maximum reduction in layer thickness and construction costs is noticed when clayey soil is blended with molasses (10%), waste foundry sand (20%), and lime (3%) in combination with each other. This novel technique of strengthening geotechnical characteristics of subgrade soil is not only helpful for reducing the pavement thickness but is a very cost-effective and also solves the disposal problem of waste foundry sand and molasses.

Similar content being viewed by others

References

Abichou TB, Benson T, Edil CH (2000) Foundry green sands as hydraulic barriers: laboratory study. J Geotech Geoenvironmental Eng 126:1174–1183

Alzaim M, Gedik A, Lav AH (2020) Effect of modulus of bituminous layers and utilization of capping layer on weak pavement subgrades. Civ Eng J 6(7):1286–1299

Amu OO, Adeyeri JB, Oduma EW, Fayokun OA (2008) Stabilization characteristics of lime on palm kernel blended lateritic soil. Trends Appl Sci Res 3:182–188

Anand D, Sharma RK, Sharma A (2021) Improving swelling and strength behavior of black cotton soil using lime and quarry dust. In: Singh H., Singh Cheema P. P., Garg P. (eds) Sustainable development through engineering innovations notes in civil engineering: 113. Springer, Singapore. https://doi.org/10.1007/978-981-15-9554-7_54

Aneke FI, Celumusa S (2021) Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Stud Constr Mater 14:e00515

Arshid MU, Kamal MA (2020) Appraisal of bearing capacity and modulus of subgrade reaction of refilled soils. Civ Eng J 6(11):2120–2130

Asgari MR, Dezfuli AB, Bayat M (2015) Experimental study on stabilization of a low plasticity clayey soil with cement/lime. Arab J Geosci 8(3):1439–1452

ASTM D2487–11 (2011) Standard practice for classification of soils for engineering purposes (unified soil classification system). ASTM International, West Conshohocken

ASTM D4318–10 (2010) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM International, West Conshohocken

ASTM D698-07e1 (2007) Standard test methods for laboratory compaction characteristics of soil using standard effort (12 400 ft-lbf/ft3(600 kN-m/m3)). ASTM International, West Conshohocken

ASTM D854–14 (2014) Standard test methods for specific gravity of soil solids by water pycnometer. ASTM International, West Conshohocken

ASTMD1883–05 (2005) Standard test method for CBR (California bearing ratio) of laboratory-compacted soils. ASTM International, West Conshohocken

Battistelli D, Ferreira DP, Costa S, Santulli C, Fangueiro R (2020) Conductive thermoplastic starch (TPS) composite filled with waste iron filings. Emerg Sci J 4(3):136–147

Bell FG (1996) Lime stabilization of clay minerals and soils. Eng Geol 42(4):223–237. https://doi.org/10.1016/0013-7952(96)00028-2

Bharathi AM, Ravichandran PT, Krishnan KD (2019) Potential use of dolomite hydrated lime in sustainable strength improvement of clayey soil. J Green Eng 9(4):489–501

Bhardwaj A, Sharma RK (2020) Effect of industrial wastes and lime on strength characteristics of clayey soil. J Eng Desg Tech 18(6):1749–1772. https://doi.org/10.1108/JEDT-12-2019-0350

Bhardwaj A, Sharma RK, Sharma A (2021) Stabilization of clayey soil using waste foundry sand and molasses. In: Singh H., Singh Cheema P.P., Garg P. (eds) Sustainable development through engineering innovations. Lecture notes in civil engineering: 113. Springer, Singapore. https://doi.org/10.1007/978-981-15-9554-7_57

Bozbey I, Garaisayev S (2010) Effects of soil pulverization quality on lime stabilization of an expansive clay. Environ Earth Sci 60(6):1137–1151

Das SK, Varma A (2011) Role of enzymes in maintaining soil health. In: soil enzymology, soil biology 22. Springer, Berlin

Dash SK, Hussain M (2012) Lime stabilization of soils: reappraisal. J Mater Civ Eng 24(6):707–714

Dong Q, Huang V, Huang B (2013) Laboratory evaluation of utilizing waste heavy clay and foundry sand blends as construction materials. J Mater Civ Eng 26(9):04014065

Dumbleton MJ, West G (1966) Some factors affecting the relation between the clay minerals in soils and their plasticity. Clay Miner 6(3):179–193

Dyer PPOL, Gutierrez Klinsky LM, Silva SA, Silva RA, de Lima MG (2019) Macro microstructural characterisation of waste foundry sand reused as aggregate. Road Mater Pavement Des. https://doi.org/10.1080/14680629.2019.1625807

Fiore S, Zanetti MC (2007) Foundry wastes reuse and recycling in concrete production. Am J Environ Sci 3(3):135–142

Gaulkar MP (1999) Construction of roads in black cotton soil. Indian Highw New Delhi 27(3):37–43

Gautam KK, Sharma RK, Sharma A (2021) Effect of municipal solid waste incinerator ash and lime on strength characteristics of black cotton soil. In: Singh H., Singh Cheema P. P., Garg P. (eds) Sustainable development through engineering innovations. Lecture notes in civil engineering: 113. Springer, Singapore. https://doi.org/10.1007/978-981-15-9554-7_10

Gedik A, Hilmi Lav A, Aysen Lav M (2018) Investigation of alternative ways for recycling waste foundry sand: an extensive review to present benefits. Can J Civ Eng 45:423–434. https://doi.org/10.1139/cjce-2017-0183

Goodhue MJ, Edil TB, Benson CH (2001) Interaction of foundry sands with geosynthetics. J Geotech Geoenviron Eng 127(4):353–436

Grower K, Goyal T (2019) Experimental study of waste foundry sand and marble dust as a soil stabilizing material. 1265–1272

Gunarti ASS, Nuryati S, Muttaqin PA, Raharja I (2020) Unconfined compression strength of soil using silica sand waste and dust sand foundry as a stabilizer. In: Journal of Physics: Conference Series 1517(1):012028.

Harichane K, Ghrici M, Kenai S, Grine K (2011) Use of natural pozzolana and lime for stabilization of cohesive soils. Geotech Geol Eng 29(5):759–769

Heidemann M, Helena PN, Daniel H, Breno SB, Yader GP (2021) Geotechnical behavior of compacted waste foundry sand. Constr Build Mater 277:122267

HPPWD (2020) Schedule of rates. Himachal Pradesh Public Works Department, Shimla

Ikeagwuani CC, Obeta IN, Agunwamba JC (2019) Stabilization of black cotton soil subgrade using sawdust ash and lime. Soils Found 59(1):162–175

IRC 37:2018 Tentative guidelines for the design of flexible pavements. Indian road congress, New Delhi.

IRC-SP-77 (2008) Manual for design, construction and maintenance of gravel roads. Indian Road Congress, New Delhi.

IS 2720 Part 40 (1977) Methods of tests for soil, part 40. Determination of free swell index of soil. Bureau of Indian Standards, New Delhi.

Kale RY, Wawage R, Kale G (2019) Effect of foundry waste on expansive soil (black cotton soil). IJSRD 7(2):1800–1804

Kavak A, Akyarli A (2007) A field application for lime stabilization. Environ Geol 51(6):987–997

Khan TA, Taha MR (2015) Effect of three bioenzymes on compaction, consistency limits, and strength characteristics of a sedimentary residual soil. Adv Mater Sci Eng. https://doi.org/10.1155/2015/798965

Khanna V, Brundaban B, Umesh CS (2019) Mechanical characterization of a bio-enzyme treated granular lateritic soil for application in low volume roads. 7th Indian Young Geotechnical Engineers Conference – 7IYGEC, NIT Silchar, Assam, India

Krithiga N, Pujitha D, Palayam T, Revathy Sri Muthukumaran A (2016) Soil stabilization using lime and fly ash 8. https://doi.org/10.31033/ijemr.v8i02.11965 .

Kumar A, Kumari S, Sharma RK (2016) Influence of use of additives on engineering properties of clayey soil. Proceedings of National conference: Civil Engineering Conference-Innovation for Sustainability

Lawrence D, Mavroulidou M (2009) Properties of concrete containing foundry sand. Proceedings of the 11th international conference on environmental science and technology, Chania, Crete, Greece: A704–A712

Little DN (1996) Fundamentals of the stabilization of soil with lime. National Lime Association, Arlington, VA 332:1–20

Lovejoy MA, Ham RK, Traeger PA, Wellander D, Hippe J, Boyle WC (1996) Evaluation of selected foundry wastes for use in highway construction. In: Proc Annu Madison Waste Conf

Luckham PF, Rossi S (1999) The colloidal and rheological properties of bentonite suspensions. Adv Colloid Interface Sci 82:43–92

M’Ndegwa JK (2011) The effect of cane molasses on strength of expansive clay soil. JETEAS 2(6):1034–1041

Majeed ZH, Taha MR (2011) Effect of nanomaterial treatment on geotechnical properties of a penang soft soil. J Asian Sci Res 2(11):587–592

Mast DG, Fox PJ (1998) Geotechnical performance of a highway embankment constructed using waste foundry sand. Geotech Spec Publ: 66–85

Monosi S, Sani D, Tittarelli F (2010) Used foundry sand in cement mortars and concrete production. TOWMJ 3:18–25

Nalbantoglu Z (2006) Lime stabilization of expansive clay. Expansive Soils – Recent advances in characterization and treatment, Taylor and Francis, London: 341–348

Narasimha RS, Rajasekaran G (1996) Reaction products formed in Lime-Stabilized Mixed clays. J Geotech Eng 122:329–336

O’Flaherty CA (1974) Highways in Arnold, E., 2nd ed. Highway Engineering 2:221–267

Paige-Green P (1998) Recent developments in soil stabilization. Proceedings: 19th ARRB conference. Australia, Sydney, pp 121–135

Raheem BS, Oladiran GF, Oke DA, Musa SA (2020) Evaluation of strength properties of subgrade materials stabilized with bio-enzyme. EJERS 5(5):607–610

Saini V, Vaishnava P (2015) Soil stabilization by using TerraZyme. Int J Adv Eng Technol 8(4):566–573

Sebki G, Brahim S, Kahina C (2019) Recycling of foundry sand wastes in self-compacting mortars: use as cementitious materials and fine aggregates. J Appl Eng Sci 9(2):195–200

Shankar A, Rai HK, Mithanthaya R (2009) Bio-enzyme stabilized lateritic soil as a highway material. J Indian Roads Congress 70(2):141–151

Sharma A, Sharma RK (2019) An experimental study on uplift behaviour of granular anchor pile in stabilized expansive soil. Int J Geotech Eng. https://doi.org/10.1080/1938636.2.2019.1597481

Sharma A, Sharma RK (2020) Effect of addition of construction–demolition waste on strength characteristics of high plastic clays. Innov Infrastruct Solut 4(1):1–11. https://doi.org/10.1007/s41062-019-0216-1

Sharma A, Sharma RK (2020) Strength and drainage characteristics of poor soils stabilized with construction demolition waste. Geotech Geol Eng 38:4753–4760. https://doi.org/10.1007/s10706-020-01324-3

Sharma A, Sharma RK (2021) Sub-grade characteristics of soil stabilized with agricultural waste, constructional waste, and lime. B Eng Geol Environ 80(3):2473–2484. https://doi.org/10.1007/s10064-020-02047-8

Sharma A, Sharma RK, Bhardwaj A (2018) Effect of construction demolition and glass waste on stabilization of clayey soil. In: International conference on sustainable waste manag through design: 87–94. Springer, Cham. https://doi.org/10.1007/978-3-030-02707-0_12

Shirsavkar SS, Koranne S (2010) Innovation in road construction using natural polymer. Electron J Geotech Eng 15(1):1614–1624

Singh A (2002) Soil engineering in theory and practice, 4th edn. CBS publishers and distributors, New-Delhi

Singh S, Sharma RK, Sharma A (2021) Arresting the heave of black cotton soil using geogrid-encased granular pile anchor. In: Singh H., Singh Cheema P.P., Garg P. (eds) Sustainable development through engineering innovations. Lecture notes in civil engineering: 113. Springer, Singapore. https://doi.org/10.1007/978-981-15-9554-7_30

Tanyu BF, Benson CH, Edil TB, Kim WH (2004) Equivalency of crushed rock and three industrial By-products used for working platforms during pavement construction. Transp Res Rec. https://doi.org/10.3141/1874-07

Taye B, Araya AA (2015) Stabilization of expansive clay soil with sugar cane molasses and cement. Dissertation, Addis Ababa University Ethiopia

Verma V, Abhishek (2018) Stabilization of Clayey Soils Using Fly Ash and RBI Grade 81. In: International conference on sustainable waste manag through design; 95–102. Springer, Cham. https://doi.org/10.1007/978-3-030-02707-0_13

Vinodhkumar S, Kulanthaivel P, Kabilan A, Lokeshkanna KM (2018) Study of black cotton soil characteristics with molasses. AJEAT 7(1):73–77

Yazoghli-Marzouk O, Vulcano-Greullet N, Cantegrit L, Friteyre L, Jullien A (2014) Recycling foundry sand in road construction-field assessment. Constr Build Mater 61:69–78. https://doi.org/10.1016/j.conbuildmat.2014.02.055

Zagvozda M, Tatjana R, Sanja D (2020) Wood bioash effect as lime replacement in the stabilisation of different clay subgrades. Int J Pavement Eng: 1–11

Zhou Z (1995) Construction and application of clay-swelling diagrams by use of XRD methods. J Petrol Technol 474:306

Zhu F, Li Z, Dong W, Yangyun Ou (2019) Geotechnical properties and microstructure of lime-stabilized silt clay. B Eng Geol Environ 78(4):2345–2354

Funding

No funding was received for carrying out the present research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Bhardwaj, A., Sharma, R.K. Designing thickness of subgrade for flexible pavements incorporating waste foundry sand, molasses, and lime. Innov. Infrastruct. Solut. 7, 132 (2022). https://doi.org/10.1007/s41062-021-00723-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-021-00723-6