Abstract

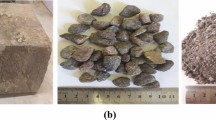

A detailed experimental investigation was carried out to understand the effect of ultrasonic pulse velocity (UPV) in concrete made with recycled brick aggregate (RBA). For this, cylindrical concrete specimens of 100 mm × 200 mm size were prepared where s/a ratio were 0.36, 0.40, and 0.44 and W/C ratio were 0.45, 0.50, and 0.55. Some cylindrical mortar specimens were also prepared by sieving fresh concrete through a 4.75 mm sieve. The compressive strength, modulus of elasticity, and UPV in mortar specimens and concrete made with RBA were tested at 7, 28, 60, and 90 days. UPV in concrete is influenced by the old mortar adhered to the surface of coarse aggregate in concrete. The results were compared to that of the control concrete specimens made with virgin brick aggregate and concrete made with virgin stone aggregate. Relationships between UPV and compressive strength, and UPV and modulus of elasticity of concrete are proposed and compared.

Similar content being viewed by others

References

Monteiro PJ, Miller SA, Horvath A (2017). Towards sustainable concrete. Nat Mater

Mehta PK (2001) Reducing the environmental impact of concrete. Concr Int 23:61–66

Mehta PK (2009) Global concrete industry sustainability. ACI Concrete Int 31:45–48

Mohammed TU, Hasnat A, Awal MA et al (2015) Recycling of brick aggregate concrete as coarse aggregate. J Mater Civ Eng 27:B4014005(1)-B4014005(9)

Torring M, Lauritzen E (2002) Total recycling opportunities—tasting the topics for the conference session. In: Challenges of concrete construction: volume 5, sustainable concrete construction: proceedings of the international conference held at the University of Dundee, Scotland, pp 501–510

Arora S, Singh S (2016) Analysis of flexural fatigue failure of concrete made with 100% coarse recycled concrete aggregates. Constr Build Mater 102:782–791

Yanagibashi K, Yonezawa T, Arakawa K, et al (2002) A new concrete recycling technique for coarse aggregate regeneration process. In: Dhir RK, Dyer TD, Halliday JE (eds) Proceedings of the international congress: challenges of concrete construction, Conf 2-sustainable concrete construction. Thomas Telford Publishing, London, pp 511–522

Sáez del Bosque IF, Zhu W, Howind T et al (2017) Properties of interfacial transition zones (ITZs) in concrete containing recycled mixed aggregate. Cement Concrete Compos 81:25–34

Medjigbodo S, Bendimerad AZ, Rozière E, et al (2018) How do recycled concrete aggregates modify the shrinkage and self-healing properties? Cement Concrete Compos 86:72–86

Etxeberria M, Vázquez E, Marí A (2006) Microstructure analysis of hardened recycled aggregate concrete. Mag Concr Res 58:683–690

Poon C, Shui Z, Lam L (2004) Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Construct Build Mater 18:461–468

Li W, Xiao J, Sun Z, et al (2012) Interfacial transition zones in recycled aggregate concrete with different mixing approaches. Construct Build Mater 35:1045–1055

Xiao J, Li W, Sun Z, et al (2013) Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation. Cement Concrete Compos 37:276–292

Tam VWY, Gao XF, Tam CM (2005) Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cement Concrete Res 35:1195–1203

Kong D, Lei T, Zheng J, et al (2010) Effect and mechanism of surface-coating pozzalanics materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete. Construct Build Mater 24:701–708

Leite MB, Monteiro PJM (2016) Microstructural analysis of recycled concrete using X-ray microtomography. Cement Concrete Res 81:38–48

Tam VWY, Tam CM (2008) Diversifying two-stage mixing approach (TSMA) for recycled aggregate concrete: TSMAs and TSMAsc. Construct Build Mater 22:2068–2077

Dineshkumar R, Harikaran C, Veerapandi P (2020) Corrosion assessment in reinforced concrete elements using half-cell potentiometer—a review. Test Eng Manag 9:1954–1957

Mohammed TU, Mahmood AH (2016) Effects of maximum aggregate size on UPV of brick aggregate concrete. Ultrasonics 69:129–136

Mohammed TU, Fateh Azam Khan M, Kabir MR, et al (2010) Recycling of concrete made with brick aggregate. In: Naik TR, Ganjian E (eds) 2nd international conference on sustainable construction materials and technologies. Ancona, Italy, pp 949–960

Akhtaruzzaman AA, Hasnat A (1983) Properties of concrete using crushed brick as aggregate. ACI Concrete Int 5:58–83

Mohammed TU, Mahmood AH, Kamal MRI, et al (2017) Effects of maximum size of brick aggregate on properties of concrete. Construct Build Mater 134:713–726

Anderson DA, Seals KR (1981) Pulse velocity as a predictor of 28- and 90-day strength. ACI Mater J 78:116–122

Trtnik G, Kavcic F, Turk G (2009) Prediction of concrete strength using ultrasonic pulse velocity and artificial neural networks. Ultrasonics 49:53–60

Parasnis DS (1986) Principles of applied geophysics, 4th edn. Springer, Dordrecht

Molhotra V, Press ISU 1976. Testing Hardened Concrete: Nondestructive Methods. ACI monograph No 9. 1st ed. Detroit. MI: American Concrete Institute, p 188

Yasuo Tanigawa and Hiroshi Mori KB, Yasuo Tanigawa KB, Hiroshi M (1984) Estimation of concrete strength by combined nondestructive testing method. ACI Mater J 82:57–76

Yıldırım H, Sengul O (2011) Modulus of elasticity of substandard and normal concretes. Construct Build Mater 25:1645–1652

Abo-Qudais SA (2005) Effect of concrete mixing parameters on propagation of ultrasonic waves. Construct Build Mater 19:257–263

Solís-Carcaño R, Moreno EI (2008) Evaluation of concrete made with crushed limestone aggregate based on ultrasonic pulse velocity. Constr Build Mater 22:1225–1231

del Rı́o LM, Jiménez A, López F, et al (2004) Characterization and hardening of concrete with ultrasonic testing. Ultrasonics 42:527–530

Ben-Zeitun AE (1986) Use of pulse velocity to predict compressive strength of concrete. Int J Cement Compos Lightweight Concrete 8:51–59

Kaplan MF (1959) The effects of age and water/cement ratio upon the relation between ultrasonic pulse velocity and compressive strength of concrete. Mag Concrete Res 11:85–92

Kaplan MF (1960) The relation between ultrasonic pulse velocity and the compressive strength of concretes having the same workability but different mix proportions. Mag Concrete Res 12:3–8

Ohdaira E, Masuzawa N (2000) Water content and its effect on ultrasound propagation in concrete—the possibility of NDE. Ultrasonics 38:546–552

Hernández MG, Izquierdo MAG, Ibáñez A, et al (2000) Porosity estimation of concrete by ultrasonic NDE. Ultrasonics 38:531–533

Mahure NV, Vijh GK, Sharma P et al (2011) Correlation between pulse velocity and compressive strength of concrete. Int J Earth Sci Eng 4:871–874

Al-Nu’man BS, Aziz BR, Abdulla SA, et al (2015) Compressive strength formula for concrete using ultrasonic pulse velocity. 26: 8–13.

Turgut P (2004) Research into the correlation between concrete strength and UPV values. NDT.net. 12:1–9

Kewalramani MA, Gupta R (2006) Concrete compressive strength prediction using ultrasonic pulse velocity through artificial neural networks. Autom Construct 15:374–379.

Mohammed TU, Rahman MN (2016) Effect of types of aggregate and sand-to-aggregate volume ratio on UPV in concrete. Construct Build Mater. 125:832–841

Turgut P (2004) Evaluation of the ultrasonic pulse velocity data coming on the field. In: 4th international conference on NDE in relation to structural integrity for nuclear and pressurized components, London, pp 573–578

Kheder GF (1999) A two stage procedure for assessment of in situ concrete strength using combined non-destructive testing. Mater Struct. 32:410–417. https://doi.org/10.1007/BF02482712.

Jain A, Kathuria A, Kumar A, et al (2013) Combined use of non-destructive tests for assessment of strength of concrete in structure. Proc Eng 54:241–251. https://doi.org/10.1016/j.proeng.2013.03.022.

Acknowledgements

The authors acknowledge the financial support and facilities provided by Islamic University of Technology (IUT) for research works in the field of concrete technology at the Department of Civil and Environmental Engineering (CEE). The authors also wish to express their gratitude to Seven Circle Bangladesh Ltd. for providing materials for this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Mohammed, T.U., Rahman, M.N., Ishraq, R. et al. Ultrasonic pulse velocity in concrete made with recycled brick aggregate. Innov. Infrastruct. Solut. 6, 162 (2021). https://doi.org/10.1007/s41062-021-00542-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-021-00542-9