Abstract

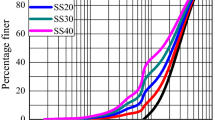

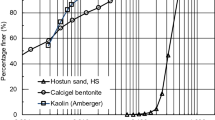

To evaluate the effect of non-plastic fines on liquefaction resistance of Babolsar sand, a series of undrained static and cyclic triaxial tests alongside a series of numerical analysis were carried out. The cyclic triaxial tests were conducted in stress-controlled conditions with 1 Hz frequency at 0.35 constant cyclic stress ratio for 50 kPa and 0.25 for 100 and 200 kPa confining pressures. The samples contained 0%, 10%, 20%, 30% and 40% of fine grains. The numerical analysis was performed by a finite difference method, and Finn’s constitutive model was applied to investigate the liquefaction resistance of the mixtures. The tests’ results showed that the number of cycles leading to liquefaction of a sand–silt mixture decreases after increasing fine-grained percentage. Poorer performance in compression and better performance in tension was observed in this situation. The test outcomes also showed that dominant behavior of the mixtures changes from sand to silt at 20% fines content. It was observed from the test results and the numerical analysis that in low percentages of silt, the behavior of the sand–silt mixture is similar to those of the clean sand sample. But by increasing silt, the mixture’s behavior becomes more dependent on contacts between fine and granular particles. The concept presented by Thevanayagam was used to check the contacts between fine and coarse particles. It was also observed that the Finn constitutive model is in good consistency with the test results as long as the behavior of the sand is dominant in the mixture.

Similar content being viewed by others

Abbreviations

- e min :

-

Minimum index void ratio

- e max :

-

Maximum index void ratio

- B :

-

Pore pressure parameter

- N :

-

Number of cycles to cause liquefaction

- \(\sigma_{3}^{{\prime }}\) :

-

Consolidation stress

- V T :

-

Total volume of soil sample

- G s :

-

Specific gravity of soil

- \(f_{\text{c}}\) :

-

Fines content

- \(R_{\text{d}}\) :

-

Size disparity

- D r :

-

Relative density

- CSR:

-

Cyclic stress ratio

- \(e_{\text{skeleton}}\) :

-

Sand skeleton void ratio

- \(e^{*}\) :

-

Intergranular contact index void ratio

- \(e_{\text{f}}^{*}\) :

-

Equivalent interfine void ratio

- \(\rho_{\text{W}}\) :

-

Density of water

- M :

-

Mass of soil

- M f :

-

Mass of fines

- e :

-

Void ratio

- ϒmin :

-

Maximum index unit weight

- ϒmax :

-

Minimum index unit weight

- D 50 :

-

Mean grain size

References

Choobbasti AJ, Naghizaderokni M, Charaty R (2017) Microzonation of liquefaction hazard using liquefaction index in Babol City. Geotech Eng 48(3):137–143

Choobbasti AJ, Ghalandarzadeh A, Esmaeili M (2014) Experimental study of the grading characteristic effect on the liquefaction resistance of various graded sands and gravelly sands. Arab J Geosci 7(7):2739–2748

Huang Y, Zhao L (2018) The effects of small particles on soil seismic liquefaction resistance: current findings and future challenges. Nat Hazards 92(1):567–579

Akhila M, Rangaswamy K, Sankar N (2019) Effect of non-plastic fines on undrained response of fine sand. Int J 16(54):170–175

Putti SP, Satyam N (2018) Ground response analysis and liquefaction hazard assessment for Vishakhapatnam city. Innov Infrastruct Solut 3(1):12

Singnar L, Sil A (2018) Liquefaction potential assessment of Guwahati city using first-order second-moment method. Innov Infrastruct Solut 3(1):36

Karim ME, Alam MJ (2014) Effect of non-plastic silt content on the liquefaction behavior of sand–silt mixture. Soil Dyn Earthq Eng 65:142–150

Naeini S, Baziar M (2004) Effect of fines content on steady-state strength of mixed and layered samples of a sand. Soil Dyn Earthq Eng 24(3):181–187

Casagrande A (1971) On liquefaction phenomena, by Professor A. Casagrande: Report of Lecture, vol 21

Castro G, Seed RB, Keller TO, Seed HB (1992) Steady-state strength analysis of lower San Fernando Dam slide. J Geotech Eng 118(3):406–427

Karim ME, Alam MJ (2017) Effect of nonplastic silt content on undrained shear strength of sand–silt mixtures. Int J Geo-Eng 8(1):14

Kim U-G, Zhuang L, Kim D, Lee J (2017) Evaluation of cyclic shear strength of mixtures with sand and different types of fines. Mar Georesour Geotechnol 35(4):447–455

Benahmed N, Nguyen TK, Hicher PY, Nicolas M (2015) An experimental investigation into the effects of low plastic fines content on the behaviour of sand/silt mixtures. Eur J Environ Civ Eng 19(1):109–128

Xenaki V, Athanasopoulos G (2003) Liquefaction resistance of sand–silt mixtures: an experimental investigation of the effect of fines. Soil Dyn Earthq Eng 23(3):1–12

Porcino DD, Diano V (2017) The influence of non-plastic fines on pore water pressure generation and undrained shear strength of sand–silt mixtures. Soil Dyn Earthq Eng 101:311–321

Akhila M, Rangaswamy K, Sankar N (2019) Undrained response and liquefaction resistance of sand–silt mixtures. Geotech Geol Eng 37(4):2729–2745

Chemmam M, Arab A, Belkhatir M, Bouferra R (2016) Behavior of loose silty sand of chlef river: effect of low plastic fine contents and other parameters. Mar Georesour Geotechnol 34(4):384–394

Arab A, Sadek M, Belkhatir M, Shahrour I (2014) Monotonic preloading effect on the liquefaction resistance of Chlef silty sand: a laboratory study. Arab J Sci Eng 39(2):685–694

Noorzad R, Amini PF (2014) Liquefaction resistance of Babolsar sand reinforced with randomly distributed fibers under cyclic loading. Soil Dyn Earthq Eng 66:281–292

Jafarian Y, Ghorbani A, Salamatpoor S, Salamatpoor S (2013) Monotonic triaxial experiments to evaluate steady-state and liquefaction susceptibility of Babolsar sand. J Zhejiang Univ Sci A 14(10):739–750

Askari F, Dabiri R, Shafiee A, Jafari MK (2011) Liquefaction resistance of sand–silt mixtures using laboratory based shear Wave velocity. Int J Civ Eng 9(2):135–144

Kuerbis R, Negussey D, Vaid Y (1988) Effect of gradation and fines content on the undrained response of sand. In: Hydraulic fill structures. Publ by ASCE, pp 330–345

Wei X, Yang J (2019) Cyclic behavior and liquefaction resistance of silty sands with presence of initial static shear stress. Soil Dyn Earthq Eng 122:274–289

Bensoula M, Missoum H, Bendani K (2018) Liquefaction potential sand–silt mixtures under static loading. Rev Constr J Constr 17(2):196–208

Hernández YA, Towhata I, Gunji K, Yamada S (2015) Laboratory tests on cyclic undrained behavior of loose sand with cohesionless silt and its application to assessment of seismic performance of subsoil. Soil Dyn Earthq Eng 79:365–378

Hsiao D-H, Phan VT-A, Hsieh Y-T, Kuo H-Y (2015) Engineering behavior and correlated parameters from obtained results of sand–silt mixtures. Soil Dyn Earthq Engi 77:137–151

Amini F, Qi G (2000) Liquefaction testing of stratified silty sands. J Geotech Geoenviron Eng 126(3):208–217

Dezfulian H (1982) Effects of silt content on dynamic properties of sandy soils. In: Proceedings of the eighth world conference on earthquake engineering, pp 63–70

Finn W, Ledbetter R, Wu G (1994) Liquefaction in silty soils: design and analysis. In: Ground failures under seismic conditions. ASCE, pp 51–76

Chang N, Yeh S, Kaufman L (1982) Liquefaction potential of clean and silty sands. In: Proceedings of the third international earthquake microzonation conference, pp 1017–1032

Thevanayagam S, Fiorillo M, Liang J (2000) Effect of non-plastic fines on undrained cyclic strength of silty sands. Soil Dyn Liquefaction 2000:77–91

Thevanayagam S (2000) Liquefaction potential and undrained fragility of silty soils. In: Proceedings of the 12th world conference earthquake engineering. New Zealand Society of Earthquake Engineering, Wellington, New Zealand

Thevanayagam S, Martin G (2002) Liquefaction in silty soils—screening and remediation issues. Soil Dyn Earthq Eng 22(9–12):1035–1042

Malidarreh N, Shooshpasha I, Mirhosseini S, Dehestani M (2018) Effects of recycled Polyethylene terephthalate fibers on strength behavior of cemented Babolsar sand. Sci Iran 27:1130–1143

Amini PF, Noorzad R (2018) Energy-based evaluation of liquefaction of fiber-reinforced sand using cyclic triaxial testing. Soil Dyn Earthq Eng 104:45–53

Koutenaei RY, Choobbasti AJ, Kutanaei SS (2019) Triaxial behaviour of a cemented sand reinforced with Kenaf fibres. Eur J Environ Civ Eng. https://doi.org/10.1080/19648189.2019.1574607

Ghadakpour M, Janalizadeh Choobbasti A, Soleimani Kutanaei S (2019) Investigation of the deformability properties of fiber reinforced cemented sand. J Adhes Sci Technol 33(17):1913–1938

Janalizadeh Choobbasti A, Soleimani Kutanaei S, Taslimi Paein Afrakoti M (2019) Modeling of compressive strength of cemented sandy soil. J Adhes Sci Technol 33(8):791–807

Zahmatkesh A, Janalizadeh Choobbasti A (2017) Calibration of an advanced constitutive model for Babolsar sand accompanied by liquefaction analysis. J Earthq Eng 21(4):679–699

Jafarzadeh F, Sadeghi H (2012) Experimental study on dynamic properties of sand with emphasis on the degree of saturation. Soil Dyn Earthq Eng 32(1):26–41

Noorzad R, Shakeri M (2017) Effect of silt on post-cyclic shear strength of sand. Soil Dyn Earthq Eng 97:133–142

Bahadori H, Ghalandarzadeh A, Towhata I (2008) Effect of non plastic silt on the anisotropic behavior of sand. Soils Found 48(4):531–545

Kutanaei SS, Choobbasti AJ (2015) Prediction of combined effects of fibers and cement on the mechanical properties of sand using particle swarm optimization algorithm. J Adhes Sci Technol 29(6):487–501

ASTM.D4253 Standard test methods for maximum index density and unit weight of soils using a vibratory table. American Society for Testing and Materials

ASTM.D4254 Standard test methods for minimum index density and unit weight of soils using a vibratory table. American Society for Testing and Materials

Wood FM, Yamamuro JA, Lade PV (2008) Effect of depositional method on the undrained response of silty sand. Can Geotech J 45(11):1525–1537

Xia H, Hu T (1991) Effects of saturation and back pressure on sand liquefaction. J Geotech Eng 117(9):1347–1362

ASTM.D5311 Standard test methods for load controlled strength of soil. American Society for Testing and Materials

ASTM.D2850 Standard test method for unconsolidated-undrained triaxial compression test on cohesive soils. American Society for Testing and Materials

Moayed RZ, Khavaninzadeh E, Tochaee MG (2019) Effect of silt presence on shear strength parameters of unsaturated sandy soils. Int J Geotech Geol Eng 13(6):439–442

Phan VT-A, Hsiao D-H, Nguyen PT-L (2016) Effects of fines contents on engineering properties of sand–fines mixtures. Procedia Eng 142:213–220

Ishihara K (1985) Stability of natural deposits during earthquakes. In: Paper presented at the the 11th international conference on soil mechanics and foundation engineering

Ishihara K, Tatsuoka F, Yasuda S (1975) Undrained deformation and liquefaction of sand under cyclic stresses. Soils Found 15(1):29–44

Rahman MM, Lo S, Gnanendran C (2008) On equivalent granular void ratio and steady state behaviour of loose sand with fines. Can Geotech J 45(10):1439–1456

Yang S, Sandven R, Grande L (2006) Instability of sand–silt mixtures. Soil Dyn Earthq Eng 26(2–4):183–190

Ni Q, Tan T, Dasari G, Hight D (2004) Contribution of fines to the compressive strength of mixed soils. Géotechnique 54(9):561–569

Lentini V, Castelli F (2019) Liquefaction resistance of sandy soils from undrained cyclic triaxial tests. Geotech Geol Eng 37(1):201–216

El-Kady MS, ElMesmary MA (2018) Cyclic strengths for high density soils related to pore water pressure. Innov Infrastruct Solut 3(1):46

Kumar A, Kumari S (2019) Numerical modeling of shallow foundation on liquefiable soil under sinusoidal loading. Geotech Geol Eng 37(2):517–532

Funding

Funding was provided by Babol Noshirvani University of Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Janalizadeh Choobbasti, A., Selatahneh, H. & Karimi Petanlar, M. Effect of fines on liquefaction resistance of sand. Innov. Infrastruct. Solut. 5, 87 (2020). https://doi.org/10.1007/s41062-020-00338-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-020-00338-3