Abstract

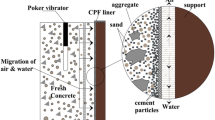

The controlled permeable formwork (CPF) liner is a novel way to improving the quality of cover zone of concrete. This technique is used to remove excess water and trapped air from the near surface of fresh concrete while retaining small particles such as cement and other fine particles. As a result, the concrete’s surface zone has a lower water-to-cement ratio, lower surface porosity and more cement content. This study looked at the effect of CPF liner on concrete’s strength, durability and chemical resistance. Three different water-to-cement ratios (0.48, 0.41, and 0.31) were used to cast concrete samples against a CPF liner and an impermeable formwork (IMF). At various ages, the compressive strength, water absorption, sorptivity, hydrochloric acid and sulphate resistance tests were performed. The findings revealed that CPF concretes had an excellent resistance to water absorption and sorptivity by 15–30% and 32–67% respectively. The residual compressive strength of CPF concrete was more by 9–144% compared to IMF concretes under hydrochloric acid environment.

Similar content being viewed by others

References

Kwasny J, Sonebi M, Plasse J, Amziane S (2015) Influence of rheology on the quality of surface finish of cement-based mortars. Constr Build Mater 89:102–109

Coutinho JS (2003) The combined benefits of CPF and RHA in improving the durability of concrete structure. Cem Concr Compos 25:51–59

Basheer L, Nanukuttan SV, Basheer PAM (2008) The influence of reusing ‘Formtex’ controlled permeability formwork on strength and durability of concrete. Mater Struct 41:1363–1375

Dey S, Kumar VV, Phani Manoj AV (2022) An experimental study on strength and durability characteristics of self-curing self-compacting concrete. Struct Concr. https://doi.org/10.1002/suco.202100446

Dey S, Kumar VV, Goud KR, Basha SK (2021) State of art review on self-compacting concrete using mineral admixtures. J Build Pathol Rehabil 6(1):1–23

McCarthy MJ, Giannakou A, Jones MR (2001) Specifying concrete for chloride environments using controlled permeability formwork. Mater Struct 34:566–576

Nolan E, Basheer PAM, Long AE (1995) Effects of three durability enhancing products on some physical properties of near surface concrete. Constr Build Mater 9:267–272

Price WF (2000) Controlled permeability formwork, CIRIA Report, C 511

Arslan M (2001) The effects of permeable formworks with sucker liners on the physical properties of concrete surfaces. Constr Build Mater 15:149–156

Law DW, Molyneaux T, Aly T (2017) Long term performance of controlled permeability formwork. Aust J Civ Eng 15:117–125

Liu J, Miao C, Chen C, Liu J, Cui G (2013) Effect and mechanism of controlled permeable formwork on concrete water adsorption. Constr Build Mater 39:129–133

Price WF, Widdows SJ (1991) The effect of permeable formwork on the surface properties of concrete. Mag Concr Res 43:93–104

Brueckner R, Williamson SJ, Clark LA (2012) Rate of the thaumasite form of sulphate attack under laboratory conditions. Cem Concr Compos 34:365–369

Chen C, Liu J, Cui G, Liu J (2012) Effect of controlled permeability formwork on the improvement of concrete performance. Procedia Eng 27:405–411

Ye J, Yu L, Chen Y (2019) Study on the mitigative effect of controlled permeability formwork liner on early-age shrinkage of box-girder concrete. J Adv Mater Sci Eng 2019:1–8. Article ID 4150279

McCarthy MJ, Giannakou A (2002) In-situ performance of CPF concrete in a coastal environment. Cem Concr Res 32:451–457

Figueiras H, Nunes S, Sousa J, Figueiras J (2009) Combined effect of two sustainable technologies: self compacting concrete and controlled permeability formwork. Constr Build Mater 23:2518–2526

Coutinho JS (2001) Effect of controlled permeability formwork (CPF) on white concrete. ACI Mater J 98:148–169

Adam AA, Law DW, Molyneaux T, Patnaikuni I, Aly T (2010) The effect of using controlled permeability formwork on the durability of concrete containing OPC and PFA. Aust J Civ Eng 6:1–12

McKenna P (2010) The effect of controlled permeability formwork on carbonation-induced corrosion. In: 3rd FIB international congress, Scotland, pp 1–8

Kothandaraman S, Kandasamy S (2016) The effect of controlled permeable formwork liner on the mechanical properties of concrete. Mater Struct 49:4737–4747

Kothandaraman S, Kandasamy S, Sivaraman K (2016) Studies on the effect of controlled permeable formwork liner on the properties of self compacting concrete. Constr Build Mater 118:319–326

Aissoun BM, Gallias JL, Khayat KH (2017) Influence of formwork material on transport properties of self-consolidating concrete near formed surfaces. Constr Build Mater 146:329–337

Garg S, Nim KS, Bajpai KK, Misra S (2019) Enhancement in the quality of near surface concrete using some formwork liners. Constr Build Mater 207:722–733

Guo BL, Wang BM, Han Y, Jiang R (2020) Improvement of concrete property with controlled permeability formwork. Rev Rom Mater 50(3):379–386

Megid WA, Khayat KH (2020) Variations in surface quality of self-consolidation and highly workable concretes with formwork material. Constr Build Mater 238. Article ID 117638

Sørensen HE, Poulsen SL (2018) Effect of curing regime and controlled permeability formwork on early chloride penetration into fly ash concrete. In: High tech concrete: where technology and engineering meet. Springer, Cham

Tahmoorian F, Nemati S, Soleimani A (2020) A state of the art on the structural performance of fabric formwork systems. Eng Solid Mech 8(1):49–62

Kasai Y, Nagano M, Sato K, Suga K (1998) Study on the evaluation of concrete quality prepared with permeable forms and plywood forms. Trans Jpn Concr Inst 10:59–66

Schubel PJ, Warrior NA, Elliott KS, Jones M (2008) An investigation into the critical factors affecting the performance of composite controlled permeability formwork liners. Constr Build Mater 22:1551–1559

Kothandaraman S, Kandasamy S (2017) The effect of controlled permeable formwork (CPF) liner on the surface quality of concrete. Cem Concr Compos 76:48–56

IS:8112: 2013 (2013) Specification for ordinary Portland cement—43 Grade. Bureau of Indian Standards, New Delhi

IS:383: 1970 (1970) Specification for coarse and fine aggregate from natural sources for concrete. Bureau of Indian Standards, New Delhi

IS:456: 2000 (2000) Plain and reinforced concrete, Code of Practice. Bureau of Indian Standards, New Delhi

IS:9103: 1999 (1999) Specification for concrete admixtures. Bureau of Indian Standards, New Delhi

ASTM B 276 (2000) Standard test method for apparent porosity in cemented carbides. American Society for Testing Materials

IS:516: 1959 (1999) Methods of tests for strength of concrete. Bureau of Indian Standards, New Delhi

ASTM C 642: 1997 (1997) Standard test method for density, absorption and voids in hardened concrete. American Society for Testing Materials

ASTM C 1585: 2004 (2004) Standard test method for measurement of rate of absorption of water by hydraulic cement concrete. American Society for Testing Materials

ASTM C 617: 2003 (2003) Standard practice for capping cylindrical concrete specimen. American Society for Testing Materials

Neville AM (1995) Properties of concrete, 4th edn. Noida, Pearson Education, p 488

Vidal EN, Blanks RF (1942) Absorptive form lining. J Am Concr Inst Proc 13(3):253–268

Peter JA, Chitharanjan N (1995) Evaluation of indigenous filter fabrics for use in controlled permeable formwork. Indian Concr J 69(4):215–219

Funding

None.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interest.

Ethics approval and consent to participate

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kandasamy, S., Gowthaman, M., Gowdhamramkarthik, P. et al. Strength and durability performance of concrete cast using permeable formwork liner. J Build Rehabil 7, 89 (2022). https://doi.org/10.1007/s41024-022-00231-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41024-022-00231-9