Abstract

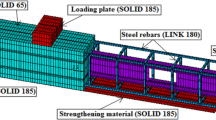

Concrete-filled steel tube (CFST) beams are widely used in civil engineering, especially for bridges and tall buildings, because of their strength, stiffness and durability. Good bonding at their interface is essential for ensuring that steel and concrete can work well together. However, if interfacial slippage does occur it not only hinders the plasticity of a beam’s performance in full section but also weakens its strength and stiffness. To study the mechanism of slip occurrence and its impact, eight prestressed CFST rectangular beams were tested under monotonic loading. Slippage was measured during the entire loading procedure. Based on the elasto-plastic theory, a nonlinear finite element model, considering slippage is developed in this paper. The results show that slippage occurred when the concrete began to crack. This plays an important role in the overall performance of a beam after the steel has yielded. The maximum slip occurred near the section of quarter-span. To some extent, the slip curves generated by this model agreed with the test results, and it could be used to predict the bending capacity of prestressed CFST beams.

Similar content being viewed by others

References

Zhao XL, Hancock GJ (1991) Tests to determine plate slenderness limits for cold-formed rectangular hollow sections of grade C450. Steel Constr 4(25):2–16

Mohanad M, Uy B (2000) Strength of concrete filled steel box columns incorporating local buckling. J Struct Eng 3(126):341–352

Zhao XL, Grzebieta R (1999) Void-filled SHS beams subjected to large deformation cyclic bending. J Struct Eng 125(125):1020–1027

Varma AH, Ricle JM, Sause R, Lu LW (2002) Experimental behavior of high strength square concrete-filled steel tube beam-columns. J Struct Eng 3(128):309–318

Varma AH, Ricles JM, Sause R, Lu LW (2002) Seismic behavior and design of high-strength square concrete-filled steel tube beam columns. J Struct Eng 2(130):169–179

Andrawes B, Pozolo A, Chen Z (2011) Development length tests of full-scale prestressed self-consolidating concrete box and I-girders. J Bridge Eng 11(18):1209–1218

Chen BC, Wang TL (2009) Overview of concrete filled steel tube arch bridges in China. Pract Period Struct Des Constr 2(14):70–80

Moon J, Roeder CW, Lehman DE, Lee HE (2012) Analytical modeling of bending of circular concrete-filled steel tubes. Eng Struct 42(12):349–361

Nakamura SI, Momiyama Y, Hosaka T, Homma K (2002) New technologies of steel/concrete composite bridges. J Constr Steel Res 58(1):99–130

Wheeler A, Bridge R (2006) The behaviour of circular concrete-filled thin-walled steel tubes in flexure. In: 5th international conference on composite construction in steel and concrete, Mpumalanga, pp 412–413

Chitawadagi MV, Narasimhan M (2009) Strength deformation behaviour of circular concrete filled steel tubes subjected to pure bending. J Constr Steel Res 65:1836–1845

Zhan YL, Zhao RD, Ma ZG, Xu TF, Song RN (2016) Behavior of prestressed concrete-filled steel tube (CFST) beam. Eng Struct 122:144–155

Morishita Y, Tomii M (1982) Experimental studies on bond strength between square steel tube and encased concrete core under cyclic shearing force and constant axial force. Trans Jpn Concr Inst 4(4):363–370

Shakir-Khalil H (1993) Push out strength of concrete-filled steel hollow section tubes. Struct Eng 13(71):230–233

Shakir-Khalil H (1993) Resistance of concrete-filled steel tubes to pushout forces. Struct Eng 13(71):234–243

Aval SBB, Saadeghvaziri MA, Golafshani AA (2002) Comprehensive composite inelastic fiber element for cyclic analysis of concrete-filled steel tube columns. J Eng Mech 4(128):428–437

Salari MR, Spacone E (2001) Finite element formulations of one-dimensional elements with bond–slip. Eng Struct 7(l.23):815–826

Vincent T, Ozbakkaloglu T (2015) Compressive behavior of prestressed high-strength concrete-filled aramid FRP tube columns: experimental observations. J Compos Constr 6(19):04015003–04015013

American Institute of Steel Construction (AISC) (2010) Load and resistance factor design specification for structural steel buildings. American Institute of Steel Construction, Chicago

Tomii M, Sakino K (1979) Experimental studies on the ultimate moment of concrete filled square steel tubular beam-columns. Trans Architect Inst Jpn 275:55–63

Tomii M, Sakino K (1979) Elasto-plastic behavior of concrete filled square steel tubular beam-columns. Trans Architect Inst Jpn 280:111–122

Acknowledgements

We gratefully acknowledge the support of the Sichuan Science and Technology Program (Grant 2018GZ0052), the National Key Research and Development Program of China (Grant 2016YFB1200401), and the Science and Technology Project of Sichuan Province (Grant 2017GZ0369) for the research reported in this paper.

Funding

The Sichuan Science and Technology Program (Grant 2018GZ0052), Sichuan provincial science and Technology Department, China. The National Key Research and Development Program of China (Grant 2016YFB1200401), Ministry of science and technology of People's Republic of China. The Science and Technology Project of Sichuan Province (Grant 2017GZ0369) Sichuan provincial science and Technology Department, China.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The following symbols were used in the paper:

\(\lambda\) = the degree of prestress.

\({M_0}\) = the decompression moment, which meant the moment that produced zero tension at the tensile fiber of the section in the middle span considering the influence of prestress.

\({M_u}\) = the ultimate moment of the composite section.

\({\sigma _h}\) = the effective compressive prestress at the tensile edge of composite section.

\({W_0}\) = the flexural modulus.

\(\alpha\) = steel ratio of composite section.

\({A_s}\), \({A_c}\) = area of steel and concrete, respectively.

\({\sigma _c}\),\({\varepsilon _c}\) = the compressive stress and strain of concrete.

\(\sigma _{c}^{'}\),\(\varepsilon _{c}^{'}\) = the compressive strength and the corresponding strain of concrete.

\({\sigma _t}\), \({\varepsilon _t}\) = the tensile stress and strain of concrete.

\({E_c}\) = the Young’s modulus of concrete.

\({\sigma _{tu}}\),\({\varepsilon _{tu}}\) = the tensile strength and the corresponding strain of concrete.

\({\sigma _s}\), \({\varepsilon _s}\) = the stress and strain of steel.

\({E_s}\) = the Young’s modulus of steel.

\({\sigma _y}\),\({\varepsilon _y}\) = the yield stress and the corresponding strain of steel.

\({\varepsilon _{sh}}\) = the strengthening strain of steel.

\({\sigma _u}\),\({\varepsilon _u}\) = the ultimate stress and the corresponding strain of steel.

\(k\) = the powering of hardening rule, taken as 3.

\({\sigma _{ps}}\),\({\varepsilon _{ps}}\) = the stress and strain of prestressed strands.

\({\sigma _{pu}}\) = the ultimate strength of prestressed strands.

\({E_p}\) = the Young’s modulus of prestressed strands.

\({E^\prime }\) = the slop at the initial point of Ramberg–Osgood curve, taken as 214 GPa.

\(m\) = the coefficient for Ramberg–Osgood curve, taken as 4.

\(\tau\) = the shear stress on the interface.

\(u\) = the slip on the interface.

Mcr = the cracking moment of mid-span.

M100 = the moment corresponding to the deformation reached the 1% of the span.

My2 = the moment corresponding to the yield state of steel at compressive side.

M, Δ = the moment and the corresponding deformation of mid-span.

Rights and permissions

About this article

Cite this article

Zhan, Y., Zhang, L., Zhao, R. et al. Theoretical and Experimental Study on the Bond–Slip Relationship in Prestressed CFST Beams. Int J Civ Eng 17, 629–643 (2019). https://doi.org/10.1007/s40999-018-0344-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-018-0344-6