Abstract

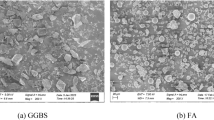

This study presents a comprehensive analysis of the development of aerated concrete (AC) blocks with a focus on the effect of various binders and additives on their mechanical and durability properties. The binders are flyash (FA), glass powder (GLP), and ground granulated blast furnace slag (GGBS). Further, cement, lime, gypsum powder, FA, GLP and GGBS were used as the individual binders in the absence of aluminium powder. Alternately, Na2SiO3 and NaOH were combined in a ratio of (Na2SiO3/NaOH = 1.5) to produce the alkaline solution utilised in the design of AC blocks. Using an accelerated curing tank, heat curing was performed. Further substitution of FA or GLP and GGBS with 50% construction & demolition waste (C&D) waste was conducted in distinct batches. Later, 4% aluminium stearate powder (ASP) and 5% chopped steel wool fibres (CSWF) by weight were added to the various batches to create AC blocks and evaluate the effect on aeration and strength enhancement. Moreover, the mechanical and durability characteristics of each batch were analysed and compared. It was discovered that the mechanical and durability properties of GGBS-based mixtures were superior. ASP was also found to increase mechanical strength and resistance to chemical attack, while decreasing block density, water absorption, and drying shrinkage. The mechanical strength increased significantly as a result of CSWF influence on the batches. Eventually, a microstructural investigation of FA and GGBS-based AC blocks with and without ASP was conducted in order to interpret the differences that aluminium stearate causes in the morphology of aerated blocks.

Similar content being viewed by others

Availability of Data

All data were self-generated through experimental investigation.

References

Abd Elhakam A, Awad E (2012) Influence of self-healing, mixing method and adding silica fume on mechanical properties of recycled aggregates concrete. Construct Build Mater 35:421–427

Aldikheeli MR, Shubber MS (2020) The effects of fibre on the mechanical properties of aerated concrete. In: IOP conference series: materials science and engineering, vol 671. IOP Publishing, p 012076

Ali T, Saand A, Bangwar DK, Buller AS, Ahmed Z (2021) Mechanical and durability properties of aerated concrete incorporating rice husk ash (RHA) as partial replacement of cement. Crystals 11(6):604. https://doi.org/10.3390/cryst11060604

Amer AAR, Abdullah MMAB, Liew YM, Aziz IHA, Wyslocki JJ, Mohd Tahir MF, Sochacki W, Garus S, Gondro J, Amer HAR (2021) Optimizing of the cementitious composite matrix by addition of steel wool fibers (chopped) based on physical and mechanical analysis. Materials 14(5):1094

Anon (2019) “Aluminium Stearate | Applications and Specifications.” Retrieved July 30, 2023. https://aluminium-stearate.com/aluminium-stearate-specifications/, https://aluminium-stearate.com/aluminium-stearate-specifications/

Anon (n.d.-a) Density vs. strength. Basalite. Retrieved July 30, 2023. https://basalite.ca/basalite-pro-resources/density-vs-strength/

Anon. n.d.-b. “IS 516 (1959) Method of tests for strength of concrete

Anon. n.d.-c. “IS 2185-3 (1984) Concrete masonry units, part 3: autoclaved cellular aerated concrete blocks

Anon. n.d.-d. “IS 6441-1 (1972) Methods of test for autoclaved cellular concrete products, part i: determination of unit weight or bulk density and moisture content.”

Anon. n.d.-e. “IS 6441-2 (1972) Methods of test for autoclaved cellular concrete products, part ii: determination of drying shrinkage”

Anon. n.d.-f. “IS 6441-5 (1972) Methods of test for autoclaved cellular concrete products, part V: determination of compressive strength.”

Anon. n.d.-g. “IS 10078 (1982) Specification for jolting apparatus for testing cement”

Anon. n.d.-h. “Standard test methods for chemical resistance of mortars, grouts, and monolithic surfacings and polymer concretes.” Retrieved February 11, 2023. https://www.astm.org/c0267-01.html

Anon. n.d.-i. “Standard test methods for sampling and testing concrete masonry units and related units.” Retrieved February 11, 2023. https://www.astm.org/c0140_c0140m-20a.html

Anupoju S (2016) Testing of concrete masonry blocks for compressive strength and density. The Constructor. Retrieved July 30, 2023. https://theconstructor.org/practical-guide/compressive-strength-concrete-blocks-masonry-units/13966/

Atoyebi OD, Ikubanni PP, Adesina A, Araoye OV, Davies IEE (2020) “Effect of curing methods on the strength of interlocking paving blocks” edited by P. Cacciola. Cogent Eng 7(1):1770914. https://doi.org/10.1080/23311916.2020.1770914

Azarhomayun F, Haji M, Kioumarsi M, Shekarchi M (2022) Effect of calcium stearate and aluminum powder on free and restrained drying shrinkage, crack characteristic and mechanical properties of concrete. Cement Concr Compos 125:104276. https://doi.org/10.1016/j.cemconcomp.2021.104276

Behera M, Bhattacharyya SK, Minocha AK, Deoliya R, Maiti S (2014) Recycled aggregate from C&D waste and its use in concrete—a breakthrough towards sustainability in construction sector: a review. Constr Build Mater 68:501–516

Bernard VA, Raj SM, Renuka SA, Umarani C, Amran M, Guindos P, Fediuk R, Vatin NI (2022) Performance investigation of the incorporation of ground granulated blast furnace slag with fly ash in autoclaved aerated concrete. Crystals 12(8):1024. https://doi.org/10.3390/cryst12081024

Bhat A, Khan Z (2020) Behaviour of autoclaved aerated concrete blocks using alkali-resistant glass fibre as additive. https://doi.org/10.35940/ijrte.F8478.038620

Bonakdar A, Babbitt F, Mobasher B (2013) Physical and mechanical characterization of fiber-reinforced aerated concrete (FRAC). Cement Concr Compos 38:82–91. https://doi.org/10.1016/j.cemconcomp.2013.03.006

C09 Committee (n.d.) Test method for electrical indication of concretes ability to resist chloride ion penetration. ASTM International. https://doi.org/10.1520/C1202-12

Chaipanich A, Chindaprasirt P (2015) The properties and durability of autoclaved aerated concrete masonry blocks. In: Eco-efficient masonry bricks and blocks. Elsevier, pp 215–30

El-Didamony H, Amer AA, Mohammed MS, El-Hakim MA (2019) Fabrication and properties of autoclaved aerated concrete containing agriculture and industrial solid wastes. J Build Eng 22:528–538. https://doi.org/10.1016/j.jobe.2019.01.023

Etxeberria M, Vázquez E, Marí A, Barra M (2007) Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem Concr Res 37(5):735–742

Fantilli A, Sicardi S, Dotti F (2016) The use of wool as fiber-reinforcement in cement-based mortar. Construct Build Mater. https://doi.org/10.1016/j.conbuildmat.2016.10.096

Favaretto P, Hidalgo G, Sampaio C, Silva R, Lermen R (2017) Characterization and use of construction and demolition waste from south of brazil in the production of foamed concrete blocks. Appl Sci 7(10):1090. https://doi.org/10.3390/app7101090

Febin G, Kottukappalli A, Abhirami AK, Vineetha V, Manisha RR, Sathyan D, Mini KM (2019) Strength and durability properties of quarry dust powder incorporated concrete blocks. Constr Build Mater 228:116793

Fomina EV, Chulenyov AS, Kozhukhova NI (2018) Properties control in autoclave aerated concrete by choosing of pore forming AL-agent. IOP Conf Ser Mater Sci Eng 365:032044. https://doi.org/10.1088/1757-899X/365/3/032044

Fudge C, Fouad F, Klingner R (2019) Autoclaved aerated concrete. In: Developments in the formulation and reinforcement of concrete. Elsevier, pp 345–63

Geetha S, Sree Varrun D, Sathya Sudhan S, Muthuraja V (2023) Studies on properties of polymer modified aerated concrete. Mater Today Proc 80:870–876. https://doi.org/10.1016/j.matpr.2022.11.321

Güçlüer K, Demir İ (n.d.) Utilization of metakaolin and blast furnace slag in autoclaved aerated concrete production

Guo Z (2014) Principles of reinforced concrete. Butterworth-Heinemann, New York

Gyurkó Z, Jankus B, Fenyvesi O, Nemes R (2019) Sustainable applications for utilization the construction waste of aerated concrete. J Clean Prod 230:430–444

Hadavand B, Imaninasab R (2019) Assessing the influence of construction and demolition waste materials on workability and mechanical properties of concrete using statistical analysis. Innovat Infrastruct Solut 4(1):29. https://doi.org/10.1007/s41062-019-0214-3

Hassan SS (2018) Effects of recycled concrete aggregate on some mechanical properties of high strength concrete. IOP Conf Ser Mater Sci Eng 433(1):012033. https://doi.org/10.1088/1757-899X/433/1/012033

Hodul J, Hodná J, Mészárosová L, Borg RP (2022) Experimental comparison of efficiency of water-soluble and solvent hydrophobic agents for concrete. Buildings 12(11):1857. https://doi.org/10.3390/buildings12111857

Hospodarova V, Junak J, Stevulova N (2015) Color pigments in concrete and their properties. Pollack Periodica 10:143–151. https://doi.org/10.1556/606.2015.10.3.15

https://www.facebook.com/fasiforyou (2020) Standard specifications of hollow and solid concrete blocks. The Constructor. Retrieved July 30, 2023. https://theconstructor.org/concrete/hollow-solid-concrete-blocks-specification/54785/

Huang X-Y, Ni W, Cui W-H, Wang Z-J, Zhu L-P (2012) Preparation of autoclaved aerated concrete using copper tailings and blast furnace slag. Constr Build Mater 27(1):1–5

Ioana A, Paunescu L, Constantin N, Rucai V, Dobrescu C, Pasare V, Istrate A (2022) High-strength and heat-insulating cellular building concrete based on calcined gypsum. Materials 16(1):118. https://doi.org/10.3390/ma16010118

Jamshaid H, Mishra RK, Raza A, Uzair Hussain Md, Rahman L, Nazari S, Chandan V, Muller M, Choteborsky R (2022) Natural cellulosic fiber reinforced concrete: influence of fiber type and loading percentage on mechanical and water absorption performance. Materials 15(3):874. https://doi.org/10.3390/ma15030874

Jiang J, Ma B, Cai Q, Shao Z, Yueyang Hu, Qian B, Wang J, Ma F, Wang L (2021) Utilization of ZSM-5 waste for the preparation of autoclaved aerated concrete (AAC): mechanical properties and reaction products. Constr Build Mater 297:123821

Kaplan G, Bayraktar OY, Gholampour A, Gencel O, Koksal F, Ozbakkaloglu T (2021) Mechanical and durability properties of steel fiber-reinforced concrete containing coarse recycled concrete aggregate. Struct Concr 22(5):2791–2812. https://doi.org/10.1002/suco.202100028

Karakurt C, Kurama H, Topcu IB (2010) Utilization of natural zeolite in aerated concrete production. Cement Concr Compos 32(1):1–8

Katar I, Ibrahim Y, Malik MA, Khahro SH (2021) Mechanical properties of concrete with recycled concrete aggregate and fly ash. Recycling 6(2):23. https://doi.org/10.3390/recycling6020023

Khunt Y, Nathwani V, Patel H, Joshi T, Gandhi D (2023) Investigation on properties of autoclave aerated concrete using different pre-curing and curing techniques. Mater Today Proc. https://doi.org/10.1016/j.matpr.2023.04.047

Kim T, Kang C, Seo K (2021) Development and characteristics of aerated alkali-activated slag cement mixed with zinc powder. Materials 14(21):6293. https://doi.org/10.3390/ma14216293

Klingner R (2008) Autoclaved aerated concrete. In: Developments in the formulation and reinforcement of concrete. Woodhead Publishing, pp. 1–43

Kunchariyakun K, Asavapisit S, Sinyoung S (2018) Influence of partial sand replacement by black rice husk ash and bagasse ash on properties of autoclaved aerated concrete under different temperatures and times. Constr Build Mater 173:220–227. https://doi.org/10.1016/j.conbuildmat.2018.04.043

Kurama H, Topcu IB, Karakurt C (2009) Properties of the autoclaved aerated concrete produced from coal bottom ash. J Mater Process Technol 209(2):767–773

Lam NT, Asamoto S, Matsui K (2018) Microstructure and shrinkage behavior of autoclaved aerated con-crete(AAC)-comparison of vietnamese and Japanese AACs. J Adv Concr Technol 16(8):333–342. https://doi.org/10.3151/jact.16.333

Liu Y, Leong BS, Zhong-Ting Hu, Yang E-H (2017) Autoclaved aerated concrete incorporating waste aluminum dust as foaming agent. Constr Build Mater 148:140–147. https://doi.org/10.1016/j.conbuildmat.2017.05.047

Ma B-G, Cai L-X, Li X-G, Jian S-W (2016) Utilization of iron tailings as substitute in autoclaved aerated concrete: physico-mechanical and microstructure of hydration products. J Clean Prod 127:162–171

Ma P, Wang C, Gao Y, Xiaowei Gu, Cheng B, Fang Z, Xiong G, Jing Wu (2022) The coupling effect of organosilicon hydrophobic agent and cement on the water resistance of phosphogypsum. Materials 15(3):845. https://doi.org/10.3390/ma15030845

Maryoto A, Gan BS, Hermanto NIS, Setijadi R (2020) Effect of calcium stearate in the mechanical and physical properties of concrete with PCC and fly ash as binders. Materials 13(6):1394

Mostafa NY (2005) Influence of air-cooled slag on physicochemical properties of autoclaved aerated concrete. Cem Concr Res 35(7):1349–1357

Nadeem Z, Mcyotto F, Wei Q (2020) Utilization of construction and demolition waste, fly ash waste in autoclaved aerated concrete, vol3

Naidu TY, Rohith, Satyanarayana GVV. (2021) Study on aerated concrete using steam curing test method. In: Tummala S, Kosaraju S, Bobba P, Singh S (eds) E3S web of conferences, vol 309, pp 01206. https://doi.org/10.1051/e3sconf/202130901206

Narayanan N, Ramamurthy K (2000) Structure and properties of aerated concrete: a review. Cement Concr Compos 22(5):321–329

Pachideh G, Gholhaki M (2019) Effect of pozzolanic materials on mechanical properties and water absorption of autoclaved aerated concrete. J Build Eng 26:100856

Perumalsamy N, Sankar A, Preethi RS, Rizwan PN (2018) Effective review on utilization of wastes in aerated cellular concrete

Pi T, Zhongheng Du, Zhang H, Wang S (2021) Experimental study on basic mechanical properties of core-column non-mortar aerated concrete block masonry. International J Concr Struct Mater 15(1):18. https://doi.org/10.1186/s40069-021-00455-y

Prakash TM, Kumar BGN (2013) Strength and elastic properties of aerated concrete block masonry. Int J Struct Civ Eng Res 1

Rafiza AR, Chan HY, Thongtha A, Jettipattaranat W, Lim KL (2019) An innovative autoclaved aerated concrete (AAC) with recycled aac powder for low carbon construction. IOP Conf Ser Earth Environ Sci 268(1):012050. https://doi.org/10.1088/1755-1315/268/1/012050

Rafiza AR, Fazlizan A, Thongtha A, Asim N, Noorashikin MS (2022) The physical and mechanical properties of autoclaved aerated concrete (AAC) with recycled AAC as a partial replacement for sand. Buildings 12(1):60. https://doi.org/10.3390/buildings12010060

Rahman RA, Fazlizan A, Asim N, Thongtha A (2020) Utilization of waste material for aerated autoclaved concrete production: a preliminary review. IOP Conf Ser Earth Environ Sci 463(1):012035. https://doi.org/10.1088/1755-1315/463/1/012035

Rahman RA, Fazlizan A, Asim N, Thongtha A (2021) A review on the utilization of waste material for autoclaved aerated concrete production. J Renew Mater 9(1):61–72

Raj A, Borsaikia AC, Dixit US (2020) Bond strength of autoclaved aerated concrete (AAC) masonry using various joint materials. J Build Eng 28:101039. https://doi.org/10.1016/j.jobe.2019.101039

Raj I, Jinu MS, John E (2021) Review on properties of GGBFS and fly ash incorporated aerated concrete with filler materials. Sustain Agri Food Environ Res 10:22334. https://doi.org/10.7770/safer-V10N1-art2482

Raj IS, Somasundaram K (2022) An optimized mix for the manufacture of sustainable aerated concrete blocks using waste rubber powder. Clean Technol Environ Policy. https://doi.org/10.1007/s10098-022-02442-7

Rathod SM, Akbari YV (2017) Performance evaluation of aerated autoclaved concrete blocks using silica 4(04):6

Różycka A, Pichór W (2016) Effect of perlite waste addition on the properties of autoclaved aerated concrete. Constr Build Mater 120:65–71

Sanjayan JG, Nazari A, Chen L, Nguyen GH (2015) Physical and mechanical properties of lightweight aerated geopolymer. Constr Build Mater 79:236–244

Seifert S, Liesch A-L, Thome V, Dittrich S, Wolfram D (2018) Application of recycled waste material for the production of autoclaved aerated concrete. Ce/papers 2(4):495–502

Shabbar R, Nedwell P, Wu Z (2016) Influence of temperature and curing method on strength of autoclaved aerated concrete. In: 36th Cement and concrete science conference, Cardiff, 5th and 6th September

Shah SHA, Ali B, Ahmed GH, Tirmazi SMT, El Ouni MH, Hussain I (2022) Effect of recycled steel fibers on the mechanical strength and impact toughness of precast paving blocks. Case Stud Construct Mater 16:e01025. https://doi.org/10.1016/j.cscm.2022.e01025

Sharma N, Sharma P (2021) Effect of hydrophobic agent in cement and concrete : a review. IOP Conf Ser Mater Sci Eng 1116:012175. https://doi.org/10.1088/1757-899X/1116/1/012175

Siddika A, Hajimohammadi A, Ferdous W, Sahajwalla V (2021) Roles of waste glass and the effect of process parameters on the properties of sustainable cement and geopolymer concrete—a state-of-the-art review. Polymers 13(22):3935. https://doi.org/10.3390/polym13223935

Silva YF, Lange DA, Delvasto S, Silva YF, Lange DA, Delvasto S (2020) Effects of the incorporation of residue of masonry on the properties of cementitious mortars. Revista De La Construcción 19(3):407–421. https://doi.org/10.7764/rdlc.19.3.407

Song Y, Li B, Yang E-H, Liu Y, Ding T (2015) Feasibility study on utilization of municipal solid waste incineration bottom ash as aerating agent for the production of autoclaved aerated concrete. Cement Concr Compos 56:51–58

Szabó R, Szűcs M, Ambrus M, Mucsi G (2023) Increasing the pozzolanic reactivity of recovered CDW cement stone by mechanical activation. Mater Proc 13(1):27. https://doi.org/10.3390/materproc2023013027

Szudek W, Gołek Ł, Malata G, Pytel Z (2022) Influence of waste glass powder addition on the microstructure and mechanical properties of autoclaved building materials. Materials 15(2):434. https://doi.org/10.3390/ma15020434

Tabsh S, Abdelfatah A (2009) Influence of recycled concrete aggregates on strength properties of concrete. Construct Build Mater 23:1163–1167. https://doi.org/10.1016/j.conbuildmat.2008.06.007

Thongtha A, Maneewan S, Punlek C, Ungkoon Y (2014) Investigation of the compressive strength, time lags and decrement factors of AAC-lightweight concrete containing sugar sediment waste. Energy Build 84:516–525. https://doi.org/10.1016/j.enbuild.2014.08.026

Varela-Rivera J, Fernandez-Baqueiro L, Alcocer-Canche R, Ricalde-Jimenez J, Chim-May R (2018) Shear and flexural behavior of autoclaved aerated concrete confined masonry walls. ACI Struct J 115(5):1453–1463

VillaMencía VR, Frías M, Ramírez SM, Carrasco LF, Giménez RG (2022) Concrete/glass construction and demolition waste (CDW) synergies in ternary eco-cement-paste mineralogy. Materials 15(13):4661. https://doi.org/10.3390/ma15134661

Volk R, Steins JJ, Stemmermann P, Schultmann F (2022) Comparison of different post-demolition autoclaved aerated concrete (AAC) recycling options. IOP Conf Ser Earth Environ Sci 1078(1):012074. https://doi.org/10.1088/1755-1315/1078/1/012074

Walczak P, Malolepszy J, Reben M, Szymański P, Rzepa K (2015) Utilization of waste glass in autoclaved aerated concrete. Procedia Eng 122:302–309

Wu H, Xiao J, Liang C, Ma Z (2021) Properties of cementitious materials with recycled aggregate and powder both from clay brick waste. Buildings 11:1–24. https://doi.org/10.3390/buildings11030119

Yan B, Ren F, Cai M, Qiao C (2019) Influence of new hydrophobic agent on the mechanical properties of modified cemented paste backfill. J Market Res 8(6):5716–5727. https://doi.org/10.1016/j.jmrt.2019.09.039

Yap ZS, Khalid NHA, Haron Z, Khu WH, Yeak SH, Amran M (2022) Rock wool-reinforced concrete: physico-mechanical properties and predictive modelling. J Build Eng 59:105128. https://doi.org/10.1016/j.jobe.2022.105128

You J, Zhou J, Xiao Y, Yang H, Yang Y (2020) Effect of curing age on material properties of autoclaved light-weight concrete wallboard. In: IOP conference series: earth and environmental science, vol. 440. IOP Publishing, p 022025

Zhang P, Li Q, Chen Y, Shi Y, Ling Y-F (2019) Durability of Steel Fiber-Reinforced Concrete Containing SiO2 Nano-Particles. Materials 12(13):2184. https://doi.org/10.3390/ma12132184

Zou D, Que Z, Cui W, Wang X, Guo Y, Zhang S (2022) Feasibility of recycling autoclaved aerated concrete waste for partial sand replacement in mortar. J Build Eng 52:104481. https://doi.org/10.1016/j.jobe.2022.104481

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

PA contributed to the project by conceptualising the study, developing the methodology, conducting formal analysis, curating the data, and writing the original draft. AKS provided support by validating the findings, allocating resources, and supervising the project. PR also played a key role by contributing to the methodology, reviewing and editing the written work, and providing supervision throughout the project.

Corresponding author

Ethics declarations

Conflict of interest

No competing interests declared by authors.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Anand, P., Sinha, A.K. & Rajhans, P. Study on Mechanical and Durability Properties of Aerated Concrete Block Containing Construction and Demolition Waste with Aluminium Stearate Powder Along with Alkaline Solution and Considering Accelerated Curing Tank. Iran J Sci Technol Trans Civ Eng 48, 797–823 (2024). https://doi.org/10.1007/s40996-023-01222-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-023-01222-7