Abstract

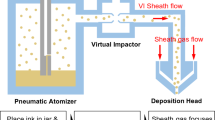

Aerosol jet printing (AJP) is a promising additive manufacturing technique for precise customization of sophisticated, electrically functional devices. However, the vast parameter space and variability in AJP processing present significant challenges to achieving consistent print morphologies with the requisite electrical performance. Moreover, the ability to robustly predict optimal operational windows to print suitable components is lacking. To address these key barriers, it is necessary to analyze the effect of system-level drift on the printed morphology and electrical performance in AJP processing. The temporal dependence in morphology and electrical performance of an Ag nanoparticle-based ink was evaluated over a 16-h print time, under fixed sheath and carrier gas flow rates. Qualitative shifts in print morphology over time were characterized by two critical transitions: (1) a transition from initially sparse and discontinuous to a fine and continuous morphology, and then (2) a transition from fine and continuous morphology to a coarse and continuous regime. The printed line cross-sections were height-profiled using confocal microscopy and fit to a characteristic Gaussian shape to create a statistical distribution of morphology over time. Using Monte Carlo sampling, cross-sections from the distribution were randomly paired to simulate an interdigitated capacitor (IDC) in a 2D finite element model. The computational workflow provided insights into the morphology-related mechanisms of failure in electrical performance and the consistency of morphology required for the electrical performance of the targeted IDC device. Collectively, this work highlights the inter-correlated parameter space that manifests as drift, as well as establishes a computational workflow to predict line quality and electrical performance as a function of time.

Similar content being viewed by others

References

Paulsen JA, Renn M, Christenson K, Plourde R (2012) Printing conformal electronics on 3D structures with Aerosol Jet technology. In: 2012 Future of Instrumentation International Workshop (FIIW) Proceedings, IEEE, pp 1–4

Kopola P, Zimmermann B, Filipovic A, Schleiermacher HF, Greulich J, Rousu S, Hast J, Myllylä R, Würfel U (2012) Aerosol jet printed grid for ITO-free inverted organic solar cells. Sol Energy Mater Sol C 107:252–258. https://doi.org/10.1016/j.solmat.2012.06.042

Gupta AA, Bolduc A, Cloutier SG, Izquierdo R (2016) Aerosol Jet Printing for printed electronics rapid prototyping. In: 2016 IEEE International Symposium on Circuits and systems (ISCAS), IEEE, pp 866–869

Lall P, Kothari N, Abrol A, Suhling J, Ahmed S, Leever B, Miller S (2019) Effect of Process Parameters on the Long-Run Print Consistency and Material Properties of Additively Printed Electronics. In: 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), IEEE, pp 1347–1358

Mahajan A, Frisbie CD, Francis LF (2013) Optimization of aerosol jet printing for high-resolution, high-aspect ratio silver lines. ACS Appl Mater Interfaces 5:4856–4864. https://doi.org/10.1021/am400606y

Li Y, Sun H, Deng X, Zhang C, Wang HP, Jin R (2020) Manufacturing quality prediction using smooth spatial variable selection estimator with applications in Aerosol Jet® printed electronics manufacturing. IISE Trans 52:321–333. https://doi.org/10.1080/24725854.2019.1593556

Miller WD, Keicher DM, Essien M (2001) Precision spray process for direct write electronic components. US Pat 6,251,488

Renn M, King B, Essien M, Keicher D (2004) Apparatus, methods and precision spray processes for direct write and maskless mesoscale material deposition. US Pat App 10/746,646

Kim D, Jeong S, Park BK, Moon J (2006) Direct writing of silver conductive patterns: improvement of film morphology and conductance by controlling solvent compositions. ApplPhys Lett 89:264101. https://doi.org/10.1063/1.2424671

Wadwah A (2015) Run-time ink stability in pneumatic aerosol jet printing using a split stream solvent add back system. RIT.

Secor EB (2018) Principles of aerosol jet printing. Flex Print Electron 3:035002. https://doi.org/10.1088/2058-8585/aace28

Wilkinson NJ, Smith MA, Kay RW, Harris RA (2019) A review of aerosol jet printing—a non-traditional hybrid process for micro-manufacturing. Int J AdvManufTechnol 105:4599–4619. https://doi.org/10.1007/s00170-019-03438-2

Secor EB (2018) Guided ink and process design for aerosol jet printing based on annular drying effects. Flex Print Elec 3:035007. https://doi.org/10.1088/2058-8585/aadffd

Salary R, Lombardi JP III, Weerawarne DL, Rao PK, Poliks MD (2018) A computational fluid dynamics (CFD) study of material transport and deposition in aerosol jet printing (AJP) process. ASME Int MechEngCongr Expos 52019:V002T02A057. https://doi.org/10.1115/IMECE2018-87647

Friend J, Yeo LY (2011) Microscale acoustofluidics: microfluidics driven via acoustics and ultrasonics. Rev Mod Phys 83:647. https://doi.org/10.1103/RevModPhys.83.647

Lee K, Hwang TH, Kim SH, Kim SH, Lee D (2013) Numerical simulations on aerodynamic focusing of particles in a wide size range of 30 nm–10 μm. Aerosol Sci Technol 47:1001–1008. https://doi.org/10.1080/02786826.2013.808737

Hoey JM, Lutfurakhmanov A, Schulz DL, Akhatov IS (2012) A review on aerosol-based direct-write and its applications for microelectronics. J Nanotechnol 2012:1–22. https://doi.org/10.1155/2012/324380

Salary R, Lombadi JP, Tootooni MS, Donovan R, Rao PK, Borgesen P, Poliks MD (2017) Computational fluid dynamics modeling and online monitoring of aerosol jet printing process. J Manuf Sci Eng 139:021015. https://doi.org/10.1115/1.4034591

Lin JL, Kao ZK, Liao YC (2013) Preserving precision of inkjet-printed features with solvents of different volatilities. Langmuir 29:11330–11336. https://doi.org/10.1021/la402461c

Goth C, Putzo S, Franke J (2011) Aerosol Jet printing on rapid prototyping materials for fine pitch electronic applications. In: 2011 IEEE 61st electronic components and technology conference (ECTC), IEEE, pp 1211–1216

Binder S, Glatthaar M, Rädlein E (2014) Analytical investigation of aerosol jet printing. Aerosol Sci Tech 48:924–929. https://doi.org/10.1080/02786826.2014.940439

Chen G, Gu Y, Tsang H, Hines DR, Das S (2018) The effect of droplet sizes on overspray in aerosol-jet printing. AdvEng Mater 20:1701084. https://doi.org/10.1002/adem.201701084

Feng JQ (2015) Sessile drop deformations under an impinging jet. Theor Comput Fluid Dyn 29:277–290. https://doi.org/10.1002/adem.201701084

Goh GL, Agarwala S, Tan YJ, Yeong WY (2018) A low cost and flexible carbon nanotube pH sensor fabricated using aerosol jet technology for live cell applications. Sens Actuators B Chem 260:227–235. https://doi.org/10.1016/j.snb.2017.12.127

Tafoya RR, Secor EB (2020) Understanding and mitigating process drift in aerosol jet printing. Flex Print 5:015009. https://doi.org/10.1088/2058-8585/ab6e74

Zhang H, Moon SK, Ngo TH, Tou J, Yusoff MA (2020) Rapid process modeling of the aerosol jet printing based on Gaussian process regression with Latin hypercube sampling. Int J Precis Eng Man 21:127–136. https://doi.org/10.1007/s12541-019-00237-3

Zhang H, Moon SK, Ngo TH (2020) 3D printed electronics of non-contact ink writing techniques: status and promise. Int J Precis Eng Man-Gt 7:511–524. https://doi.org/10.1007/s40684-019-00139-9

Salary RR, Lombardi JP III, Weerawarne DL, Tootooni MS, Rao PK, Poliks MD (2018) In situ functional monitoring of aerosol jet-printed electronic devices using a combined sparse representation-based classification (SRC) approach. ASME Int Man Sci EngConf 51357:V001T01A040. https://doi.org/10.1115/MSEC2018-6586

Smith M, Choi YS, Boughey C, Kar-Narayan S (2017) Controlling and assessing the quality of aerosol jet printed features for large area and flexible electronics. Flex Print Electron 2:015004. https://doi.org/10.1088/2058-8585/aa5af9

Salary RR, Lombardi JP, Rao PK, Poliks MD (2017) Online monitoring of functional electrical properties in aerosol jet printing additive manufacturing process using shape-from-shading image analysis. J Man Sci Eng. https://doi.org/10.1115/1.4036660

Lall P, Kothari N, Goyal K, Leever B, Miller S (2020) Extended-time process consistency and process-property relationships for flexible additive-printed electronics. In: 2020 Pan Pac Miel Symp. pp 1–16. https://doi.org/10.23919/PanPacific48324.2020.9059434

Lall P, Abrol A, Kothari N, Leever B, Miller S (2020) Process Capability of Aerosol-Jet Additive Processes for Long-Runs up to 10-Hours. J Electron Packag 142(4)

Sun H, Wang K, Li Y, Zhang C, Jin R (2020) Quality modeling of printed electronics in aerosol jet printing based on microscopic images. J Manuf Sci E 139:071012. https://doi.org/10.1115/1.4035586

den Otter MW (2002) Approximate expressions for the capacitance and electrostatic potential for the capacitance and electrostatic potential of interdigitated electrodes. Sens Actuator APhys 96:140–144. https://doi.org/10.1016/S0924-4247(01)00783-X

Igreja R, Dias CJ (2004) Analytical evaluation of the interdigital electrodes capacitance for a multi-layered structure. Sens Actuator APhys 112(291):301. https://doi.org/10.1016/j.sna.2004.01.040

Torabi S, Cherry M, Duijnstee EA, Le Corre VM, Qiu L, Hummelen JC, Palasantzas G, Koster LJA (2017) Rough electrode creates excess capacitance in thin-film capacitors. ACS Appl Mater Interfaces 9:27290–27297. https://doi.org/10.1021/acsami.7b06451

Oberländer J, Jildeh ZB, Kirchner P, Wendeler L, Bromm A, Iken H, Schöning MJ (2015) Study of interdigitated electrode arrays using experiments and finite element models for the evaluation of sterilization processes. Sensors 10:26115–26127. https://doi.org/10.3390/s151026115

González G, Kolosovas-Machuca ES, López-Luna E, Hernández-Arriaga H, González FJ (2015) Design and fabrication of interdigital nanocapacitors coated with HfO2. Sensors 15:1998–2005. https://doi.org/10.3390/s150101998

Biegler M, Graf B, Rethmeier M (2018) In-situ distortions in LMD additive manufacturing walls can be measured with digital image correlation and predicted using numerical simulations. AdditManuf 20:101–110. https://doi.org/10.1016/j.addma.2017.12.007

Stender ME, Beghini LL, Sugar JD, Veilleux MG, Subia SR, Smith TR, San Marchi CW, Brown AA, Dagel DJ (2018) A thermal-mechanical finite element workflow for directed energy deposition additive manufacturing process modeling. AdditManuf 21:556–566. https://doi.org/10.1016/j.addma.2018.04.012

Gu Y, Gutierrez D, Das S, Hines DR (2017) Inkwells for on-demand deposition rate measurement in aerosol-jet based 3D printing. J MicromechMicroeng 27:097001. https://doi.org/10.1088/1361-6439/aa817f

Lombardi JP, Salary RR, Weerawarne DL, Rao PK, Poliks MD (2019) Image-based closed-loop control of aerosol jet printing using classical control methods. J Man Sci Eng. https://doi.org/10.1115/1.4043659

Rubinstein RY, Kroese DP (2016) Simulation and the Monte Carlo method. Wiley, New York. https://doi.org/10.1002/9781118631980

Haldar A, Mahadevan S (2000) Probability, reliability, and statistical methods in engineering design. Wiley, New York. https://doi.org/10.1002/bate.200002930

(2013) COMSOL multiphysics reference manual, version 5.3. www.comsol.com COMSOL

Acknowledgements

The authors acknowledge the support of the Air Force Research Laboratory.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yoo, D., Mahoney, C.M., Deneault, J.R. et al. Mapping drift in morphology and electrical performance in aerosol jet printing. Prog Addit Manuf 6, 257–268 (2021). https://doi.org/10.1007/s40964-021-00165-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-021-00165-7