Abstract

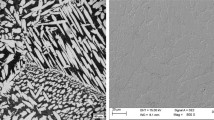

Potentiodynamic polarization, electrochemical impedance spectroscopy (EIS), and microstructure characterization were performed on directionally solidified samples of the Al–3Cu–2Si alloy in order to study their corrosion behavior in a 0.2 M HCl electrolyte. Corrosion resistance of the investigated samples was correlated with solidification parameters, such as growth (VL), cooling rates (TR) and secondary dendritic spacing (λ2). Optical microscopy was used to characterize both the as-cast and corroded microstructures. For an immersion time of 24 hours in acidic solution, optical micrographs indicated that Si addition to Al-3Cu alloy promoted a significant decrease in the average fractions of α-Al phase increasing anodic activity of the Al-3Cu-2Si alloy. Using Tafel extrapolation, it is shown that the secondary dendritic arm spacing (λ2) acts as a factor influencing the corrosion current density (Icorr). All the EIS diagrams reveal a unique capacitive time constant and the size of the semi-circle decreases with increasing the time of immersion. Nyquist plots demonstrate that higher λ2 values cause a decrease in resistance of polarization, indicating the presence of a very thin film of aluminum oxide associated with a lower corrosion resistance.

Graphic Abstract

Similar content being viewed by others

Change history

04 April 2023

A Correction to this paper has been published: https://doi.org/10.1007/s40962-023-01031-8

References

L. Jin, K. Liu, X. G. Chen, Evolution of dispersoids and their effects on elevated-temperature strength and creep resistance in Al-Si-Cu 319 cast alloys with Mn and Mo additions. Mater. Sci. Eng., A. 770, 138554 (2020). https://doi.org/10.1016/j.msea.2019.138554.

G.K. Sigworth, The Corrosion of Al–Cu-Based Alloys and Comments on the Paper “Effect of Solidification Time on Microstructure, Wettability and Corrosion Properties of A205-T7 Aluminum Alloys” by Amir Kordijazi et al. Inter Metalcast.15, 13–16 (2020). https://doi.org/10.1007/s40962-020-00475-6

M.G. Akhil, S. Preenu, S. Hari, M. Ravi, Effect of heat treatment on the mechanical properties of squeeze-cast Al–5Si–3Cu alloy for automotive applications. Trans. Indian Inst. Met. 72, 1129–1132 (2019). https://doi.org/10.1007/s12666-019-01562-x

J. Esquivel, R.K. Gupta, Corrosion-Resistant Metastable Al alloys: An overview of corrosion mechanisms. J. Electrochem. Soc. 167(8), 081504 (2020). https://doi.org/10.1149/1945-7111/ab8a97

S. El-Hadad, M.E. Moussa, M. Waly, Effects of Alloying with Sn and Mg on the Microstructure and Electrochemical Behavior of Cast Aluminum Sacrificial Anodes. Inter. Metalcast. 15, 548–565 (2021). https://doi.org/10.1007/s40962-020-00483-6

J. Scepanovic, V. Asanovic, S. Herenda, D. Vuksanovic, D. Radonjic, F. Korac, Microstructural Characteristics, Mechanical Properties, Fracture Analysis and Corrosion Behaviorof Hypereutectic Al–13.5Si Alloy. Inter.Metalcast.13, 700–714 (2019). https://doi.org/10.1007/s40962-019-00315-2.

E. Noor, Evaluation of inhibitive action of some quaternary N-heterocyclic compounds on he corrosion of Al–Cu alloy in hydrochloricacid. Mater. Chem. Phys. 114(2–3), 533–541 (2009). https://doi.org/10.1016/j.matchemphys.2008.09.065

J. Talati, D. Gandhi, N-heterocyclic compounds as corrosion inhibitors for aluminium-copper alloy in hydrochloric acid. Corros. Sci. 23(12), 1315–1332 (1983). https://doi.org/10.1016/0010-938X(83)90081-1

H. Santos, F. Reis, C. Kunioshi, J. Rossi, I. Costa, Corrosion performance of Al-Si-Cu hypereutectic alloys in a synthetic condensed automotive solution. Mater. Res. 8(2), 155–159 (2005). https://doi.org/10.1590/S1516-14392005000200011

W.R. Osório, L.C. Peixoto, D.J. Moutinho, L.G. Gomes, I.L. Ferreira, A. Garcia, Corrosion resistance of directionally solidified Al–6Cu–1Si and Al–8Cu–3Si alloys castings. Mater. Des. 32(7), 3832–3837 (2011). https://doi.org/10.1016/j.matdes.2011.03.013

N. Birbilis, R.G. Buchheit, Electrochemical characteristics of intermetallic phases in Aluminum Alloys: an experimental survey and discussion. J. Electrochem. Soc. 152, B140 (2005). https://doi.org/10.1149/1.1869984

J. Li, J. Dang, A summary of corrosion properties of Al-Rich solid solution and secondary phase particles in Al alloys. Metals. 7(3), 84 (2017). https://doi.org/10.3390/met7030084

Z. Szklarska-Smialowska, Pitting corrosion of aluminum. Corros. Sci. 41(9), 1743–1767 (1999). https://doi.org/10.1016/S0010-938X(99)00012-8

K.M. Fleming, A. Zhu, J.R. Scully, Corrosion of AA6061 brazed with an Al-Si Alloy: Effects of Si on metallurgical and corrosion behavior. Corrosion 68(12), 1126–1145 (2012). https://doi.org/10.5006/0677

G. Svenningsen, M.H. Larsen, J.C. Walmsley, J.H. Nordlien, K. Nisancioglu, Effect of artificial aging on intergranular corrosion of extruded AlMgSi alloy with small Cu content. Corros. Sci. 48(6), 1528–1543 (2006)

A. Kordijazi, S. Behera, S. Suri, Z. Wang, M. Povolo, N. Salowitz, P. Rohatgi, Data-driven modeling of wetting angle and corrosion resistance of hypereutectic cast Aluminum-Silicon alloys based on physical and chemical properties of surface. Surf. Interfaces. 20, 100549 (2020). https://doi.org/10.1016/j.surfin.2020.100549

F.L. Zeng, Z.L. Wei, J.F. Li, C.X. Li, X. Tan, Z. Zhang, Z.Q. Zheng, Corrosion mechanism associated with Mg2Si and Si particles in Al–Mg–Si alloys. Trans. Nonferrous Met. Soc. China. 21(12), 2559–2567 (2011). https://doi.org/10.1016/S1003-6326(11)61092-3

K. Mizuno, A. Nylund, I. Olefjord, Surface reactions during pickling of an aluminium–magnesium–silicon alloy in phosphoric acid. Corros. Sci. 43(2), 381–396 (2001). https://doi.org/10.1016/S0010-938X(00)00069-X

M.H. Larsen, J.C. Walmsley, O. Lunder, K. Nisancioglu, Effect of Excess silicon and small copper content on intergranular corrosion of 6000-series aluminum alloys. J. Electrochem. Soc. 157(2), C61 (2010). https://doi.org/10.1149/1.3261804

S.K. Kairy, N. Birbilis, Clarifying the role of Mg2Si and Si in localized corrosion of aluminum alloys by quasi in situ transmission electron microscopy. Corrosion 76(5), 464–475 (2020). https://doi.org/10.5006/3457

Y. Zou, H. Yan, Z. Hu, Q. Ran, Effect of (Pr + Ce) addition and T6 heat treatment on microhardness and corrosión of AlSi5Cu1Mg alloy. Mater. Res. Express. 7(2), 026526 (2020). https://doi.org/10.1088/2053-1591/ab6fa7

A. Barros, C. Cruz, A. P. Silva, N. Cheung, A. Garcia, O. Rocha, A. Moreira, HorizontallySolidified Al–3 wt%Cu–(0.5 wt%Mg) Alloys: TailoringT hermal Parameters, Microstructure, Microhardness, and Corrosion Behavior. Acta Metall. Sin. (Engl. Lett.). 32, 695-709 (2019). https://doi.org/10.1007/s40195-018-0852-z.

D.L. Soares, A.S. Barros, M. Dias, A.L. Moreira, J.C. Filho, A.P. Silva, O.L. Rocha, The role of therma land microstructural parameters on corrosion resistance of unsteady-state horizontally solidified Aluminum-Copper hypoeutectic alloys. Int. J. Electrochem. Sci.12, 413-428 (2017). https://doi.org/10.20964/2017.01.63.

S. Zor, M. Zeren, H. Ozkazanc, E. Karakulak, Effect of Cu content on the corrosion of Al-Si eutectic alloys in acidic solutions. Anti-Corros. Methods Mater. 57(4), 185–191 (2010). https://doi.org/10.1108/00035591011058192

C. Cruz, T. Lima, M. Soares, E. Freitas, E. Fujiwara, A. Garcia, N. Cheungt, Effect of Microstructure Features on the Corrosion Behavior of the Sn-2.1 wt%Mg Solde rAlloy. Electron. Mater. Lett. 16, 276–292 (2020). https://doi.org/10.1007/s13391-020-00202-7.

P.S. Kumar, V. Kavimani, K.S. Prakash, V.M. Krishna, G.S. Kumar, Effectof TiB2 on the corrosion resistance behavior of In situ Al composites. Inter Metalcast. 14, 84–91 (2020). https://doi.org/10.1007/s40962-019-00330-3

A. Kordijazi, D. Weiss, S. Das, S. Behera, H.M. Roshan, P. Rohatgi, Effectof solidification time on microstructure, wettability, and corrosion properties of A205–T7 aluminum alloys. Inter Metalcast. 15, 2–12 (2021). https://doi.org/10.1007/s40962-020-00457-8

T. Dorin, N. Stanford, N. Birbilis, R.K. Gupta, Influence of cooling rate on the microstructure and corrosion behavior of Al–Fe alloys. Corros. Sci. 100, 396–403 (2015). https://doi.org/10.1016/j.corsci.2015.08.017

A.V. Rodrigues, T.S. Lima, T.A. Vida, C. Brito, A. Garcia, N. Cheung, Microstructure and tensile/corrosion properties relationships of directionally solidified Al–Cu–Ni alloys. Met. Mater. Int. 24, 1058–1076 (2018). https://doi.org/10.1007/s12540-018-0116-5

W.R. Osório, E.S. Freitas, A. Garcia, Corrosion performance basedonthe microstructura lArray of Al-based monotectic alloys in a NaCl solution. J. Mater. Eng. Perform. 23, 333–341 (2014). https://doi.org/10.1007/s11665-013-0741-6

C. Brito, T. Vida, E. Freitas, N. Cheung, J.E. Spinelli, A. Garcia, Cellular/dendritic arrays and intermetallic phases affecting corrosion and mechanical resistances of an Al–Mg–Si alloy. J. Alloys Compd. 673, 220–230 (2016). https://doi.org/10.1016/j.jallcom.2016.02.161

A. Barros, C. Cruz, A.P. Silva, N. Cheung, A. Garcia, O. Rocha, A. Moreira, Length scale of solidification microstructure tailoring corrosion resistance and microhardness in T6 heattreatmentof an Al–Cu–Mg alloy. Corros. Eng. Sci. Technol. 55(6), 471–479 (2020). https://doi.org/10.1080/1478422X.2020.1742410

T. Soares, C. Cruz, A. Barros, A. Garcia, N. Cheung, Microstructure growth morphologies, macrosegregation, and microhardness in Bi–Sb thermal interface alloys. Adv. Eng. Mater. 22(6), 1901592 (2020). https://doi.org/10.1002/adem.201901592

C. Puncreobutr, P.D. Lee, K.M. Kareh, T. Connolley, J.L. Fife, A.B. Phillion, Influence of Fe-rich intermetallics on solidification defects in Al–Si–Cu alloys. Acta Mater. 68, 42–51 (2014). https://doi.org/10.1016/j.actamat.2014.01.007

M.G.C. Xavier, T.M.G. Souza, N. Cheung, A. Garcia, J.E. Spinelli, Effects of cobalt and solidification cooling rate on intermetallic phases and tensile properties of a -Cu, -Zn,-Fe containing Al-Si alloy. Int. J. Adv. Manuf. Technol. 107, 717–730 (2020). https://doi.org/10.1007/s00170-020-05077-4

F. Souza, J. Lima, C. Rizziolli, I. Magno, A. Barros, A. Moreira, O. Rocha, Microstructure and microhardness in horizontally solidified Al–7Si–0.15Fe–(3Cu; 0.3Mg) alloys Mater. Sci. Technol. 34(10), 1252–1264 (2018). https://doi.org/10.1080/02670836.2018.1444923.

M.O. Costa, C.R. Barbosa, H.M. Azevedo, G.H. Machado, F.S. Rocha, A.S. Moreira, O.L. Rocha, Thermal analysis via horizontal solidification of Al3Cu2Si (mass%) alloy: thermal and microstructural parameters, intermetallic compounds and microhardness. J. Therm. Anal. Calorim. (2021). https://doi.org/10.1007/s10973-020-10419-1

S. Wolynec, Electrochemical Corrosion Techniques, vol. 1 (Edusp, São Paulo, 2003), pp. 45-62.

C.R. Barbosa, T.C. Silva, H.M. Azevedo, J.C. Filho, A.S. Moreira, O.L. Rocha, Correlation between unsteady-state solidification and electrochemical corrosion parameters of na AlSiMg alloy. Inter. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00571-1

A.I. Muñoz, S. Mischler, Interactive effects of Al buminand Phosphate ionson the corrosion of CoCrMo implant alloy. J. Electrochem. Soc. 154, C562 (2007). https://doi.org/10.1149/1.2764238

B. Coates, S.A. Argyropoulos, The effects of surface roughnessand metal temperature on the heat-transfer coefficient at the metal mold interface. Metall. Mater. Trans. B. 38(2), 243–255 (2007). https://doi.org/10.1007/s11663-007-9020-y

Z.P. Guo, S.M. Xiong, B.C. Liu, M. Li, J. Allison, Effect of process parameters, casting thickness, and alloys on the interfacial heat-transfer coefficient in the high-pressure die-casting process. Metall. Mater. Trans. A. 39(12), 2896 (2008). https://doi.org/10.1007/s11661-008-9640-0

K.A. Yasakau, M.L. Zheludkevich, S.V. Lamaka, M.G.S. Ferreira, Role of intermetallic phases in localized corrosion of AA5083. Electromic. Act. 52(27), 7651–7659 (2007). https://doi.org/10.1016/j.electacta.2006.12.072

Acknowledgements

The authors acknowledge the financial support provided by UFPA - Federal University ofPará, PPGEM/ITEC/UFPA - Postgraduate Program in Mechanical Engineering, FEQ/ITEC/UFPA - Faculty of Chemical Engineering, IFPA - Federal Institute of Education, Science and Technology of Pará, PPGEMat/IFPA - Postgraduate Program in Materials Engineering, and CNPq - National Council for Scientific and Technological Development (Grants 302846/2017-4 and 304924/2020-2).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Otavio L. Rocha was added as an author.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Silva, T.C., Barros, A.S., Filho, J.C. et al. Study of Electrochemical Corrosion in Samples of a Horizontally Solidified AlCuSi Alloy. Inter Metalcast 16, 1191–1205 (2022). https://doi.org/10.1007/s40962-021-00657-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00657-w