Abstract

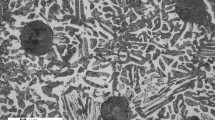

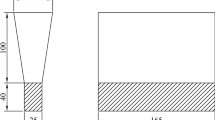

Ferritic ductile iron (DI) GJS 400 and high-silicon strengthened ductile irons (HSSDIs) with 3.5 and 4.5 wt% of silicon contents were produced with different cooling rates, and the microstructures were analyzed to find the main microstructure parameters. The Y-blocks GJS 400 presented good nodularity, while the heavy section GJS 400 presented some graphite degeneracy with a lower nodularity. The 3.5 wt% HSSDI shown a good nodularity, while with increasing silicon content to 4.5 wt%, significant graphite degeneracy occurred with the appearance of chunky graphite. Samples were tensile tested and the tensile data were analyzed through the physical-based constitutive Voce equation, and the Voce parameters were plotted to produce a matrix assessment diagram (MAD). Y-blocks and heavy section GJS 400 data lied on two distinct lines in MAD, and they had, however, positive and negative intercepts which meant indeed two contradictory plastic behaviors. The intercept of the best fitting line of the GJS 400 Y-blocks data was positive and so consistent with the physical meaning of Voce equation, while the intercept of the best fitting line of the GJS 400 heavy section data was negative, which meant an unexpected opposite plastic behavior. Same behavior was reported for the investigated HSSDIs, resulting in positive intercept of the best fitting line in MAD for the 3.5 wt% HSSDI data and negative intercept for the 4.5 wt% HSSDI data. The uniform strain energy density (SEDU) that is the area below the tensile flow curve up to the uniform strain, i.e., the strain where necking begins, was also investigated. SEDU resulted to be almost constant for all the GJS 400 Y-blocks tensile flow curves and 3.5 wt% HSSDI, which was typical of a sound material, while in GJS 400 heavy section and 4.5 wt% HSSDI, SEDU changed significantly in a systematic way, indicating that metallurgical defects had affected the plastic behavior. So it was concluded that in the MAD the best fitting line of the tensile data with positive intercept was a possible indication of the material soundness, while the negative intercept was indication of defected material. The results suggested that the MAD analysis produced from tensile Voce parameters can be a useful and easy tool for industry not only to classify the production routes of DIs (Si content mainly and heat treatments), but also to identify possible microstructure poorness within a single DI grade.

Similar content being viewed by others

References

F. Zanardi, F. Bonollo, N. Bonora, A. Ruggiero, G. Angella, A contribution to new material standards for ductile irons and austempered ductile irons. Int. J. Metalcast. 11, 136–147 (2017). https://doi.org/10.1007/s40962-016-0095-6

Ductile iron data for design engineers/section III engineering data/part 1 tensile properties/relationships between tensile properties. www.ductile.org. Accessed 10 June 2019

U.F. Kocks, H. Mecking, Physics and phenomenology of strain hardening: the FCC case. Prog. Mater Sci. 48, 171–273 (2003). https://doi.org/10.1016/S0079-6425(02)00003-8

Y. Estrin, Dislocation theory based constitutive modelling: foundations and applications. J. Mater. Process. Technol. 80–81, 33–39 (1998). https://doi.org/10.1016/S0924-0136(98)00208-8

G. Angella, F. Zanardi, R. Donnini, On the significance to use dislocation-density-related constitutive equations to correlate strain hardening with microstructure of metallic alloys: the case of conventional and austempered ductile irons. J. Alloys Compd. 669, 262–271 (2016). https://doi.org/10.1016/j.jallcom.2016.01.233

R. Donnini, F. Zanardi, F. Vettore, G. Angella, Evaluation of microstructure quality in ductile irons based on tensile behaviour analysis, in Mat Sci Forum, 11th International Symposium on the Science and Processing of Cast Iron, SPCI-XI 2017; Jonkoping; Sweden, vol. 925 (2018), pp. 342–349. https://doi.org/10.4028/www.scientific.net/MSF.925.342

G. Angella, F. Zanardi, Microstructure quality assessment of isothermed ductile irons through tensile tests, in 73rd World Foundry Congress Creative Foundry; WFC 2018—Proceedings (2018), pp. 265–266. ISBN: 978-839043063-8

G. Angella, F. Zanardi, Validation of a new quality assessment procedure for ductile irons production based on strain hardening analysis. Metals 9(8), 837 (2019). https://doi.org/10.3390/met9080837

J. Lacaze, L. Magnusson, J. Sertucha, Review of microstructural features of chunky graphite in ductile cast irons, in 2013 Keith Millis Symposium on Ductile Cast Iron, AFS, Nashville, USA (2013), pp. 360–368. ISBN 978-0-87433-419-7

B. Bauer, I. Mihalic Pokopec, M. Petrič, P. Mrvar, Effect of Si and Ni addition on spheroidal morphology in heavy section spheroidal graphite iron parts, in Mat Sci Forum, 11th International Symposium on the Science and Processing of Cast Iron, SPCI-XI 2017; Jonkoping; Sweden, vol. 925 (2018), pp. 70–77. https://doi.org/10.4028/www.scientific.net/MSF.925.70

P. Ferro, A. Fabrizi, R. Cervo, C. Carollo, Effect of inoculants of containing rare earth metals and bismuth on microstructure and mechanical properties of heavy-sections near eutectic ductile cast iron castings. J. Mater. Process. Technol. 213, 1601–1608 (2013). https://doi.org/10.1016/j.jmatprotec.2013.03.012

M. Benedetti, E. Torresani, V. Fontanari, D. Lusuardi, Fatigue and fracture resistance of heavy-section ferritic ductile cast iron. Metals 7, 88–106 (2017). https://doi.org/10.3390/met7030088

P. Weiβ, J. Brachmann, A. Bührig-Polaczek, S.F. Fischer, Influence of nickel and cobalt on microstructure of silicon solution strengthened ductile iron. Mater. Sci. Technol. 31, 1479–1485 (2015). https://doi.org/10.1179/1743284714Y.0000000735

U. de la Torre, A. Loizaga, J. Lacaze, J. Sertucha, As cast high silicon ductile irons with optimized mechanical properties and remarkable fatigue properties. Mater. Sci. Technol. 30, 1425–1431 (2014). https://doi.org/10.1179/1743284713Y.0000000483

J. Sertucha, J. Lacaze, J. Serrallach, R. Suárez, F. Osuna, Effect of alloying on mechanical properties of as cast ferritic nodular cast irons. Mater. Sci. Technol. 28, 184–191 (2012). https://doi.org/10.1179/1743284711Y.0000000014

U. de la Torre, J. Lacaze, J. Sertucha, Chunky graphite formation in ductile cast irons: effect of silicon, carbon and rare earths. Int. J. Mater. Res. (Form. Z. Metall.) 107, 1041–1050 (2016). https://doi.org/10.3139/146.111434

G. Angella, R. Donnini, D. Ripamonti, M. Górny, F. Zanardi, The role of microstructure on tensile plastic behaviour of ductile iron GJS 400 produced through different rates—part II: tensile modeling. Metals 9, 1019–1022 (2019). https://doi.org/10.3390/met9091019

G. Bertuzzi, G. Scarpa, Comparison of casting simulation results and experimental data in heavy section ductile iron production, in International CAE Conference 2015, Pacengo del Garda (VR), Italy, 19–20 October (2015), pp. 1–9

M. Gagné, D. Argo, Heavy section ductile iron castings—part I: structure and properties, in International Conference on Advanced Casting Technology, ed. by J. Easwaren (ASM International, 1987), pp. 231–244. ISBN: 0871702770

R. Källbom, K. Hamberg, L.E. Björkegren, Chunky-graphite—formation and influence on mechanical properties in ductile cast iron, in Competent Design by Castings, eds. by J. Samuelson, G. Marquis, J. Solin (2005). ISBN: 951.38.6299.2

M. Tiryakioğlu, J. Campbell, J.T. Staley, Evaluating structural integrity of Al–7%Si–Mg alloys via work hardening characteristics: I. Concept of target properties. Mater. Sci. Eng. A 368, 205–211 (2004). https://doi.org/10.1016/j.msea.2003.10.311

M. Tiryakioğlu, J.T. Staley, J. Campbell, Evaluating structural integrity of Al–7%Si–Mg alloys via work hardening characteristics: II. A new quality index. Mater. Sci. Eng. A 368, 231–238 (2004). https://doi.org/10.1016/j.msea.2003.10.310

M. Tiryakioğlu, N.D. Alexopoulos, J. Campbell, On the ductility potential of cast Al–Cu–Mg (206). Alloys Mater. Sci. Eng. A 506, 23–26 (2009). https://doi.org/10.1016/j.msea.2008

M. Tiryakioğlu, J.T. Staley Jr., J. Campbell, The effect of structural integrity on the tensile deformation characteristics of A206-T71 alloy castings. Mater. Sci. Eng. A 487, 383–387 (2008). https://doi.org/10.1016/j.msea.2007.11.005

M. Tiryakioğlu, J. Campbell, Quality index of aluminum casting alloys. Int. J. Metalcast. 8, 39–42 (2014). https://doi.org/10.1007/BF03355589

Acknowledgements

Mr. Davide Della Torre, Tullio Ranucci and Marcello Taloni are warmly thanked for their experimental support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Angella, G., Cova, M., Bertuzzi, G. et al. Soundness Discrimination in Ferrite Ductile Irons Through Tensile Data Analysis. Inter Metalcast 14, 816–826 (2020). https://doi.org/10.1007/s40962-020-00435-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00435-0