Abstract

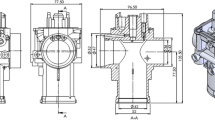

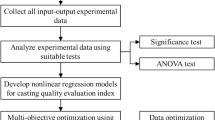

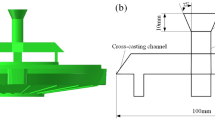

The main aim of this research was to simulate high-pressure die casting of A356 semi-solid aluminum alloy using casting process simulation tool. Taking into account the viscosity of the semi-solid slurry and the mold-filling characteristics in high-pressure die casting, the mold for semi-solid aluminum alloy had been designed. Also, the influence of the three input parameters (liquid fraction of slurry, plunger velocity at 2nd phase and mold geometry) on the casting time, shrinkage and bubble formation during semi-solid high-pressure die casting processes were investigated. The Taguchi-based ‘grey relational analysis’ approach was used to identify the optimal process parameters. A method used in this study for finding out the importance of the controllable parameter on the performance characteristic is called the analysis of variance. It was observed that the optimal parameters are the liquid fraction of 50%, the plunger velocity at 2nd phase of 1 m/s and the angle between the vertical plane and the cavity of 60°.

Similar content being viewed by others

References

D.B. Spencer, R. Mehrabian, M.C. Flemings, Rheological behavior of Sn–15%Pb in the crystallization range. Metall. Mater. Trans. B 3(7), 1925–1932 (1972)

R. Koeune, J.P. Ponthot, in Advanced Computational Materials Modeling: From Classical to Multi-scale Techniques, ed. by M.V. Júnior, E.A. de Souza Neto, P.A. Munoz-Rojas (Wiley, Berlin, 2011), p. 205. https://doi.org/10.1002/9783527632312.ch6

A. Pola, M. Tocci, P. Kapranos, Microstructure and properties of semi-solid aluminum alloys: a literature review. Metals 8(3), 181 (2018)

A. Fabrizi, S. Capuzzi, A. De Mori, G. Timelli, Effect of T6 heat treatment on the microstructure and hardness of secondary AlSi9Cu3(Fe) alloys produced by semi-solid SEED process. Metals 8(10), 750 (2018)

J. Wang, A.B. Phillion, G. Lu, Development of a visco-plastic constitutive modeling for thixoforming of AA6061 in semi-solid state. J. Alloys Compd. 609, 290–295 (2014)

M.S. Salleh, M.Z. Omar, J. Syarif, M.N. Mohammed, An overview of semisolid processing of aluminium alloys. ISRN Mater. Sci. (2013). https://doi.org/10.1155/2013/679820

Q.Y. Pan, M. Arsenault, D. Apelian, M.M. Makhlouf, SSM processing of AlB 2 grain refined Al–Si alloys, in Transactions of the American Foundry Society, pp. 273–287 (2004). ISBN: 0-87433-277-X

B. Zhou, Y. Kang, M. Qi, H. Zhang, G. Zhu, R-HPDC process with forced convection mixing device for automotive part of A380 aluminum alloy. Materials 7(4), 3084–3105 (2014)

X. Jian, T.T. Meek, Q. Han, Refinement of eutectic silicon phase of aluminium A356 alloy using high-intensity ultrasonic vibration. Scr. Mater. 54(5), 893–896 (2006)

B.G.E., M. Nouri, R. Beygi, M.Z. Mehrizi, A. Nouri, M. Ebrahimi, Effects of Sr on the microstructure of electromagnetically stirred semi solid hypoeutectic Al–Si alloys, in 6th International Symposium on Metalcasting, Shape Casting, pp. 133–140 (2016). https://doi.org/10.1007/978-3-319-48166-1_17S

S. Nafisi, R. Ghomashchi, Semi-Solid Processing of Aluminum Alloys (Springer, Basel, 2016), pp. 30–33. ISBN 978-3-319-40335-9

O. Bustos, S. Ordoñez, R. Colás, Rheological and microstructural study of A356 alloy solidified under magnetic stirring. Int. Metalcast. 7(1), 29–37 (2013). https://doi.org/10.1007/BF03355542

V.M. Nimbalkar, B. Bhanushali, M. Mohape, S.G. Pandav, V.P. Deshmukh, S. Dineshraj, S.C. Sharma, Development of thin walled A-356 components by new rheocasting semi-solid metal processing technology (NRC). Mater. Sci. Forum 830, 27–29 (2015)

F. Czerwinski, Magnesium Injection Molding (Springer, New York, 2008), pp. 135–145. ISBN 978-0-387-72528-4

J.L. Fu, H.J. Jiang, K.K. Wang, Influence of processing parameters on microstructural evolution and tensile properties for 7075 Al alloy prepared by an ECAP-based SIMA process. Chin Shu Hsueh Pao 31(4), 337–350 (2018). https://doi.org/10.1007/s40195-017-0672-6

A. Leatham, A. Ogilvy, P. Chesney, J.V. Wood, Osprey process-production flexibility in materials manufacture. Met. Mater. 5(3), 140–143 (1989)

A. Heinz, A. Haszler, C. Keidel, S. Moldenhaue, R. Benedictus, W.S. Miller, Recent development in aluminium alloys for aerospace applications. Mater. Sci. Eng. A 280(1), 102–107 (2000)

W.S. Miller, L. Zhuang, J. Bottema, A. Wittebrood, P. De Smet, A. Haszler, A. Vieregge, Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 280(1), 37–49 (2000)

M. Sadeghi, J. Mahmoudi, Experimental and theoretical studies on the effect of die temperature on the quality of the products in high-pressure die-casting process. Adv. Mater. Sci. Eng. 2012, 434605 (2012)

G.O. Verran, R.P.K. Mendes, M.A. Rossi, Influence of injection parameters on defects formation in die casting Al12Si1, 3Cu alloy: Experimental results and numeric simulation. J. Mater. Process. Technol. 179(1–3), 190–195 (2006)

M. Avalle, G. Belingardi, M.P. Cavatorta, R. Doglione, Casting defects and fatigue strength of a die cast aluminium alloy: a comparison between standard specimens and production components. Int. J. Fatigue 24(1), 1–9 (2002)

S. Nourouzi, H. Baseri, A. Kolahdooz, S.M. Ghavamodini, Optimization of semi-solid metal processing of A356 aluminum alloy. J. Mech. Sci. Technol. 27(12), 3869–3874 (2013)

H. Khosravi, R. Eslami-Farsani, M. Askari-Paykani, Modeling and optimization of cooling slope process parameters for semi-solid casting of A356 Al alloy. Trans. Nonferr. Met. Soc. China 24(4), 961–968 (2014)

Y.B. Suslu, M.S. Acar, M. Senol, M. Mutlu, O. Keles, Optimization in novel partial-solid high pressure aluminum die casting by Taguchi method, in TMS Annual Meeting & Exhibition, pp. 293–300 (2018). https://doi.org/10.1007/978-3-319-72284-9_40

NOVAFLOW&SOLID 6.4; Manual—2018-08-29; NovaCastSystems AB

P.K. Seo, M.D. Lim, C.G. Kang, Numerical visualization of viscosity in phase transformation forming process with controlled liquid fraction. J. Mater. Process. Technol. 153, 450–456 (2004)

R. Rao Venkata, Advanced Modeling and Optimization of Manufacturing Processes: International Research and Development (Springer, London, 2010), pp. 10–13. ISBN 978-0-85729-014-4

P. Achuthamenon Sylajakumari, R. Ramakrishnasamy, G. Palaniappan, Taguchi grey relational analysis for multi-response optimization of wear in co-continuous composite. Materials 11(9), 1743 (2018). https://doi.org/10.3390/ma11091743

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

ID contributed to the study conception and design. Solid modeling in CATIA V5 was performed by SJ and ID. JK designed Taguchi plan of the experiments. SJ and ID performed the simulations. The Taguchi-based grey relational analysis was performed by DB and JK. The first draft of the manuscript was written by ID. All authors peer-reviewed paper writing and editing. All authors reviewed the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dumanić, I., Jozić, S., Bajić, D. et al. Optimization of Semi-solid High-Pressure Die Casting Process by Computer Simulation, Taguchi Method and Grey Relational Analysis. Inter Metalcast 15, 108–118 (2021). https://doi.org/10.1007/s40962-020-00422-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00422-5