Abstract

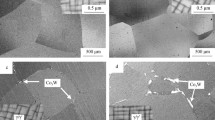

In this study, the solid and liquid oxidation behaviors of Al–Mg alloys that had a trace of Ca were investigated. With increasing Ca content, the grains of α-Al dendrites in Al–7.5mass%Mg alloys were refined by the formation of two Ca-containing particles at grain boundaries. Using thermal gravimetric analysis result at 515 °C for 24 h under O2 atmosphere, Al–7.5mass%Mg alloy exhibited a parabolic behavior in its weight gain during oxidation. However, there was nearly no difference in the weight change during oxidation of the Al–7.5mass%Mg alloys that contained a trace of Ca. From the auger electron spectroscopy and transmission electron microscopy/energy-dispersive X-ray spectroscopy results for the oxidized surface, it is believed that the improvement in the oxidation resistance in Al–7.5mass%Mg alloys that contain Ca may be attributed to the formation of a mixed oxide layer that includes CaO, MgO, and Al2O3 on the surface. After a melt holding test for 3 h, there was no notable difference in Mg loss during oxidation between Al–7.5mass%Mg and Al–7.5mass%Mg–0.1mass%Ca alloys. However, for a melt oxidation time for 24 h, the Mg reduction of Al–7.5mass%Mg alloy reached approximately 15%, whereas in Ca added alloy, the reduction was controlled under 8%. The cross section of Al–10mass%Mg alloy that solidified after the melt holding test showed a significant contamination due to oxide inclusions. However, Ca added alloys had good internal soundness throughout all the conditions. It was confirmed that the protective layer formed by Ca-containing can suppress the formation of Mg-based oxide inclusions and result in an increase in the alloy internal soundness during the melting process.

Similar content being viewed by others

References

L.F. Mondolfo, Aluminum Alloys: Structure and Properties (Butter-worth and Co., London, 1976)

G.E. Totten, D.S. MacKenzie, Handbook of Aluminum (MARCEL DEFFER, New York, 2003)

J.R. Davis, Aluminum and Aluminum Alloys (ASM International, Materials Park, 1993)

M.-N. de Noirfontaine, G. Baldinozzi, M.-G. Barthés-Labrousse, J. Kusinski, G. Boëmare, M. Herinx, M. Feuerbacher, Oxid. Met. 73, 219 (2010)

D.L. Belitskus, Oxid. Met. 3, 313 (1971)

M. Okayasu, S. Takeuchi, Int. Metalcast. 12, 298 (2017)

K. Prapasajchavet, Y. Harada, S. Kumai, Inter. Metalcast. 11, 123 (2017)

D.J. Field, G.M. Scamans, E.P. Butler, Metall. Mater. Trans. A 18A, 463 (1987)

I. Haginoya, T. Fukusako, T. Jpn, I. Met. 24, 613 (1983)

K.R. Ravi, R.M. Pillai, K.R. Amaranathan, B.C. Pai, M. Chakraborty, J. Alloys Comp. 456, 201 (2008)

H. Sharifi, A.R. Khavandi, M. Divandari, M.I. Hasbullah, Int. J. Min. Met. Mater. 19, 77 (2012)

C. Houska, Met. Mater. 4, 100 (1988)

C. Strupp, Ann. Occup. Hyg. 55, 43 (2011)

S.H. Ha, J.K. Lee, S.K. Kim, Mater. Trans. 49, 1081 (2008)

B.S. You, W.W. Park, I.S. Chung, Scr. Mater. 42, 1089 (2000)

J. Jeong, J. Im, K. Song, M. Kwon, S.K. Kim, Y.B. Kang, S.H. Oh, Acta Mater. 61, 3267 (2013)

S.K. Kim, T.H. Nam, S.H. Kim, J.G. Kim, Mater. Corros. 63, 1 (2012)

S.K. Kim, J.K. Lee, Y.O. Yoon, H.H. Jo, J. Mater. Process. Technol. 187–188, 757 (2007)

D.I. Jang, Y.O. Yoon, S.B. Jung, S.K. Kim, Mater. Trans. 49, 976 (2008)

D.B. Lee, L.S. Hong, Y.J. Kim, Mater. Trans. 49, 1084 (2008)

G.Y. Oh, Y.G. Jung, W.S. Yang, S.K. Kim, H.K. Lim, Y.J. Kim, Mater. Trans. 56, 1887 (2015)

H. Okamoto, J. Phase Equilib. Diffus. 24, 91 (2003)

C.W. Bale, P. Chartrand, S.A. Degterov, G. Eriksson, K. Hack, R.B. Mahfoud, J. Melançon, A.D. Pelton, S. Petersen, Calphad 26, 189 (2002)

G.K. Sigworth, T.A. Kuhn, Inter. Metalcast. 1, 31 (2007)

K.C. Vlach, O. Salas, H. Ni, V. Jayaram, C.G. Levi, R. Mehrabian, J. Mater. Res. 6, 1982 (1991)

P.C. Chen, T.S. Shih, C.Y. Wu, Mater. Trans. 50, 2366 (2009)

A. Bahadur, Mater. Sci. 22, 1941 (1987)

D.R. Gaskell, in Encyclopedia of Materials: Science and Technology, ed. by K.H. Buschow (Elsevier, New York, 2001), pp. 5481–5486

M.H. Zayan, O.M. Jamjoom, N.A. Razik, Oxid. Met. 34, 323 (1990)

N.B. Pilling, R.E. Bedworth, J. Inst. Metals 29, 529 (1923)

Y.M. Kim, C.D. Yim, H.S. Kim, B.S. You, Scr. Mater. 65, 958 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ha, SH., Yoon, YO., Kim, BH. et al. Oxide Scale Behavior and Surface Protection of Al–Mg Alloys Containing a Trace of Ca. Inter Metalcast 13, 121–129 (2019). https://doi.org/10.1007/s40962-018-0234-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-018-0234-3