Abstract

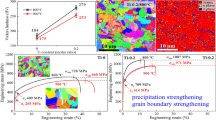

The research involved here was accomplished through a study of the tensile properties in both the as-cast and heat-treated conditions, where the effects of different heat treatments, i.e., T5, T6, T62 and T7, commonly applied to aluminum casting alloys were evaluated at ambient temperature and at high temperature (250 °C) using different holding or stabilization times at testing temperature. The tensile data showed that the ultimate tensile strength (UTS) and percentage elongation values of the six alloys increased in the one-step solution heat-treated condition compared to the as-cast case. The multi-step solution heat treatment displayed higher tensile properties than those achieved with the one-step solution treatment. The use of the T62 treatment (multi-step solution treatment followed by artificial aging) allows for maximum dissolution of the copper phases in the multiple stages of solution treatment, resulting in the greatest improvement in both UTS and yield strength (YS). At ambient temperature, T6 and T62 treatments provide the best improvements in both UTS and YS values of all alloys. The T62-tempered alloy showed maximum improvement with a UTS value of ~ 401.55 MPa. Likewise, in the Al–2%Cu–8%Si series the T62-tempered alloy displayed the highest UTS with a value of ~ 293.5 MPa. The YS values improved overall after solution treatment. The YS values followed the same trend as the UTS at both ambient and high-temperature testing. At high-temperature testing at 250 °C after one hour of stabilization, the UTS of the alloys increased with the T6 and T62 heat treatment conditions, but remained the same after T5 heat treatment; the highest UTS value was exhibited by the T62-tempered alloy with ~ 195 MPa.

Similar content being viewed by others

References

A. Cuniberti, A. Tolley, M.V. Castro Riglos, R. Giovachini, Influence of natural aging on the precipitation hardening of an AlMgSi alloy. Mater. Sci. Eng., A 527(20), 5307–5311 (2010)

A. Mohamed and F. Samuel, “A Review on the Heat Treatment of Al-Si-Cu/Mg Casting Alloys,” in Heat Treatment - Conventional and Novel Applications, Dr. Frank Czerwinski (Ed.), ISBN: 978-953-51-0768-2, InTech, doi: 10.5772/50282, 2012

J.E. Hatch, Aluminum: Properties and Physical Metallurgy (American Society for Metals, Materials Park, 1984), p. 135

G.E. Totten, D.S. Mackenzie (eds.), Handbook of Aluminum (Marcel Dekker Inc, New York, Basel, 2003), p. 1296

H. Sehitoglu, T. Foglesong, H.J. Maier, Precipitation Effects on the Mechanical Behaviour of Aluminum Copper Alloys: Part I. Experiments. Metallurgical and Materials Transactions A 36A, 749–761 (2005)

R.N. Lumley, J. Buha, I.J. Polmear, A.J. Morton, A.G. Crosky, Secondary Precipitation in Aluminum Alloys & Its Role in Modern Heat Treatment. Mater. Sci. Forum 519, 283–290 (2006)

W. Reif, S. Yu, J. Dutkiewicz, R. Ciach, J. Krol, Pre-Ageing of AlSiCuMg Alloys in Relation to Structure and Mechanical Properties. Mater. Des. 18(4), 253–256 (1997)

R.K. Mishra, G.W. Smith, W.J. Baxter, A.K. Sachdev, V. Franetovic, The Sequence of Precipitation in 339 Aluminum Castings. Journal of Materials Science 36(2), 461–468 (2001)

H. Suzuki, I. Arai, M. Kanno, K. Itoi, Effect of Silicon Addition on the Aging Behavior of an Al-2%Cu-0.9%Mg Alloy. J. Jpn. Inst. Met. 27(5), 239–245 (1977)

Y.J. Li, S. Brusethaug, A. Olsen, Influence of Cu on the Mechanical Properties and Precipitation Behavior of AlSi7Mg0.5 Alloy During Aging Treatment. Scripta Mater. 54(1), 99–103 (2006)

H.R. Ammar, C. Moreau, A.M. Samuel, F.H. Samuel, H.W. Doty, Influences of alloying elements, solution treatment time and quenching media on quality indices of 413-type Al–Si casting alloys. Mater. Sci. Eng., A 489(1), 426–438 (2008)

R.N. Lumley et al., The role of alloy composition in the heat treatment of aluminium high pressure die castings. Metallurgical Science and Technology 26(2), 283–290 (2013)

K. Wojciech, S.A. Babak, M. Niewczas, Structure and properties of cast Al–Si based alloy with Zr–V–Ti additions and its evaluation of high temperature performance. J. Alloy. Compd. 595, 67–79 (2014)

Z. Nie, T. Jin, J. Fu, G. Xu, J. Yang, J. Zhou, T. Zuo, Research on rare earth in aluminum. Mater. Sci. Forum 396–402, 1731–1736 (2002)

G.A. Zaki, A.M. Samuel, H.W. Doty, F.H. Samuel, Effect of metallurgical parameters on the performance of Al–Cu based alloys. International Journal of Metallurgical & Materials Science and Engineering 6(1), 35–56 (2016)

G.A. Zaki, A.M. Samuel, H.W. Doty, F.H. Samuel, Effect of Metallurgical Parameters on the Performance of Al-2%Cu-Based Alloys. Int. J. Metalcast. 11(3), 581–597 (2017)

G.A. Zaki, A.M. Samuel, H.W. Doty, F.H. Samuel, Microstructural evolution during solidification of Al–Cu-based alloys. Int. J. Mater. Res. 106(11), 1144–1153 (2015)

A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel, Defects related to incipient melting in Al-Si-Cu-Mg alloys. Mater. Des. 52, 947–956 (2013)

A.M.A. Mohamed, F.H. Samuel and S. Al kahtani, Influence of Mg and solution heat treatment on the occurrence of incipient melting in Al-Si-Cu-Mg cast alloys. Mater. Sci. Eng., A 543, 22–34 (2012)

F.H. Samuel, Incipient melting of Al5Mg8Si6Cu2 and Al2Cu intermetallics in unmodified and strontium-modified Al-Si-Cu-Mg (319) alloys during solution heat treatment. Journal of Materials Science 33(9), 2283–2297 (1998)

K. Yu, W. Li, S. Li, J. Zhao, Mechanical Properties and Microstructure of Aluminum Alloy 2618 with Al3(Sc, Zr) Phases. Mater. Sci. Eng., A A368, 88–93 (2004)

J.H. Sokolowski, X.-C. Sun, G. Byczynski, D.E. Penord, R. Thomas, A. Esseltine, The Removal of Copper-Phase Segregation and the Subsequent Improvement in Mechanical Properties of Cast 319 Aluminum Alloys by a Two-Stage Solution Heat-Treatment. J. Mater. Process. Technol. 53, 385–392 (1995)

P. Sepehrband, R. Mahmudi, F. Khomamizadeh, Effect of Zr Addition on the Aging Behavior of A319 Aluminum Cast Alloy. Scripta Mater. 52, 253–257 (2005)

R. Mahmudi, P. Sepehrband, H.M. Ghasemi, Improved properties of A319 aluminum casting alloy modified with Zr. Mater. Lett. 60, 2606–2610 (2006)

E. Rincon, H.F. Lopez, M.M. Cisneros, H. Mancha, M.A. Cisneros, Effect of temperature on the tensile properties of an as-cast aluminum alloy A319. Mater. Sci. Eng., A 452–453, 682–687 (2007)

Z. Li, A.M. Samuel, F.H. Samuel, C. Ravindran, S. Valtierra, H.W. Doty, Parameters controlling the performance of AA319-type alloys Part I: Tensile Properties. Material Science and Engineering A A367, 96–110 (2004)

M. Drouzy, S. Jacob, M. Richard, Interpretation of Tensile Results by Means of Quality Index and Probable Yield Strength. AFS International Cast Metals Journal 5, 43–50 (1980)

S. Jacob, Quality Index in Predicting of Properties of Aluminum Castings-A Review. AFS Transactions 108, 811–818 (2000)

Acknowledgements

The authors wish to thank Amal Samuel for enhancing the quality of the electron images presented in this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ibrahim, A.I., Samuel, A.M., Doty, H.W. et al. Response of Varying Levels of Silicon and Transition Elements on Room- and Elevated-Temperature Tensile Properties in an Al–Cu Alloy. Inter Metalcast 12, 396–414 (2018). https://doi.org/10.1007/s40962-017-0177-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-017-0177-0