Abstract

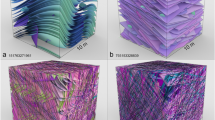

The subsidence of offshore wells and platforms is a profound problem in the oil and gas industry. A new approach to reservoir geomechanical studies is used to analyze wellbore instabilities and investigate the subsidence of reservoirs. This study comprises an integrated workflow for developing a 3D geomechanical earth model for the North-Heera field, India. 1D Mechanical Earth Models are constructed for 40 wells to study the wellbore instabilities of drilled wells in this region and determine the mud weight for successful drilling and completions for future developments. A 3D geomechanical model is developed by integrating geological surfaces, fault lines, wireline logs, drilling, and completion data. Heterogeneous 3D models are developed using local grid refinement by a simple kriging approach. Analyzing these models identifies that the shallow zones of depth between 300 and 1000 m have a significant spatial gradient in elastic properties. Series of triaxial loading tests are conducted on the core samples collected from different wells drilled in this block. Mohr–Coulomb's failure criteria derived from loading tests aid in determining the rock strength parameters derived from wireline logs. The combined analysis of geomechanical models and rock failure parameters derived from loading tests facilitates investigating the weak formations zones causing wellbore instability problems and subsidence in shallow depths

Article Highlights

-

Construction of 3D geomechanical models for the offshore field.

-

Pore pressures were estimated for all the wells using NCT methods.

-

Stress–strain curve analysis from a series of triaxial compression tests.

-

Integrated geomechanical approach for analyzing rock parameters of shale layers.

Similar content being viewed by others

Abbreviations

- 1D:

-

One dimensional

- 3D:

-

Three dimensional

- LGR:

-

Local grid refinement

- ONGC:

-

Oil and Natural Gas Corporation Limited

- DGH:

-

Director General of Hydrocarbons

- DST:

-

Drill stem test

- Shim:

-

Minimum horizontal stress

- SHmax:

-

Maximum horizontal stress

- LOT:

-

Leak Off Test

- PR:

-

Poison’s ratio

- UCS:

-

Unconfined compressive strength

- IFC:

-

Internal friction coefficient

- YM:

-

Young’s modulus

- NCT:

-

Normal Compaction Trend

- σv :

-

Vertical stress

- σw:

-

Vertical load by a water column

- σo:

-

Vertical load at the point where the density log began

- ρ:

-

Density

- α:

-

Biot’s constant

- Pp:

-

Pore pressure

- E:

-

Young’s modulus

- εx:

-

Compressional horizontal strain (x-direction)

- εy:

-

Extensional horizontal strain (y-direction)

- FIT:

-

Formation integrity test

- Gdyn:

-

Dynamic Bulk modulus

- νdyn:

-

Dynamic Poison’s ratio

- Edyn:

-

Dynamic Young’s modulus

- Vp:

-

P-wave velocity

- Vs:

-

S-wave velocity

- UCSlimestone :

-

Unconfined compressive strength of limestone

- UCSshale :

-

Unconfined compressive strength of shale

- Ø:

-

Internal friction coefficient

- MPa:

-

Mega Pascal

- GPa:

-

Giga Pascal

- Pf:

-

Fracture pressure

- ν:

-

Poison’s ratio

- Dn:

-

Density

- Ω:

-

Resistivity

- µi:

-

Coefficient of internal friction

- C0:

-

Cohesion

References

Al-Awad MNJ, Smart BGD (1996) Characterization of shale-drilling fluid interaction mechanisms related to wellbore instability. J King Saud Univ Eng Sci 8:187–214. https://doi.org/10.1016/s1018-3639(18)30657-3

Al-Zubaidi NS, Al-Neeamy AK (2020) 3D mechanical earth model for Zubair oilfield in southern Iraq. J Pet Explor Prod Technol 10:1729–1741. https://doi.org/10.1007/s13202-020-00863-y

Ali AHA, Brown T, Delgado R et al (2003) Watching rocks change—mechanical earth modeling. Oilf Rev 15:22–39

Ambati V, Mahadasu NB, Nair RR (2021) Reservoir wellbore stability analysis and weak zones identification using the 1D MEM, swelling tests and UCS: a case study from Mumbai offshore. Arab J Sci Eng, India. https://doi.org/10.1007/s13369-021-05530-w

Brudy M (1998) Determination of the state of stress by analysis of drilling-induced fractures—results from the northern North Sea. In: Proceedings of the SPE/ISRM rock mechanics in petroleum engineering conference. Society of Petroleum Engineers, pp 141–149

Chang C, Zoback MD, Khaksar A (2006) Empirical relations between rock strength and physical properties in sedimentary rocks. J Pet Sci Eng 51:223–237. https://doi.org/10.1016/j.petrol.2006.01.003

Dusseault MB, Rothenburg L (2002) Analysis of deformation measurements for reservoir management. Oil Gas Sci Technol 57:539–554. https://doi.org/10.2516/ogst:2002036

Eaton BA (1975) The equation for geopressure prediction from well logs. In: Fall meeting of the society of petroleum engineers of AIME. Society of Petroleum Engineers, p 219

Fertl H, George V, Chilingarian HHRI (1976) Chapter 1 abnormal formation pressure environments. In: Developments in petroleum science, pp 1–48

Fjaer E, Holt RM, Horsrud P et al (2008) Petroleum related rock mechanics, 1st edn. Elsevier

Fjar E, Horsrud P, Raaen AM, Risnes R (2008) RMH petroleum related rock mechanics, 2nd edn. Elsevier, Amsterdam

Fung LSK, Ll B, Ravi S (1994) Hybrid-CVFE method for flexible-grid reservoir simulation. SPE Reserv Eng 9:188–194. https://doi.org/10.2118/25266-PA

Gholami R, Rabiei M, Rasouli V et al (2015) Application of quantitative risk assessment in wellbore stability analysis. J Pet Sci Eng 135:185–200. https://doi.org/10.1016/j.petrol.2015.09.013

Goswami BG, Singh H, Bhatnagar AK et al (2007) Petroleum Systems of the Mumbai Offshore Basin, India

Guerra C, Fischer K, Henk A (2019) Stress prediction using 1D and 3D geomechanical models of a tight gas reservoir—A case study from the Lower Magdalena Valley Basin, Colombia. Geomech Energy Environ 19:100113. https://doi.org/10.1016/j.gete.2019.01.002

Hamid O, Omair A, Guizada P (2017) Reservoir Geomechanics in Carbonates. In: SPE Middle East Oil & Gas Show and Conference. Society of Petroleum Engineers, pp 2330–2339

Hodam S, Sarkar S, Marak AGR et al (2017) Spatial interpolation of reference evapotranspiration in India: comparison of IDW and kriging methods. J Inst Eng Ser A 98:511–524. https://doi.org/10.1007/s40030-017-0241-z

Kovach RL (1974) Source mechanisms for wilmington oil field, California, subsidence earthquakes. Bull Seismol Soc Am 64:699–711

Kovari K, Tisa A, Einstein HH, Franklin JA (1983) Suggested methods for determining the strength of rock materials in triaxial compression: Revised version. Int J Rock Mech Min Sci Geomech Abstr 20:285–290. https://doi.org/10.1016/0148-9062(83)90598-3

Labuz JF, Zang A (2012) Mohr-Coulomb failure criterion. Rock Mech Rock Eng 45:975–979. https://doi.org/10.1007/s00603-012-0281-7

Liu Z, Guo Y, Du S et al (2017) Research on calibrating rock mechanical parameters with a statistical method. PLoS ONE 12:e0176215. https://doi.org/10.1371/journal.pone.0176215

Marzano F, Pregliasco M, Rocca V (2020) Experimental characterization of the deformation behavior of a gas-bearing clastic formation: soft or hard rocks? A case study. Geomech Geophys Geo Energy Geo Resour 6:10. https://doi.org/10.1007/s40948-019-00130-3

Mayuga MN (1968) Geology of California’s giant-wilmington oil field: ABSTRACT. Am Assoc Pet Geol Bull. https://doi.org/10.1306/5D25C37D-16C1-11D7-8645000102C1865D

Mishra DA, Janeček I (2017) Laboratory triaxial testing—from historical outlooks to technical aspects. Procedia Eng 191:342–351. https://doi.org/10.1016/j.proeng.2017.05.190

Molaghab A, Taherynia MH, Fatemi Aghda SM, Fahimifar A (2017) Determination of minimum and maximum stress profiles using wellbore failure evidences: a case study—a deep oil well in the southwest of Iran. J Pet Explor Prod Technol 7:707–715. https://doi.org/10.1007/s13202-017-0323-5

Moos D, Peska P, Finkbeiner T, Zoback M (2003) Comprehensive wellbore stability analysis utilizing quantitative risk assessment. J Pet Sci Eng 38:97–109. https://doi.org/10.1016/S0920-4105(03)00024-X

Noohnejad A, Ahangari K, Goshtasbi K (2021) Comprehensive mechanical earth modeling using well data. Innov Infrastruct Solut 6:9. https://doi.org/10.1007/s41062-020-00369-w

Ouellet A, Bérard T, Desroches J et al (2011) Reservoir geomechanics for assessing containment in CO2 storage: a case study at Ketzin, Germany. Energy Procedia 4:3298–3305. https://doi.org/10.1016/j.egypro.2011.02.250

Paramasivam CR, Venkatramanan S (2019) An introduction to various spatial analysis techniques. In: GIS and geostatistical techniques for groundwater science. Elsevier, pp 23–30

Rahimi R, Nygaard R (2018) Effect of rock strength variation on the estimated borehole breakout using shear failure criteria. Geomech Geophys Geo Energy Geo Resour 4:369–382. https://doi.org/10.1007/s40948-018-0093-7

Ranjbar A, Hassani H, Shahriar K (2017) 3D geomechanical modeling and estimating the compaction and subsidence of Fahlian reservoir formation (X-field in SW of Iran). Arab J Geosci 10:116. https://doi.org/10.1007/s12517-017-2906-3

Ringstad C, Lofthus EB, Sonstebo EF et al (1998) Prediction of rock parameters from micro-indentation measurements: the effect of sample size. In: Proceedings of the SPE/ISRM rock mechanics in petroleum engineering conference. Society of Petroleum Engineers, pp 487–492

Saputro NE, Haris A (2018) 3D geomechanical modeling driven by acoustic impedance and seismic velocity: a case study of carbonate reservoir, East Java Basin, p 020253

Vachaparampil A, Ghassemi A (2017) Strength criteria for shale under true-triaxial stresses. 51st US Rock Mech/Geomech Symp 2017 2:845–855

Vishkai M, Wang J, Wong RCK et al (2017) Modeling geomechanical properties in the montney formation, Alberta, Canada. Int J Rock Mech Min Sci 96:94–105. https://doi.org/10.1016/j.ijrmms.2017.04.001

Wackernagel H (2003) Multivariate geostatistics. Springer, Berlin

Xie J, Qiu K, Zhong B et al (2018) Construction of a 3D geomechanical model for development of a shale gas reservoir in the Sichuan Basin. SPE Drill Complet 33:275–297. https://doi.org/10.2118/187828-PA

Zain-Ul-Abedin M, Henk A (2020) Building 1D and 3D mechanical earth models for underground gas storage—a case study from the Molasse Basin. Southern Germany Energies 13:5722. https://doi.org/10.3390/en13215722

Zare M, Rajabi M, Haghighi M, Velayati A (2018) 1D mechanical earth model in a carbonate reservoir of the Abadan Plain. Southwest Iran Implic Wellbore Stab 42298:2014–2018. https://doi.org/10.1306/42298Reisabadi2018

Zhao W, Liu Y, Wang T et al (2021) Stability analysis of wellbore for multiple weakness planes in shale formations. Geomech Geophys Geo Energy Geo Resour 7:44. https://doi.org/10.1007/s40948-021-00228-7

Zoback MD (2007) Reservoir geomechanics. Cambridge University Press, Cambridge

Acknowledgements

This paper authors extend their gratitude to Oil and Natural Gas Corporation Limited (ONGC) and Baker Hughes for their continuous support to make this research work possible and thank ONGC-Mumbai and Centre of Excellence in Well Logging Technology (CEWELL)-Baroda for providing data for this research under the PAN-IIT ONGC project. We thank Mr. Priti Prasad Deo, former executive director of CEWELL of ONGC for his continuous support and valuable discussions. We also thank Prof. M.K. Mishra (National Institute of Technology Rourkela) for his support during the course of experimental work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors of this article don’t have any conflicting interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ambati, V., Mahadasu, N., Koehn, D. et al. Construction of a 3D geomechanical model using integrated workflow to study zones causing subsidence and wellbore instabilities. Geomech. Geophys. Geo-energ. Geo-resour. 7, 83 (2021). https://doi.org/10.1007/s40948-021-00280-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-021-00280-3