Abstract

Depending on composition, processing, microstructure, and loading mode, steels may demonstrate various inelastic deformation mechanisms, notably dislocation glide, deformation twinning, and solid-solid phase changes. Damage in the form of voids, often leading to failure by macro-cracking, is also of current interest. A finite-deformation constitutive model is constructed in order to address such mechanisms in isotropic polycrystals under static and dynamic loading, where the latter encompasses high pressures and extreme strain rates pertinent to ballistic penetration. Slip and twinning are isochoric, and their relative contributions to kinematics are not explicitly distinguished in the present application. Phase changes among, e.g., face-centered-cubic (FCC), body-centered-cubic (BCC), body-centered-tetragonal (BCT), and hexagonal (HCP) structures are admitted, with corresponding deviatoric and volumetric strains. Porosity from voids contributes to volumetric strain. A new consistent thermodynamic framework incorporating an Eulerian strain tensor and internal state variables is developed, whereby kinetic equations for slip–twinning, phase changes, and damage evolution result in contributions to dissipation. An objective rate form of the model, derived assuming small deviatoric elastic strain, is implemented numerically. The model is applied to three different primarily austenitic, medium-high Mn steels. Specifically, representations of a slip-dominated (SLIP), a TRIP (transformation-induced plasticity) and a TWIP (twinning-induced plasticity) steel are calibrated to quasi-static tension, quasi-static compression, and dynamic compression data, at both room and high temperatures. A novel functional form of material strength distinguishes hardening profiles of the different alloys. Experimental data are reasonably well represented. Model extrapolations for dynamic strength and pressure in regimes pertinent to shock compression are analyzed. Predictions for multi-axial loading of shear with simultaneous expansion or contraction demonstrate competing physical mechanisms among the alloys that could be leveraged for optimal ballistic performance.

Similar content being viewed by others

Notes

EOS is an acronym for equations of state herein relating pressure, specific volume, temperature, and thermoelastic free energy of “Thermoelasticity” section.

References

Crouch IG, Cimpoeru SJ, Li H, Shanmugam D (2017) Armour steels. In: Crouch IG (ed) Theoretical and applied mechanics. Woodhead, Amsterdam, pp 55–115

De Cooman BC, Estrin Y, Kim SK (2018) Twinning-induced plasticity (TWIP) steels. Acta Mater 142:283–362

Madilava M, Schwedt A, Wong SL, Roters F, Prahl U, Bleck W (2018) Temperature dependent strain hardening and fracture behavior of TWIP steel. Int J Plast 104:80–103

Lani F, Furnemont Q, Van Rompaey T, Delannay F, Jacques PJ, Pardoen T (2007) Multiscale mechanics of TRIP-assisted multiphase steels: II. Micromechanical modelling. Acta Mater 55:3695–3705

Wengrenovich NJ, Olson GB (2015) Optimization of a TRIP steel for adiabatic fragment protection. Mater Today 2S:639–642

Bronkhorst CA, Cerreta EK, Xue Q, Maudlin PJ, Mason TA, Gray GT (2006) An experimental and numerical study of the localization behavior of tantalum and stainless steel. Int J Plast 22:1304–1335

Vernerey FJ, McVeigh C, Liu WK, Moran B, Tewari D, Parks DM, Olson GB (2006) The 3-D computational modeling of shear-dominated ductile failure in steel. JOM 58:45–51

Zukas JA, Nicholas T, Swift HF, Greszczuk LB, Curran DR (1992) Impact dynamics. Krieger, Malabar

Børvik T, Langseth M, Hopperstad OS, Malo KA (1999) Ballistic penetration of steel plates. Int J Impact Eng 22:855–886

Wright TW (2002) The physics and mathematics of adiabatic shear bands. Cambridge University Press, Cambridge

McVeigh C, Vernerey F, Liu WK, Moran B, Olson G (2007) An interactive micro-void shear localization mechanism in high strength steels. J Mech Phys Solids 55:225–244

Kadkhodapour J, Anbarlooie B, Hosseini-Toudeshky H, Schmauder S (2014) Simulation of shear failure in dual phase steels using localization criteria and experimental observation. Comput Mater Sci 94:106–113

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: Part I—yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99:2–15

Needleman A, Tvergaard V (1992) Analyses of plastic flow localization in metals. Appl Mech Rev 45:S3–S18

Nemat-Nasser S (2004) Plasticity: a treatise on finite deformation of heterogeneous inelastic materials. Cambridge University Press, Cambridge

Davison L (2008) Fundamentals of shock wave propagation in solids. Springer, Berlin

Clayton JD (2011) Nonlinear mechanics of crystals. Springer, Dordrecht

Clayton JD (2019) Nonlinear elastic and inelastic models for shock compression of crystalline solids. Springer, Cham

Curtze S, Kuokkala VT (2010) Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater 58:5129–5141

Cherkaoui M, Berveiller M, Lemoine X (2000) Couplings between plasticity and martensitic phase transformation: overall behavior of polycrystalline TRIP steels. Int J Plast 16:1215–1241

Turteltaub S, Suiker ASJ (2005) Transformation-induced plasticity in ferrous alloys. J Mech Phys Solids 53:1747–1788

Turteltaub S, Suiker ASJ (2006) A multiscale thermomechanical model for cubic to tetragonal martensitic phase transformations. Int J Solids Struct 43:4509–4545

Tjahjanto DD, Turteltaub S, Suiker ASJ (2008) Crystallographically based model for transformation-induced plasticity in multiphase carbon steels. Contin Mech Thermodyn 19:399–422

Wong SL, Madilava M, Prahl U, Roters F, Raabe D (2016) A crystal plasticity model for twinning- and transformation-induced plasticity. Acta Mater 118:140–151

Yuan F, Bian X, Jiang P, Yang M, Wu X (2015) Dynamic shear response and evolution mechanisms of adiabatic shear band in an ultrafine-grained austenite–ferrite duplex steel. Mech Mater 89:47–58

Stringfellow RG, Parks DM, Olson GB (1992) A constitutive model for transformation plasticity accompanying strain-induced martensitic transformations in metastable austenitic steels. Acta Metall Mater 40:1703–1716

Tomita Y, Iwamoto T (1995) Constitutive modeling of TRIP steel and its application to the improvement of mechanical properties. Int J Mech Sci 37:1295–1305

Serri J, Martiny M, Ferron G (2005) Finite element analysis of the effects of martensitic phase transformation in TRIP steel sheet forming. Int J Mech Sci 47:884–901

Kohar CP, Cherkaoui M, El Kadiri H, Inal K (2016) Numerical modeling of TRIP steel in axial crashworthiness. Int J Plast 84:224–254

Duvall GE, Graham RA (1977) Phase transitions under shock-wave loading. Rev Mod Phys 49:523–579

Barton NR, Benson DJ, Becker R (2005) Crystal level continuum modelling of phase transformations: the \(\alpha \leftrightarrow \epsilon\) transformation in iron. Model Simul Mater Sci Eng 13:707–731

Levitas VI (1998) Thermomechanical theory of martensitic phase transformations in inelastic materials. Int J Solids Struct 35:889–940

Grujicic M, Sankaran N (1997) Dispersed-phase martensitic transformation controlled deformation behavior of two-phase metallic materials. Int J Solids Struct 34:4421–4446

Lloyd JT, Williams CL, Clayton JD (2020a) Dynamic strength of AZ31B-4E and AMX602 magnesium alloys under shock loading. J Dyn Behav Mater. https://doi.org/10.1007/s40870-019-00230-x

Clayton JD (2009) A continuum description of nonlinear elasticity, slip and twinning, with application to sapphire. Proc R Soc Lond A 465:307–334

Clayton JD (2014a) An alternative three-term decomposition for single crystal deformation motivated by non-linear elastic dislocation solutions. Q J Mech Appl Math 67:127–158

Clayton JD (2013) Nonlinear Eulerian thermoelasticity for anisotropic crystals. J Mech Phys Solids 61:1983–2014

Lloyd JT, Clayton JD, Becker R, McDowell DL (2014a) Simulation of shock wave propagation in single crystal and polycrystalline aluminum. Int J Plast 60:118–144

Clayton JD (2014b) Shock compression of metal crystals: a comparison of Eulerian and Lagrangian elastic–plastic theories. Int J Appl Mech 6:1450048

Clayton JD (2015) Crystal thermoelasticity at extreme loading rates and pressures: analysis of higher-order energy potentials. Extreme Mech Lett 3:113–122

Bennett KC, Regueiro RA, Borja RI (2016) Finite strain elastoplasticity considering the Eshelby stress for materials undergoing plastic volume change. Int J Plast 77:214–245

Thurston RN (1974) Waves in solids. In: Truesdell C (ed) Handbuch der Physik, vol VI. Springer, Berlin, pp 109–308

Clayton JD (2014c) Differential geometry and kinematics of continua. World Scientific, Singapore

Birch F (1947) Finite elastic strain of cubic crystals. Phys Rev 71:809–824

Jeanloz R (1989) Shock wave equation of state and finite strain theory. J Geophys Res 94:5873–5886

Simo J, Hughes TJR (1998) Computational inelasticity. Springer, New York

Johnson GR, Cook WH (1983) A constitutive model and data for materials subjected to large strains, high strain rates, and high temperatures. In: Proceedings of the 7th international symposium on ballistics, The Hague, Netherlands, pp 541–547

Lloyd JT, Field DM, Limmer KR (2020b) A four parameter hardening model for TWIP and TRIP steels. Mater Des 194:108878

Leblond JB, Mottet G, Devaux JC (1986) A theoretical and numerical approach to the plastic behaviour of steels during phase transformations—I. Derivation of general relations. J Mech Phys Solids 34:395–409

Mackenzie JK (1950) The elastic constants of a solid containing spherical holes. Proc Phys Soc B 63:2–11

Clayton JD, Freed AD (2020) A constitutive framework for finite viscoelasticity and damage based on the Gram–Schmidt decomposition. Acta Mech 231:3319–3362

Clayton JD, Knap J (2014) A geometrically nonlinear phase field theory of brittle fracture. Int J Fract 189:139–148

Clayton JD, Knap J (2016) Phase field modeling of coupled fracture and twinning in single crystals and polycrystals. Comput Methods Appl Mech Eng 312:447–467

Kachanov M, Tsukrov I, Shafiro B (1994) Effective moduli of solids with cavities of various shapes. Appl Mech Rev 47:S151–S174

Cocks ACF, Ashby MF (1980) Intergranular fracture during power-law creep under multiaxial stresses. Met Sci 14:395–402

Cocks ACF, Ashby MF (1982) On creep fracture by void growth. Prog Mater Sci 27:189–244

Bammann DJ, Chiesa ML, Horstemeyer MF, Weingarten LI (1993) Failure in ductile materials using finite element methods. In: Jones N, Wierzbicki T (eds) Structural crashworthiness and failure. Elsevier Applied Science, The Universities Press, Belfast, pp 1–54

Barton NR (2015) Results from a new Cocks–Ashby style porosity model. AIP Conf Proc 1793:100029

Whittington WR, Oppedal AL, Turnage S, Hammi Y, Rhee H, Allison PG, Crane CK, Horstemeyer MF (2014) Capturing the effect of temperature, strain rate, and stress state on the plasticity and fracture of rolled homogeneous armor (RHA) steel. Mater Sci Eng A 594:82–88

Marin EB, McDowell DL (1996) Associative versus non-associative porous viscoplasticity based on internal state variable concepts. Int J Plast 12:629–669

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech 21:31–48

Celentano DJ, Chaboche JL (2007) Experimental and numerical characterization of damage evolution in steels. Int J Plast 23:1739–1762

Chung K, Ma N, Park T, Kim D, Yoo D, Kim C (2011) A modified damage model for advanced high strength steel sheets. Int J Plast 27:1485–1511

Abu Al-Rub RK, Ettehad M, Palazotto AN (2015) Microstructural modeling of dual phase steel using a higher-order gradient plasticity-damage model. Int J Solids Struct 58:178–189

Becker R, Needleman A, Richmond O, Tvergaard V (1988) Void growth and failure in notched bars. J Mech Phys Solids 36:317–351

Noble CR, Anderson AT, Barton NR et al (2017) ALE3D: an arbitrary Lagrangian–Eulerian multi-physics code. Technical Report LLNL-TR-732040. Lawrence Livermore National Laboratory (LLNL), Livermore

Field DM, Baker DS, Van Aken DC (2017) On the prediction of \(\alpha\)-martensite temperatures in medium manganese steels. Metall Mater Trans A 48:2150–2163

Magagnosc DJ, Field DM, Meredith CS, Walter TR, Limmer KR, Lloyd JT (2021) Superior strength and ductility in a low density duplex steel studied by in-situ neutron diffraction. Mater Sci Eng A 799:140252

Field DM et al (2020) Variable properties in a two-stage TRIP Mn steel. Mater Des (in preparation)

Meredith CS et al (2020) Mechanical behavior and microstructural evolution of TRIP, TWIP, and SLIP multi-phase steels at dynamic strain rates (in preparation)

Roters F, Raabe D, Gottstein G (2000) Work hardening in heterogeneous alloys—a microstructural approach based on three internal state variables. Acta Mater 48:4181–4189

Steinmetz DR, Jäpel T, Wietbrock B, Eisenlohr P, Gutierrez-Urrutia I, Saeed-Akbari A, Hickel T, Roters F, Raabe D (2013) Revealing the strain-hardening behavior of twinning-induced plasticity steels: theory, simulations, experiments. Acta Mater 61:494–510

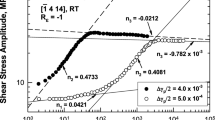

Millett JCF, Bourne NK, Rosenberg Z (1997) Shear stress measurements in copper, iron, and mild steel under shock loading conditions. J Appl Phys 81:2579–2583

Whiteman G, Millett JCF, Bourne NK (2007) Shear stress measurements in copper, iron, and mild steel under shock loading conditions. AIP Conf Proc 955:673–676

Whiteman G, Millett JCF (2012) Shear stress measurements in stainless steel 2169 under 1D shock loading. Exp Mech 52:265–273

Guinan MW, Steinberg DJ (1974) Pressure and temperature derivatives of the isotropic polycrystalline shear modulus for 65 elements. J Phys Chem Solids 35:1501–1512

Miller MP, McDowell DL (1996) Modeling large strain multiaxial effects in FCC polycrystals. Int J Plast 12:875–902

Lloyd JT, Clayton JD, Austin RA, McDowell DL (2014b) Plane wave simulation of elastic–viscoplastic single crystals. J Mech Phys Solids 69:14–32

Lloyd JT, Clayton JD, Austin RA, McDowell DL (2015) Shock compression modeling of metallic single crystals: comparison of finite difference, steady wave, and analytical solutions. Adv Model Simul Eng Sci 2:14

Winey JM, Gupta YM (2006) Nonlinear anisotropic description for the thermomechanical response of shocked single crystals: inelastic deformation. J Appl Phys 99:023510

Vogler TJ, Clayton JD (2008) Heterogeneous deformation and spall of an extruded tungsten alloy: plate impact experiments and crystal plasticity modeling. J Mech Phys Solids 56:297–335

Vogler TJ, Chhabildas LC (2006) Strength behavior of materials at high pressures. Int J Impact Eng 33:812–825

Brown JL, Alexander CS, Asay JR, Vogler TJ, Ding JL (2013) Extracting strength from high pressure ramp-release experiments. J Appl Phys 114:223518

Swegle JW, Grady DE (1985) Shock viscosity and the prediction of shock wave rise times. J Appl Phys 58:692–701

Johnson JN, Tonks DL (1992) Dynamic plasticity in transition from thermal activation to viscous drag. In: Shock compression of condensed matter-1991. Elsevier, Amsterdam, pp 371–378

Preston DL, Tonks DL, Wallace DC (2003) Model of plastic deformation for extreme loading conditions. J Appl Phys 93:211–220

Austin RA, McDowell DL (2011) A dislocation-based constitutive model for viscoplastic deformation of FCC metals at very high strain rates. Int J Plast 27:1–24

Austin RA, McDowell DL (2012) Parameterization of a rate-dependent model of shock-induced plasticity for copper, nickel, and aluminum. Int J Plast 32:134–154

Marsh S (ed) (1980) LASL shock Hugoniot data. University of California Press, Berkeley

Needleman A (1988) Material rate dependence and mesh sensitivity in localization problems. Comput Methods Appl Mech Eng 67:69–85

Wright TW, Batra RC (1985) The initiation and growth of adiabatic shear bands. Int J Plast 1:205–212

Savinykh AS, Garkushin GV, Razorenvo SV, Wolf S, Kruger L (2015) Influence of the temperature-induced martensitic-austenitic transformation on the strength properties of high-alloy steels under dynamic loading. Combust Explos Shock Waves 51:124–129

Eckner R, Kruger L, Motylenko M, Savinykh AS, Razorenov SV, Garkushin GV (2018) Deformation mechanisms and microplasticity of austenitic TRIP/TWIP steel under flyer plate impact. EPJ Web Conf 183:03007

Acknowledgements

J.D.C. and J.T.L. acknowledge support of the CCDC Army Research Laboratory. The authors thank D.M. Field, D.J. Magagnosc, C.S. Meredith, and T.R. Walter for sharing various data on steel alloys prior to external publication.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Theoretical Derivations

Equation (19) is derived as

Equation (42) is derived as

Equation (43) is derived as

Equation (44) is derived as

Equation (45) is derived as

Equation (46) is derived as

Equation (72) is derived as

where

Equation (79) is derived as

Equation (90) is derived as

Appendix 2: Data Analysis

In most cases, 2–3 experiments were performed for each alloy at each initial temperature and loading rate. For every loading protocol, the number of experiments is shown in Table 5 along with experimental variation in effective stress, model prediction of effective stress, and the error in this prediction relative to the experimental mean. Comparisons are made at two discrete strain levels \(\epsilon\) in each case, corresponding to availability of test data (e.g., some compression experiments were unloaded prior to attainment of very large deformations). Stress variability is defined as \({\varDelta }\sigma = {\text {max}}_{i} | {\bar{\sigma }} - \sigma _{i} |,\) where \({\bar{\sigma }}\) is the mean among tests and \(\sigma _{i}\) is the measured value for experiment i, where i runs from 1 to the number of tests shown in corresponding rows of the table. Modeling error in the rightmost column is defined, at each \(\epsilon ,\) as \(|\sigma - {\bar{\sigma }} | / {\bar{\sigma }} ,\) with the model result denoted simply by \(\sigma .\) Agreement with tensile data is generally superior to that with compression data since the calibration procedure of “Static and Dynamic Loading” section focuses on the tensile response. Of the 36 cases quantified in Table 5, modeling error exceeds 4% only 11 times. The most inaccurate results, with error exceeding 13%, correspond to static compression of the TWIP steel at room temperature (noting that the model, calibrated to tensile response, fails to capture tension–compression asymmetry in the TWIP alloy), and to dynamic high-temperature compression of the TWIP steel, for which thermal softening is apparently not well represented.

Since experimental data on the three alloys of Table 1 for compression and tension are available, but torsion data are notably absent, model predictions for all three stress states and all three steels are compared versus one another and versus trends for several other steels reported elsewhere. Results for the SLIP and TWIP steels are shown in Fig. 13a. These show negligible effect of triaxiality on stress–strain behavior, with the exception of tensile softening due to porosity that initiates at \(\epsilon \gtrsim 0.35\) in the SLIP steel. In each case, effective stress \(\sigma\) is von Mises stress, and effective strain is \(\epsilon = \sqrt{2/3} \int {{{\varvec{d}}}}: {{{\varvec{d}}}} \text {d}t.\) For tension and compression, these definitions are consistent with true stress and logarithmic strain measures used in “Static and Dynamic Loading” section. For free-end torsion, \(\sigma = \sqrt{3} \tau\) and \(\epsilon = \gamma / \sqrt{3},\) with \(\tau\) and \(\gamma\) the usual engineering shear stress and strain measures.

Results in Fig. 13b demonstrate a marked effect of stress state on strength behavior of the TRIP steel. For strain-assisted transformation, stress in tension very slightly exceeds that in torsion, since the contribution of tensile pressure is not enough to drastically accelerate phase changes in the former relative to the latter. In contrast, martensitic transformation is impeded by compressive stress, leading to a softer response. Stress-assisted transformation corresponds to the results shown in Fig. 3a, and is thought more realistic than strain-assisted transformation for static tensile loading. In this case, strain accommodation by phase changes initiated prior to plastic yield induces a load reduction, which in turn retards the transformation rate at low applied strains.

Trends predicted in Fig. 13 are similar, but not identical, to those reported for RHA steel in [59]. Quasi-static room temperature data for RHA show very similar plastic strength behavior for tension, compression, and shear, at least until damage accumulates. At larger strain levels, porosity nucleated at hard particles was more severe in torsion than in tension, leading to softer torsional behavior and earlier failure [59]. This behavior cannot be captured by the traditional Cocks–Ashby type damage model (89), used in the present work, which requires positive mean stress for porosity increases.

Data and/or modeling on 304L stainless steel in [77] show tensile strength exceeding compressive strength, with torsional hardening the lowest among the three stress states. Expansive martensitic transformation from the \(\gamma\) to \(\alpha '\) phase was reported to be greater in compression loading than torsional loading, despite the negative contribution to mechanical driving force induced by pressure in the former. Less localized slip and different dislocation structures observed in torsion than compression were suggested as responsible for the observed stress-state dependencies [77]. If relative torsional softening occurs in any of the three alloys of present study—which must be confirmed or refuted by future torsion experiments—adjustments to the present model framework are necessary to capture such behavior. For example, a \(J_{3}\)-based yield function is advocated in [29, 77], which provides satisfactory description of their experimental results.

Table 6 compares experimental data and model calibrations for quasi-static tensile failure behavior of the three alloys in Table 1, at room and elevated temperatures. The logarithmic tensile strain to failure is \(\epsilon _{F}.\) This is the average ductility among experimental tests, while it is the exact failure strain imposed in calibration of porosity \(\phi _{F}\) for the damage model. The experimental variation of ductility is \({\varDelta }\epsilon _{F} = {\text {max}}_{i} | \epsilon _{F} - \epsilon _{i} |\) with \(\epsilon _{i}\) the strain to failure of each experiment i at the given temperature for the alloy under consideration. Similarly, experimental variation of tensile strength at failure is \({\varDelta }\sigma _{F} = {\text {max}}_{i} | {\bar{\sigma }}_{F} - \sigma _{i} |,\) where \({\bar{\sigma }}_{F}\) is the average over experiments i with individual tensile strengths \(\sigma _{i}.\) The predicted tensile strength of the model at \(\epsilon _{F}\) is \(\sigma _{F},\) and the error in this prediction is \(|\sigma _{F} - {\bar{\sigma }}_{F} | / {\bar{\sigma }}_{F}.\) In order to achieve perfect agreement in \(\epsilon _{F}\) between model and experiment, a composition- and temperature-dependent failure porosity \(\phi _{F}\) must be assigned in each case. Determination of whether or not such values are physically descriptive requires microscopy of fractured surfaces as in [59], for example. Agreement between model and experiment for tensile strength at \(\epsilon _{F}\) is within 8% error, and within 4.5% when high temperature data for TWIP and TRIP steels are excluded.

Rights and permissions

About this article

Cite this article

Clayton, J.D., Lloyd, J.T. A Dynamic Finite-Deformation Constitutive Model for Steels Undergoing Slip, Twinning, and Phase Changes. J. dynamic behavior mater. 7, 217–247 (2021). https://doi.org/10.1007/s40870-020-00279-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-020-00279-z