Abstract

Batch adsorption experiments and column adsorption experiments were conducted using gel-based 201 × 7 resin to investigate the selective removal of \({{\text{MoO}}}_{4}^{2-}\) from sodium-tungstate-molybdenum aqueous. The results of the batch adsorption experiments demonstrated that gel-based 201 × 7 resin has selective removal of W and Mo. The pH value of the mixed sodium-tungstate-molybdenum aqueous (containing 9.11 g/L of Mo and 112.9 g/L of W) was adjusted to 7 by H2WO4. And W was existed as polymerised ions while Mo was existed as monodentate ions. In addition, the use of H2WO4 as an acidification agent and an alternative resource for tungsten presents high potential for industrial applications. Column adsorption experiments further demonstrated that the ratio of molybdenum removal reached 91.29% for three consecutive cycles with the pH value to 7 by H2WO4, and the separation between W and Mo was more effective. Thus, this method could be highly efficient for separating W and Mo in sodium-tungstate-molybdenum aqueous and presents better industrial prospects.

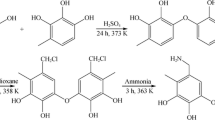

Graphical Abstract

Similar content being viewed by others

References

Wang X, Qin W, Jiao F, Dong L, Guo J, Zhang J, Yang C (2022) Review of tungsten resource reserves, tungsten concentrate production and tungsten beneficiation technology in China. Trans Nonferrous Metals Soc China 32(7):2318–2338. https://doi.org/10.1016/s1003-6326(22)65950-8

Jenus P, Abram A, Novak S, Kelemen M, Pecovnik M, Schwarz-Selinger T, Markelj S (2023) Deuterium retention in tungsten, tungsten carbide and tungsten-ditungsten carbide composites. J Nuclear Mater. https://doi.org/10.1016/j.jnucmat.2023.154455

Yuan J, Huang Y, Wang L, Jia C, Zhang F, Yang L (2023) Effect of the dissolution characteristic of tungsten carbide particles on microstructure and properties of Ni-WC/W2C reinforcement coating manufactured by TIG cladding. Int J Refract Metals Hard Mater. https://doi.org/10.1016/j.ijrmhm.2022.106047

Johnson JL (2023) Enhanced sintering of tungsten. Int J Refract Metals Hard Mater. https://doi.org/10.1016/j.ijrmhm.2022.106017

Deng X-C, Lan X, Wang Y-L, Zhang G-H (2023) Effect of Mo2C on the microstructure and properties of (W, Mo)C-10Co cemented carbides. Int J Refract Metals Hard Mater. https://doi.org/10.1016/j.ijrmhm.2023.106103

Qu M, Yan S, Lian Y, Liu X, Wirtz M (2023) Dependence of tungsten crack behaviors on heat source parameters under transient heat flow. Mater Sci Eng Struct Mater Prop Microstruct Proc. https://doi.org/10.1016/j.msea.2023.145079

Li J, Luo Y, Cui M, Zhao Z, Liu X, Chen X, He L, Sun F (2023) Preparation ultrafine WC based on the new tungsten metallurgy system of ?no ammonia transformation- no hydrogen reduction? Int J Refract Metals Hard Mater. https://doi.org/10.1016/j.ijrmhm.2023.106212

Lei Y, Sun F, Liu X, Zhao Z (2022) Understanding the wet decomposition processes of tungsten ore: Phase, thermodynamics and kinetics. Hydrometallurgy. https://doi.org/10.1016/j.hydromet.2022.105928

Li J, Ye J (2023) Enhanced oxidation resistance of single crystal tungsten powder by forming tungsten carbide on the surface. Int J Refract Metal Hard Mater 115:106215. https://doi.org/10.1016/j.ijrmhm.2023.106215

Kądzielawa AP, Legut D (2023) On the miscibility gap in tungsten-based alloys. Int J Refract Metals Hard Mater. https://doi.org/10.1016/j.ijrmhm.2023.106272

Hu Z, Liu Y, Chen S, Liu S, Yu L, Liu Y, Ma Z (2023) Achieving high-performance pure tungsten by additive manufacturing: processing, microstructural evolution and mechanical properties. Int J Refract Metals Hard Mater. https://doi.org/10.1016/j.ijrmhm.2023.106211

Li Z, Lu J, Wu S, Zhang G, Guan W, Zeng L, Li Q, Cao Z (2020) Sustainable extraction and complete separation of tungsten from ammonium molybdate solution by primary amine N1923. Acs Sustain Chem Eng 8(18):6914–23. https://doi.org/10.1021/acssuschemeng.9b06383

Wang H, Liu P, Chen X, Liu X, Chen A, Li J, He L, Sun F, Zhao Z (2022) Efficient dissolution of tungstic acid by isopolytungstate solution based on the polymerization theory of tungsten. Hydrometallurgy. https://doi.org/10.1016/j.hydromet.2022.105835

Li J, Cui M, Zhao Z, Liu X, Chen X, He L, Sun F, Xiao L, Li X, Wang L (2022) Extraction of tungsten from scheelite concentrate using a methanesulfonic acid- phosphoric acid coleaching process followed by solvent extraction with N1923. Hydrometallurgy. https://doi.org/10.1016/j.hydromet.2022.105917

Xia X, Zhang G, Guan W, Zhou Q, Zeng L, Wu S, Li Q, Cao Z, Fang K, Shi C (2023) A novel method for preparing tungsten and molybdenum peroxy complex solution and its application to tungsten- molybdenum separation. Hydrometallurgy. https://doi.org/10.1016/j.hydromet.2022.105974

Guan W, Zhang G, Gao C (2012) Solvent extraction separation of molybdenum and tungsten from ammonium solution by H2O2-complexation. Hydrometallurgy 127:84–90. https://doi.org/10.1016/j.hydromet.2012.07.008

Zhao Z, Gao L, Cao C, Li J, Chen X, Chen A, Liu X, Sun P, Huo G, Li Y, Li H (2012) Separation of molybdenum from tungstate solution-scavenging thiomolybdate by copper compound. Metall Mater Trans Process Metall and Mater Proc Sci 43(6):1284–1289. https://doi.org/10.1007/s11663-012-9743-2

Xiao LS, Zhang QX, Gong BF, Huang SY (2001) Separation of molybdenum from tungstate solution by a combination of moving packed bed and fluid bed ion-exchange techniques. Int J Refract Metals Hard Mater 19(3):145–148. https://doi.org/10.1016/S0263-4368(01)00008-7

Li J, Cao Z, Zeng L, Xu M, Zhang G, Li Q, Guan W (2019) A new recyclable sulfurizing reagent for Mo-S complexes and separation of molybdenum from tungstate solutions. Sep Purif Technol 212:490–490. https://doi.org/10.1016/j.seppur.2018.11.0316

Guo F, Xi X, Ma L, Nie Z (2022) Property and mechanism on sorption of molybdenum from tungstate solution with a porous amine resin. J Clean Prod. https://doi.org/10.1016/j.jclepro.2021.130304

Thi Hong N, Lee MS (2015) Separation of molybdenum(VI) and tungsten(VI) from sulfate solutions by solvent extraction with LIX 63 and PC 88A. Hydrometallurgy 155:51–55. https://doi.org/10.1016/j.hydromet.2015.04.014

Moris MA, Diez FV, Coca J (1999) Solvent extraction of molybdenum and tungsten by alamine 336 and DEHPA in a rotating disc contactor. Sep Purif Technol 17(3):173–179. https://doi.org/10.1016/s1383-5866(99)00022-2

Hoai Thanh T, Thi Hong N, Lee MS (2017) Separation of molybdenum(VI), rhenium(VII), tungsten(VI), and vanadium (V) by solvent extraction. Hydrometallurgy 171:298–305. https://doi.org/10.1016/j.hydromet.2017.06.006

Xiao L, Ji L, Chen A, Chen X, Liu X, Li J, He L, Sun F, Zhao Z (2023) Separation of molybdenum from peroxotungstic acid solution by solvent extraction with TBP and TRPO. Miner Eng. https://doi.org/10.1016/j.mineng.2023.108063

Xia X-B, Zhang G-Q, Guan W-J, Zeng L, Wu S-X, Li Q-G, Cao Z-Y (2022) Mathematical model and reaction mechanism of molybdenum and tungsten extraction with TRPO from peroxide solution. Trans Nonferrous Metals Soc China 32(9):3123–3135. https://doi.org/10.1016/s1003-6326(22)66008-4

Xia X, Zhang G, Guan W, Zeng L, Wu S, Cao Z, Li Q, Zhou Q, Fang K, Shi C (2022) Extraction equilibrium of molybdenum(VI) and tungsten(VI) in aqueous solutions containing hydrogen peroxide by synergistic solvent extraction with TRPO and TBP. Hydrometallurgy. https://doi.org/10.1016/j.hydromet.2022.105818

Lu X-Y, Huo G-S, Liao C-H (2014) Separation of macro amounts of tungsten and molybdenum by ion exchange with D309 resin. Trans Nonferrous Metals Soc China 24(9):3008–3013. https://doi.org/10.1016/s1003-6326(14)63438-5

Huo G, Peng C, Song Q, Lu X (2014) Tungsten removal from molybdate solutions using ion exchange. Hydrometallurgy 147:217–222. https://doi.org/10.1016/j.hydromet.2014.05.015

Zhang J, Liu X, Chen X, Li J, Zhao Z (2014) Separation of tungsten and molybdenum using macroporous resin: competitive adsorption kinetics in binary system. Hydrometallurgy 144:77–85. https://doi.org/10.1016/j.hydromet.2013.12.002

Zhao Z, Zhang J, Chen X, Liu X, Li J, Zhang W (2013) Separation of tungsten and molybdenum using macroporous resin: Equilibrium adsorption for single and binary systems. Hydrometallurgy 140:120–127. https://doi.org/10.1016/j.hydromet.2013.09.014

Xiao C, Xiao L, Cao Z, Zeng L (2015) Study on removal of tungsten from molybdate solutions. Can Metall Quart 54(4):490–193. https://doi.org/10.1179/1879139515y.0000000015

Mal D, Puspalata R, Amirthapandian S, Bera S, Mohan TVK (2023) Effects of microstructure on radiolytic degradation of nuclear grade cationic resins: gel versus macro-porous. Radiat Phys Chem. https://doi.org/10.1016/j.radphyschem.2023.1110816

Zhao Z, Hu F, Hu Y, Wang S, Sun P, Huo G, Li H (2010) Adsorption behaviour of WO42- onto 201 x 7 resin in highly concentrated tungstate solutions. Int J Refract Metals Hard Mater 28(5):633–637. https://doi.org/10.1016/j.ijrmhm.2010.04.005

Liu S, Feng Y, Li H (2023) Separation of vanadium and tungsten in roasting-acid leaching solutions of the spent selective catalytic reducing denitration catalyst by co-extraction using hydroxyoxime extractant-quaternary ammonium salt extractant LIX984-N263 extractant. Aiche J. https://doi.org/10.1002/aic.17921

Ning P, Cao H, Zhang Y (2009) Selective extraction and deep removal of tungsten from sodium molybdate solution by primary amine N1923. Sep Purif Technol 70(1):27–33. https://doi.org/10.1016/j.seppur.2009.08.006

Lide D (2006) CRC handbook of chemistry and physics–87th edition 2006–2007 [Z]. Taylor & Francis Group, Boca Raton

Zhang J, Zhao Z, Chen X-Y, Liu X (2013) Thermodynamic analysis for separation of tungsten and molybdenum in W-Mo-H2O system. Chin J Nonferrous Metals 23(5):1463–1670. https://doi.org/10.19476/j.ysxb.1004.0609.2013.05.040

Acknowledgements

This research was financially supported by National Natural Science Foundation of China (No. 51974372; No. 52174339).

Funding

This research was financially supported by National Natural Science Foundation of China (No. 52174339, No. 52374363 and No. 51974372).

Author information

Authors and Affiliations

Contributions

JZ: Data curation, Methodology, Writing—original draft. YQ and ZW: Investigation. XC: Conceptualization, Resources, Writing—review & editing. AC: Writing—review & editing. XL: Writing—review & editing., JL: Writing—review & editing. LH: Writing—review & editing. FS: Conceptualization, Validation. ZZ: Funding acquisition, Writing – review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work.

Additional information

The contributing editor for this article was Grace Ofori-Sarpong.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, J., Qiu, Y., Wang, Z. et al. Molybdenum Separation from Sodium-Tungstate-Molybdenum Aqueous Solutions Using an Anionic Gel-Based 201 × 7 Resin. J. Sustain. Metall. 10, 184–194 (2024). https://doi.org/10.1007/s40831-024-00786-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-024-00786-6