Abstract

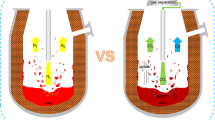

A numerical model was developed to investigate the possibility of using CO2 to replace conventional N2 for the converter slag-splashing process and, thus, promote the recycling of CO2 in the steel industry. The validity of the numerical model was demonstrated using one-dimensional isentropic flow theory and experimental data. By comparing with N2 and O2, it was found that CO2 has a lower velocity and dynamic pressure, higher temperature at the exit of the oxygen lance, and the difference between the three gases decreases gradually with the increasing of axial distance. The oxygen lance is required to have excellent stirring and splashing performance simultaneously for the CO2 slag-splashing process. The five-hole oxygen lance with a central nozzle combines the advantages of single-hole and four-hole oxygen lances, with higher impact force, slower decay of dynamic pressure, higher impact area, and more tremendous average turbulent kinetic energy at a low lance position, providing a better choice for slag splashing. Decreasing the axial distance, increasing the CO2 stagnation pressure, and raising the CO2 preheating temperature could improve the CO2 jet performance by different degrees. This work provides a theoretical basis for the application of CO2 in the converter slag-splashing process.

Graphical Abstract

Similar content being viewed by others

References

Kim Y, Worrell E (2002) International comparison of CO2 emission trends in the iron and steel industry. Energy Policy 30:827–838. https://doi.org/10.1016/S0301-4215(01)00130-6

Deng L, Adams TA II (2020) Techno-economic analysis of coke oven gas and blast furnace gas to methanol process with carbon dioxide capture and utilization. Energy Convers Manage 204:112315. https://doi.org/10.1016/j.enconman.2019.112315

Chen Q, Gu Y, Tang Z, Wei W, Sun Y (2018) Assessment of low-carbon iron and steel production with CO2 recycling and utilization technologies: a case study in China. Appl Energy 220:192–207. https://doi.org/10.1016/j.apenergy.2018.03.043

Ryan NA, Miller SA, Skerlos SJ, Cooper DR (2020) Reducing CO2 emissions from US steel consumption by 70% by 2050. Environ Sci Technol 54:14598–14608. https://doi.org/10.1021/acs.est.0c04321

Holappa L (2020) A general vision for reduction of energy consumption and CO2 emissions from the steel industry. Metals 10:1117. https://doi.org/10.3390/met10091117

Ren L, Zhou S, Peng T, Ou X (2021) A review of CO2 emissions reduction technologies and low-carbon development in the iron and steel industry focusing on China. Renew Sustain Energy Rev 143:110846. https://doi.org/10.1016/j.rser.2021.110846

Mandova H, Leduc S, Wang C, Wetterlund E, Patrizio P, Gale W, Kraxner F (2018) Possibilities for CO2 emission reduction using biomass in European integrated steel plants. Biomass Bioenergy 115:231–243. https://doi.org/10.1016/j.biombioe.2018.04.021

Bailera M, Lisbona P, Peña B, Romeo LM (2021) A review on CO2 mitigation in the iron and steel industry through power to X processes. J CO2 Util 46:101456. https://doi.org/10.1016/j.jcou.2021.101456

Nwachukwu CM, Wang C, Wetterlund E (2021) Exploring the role of forest biomass in abating fossil CO2 emissions in the iron and steel industry-the case of Sweden. Appl Energy 288:116558. https://doi.org/10.1016/j.apenergy.2021.116558

Dreillard M, Broutin P, Briot P, Huard T, Lettat A (2017) Application of the DMXTM CO2 capture process in steel industry. Energy Procedia 114:2573–2589. https://doi.org/10.1016/j.egypro.2017.03.1415

Yun S, Jang MG, Kim JK (2021) Techno-economic assessment and comparison of absorption and membrane CO2 capture processes for iron and steel industry. Energy 229:120778. https://doi.org/10.1016/j.energy.2021.120778

Mastropasqua L, Pierangelo L, Spinelli M, Romano MC, Campanari S, Consonni S (2019) Molten carbonate fuel cells retrofits for CO2 capture and enhanced energy production in the steel industry. Int J Greenhouse Gas Control 88:195–208. https://doi.org/10.1016/j.ijggc.2019.05.033

Chung W, Roh K, Lee JH (2018) Design and evaluation of CO2 capture plants for the steelmaking industry by means of amine scrubbing and membrane separation. Int J Greenhouse Gas Control 74:259–270. https://doi.org/10.1016/j.ijggc.2018.05.009

Ibrahim MH, El-Naas MH, Zevenhoven R, Al-Sobhi SA (2019) Enhanced CO2 capture through reaction with steel-making dust in high salinity water. Int J Greenhouse Gas Control 91:102819. https://doi.org/10.1016/j.ijggc.2019.102819

Yasipourtehrani S, Tian S, Strezov V, Kan T, Evans T (2020) Development of robust CaO-based sorbents from blast furnace slag for calcium looping CO2 capture. Chem Eng J 387:124140. https://doi.org/10.1016/j.cej.2020.124140

Mendoza EYM, Santos AS, López EV, Drozd V, Durygin A, Chen J, Saxena SK (2019) Iron oxides as efficient sorbents for CO2 capture. J Mater Res Technol 8:2944–2956. https://doi.org/10.1016/j.jmrt.2019.05.002

Dindi A, Quang DV, Vega LF, Nashef E, Abu-Zahra MR (2019) Applications of fly ash for CO2 capture, utilization, and storage. J CO2 Util 29:82–102. https://doi.org/10.1016/j.jcou.2018.11.011

Kar S, Kothandaraman J, Goeppert A, Prakash GS (2018) Advances in catalytic homogeneous hydrogenation of carbon dioxide to methanol. J CO2 Util 23:212–218. https://doi.org/10.1016/j.jcou.2017.10.023

Han B, Wei G, Zhu R, Wu W, Jiang J, Feng C, Dong J, Hu S, Liu R (2019) Utilization of carbon dioxide injection in BOF–RH steelmaking process. J CO2 Util 34:53–62. https://doi.org/10.1016/j.jcou.2019.05.038

Dong K, Wang X (2019) CO2 utilization in the ironmaking and steelmaking process. Metals 9:273–281. https://doi.org/10.3390/met9030273

Zhu R, Han BC, Dong K, Wei GS (2020) A review of carbon dioxide disposal technology in the converter steelmaking process. Int J Miner Metall Mater 27:1421–1429. https://doi.org/10.1007/s12613-020-2065-5

Feng C, Zhu R, Dong K, Wei G, Han B, Li W, Wu W (2021) Effects of nozzle layout and parameters on the jet characteristics of a CO2+ O2 mixed oxygen lance. Metall Mater Trans B 52:425–439. https://doi.org/10.1007/s11663-020-02048-8

Feng C, Xia T, Wei G, Dong J, Zhu R, Dong K (2021) Supersonic jet characteristics of two parameter oxygen lance nozzle. Ironmak Steelmak 49:1–13. https://doi.org/10.1080/03019233.2021.1968261

Yi C, Zhu R, Chen BY, Wang CR, Ke JX (2009) Experimental research on reducing the dust of BOF in CO2 and O2 mixed blowing steelmaking process. ISIJ Int 49:1694–1699. https://doi.org/10.2355/isijinternational.49.1694

Zhao HX, Yuan ZF, Wang WJ, Pan YF, Li SQ (2010) A novel method of recycling CO2 for slag splashing in converter. J Iron Steel Res Int 17:11–16. https://doi.org/10.1016/S1006-706X(10)60190-2

Wang WJ, Yuan ZF, Matsuura H, Zhao HX, Dai C, Tsukihashi F (2010) Three-dimensional compressible flow simulation of top-blown multiple jets in converter. ISIJ Int 50:491–500. https://doi.org/10.2355/isijinternational.50.491

Liu K, Yuan ZF, Shi CH, Zhao HM, Wang H (2022) Effect of CaO-SiO2-FeO slag system on coal gasification reaction in CO2-Ar atmosphere and kinetic analysis. J CO2 Util 56:101850. https://doi.org/10.1016/j.jcou.2021.101850

Thitakamol B, Veawab A, Aroonwilas A (2007) Environmental impacts of absorption-based CO2 capture unit for post-combustion treatment of flue gas from coal-fired power plant. Int J Greenhouse Gas Control 1:318–342. https://doi.org/10.1016/S1750-5836(07)00042-4

Ansys, Inc. (2018) ANSYS Fluent theory guide 19.2. Ansys, Inc., Canonsburg

Leisieur M (1997) Turbulence in fluids. Kluwer Academic Publisher, Netherlands

Banerjee R (2008) Turbulent conjugate heat and mass transfer from the surface of a binary mixture of ethanol/iso-octane in a countercurrent stratified two-phase flow system. Int J Heat Mass Transf 51:5958–5974. https://doi.org/10.1016/j.ijheatmasstransfer.2008.04.057

Launder BE, Spalding DB (1974) The numerical computation of turbulent flows. Comput Methods Appl Mech Eng 3:269–288. https://doi.org/10.1016/B978-0-08-030937-8.50016-7

Yuan ZF, Pan YF (2007) Oxygen lance technology for steelmaking. Metallurgical Industry Press, Beijing

Li XM, Lu M, Xing XD, Zhou C (2021) Concise course of software for scientific research. Metallurgical Industry Press, Beijing

Miller DR, Comings EW (1957) Static pressure distribution in the free turbulent jet. J Fluid Mech 3:1–16. https://doi.org/10.1017/S0022112057000440

Forstall W, Gaylord E (1955) Momentum and mass transfer in a submerged water jet. J Appl Mech 22:161–164. https://doi.org/10.1115/1.4011034

Cheslak FR, Nicholls JA, Sichel M (1969) Cavities formed on liquid surfaces by impinging gaseous jets. J Fluid Mech 36:55–63. https://doi.org/10.1017/S0022112069001509

Zhang CX, Cai ZP, Xu ZH, Liang Y (1995) Mathematical model of velocity distribution in flow field of multijet for large scale oxygen lance. Chin J Eng 17:94–99. https://doi.org/10.13374/j.issn1001-053x.1995.s1.020

Li M, Li Q, Kuang S, Zou Z (2016) Computational investigation of the splashing phenomenon induced by the impingement of multiple supersonic jets onto a molten slag–metal bath. Ind Eng Chem Res 55:3630–3640. https://doi.org/10.1021/acs.iecr.5b03301

Sambasivam R, Lenka S, Durst F, Bock M, Chandra S, Ajmani S (2007) A new lance design for BOF steelmaking. Metall Mater Trans B 38:45–53. https://doi.org/10.1007/s11663-006-9004-3

Rao JP, Li GQ, Yang ZZ (2011) Research and application of new oxygen lance for BOF steelmaking. Adv Mater Res 335:74–79. https://doi.org/10.4028/www.scientific.net/AMR.335-336.74

Zhao F, Liu F, Sun D, Zhu R, Dong K (2021) Behaviors of supersonic oxygen multi-jets with various preheating temperatures. Metall Mater Trans B 52:2626–2641. https://doi.org/10.1007/s11663-021-02211-9

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Number 51974022).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Veena Sahajwalla.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, H., Yuan, Z., Mei, L. et al. The Behavior of CO2 Supersonic Jets in the Converter Slag-Splashing Process. J. Sustain. Metall. 8, 1803–1815 (2022). https://doi.org/10.1007/s40831-022-00607-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-022-00607-8