Abstract

This paper reviews the original achievements and advances regarding the field effect transistor (FET) fabricated from one of the most studied transition metal dichalcogenides: two-dimensional MoS2. Not like graphene, which is highlighted by a gapless Dirac cone band structure, Monolayer MoS2 is featured with a 1.9 eV gapped direct energy band thus facilitates convenient electronic and/or optoelectronic modulation of its physical properties in FET structure. Indeed, many MoS2 devices based on FET architecture such as phototransistors, memory devices, and sensors have been studied and extraordinary properties such as excellent mobility, ON/OFF ratio, and sensitivity of these devices have been exhibited. However, further developments in FET device applications depend a lot on if novel physics would be involved in them. In this review, an overview on advances and developments in the MoS2-based FETs are presented. Engineering of MoS2-based FETs will be discussed in details for understanding contact physics, formation of gate dielectric, and doping strategies. Also reported are demonstrations of device behaviors such as low-frequency noise and photoresponse in MoS2-based FETs, which is crucial for developing electronic and optoelectronic devices.

Similar content being viewed by others

1 Introduction

TMDCs (MoSe2, MoTe2, WS2, and WSe2, etc.) are well studied layered materials with sizable bandgap, which can be changed from bulk to layered form (indirect to direct transition), thus resulting in unique physical properties that are expected to be employed in future semiconducting devices [1, 2]. In particular, molybdenum disulfide (MoS2), which is conventionally prepared by scotch tape technique and chemical vapor deposition (CVD) method, has been a subject of great interest for several decades due to its interesting electronic and optical properties in its layered form, nanostructure and other architectures [3–12]. Numerous studies worldwide have studied how to apply this promising material in next-generation electronic and optoelectronic devices such as resonators [13], phototransistors [14], chemical sensors [15], photodetectors [16], amplifiers [17], and batteries [18, 19]. Specially, controllable valley polarization of MoS2 layered material suggests its potential in valleytronic devices [20, 21]. Being an example of the simplest form of layered MoS2, monolayer MoS2 has been under intensive investigation, in contrast to graphene [22], another monolayer of carbon, which remains immature due to its gapless characteristic. Several research groups have also investigated nanostructures of MoS2 in fabricating MoS2 devices, including nanosheet and nanoribbon transistors [23–25]. Bandgap of MoS2 layered structure varies from 1.2 eV for indirect bandgap to 1.9 eV for direct bandgap [26], playing a critical role in the development of future semiconductor devices, esp. optoelectronic devices. Since the first investigation of single-layer MoS2-based transistor and MoS2-based FET structure has become an important issue in electronic and optoelectronic devices evolution, additional knowledge in this respect is necessary for enhancing the performance of MoS2-based FET in future electronic and optoelectronic devices.

2 MoS2-Based FETs Engineering

2.1 Contact Engineering

MoS2-based FET has been demonstrated to exhibit high ON/OFF ratio exceeding 108, suggested hundreds of mobilities and low subthreshold swing at room temperature, indicating its potential employment in future electronic devices [27, 28]. However, due to the obstacle of contact resistance in achieving high-performance circuit [29], it is essential to study the contact engineering as well as intrinsic properties of MoS2-based FET to approach roadmap of prospective applications of MoS2 and other 2D TMDCs.

Choosing various contact metals with different work function is critical in fabricating MoS2-based FETs, low contact resistance is expected and able to form lower Schottky barrier at MoS2-metal interface, thus allowing high performance in MoS2-based FET [30, 31]. Utilizing low work function metal scandium (Sc) as contact metal have realized a low contact resistance and high carrier injection n-type MoS2-based FET, which is demonstrated to largely eliminate the effect of contact resistance, thus reaching relatively high mobility up to 700 cm2 (V s)−1 in a high-k dielectric environment (will be discussed later) [32].

Kaustav Banerjee et al. have proposed a comprehensive study of contact metals (In, Ti, and Mo) of MoS2-based FETs. Generally, carrier injection is suppressed due to the formation of tunnel barrier by 2D MoS2 at the MoS2-metal interface. Meanwhile, to date, no appropriate contact metal can form ohmic contact with MoS2, resulting in the formation of Schottky barrier at MoS2-metal interface. To reduce both the Schottky barrier and contact resistance of MoS2 FET, metal In performs well to some degree but creates a large tunnel barrier; in contrast, tunnel barrier is barely observed when using Pd as the contact metal to MoS2 [33]. Furthermore, employing metal Ti as contact metal can lead to a lower Schottky Barrier. However, it is still able to reduce the injection of electrons and the unstable properties of Ti also limit its high performance in MoS2 FETs [34].

To overcome the difficulties mentioned above, Kaustav Banerjee et al. propose an effective method to utilize Mo as contact metal and fabricate Mo (10 nm)/Au (100 nm) source/drain contacts on the Al2O3/Si substrate to achieve 1-layer and 4-layers MoS2 FETs [35]. As illustrated in Fig. 1, the drain-source current (I ds) versus back-gate voltage (V bg) curves (blue for log scale, black for linear) for 1-layer and 4-layers MoS2 FETs are shown in Fig. 1a, exhibiting evident n-type property with ON/OFF ratio exceeding 103 (under condition of 0.1 V drain-source voltage (V ds)). Figure 1b describes the V bg (ranging from −40 to 30 V) and corresponding contact resistance (R contact), channel resistance (R channel), and total resistance (R total) of 4-layers MoS2 FET under the condition of I ds = 0.1 µA. Compared with the contact resistance of Ti contact [36] (~80 kΩ µm) and Ni/Au contact [31] (~4.5 kΩ µm) MoS2 FET, the contact resistance of Mo contact MoS2 FET is much lower (~2 kΩ µm), manifesting more potential for high-performance digital circuit. In addition, Fig. 1c, d illustrates the output characteristics (I ds vs. V ds) of 1-layer and 4-layers MoS2 FETs with an inconspicuous Schottky contact, the black arrow denotes the increasing V bg (from −30 to 30 V). Moreover, pinch-off saturation is not available for these MoS2 FETs, but velocity saturation is suitable for use of as-fabricated device, which is suggested by ΔI in Fig. 1c, d. To summarize, Mo contact multilayer MoS2 FETs possess low contact resistances (~2 kΩ µm), high ON-currents (271 µA µm−1 at V ds = 8 V), and reasonable mobilities (~27 cm2 (V s)−1), exhibiting more potential applications in high performance digital devices than monolayer MoS2 FETs.

a I ds (drain-source current) versus V bg (back-gate voltage) curves for 1-layer and 4-layers MoS2 FETs(V ds = 0.1 V). b Different V bg and corresponding contact resistance (R contact), channel resistance (R channel) and total resistance (R total) of 4-layers MoS2 FET under the condition of I ds = 0.1 µA. c and d illustrated the output characteristics(I ds vs. V ds) of 1-layer and 4-layers MoS2 FET, respectively. Adopted from [34]

For most of the contact metals, Fermi level pinning close to the conduction band of MoS2 leads to limitation of hole injection, further detrimentally impact the realization of high-performance p-type MoS2 FET. Marcio Fontana et al. have demonstrated that Pd contact metal was available to form p-type MoS2 three-contact devices [37]. However, it depends a lot on large gate fields of these devices, which facilitates the decrease of Schottky barrier height in external electric field. Herein, Steven Chuang et al. introduced MoO x (x≦3) as contact metal fabricated on MoS2 FET, which exhibits p-type behavior, demonstrating that the MoO x is an efficient hole injection layer to MoS2 [38]. As a high work function material (6.6 eV) [39], MoO x is regarded as a promising candidate for hole injector of MoS2. In this experiment, Steven Chuang et al. fabricated 30 nm Pd/30 nm MoO x contact on 260 nm SiO2/Si substrate and successfully achieve p-type MoS2 FET. The schematic architecture and optical image of as-fabricated FET are shown in Fig. 2a. Figure 2b exhibits I ds versus gate-source voltages (V gs) characteristics, different drain voltages (V d) in red curve (−0.4 V) and blue curve (−1.5 V) are measured, and locus of circle and solid line denotes experimental and simulated results, respectively. Figure 2c shows I ds versus V ds characteristics and V gs along the arrow varying from 0 to 15 V with a 2.5 V step are concerned. Figure 2d displays the band diagram of as-fabricated p-type FET for the ON/OFF state. The MoS2 FET with MoO x contact is demonstrated presenting evident p-type characteristics with on-current (I on)/off-current (I off) ~104, manifesting expected hole contact of MoO x electrode to the valence band. More importantly, this work leads to the exploration in high work function materials employed as alternative metal contacts to realize high-performance MoS2-based FETs.

a Schematic architecture and optical image of as-fabricated FET. b I ds versus V gs characteristics, V d in red curve (−0.4 V) and blue curve (−1.5 V) are measured, locus of circle and solid line denote experimental and simulated results, respectively. c I ds versus V ds characteristics and V gs ranging from 0 to 15 V with a 2.5 V step are concerned. d Band diagram of as-fabricated p-type FET for the ON and OFF state. Adopted from [38]. (Color figure online)

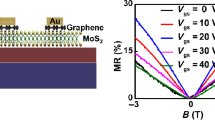

At the same time, MoS2-based FETs are also supposed to be employed into applications of spintronics, which are usually fabricated by ferromagnetic contacts, thus forming the MoS2/ferromagnetic interface. Again, Schottky barrier is demonstrated to exist at this interface [40], hindering the spin injection of electrons. To reduce the Schottky barrier and investigate future spin transport of MoS2-based devices, thin MgO layer, an additional tunnel barrier is utilized in single-layer MoS2 FET (Co contact), which results in the large decrease (about 84 %) of Schottky barrier [41]. Based on this investigation, Saroj Prasad Dash et al. further introduce TiO2 tunnel barrier in multilayer MoS2 FET (Co contact) to tune the contact resistance, which performs well and leads to a large increase of on-state current and mobility. Moreover, the channel conductance and magnetoresistance can be controlled by applying different gate voltages, which increase the possibilities for employment of MoS2 and other TMDCs for prospective applications of spintronics [42].

To study the intrinsic properties and estimate the quality of contact metals in MoS2-based FETs, four-terminal measurement is more important compared with two-terminal measurement [43, 44]. Toward this effort, N. R. Pradhan et al. fabricated the MoS2-based FET with approximate 20 layers MoS2, 300 nm silicon dioxide, and 8 Au contacts, and then, four-terminal measurement was used to study the intrinsic properties of MoS2-based FET, which could measure the effective mobility regardless of the impact of contact resistance at MoS2-metal interface. Compared with the past work by Peide D. Ye et al. [31], which was almost the same condition of as-fabricated FET, they found a large increase (~1 order of magnitude) of as-fabricated device in mobility (~300 vs. ~28 cm2 (V s)−1). In addition, Pablo Jarillo-Herrero et al. demonstrated that Hall measurement was able to nearly eliminate the contact resistance as well and Luis Balicas investigated another TMDC FET, i.e., the MoSe2 FET and found that the Hall mobilities (~250 cm2 (V s)−1) was higher than previously two-terminal measurement (~150–200 cm2 (V s)−1) [45, 46]. That is, four-terminal measurement is vital in investigating intrinsic properties of MoS2-based FETs and estimating the quality of contact metals. Future studies about MoS2-based FETs, even TMDCs devices should pay more attention to the four-terminal measurement.

In addition, Heung Cho Ko et al. utilized graphene as the electrodes for MoS2-based FET, which was also demonstrated to effectively reduce the Schottky barrier at MoS2/grapheme interface [47]. It is worth mentioning that Manish Chhowalla et al. proposed a novel method to reduce the contact resistance of MoS2-based FETs, they primarily considered two phases of MoS2: metallic 1T MoS2 and semiconducting 2H MoS2, later fabricated 1T MoS2 for electrodes and 2H MoS2 nanosheets for channel material in FET, and then, a very low contact resistance reaching 200–300 Ω µm was achieved under none gate bias, resulting in a high ON/OFF ratio exceeding 107, subthreshold swing (95 mV/decade) and 85 μA μm−1 drive currents values [48].

2.2 Dielectric Formation

To achieve high-performance MoS2-based FETs, the formation of high-k gate dielectric is important. For example, Madan Dubey et al. fabricated the MoS2 FET with and without a high-k Al2O3 dielectric, and then, measurements of mobilities indicated an increase of 6.0–16.1 cm2 (V s)−1 [49]. In studies of Saptarshi Das et al. which was discussed above, they similarly introduced the high-k Al2O3 dielectric, thus resulting in the increase of mobilities from 184 to 700 cm2 (V s)−1 [32]. Moreover, both theoretical and experimental studies show that high-k HfO2 dielectric is able to effectively enhance the performance of MoS2-based FETs [27, 50, 51]. High-k gate dielectric is suggested to reduce the Coulombic scattering, which improves the electronic properties of channel in MoS2-based FETs [52].

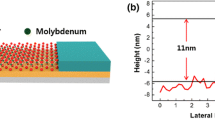

Generally, considering the uniformity and controllable thickness of the material to deposit, atomic layer deposition (ALD) technology is an effective method to deposit high-k gate dielectric. However, high-quality gate dielectric is difficult to deposit on 2D MoS2 by ALD, which attributes to the absence of dangling bonds and other active elements at the surface. Toward this effort, Peide D. Ye et al. investigated the deposition of high-k Al2O3 on MoS2 by ALD; they utilized water and trimethylaluminum (TMA) as precursor and lowered the temperature of substrate down to 200 °C, which successfully resulted in the formation of 10 nm uniform Al2O3 dielectric on MoS2 by physical adsorption [53]. However, reaction of precursors in low temperature could further lead to the impurities resided in as-deposited high-k film, which limited its electronic properties [54]. To overcome it, Hyoungsub Kim et al. introduced oxygen plasma treatment in deposition of Al2O3 and HfO2 on multilayer MoS2 by the same method of ALD; they used X-ray photoelectron spectroscopy (XPS) analysis and found that oxygen plasma-treated MoS2 formed Mo-oxide layer at its surface, which is demonstrated to improve the quality of as-grown high-k Al2O3 and HfO2 dielectric. This work indicates the promising of plasma-treated ALD method in formation of high-k gate dielectric on MoS2-based FET [55].

Deposition of high-k Al2O3 on ultraviolet-ozone (UV-O3)-treated MoS2 has also been studied. Uniform high-k Al2O3 film was achieved due to the removal of contaminations and the formation of slight S–O bonds at the MoS2 surface. It is necessary to mention that UV-O3 exposure did not break the Mo–S bonds and was a non-disruptive method to achieve high-quality Al2O3 dielectric deposition. The surface of UV-O3-treated MoS2 is also demonstrated to be a suitable layer for controllable deposition of uniform and ultrathin Al2O3 (~4 nm), which is more practical in MoS2-based FET technology [56]. In addition, Lanxia Cheng et al. investigated the ALD deposition of Al2O3 dielectric on MoS2 by precursors of TMA/H2O and TMA/O3 and studied the properties of two types of as-deposited thin films. They claimed that O3 was an important factor in high-quality ALD deposition, which resulted in the deposition of uniform, lower thickness (~5 nm) of dielectric layer without the S–O bonds generation at MoS2 surface and the improvement of growth rate [57].

The formation of high-k dielectric is critical for MoS2-based FETs technology, and the nature of no dangling bonds at the surface of 2D MoS2 allows discovering suitable precursors and pretreatments for ALD deposition, which is relatively effective in gate dielectric deposition. Lowering the temperature of substrate to achieve physical adsorption can lead to uniform high-k dielectric layer deposition, but it is limited by essential clean surface of MoS2 and hard to control the parameters of deposition. Oxygen plasma-treated MoS2 surface is also demonstrated to form high quality, uniform dielectric layer, but this method is regarded as destructive. These two methods are not very practical in MoS2-based FETs as the formation of uniformity layer can be achieved only when the thickness is enough (about 10 nm), which limit the scaling down of FET. In contrast, UV-O3 exposure and O3 precursor are non-destructive and able to deposit ultrathin dielectric layer (~5 nm), which are expected in gate dielectric formation of MoS2-based FETs and other TMDCs-based FETs.

2.3 Doping Strategies

Appropriate doping is another effective method to achieve high-performance MoS2-based FETs, which is demonstrated to strongly affect the contact resistance of MoS2 FET instead of utilizing different contact metals, such as n-type doping from polyethyleneimine (PEI) molecules on multilayer MoS2-based FET [58]. Ultrathin MoS2 limits the doping methods (ion implantation, etc.) employed in other semiconductors, leading to the exploration of novel doping methods in MoS2-based FET technology.

Cesium Carbonate (Cs2CO3) has been employed to dope monolayer MoS2 FET [59], resulting in stable n-type doping and largely enhance the electron concentration in monolayer MoS2 (about 1 order of magnitude). Potassium has also been demonstrated to achieve degenerate n-doping of MoS2 FET in vacuum, indicating the essential of degenerate doping in high-performance MoS2 FET [60]. However, the unstable nature of Potassium limits its practical application. Herein, Daisuke Kiriya et al. proposed a doping strategy based on benzyl viologen (BV) [61], as illustrated in Fig. 3. Figure 3a depicts the schematic diagram of BV doping on trilayer MoS2 FET and the as-fabricated FET was put into the BV solution for 12-h doping; transfer characteristics of as-fabricated MoS2-based FET with and without doping are compared and shown in Fig. 3b. Before BV doping, the ON/OFF of MoS2 FET mainly depends on V gs (ranging from −40 to 40 V) and the I ds is about 2 × 10−5 A (V gs = 40 V), following that BV doping indicates the less dependence of V gs and the increase of I ds, which demonstrates the effective doping of BV method. Raman spectroscopy measurement is shown in Fig. 3c, depicting a red shift and realization of high electron density. Moreover, Fig. 3d shows that the as-doped FET is put into toluene and corresponding transfer characteristics with different time, which is promising for tuning the dopants density. This work represents an effective n-type doping method, which also reduces the contact resistance and improves the performance of MoS2-based FET.

a Schematic diagram of BV doping on trilayer MoS2 FET. b Transfer characteristics of as-fabricated MoS2-based FET with and without doping. c Raman spectroscopy measurement. d Transfer characteristics of as-fabricated MoS2-based FET with different time in toluene. Adopted from [61]

Elements from halogen family are promising in doping MoS2. Toward this effort, chloride (Cl) molecular has been utilized to dope MoS2 FET by Lingming Yang et al. [62]. Few layer MoS2 is immersed into 1, 2 dichloroethane (DCE) over 12 h and then fabricated in MoS2 FET; n-type doping is elucidated by change of Fermi level, which is measured by XPS at the surface before and after doping. More importantly, the contact resistance of as-fabricated FET is reduced to a very low value (0.5 kΩ µm) after Cl molecular doping, thus resulting in a high drain current (460 mA mm−1). In addition, WS2 FET is also doped by the same method and even more effective than MoS2 FET, indicating that the Cl molecular doping is available in other TMDCs.

Doping strategies are significant in MoS2-based FETs and other TMDCs-based devices, and proper doping methods are expected in FET fabricated from ultrathin semiconducting materials. Note that, doping methods of 2D materials are still immature; studies are essential to explore stable, effective, and controllable doping strategies, which are practical and convenient in future nanoelectronic and optoelectronic devices.

3 Low-Frequency Noise (LFN) Analysis in MoS2-Based FETs

The low-frequency noise (LFN) has been demonstrated as a limiting factor in high-performance electronic devices [63] and is generally called 1/f noise or flicker noise, which is first discovered in 1925 [64]. LFN determines the minimum value of signal level in electronic devices and circuits, affecting the realization of scaling down and lower power consumption in future circuits [65, 66], showing that it is necessary to study the LFN in MoS2-based FETs as this 2D layered material has been widely utilized for the fabrication of ultrascaled FET [67] and integrated circuits [68]. Analysis of LFN (measure the fluctuations of mobility conductivity or fluctuation of FET channel induced by carrier trapping or de-trapping) can help evaluate the quality of MoS2 FET [69]. Furthermore, for practical usage of MoS2 FET analog and digital electronic devices, it is necessary to reach the minimum requirement of LFN [70, 71].

Toward this effort, the LFN of bilayer MoS2 FET has been studied in details by Xie et al. [72]. The MoS2 FET is fabricated by a 1.2-nm-thick MoS2 (bilayer) thin film on a 300 nm SiO2/highly doped n-type Si substrate with 30-nm Ti/100-nm Au film as electrodes. The corresponding noise characteristics are measured and a new model of understanding the LFN in bilayer MoS2 FET was proposed. Different from 3D materials, the results exhibit a longer trap decay time in 2D materials with van der Waals bond (MoS2). Based on this model, an annealing is processed toward this bilayer MoS2 FET. Figure 4a shows the I ds versus V gs characteristics (V gs ranging from −20 to 40 V) at V ds = 3 V of this FET, the red locus of points represents the curve after annealing under condition of no threshold voltage (V T), and black locus of points represents the curve before annealing(V T = 15 V), respectively. Figure 4b exhibits the noise measurements (V gs ranging from −20 to 40 V) before and after annealing at V ds = 3 V. A remarkable movement of noise peak to lower V gs after annealing was observed, indicating that the decrease of trap density (annealing process) can effectively reduce the LFN in as-fabricated MoS2 FET.

a I ds versus V gs characteristics at V ds = 3 V of this FET, the red locus of points represents the curve after annealing (V T = 0 V) and black locus of points represents the curve before annealing (V T = 15 V). b The noise measurements before and after annealing at V ds = 3 V. Adopted from [72]. (Color figure online)

While 1/f noise has been investigated in monolayer [73] and bilayer MoS2 FET, study of LFN in multilayer MoS2 FET is essential for its optimization. In order to achieve these goals, Kwon et al. [74] have investigated the LFN in multilayer MoS2 FET, which is architectured with a 40–50-nm MoS2 thin-film channel layer, 10 nm Ti/300 nm Au contact, and SiO2 on p-type silicon substrate. They studied the LFN behavior 1/f γ of as-fabricated MoS2 FET, where the γ is an exponent associated with distribution of traps. With the increase of gate voltage (V G), the trap in as-fabricated FET will be filled and γ will decrease and be stable at a value of 0.95. In contrast to the dominance of mobility fluctuation noise mechanism in monolayer MoS2 FET [73], the dominance of noise mechanism in as-fabricated multilayer MoS2 FET is demonstrated to be the carrier number fluctuation. Moreover, they found LFN characteristics of multilayer MoS2 FET are better than monolayer MoS2 FET, which attributes to its lower Hooge parameter related to the level of LFN. In addition, Renteria et al. [75] studied the relative contribution of channel and contact for LFN in multilayer MoS2 FET and demonstrated that the main mechanism of LFN is carrier number fluctuation, as depicted by Kwon et al. Moreover, they proposed a comparison of as-fabricated multilayer MoS2 FETs before and after aging. Figure 5 shows the noise spectral density before and after aging. It has been observed that the channel noise of MoS2 FET increased more than one order of magnitude after aging, but the increase of contact noise is very few. Thus, the phenomenon is mainly caused by the aging of the MoS2 channel rather than the aging of contact. This new phenomenon can be utilized in MoS2-based FET and other TMDCs- based FETs in terms of the optimization in channel implementation.

Noise spectral density as a function of gate bias before and after aging in as-fabricated MoS2 device. Adopted from [75]

In addition, MoS2-metal contacts of MoS2-based FETs are also demonstrated to impact LFN [76]. The vacuum annealing strongly increases the transparency of contacts in FET, thus resulting the decrease of LFN. To conclude, LFN has been investigated in MoS2-based FETs, indicating the related factors are trap density, channel, and contact, which should be concerned for future circuits based on MoS2 and other 2D TMDCs.

4 Optical Properties of MoS2-Based FETs

TMDCs have been widely fabricated in P–N junction devices, heterostructures, and phototransistors due to the outstanding photovoltaic effect [2, 77, 78]. Particularly, MoS2-based FETs have already been demonstrated to show a strong photoresponse [79]. To comprehensive study the optical properties of MoS2-based FETs, the number of MoS2 layers is concerned; herein, Jonghwa Eom et al. investigated layer-dependent MoS2 FETs (monolayer, bilayer, and multilayer) and measured the photocurrent response under different V ds by using a 220 nm deep ultraviolet (DUV) light [80]. In Fig. 6, photocurrent (I ph) of monolayer, bilayer, and multilayer MoS2 FETs was measured in air (under the condition of V ds = 0.5, 2.0, 5.0 V and VG = 0) and illustrated in Fig. 6a–c, respectively. Figure 6d summarizes the results from Fig. 6a–c as a function of V ds (0–5 V). They observed that monolayer and bilayer MoS2 FET exhibited a smaller value of photocurrent than multilayer MoS2 FET, which mainly attributed to a narrower bandgap and higher density of states in multilayer MoS2 FET. After turning off the light, relaxation time of photocurrent response was also measured in monolayer, bilayer, and multilayer MoS2 FETs; again, the smaller bandgap of multilayer MoS2 resulted in a shorter relaxation time in multilayer MoS2 FET. This work suggested that multilayer MoS2 FET was more promising than few layer MoS2 FET in photovoltaic applications, and as discussed above, multilayer MoS2-based FET with graphene electrode not only reduced the Schottky barrier height at MoS2/grapheme interface, but shows a 74 % optical transmittance (wavelength ranging from 400 to 800 nm), which is promising for transparent devices [47].

a−c Photocurrent (I ph) of monolayer, bilayer and multilayer MoS2 FETs measured in air (under the condition of V ds = 0.5, 2.0, 5.0 V and V G = 0), respectively. d Relative I ph as a function of V ds (0–5 V). Adopted from [80]

The photocurrent of MoS2 FET is always a significant topic to discuss. Cho et al. [81] have studied the decay of photocurrent in MoS2 FET; they fabricated the multilayer MoS2 nanosheet FETs and measured the decrease of photocurrent before and after turning off the UV light. Figure 7 illustrates the photocurrent measurements at different atmosphere in the same V ds (0.1 V), and two constant of decay time τ 1 and τ 2 are also shown in Fig. 7. Figure 7a exhibits the photocurrent measurement under 3.3 × 10−4 Torr vacuum condition (shadow region represents on-state UV light). Figure 7b–d exhibits the measurements under oxygen condition of 1.4 Torr, 0.98 × 101 Torr, and 2.2 × 102 Torr. With the increase of oxygen pressure, photocurrent decreases faster, which is attributed to the charge trapping at the associated oxygen defect sites on MoS2 surface. In addition, they measured the decrease of photocurrent under different gate-bias stresses and found that when the gate-bias stress was negative, the decrease of photocurrent became slower and vice versa. Further study revealed that this phenomenon was caused by the increase of charge trapping (oxygen site) on MoS2 interface as well [82]. Moreover, resonant plasmonic nanoshells have also been deposited to fabricate MoS2 FET, which is demonstrated to be capable for the enhancement of photocurrent and photoluminescence [83].

Photocurrent measurement under a 3.3 × 10−4 Torr vacuum condition, the shadow region means the UV light is on b–d shows the measurements under oxygen condition of 1.4 Torr, 0.98 × 101 Torr, and 2.2 × 102 Torr, respectively. Adopted from [81]

As discussed above, regarding the transient time constant, isolated MoS2 FET manifested its potential in optoelectronics, which could reach magnitude of millisecond. However, Feng Wang et al. have investigated the optical properties of MoS2-WS2 heterostructure and the ultrafast dynamics of hole transfer and found a remarkable rise time shorter than 50 fs, which is demonstrated to hold large promising in future optoelectronic applications [84]. Based on this novel investigation, Su-Huai Wei et al. fabricated MoS2-WS2 heterostructure-based FET, which was demonstrated to possess high ON/OFF ratio exceeding 105 and high photoresponsivity reaching 1.42 A W−1 [85].

The photoresponse of MoS2-based FETs shows promising for prospective applications of optoelectronics, compared with few layer MoS2; multilayer MoS2 is demonstrated to manifest better performance in photocurrent generation. Moreover, plasma-treated, novel nanostructured, and heterostuctured MoS2 are expected to fabricate high-performance MoS2-based FETs.

5 MoS2-Based FETs Applications

5.1 Applications of MoS2-Based FETs in Sensors

Due to the planar, atomic thin structure, possibility of large scale preparation, high surface-to-volume ratio and suggested bandgap, MoS2-based FET has been studied in sensor applications. Toward this effort, high-sensitivity pH sensor with reasonable range (3–9) and selectivity biosensor for protein detection (available at 100 femtomolar concentration) have been achieved by MoS2-based FET [86]. Similarly, for label-free biosensors, MoS2 nanosheet is promising and fabricated in FET, which exhibits high sensitivity in detecting cancer biomaker [87]. The as-fabricated FET is employed in liquid phase to selectively detect prostate-specific antigen (PSA) (cancer biomaker) by the change of drain current. That is, this method is potential for facilitating the development of cancer diagnostics in earlier time.

For gas sensor, Liu et al. [88] have focused on the Schottky-contacted CVD grown monolayer MoS2 FET. They fabricated the MoS2 FETs with 5 nm Ti/50 nm Au metal contact; the schematic diagram and optical image of MoS2 FETs are shown in Fig. 8a, b, respectively. Figure 8c exhibits the I ds versus V ds output characteristics of as-fabricated FET, and transfer characteristics (I ds vs. V bg) is illustrated in Fig. 8d, manifesting the n-type characteristic, which corresponds to the n-type electronic property of MoS2 semiconductor [89]. Note that, there exists a Schottky barrier (SB) in as-fabricated MoS2 FET-based sensor (Fig. 8c). Later, they investigated the sensitivity and the mechanism of as-fabricated FET for detecting two poisonous gases: NO2 and NH3. Generally, conductance (resistance) change is measured to reflect performance of sensing and total resistance of as-fabricated FET is expressed as follows:

a Schematic diagram and b Optical image of the MoS2 FETs. c Output characteristics (I ds vs. V ds) and d Transfer characteristics (I ds vs. V bg) of the MoS2 FETs. Adopted from [88]

In this equation, R channel is only related to carrier concentration, but R contact is related to both carrier concentration and the Schottky barrier height. The relationship is exponential, thus indicating that the Schottky barrier is a key factor in sensitivity. With a conductance change larger than 20 and 40 %, the sensitivity of this MoS2 FET-based chemical sensor can reach 20 parts per billion (ppb) for NO2 and 1 parts per million (ppm) for NH3, respectively. This detection limit is the lowest gas concentration detected compared with the other experiments: Li et al. [90] used multilayer MoS2 film FET to detect NO (detection limit ~800 ppb) and Late et al. [91] presented a detection limit of several hundred ppm for both NH3 and NO2 using atomically thin-layered MoS2 transistors. Moreover, Liu et al. found part of MoS2 devices exhibiting more Ohmic contact, but the little conductance change (<5 %) upon exposure to NO2 at concentrations up to 400 ppb further manifests that Schottky barrier modulation plays a more important role in these MoS2 FET-based sensors. That is, it is realizable to modulate the Schottky barrier contact of MoS2-based FET sensor and achieve higher performance at the sub-ppb level.

Moreover, in monolayer MoS2-based FET sensor, sensitivity of detecting triethylamine (TEA) can be enhanced by illumination [92] as illustrated in Fig. 9. ΔG stands for the decrease of initial conductance (G 0) of FET when exposed to TEA, the calculated ΔG/G 0 is the sensitivity. The black line represents that the light is on and red line for off state, showing the increase of sensitivity with longer time (about 1 order of magnitude), which may attributes to the enhancement of conductivity under illumination. Convenient way of fabricating MoS2-based FET sensor is expected, which is significant in practical applications [25]. In addition, Lee et al. fabricated the sensor without dielectric layer on multilayer MoS2 FETs, which possess hydrophobic interface that serves as novel non-dielectric layer, thus resulting in the improvement of sensitivity [93]. With the nature of 2D structure, MoS2-based FET sensors should be studied further to explore higher sensitivity, lower cost, more effective biosensors, and chemical gas sensors, which are potential for next-generation medical diagnosis of cancer, environment monitoring, and food safety.

Sensitivity of triethylamine (TEA) with and without illumination. Black line represents on-state light and red line for off state. Adopted from [92]. (Color figure online)

5.2 Applications of MoS2-Based FETs in Memory Devices

Multibit memory devices have attracted much attention and investigations, which are generally fabricated by organic semiconductor materials [94], nanostructure materials [95], and phase-change materials [96]. It is significant to explore a novel convenient method to fabricate multibit memory. Toward this effort, Chen et al. [97] have explored an approach to fabricated MoS2 FET-based 2–4 bit memory devices. They proposed a plasma-treated way and found that this plasma-treated MoS2 FET could act as multibit memory devices as illustrated in Fig. 10. Figure 10a is the schematic diagram of plasma-treated MoS2 FET, of which a 15–30-nm MoS2 film served as the active layer with 5 nm Ti/50 nm Au electrode. The optical image of as-treated MoS2 FET is shown in Fig. 10b. Herein, D and S are the Ti electrode and Au electrode, respectively. Figure 10c shows the transport characteristic curve (I DS (I ds) vs. V G); in addition, the measurements of retention are given in Fig. 10d, and it can be seen that the write/read ratio is about 103 after 1 h and 400 after 3 days. Accordingly, a write/read ratio value of about 64 of the as-fabricated FET aged after 10 years can be inferred, which is still valid for circuit application. It is further found that the plasma-treated MoS2 FET is faster in programing than the untreated one in their experiments. A physical model for explaining the performance enhancement was proposed as following: The plasma-treated channel top layer could be separated and forms an ambipolar charge-trapping layer, allowing the high-performance non-volatile retention and multibit states in this FET. This method is certainly worth considering for fabrication of nanodevices since it is technically convenient and provides a relatively simple way for realizing non-volatile memory devices, which also offers an effective method to scale down current circuit in future nanoelectronics.

a The schematic diagram of plasma-treated MoS2 FET. b The optical image of as-treated MoS2 FET. c Transfer characteristic curve (I ds vs. V G). d Retention measurements of this FET. Adopted from [97]

Moreover, MoS2 nanoflakes have been employed as charge-trapping layer (nano-floating gate) to fabricate organic nano-floating gate memories (NFGMs) by Kang et al. [98], which are based on organic (poly (3-hexylthiophene) (P3HT)) FET. The inserted solution process is convenient and realized at low temperature to introduce MoS2 nanoflakes between two dielectric layers: polystyrene (PS) and poly (methyl methacrylate) (PMMA). The as-fabricated memory device exhibits multilevel non-volatile memory nature, as illustrated in Fig. 11. Figure 11a depicts the endurance of this NFGM, which is more than 102 times (under the condition of V d = −5 V and V g = 0 V). Programing process and corresponding voltages are shown in Fig. 11b, and the four voltage steps are from −80 to 80 V (−80, +30, +50, +80 V). Figure 11c, d illustrates the retention characteristics by measuring four current levels (Abs (I d) represents the absolute value of drain current) at V d = −5 V and V g = 0 V with 60 s delay, indicating the stable retention times after 10 years. This MoS2-based organic FET is a 2-bit memory device controlled by V and potential for inexpensive memory devices.

a Endurance measurement of as-fabricated NFGM under the condition of V d = −5 V and Vg = 0 V. b Programming process and corresponding voltages are shown, four voltage steps are −80, +30, +50, and +80 V. c and d illustrate the retention characteristics of four current levels at V d = −5 V and V g = 0 V with 60 s delay. Adopted from [98]

6 Conclusions

In this paper, we have reviewed state-of-the-art approaches in MoS2 FETs, such as progresses on manufacturing of MoS2 FETs, MoS2 FET-based memory devices, and MoS2 FET-based sensors. To understanding the contact physics based on Schottky barrier, different species of metals utilized to achieve high-performance n-type and p-type MoS2 FETs are reviewed, and optimization of ferromagnetic contact for spintronics applications are discussed too. Intrinsic properties measured by four-terminal measurements are highlighted, which is an effective method to estimate contact quality of MoS2-based FETs. In addition, gate dielectric formation and doping strategies are studied and provide guidelines for prospective manufacturing of MoS2-based FETs.

Low-frequency noise (LFN) analysis was carried out for studying the performance of MoS2 FETs. FETs made of bilayer MoS2 present a longer trap decay time. Further analysis shows that the LFN subjects not only to the physical properties of the channels but also the behavior of contacts in MoS2 FETs. The noise increase in aged MoS2 FETs is caused by aging of the MoS2 channels rather than the aging of contacts. This phenomenon is significant in MoS2 as well as in other 2D materials FETs for the optimization of channel implementation.

Photoresponse of MoS2-based FETs are critical and considered in this review, mainly focusing on the photocurrent generation with and without illumination. Moreover, MoS2-based FETs are utilized in gas and biological sensors, showing its high sensitivity and selectivity. MoS2 nanoflakes are fabricated and successfully employed in organic nano-floating gate memories (NFGMs) as non-volatile random-access memory (NVRAM), providing an instance for nanomaterials used in memory devices. The plasma-treated MoS2 FETs can serve as multibit memory devices and exhibit excellent storage capacities, suggesting the significance of plasma in performance improving of MoS2 electronic devices.

To conclude, MoS2 FETs based on thin-film and nano-size structures are investigated. Some key optical and electronic properties of these MoS2 FET devices are unique and superior than FETs made of conventional semiconductors, thus are suitable for novel electronic and optoelectronic applications.

References

D. Jariwala, V.K. Sangwan, L.J. Lauhon, T.J. Marks, M.C. Hersam, Emerging device applications for semiconducting two-dimensional transition metal dichalcogenides. ACS Nano 8(2), 1102–1120 (2014). doi:10.1021/nn500064s

Q.H. Wang, K. Kalantar-Zadeh, A. Kis, J.N. Coleman, M.S. Strano, Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 7(11), 699–712 (2012). doi:10.1038/nnano.2012.193

G. Plechinger, J. Mann, E. Preciado, D. Barroso, A. Nguyen, J. Eroms, C. Schueller, L. Bartels, T. Korn, A direct comparison of CVD-grown and exfoliated MoS2 using optical spectroscopy. Semicond. Sci Tech. 29(6), 064008 (2014). doi:10.1088/0268-1242/29/6/064008

E.S. Kadantsev, P. Hawrylak, Electronic structure of a single MoS2 monolayer. Solid State Commun. 152(10), 909–913 (2012). doi:10.1016/j.ssc.2012.02.005

A. Kumar, P.K. Ahluwalia, A first principle comparative study of electronic and optical properties of 1H-MoS2 and 2H-MoS2. Mater. Chem. Phys. 135(2–3), 755–761 (2012). doi:10.1016/j.matchemphys.2012.05.055

Q. Zhang, Y. Cheng, L.Y. Gan, U. Schwingenschloegl, Giant valley drifts in uniaxially strained monolayer MoS2. Phys. Rev. B 88(24), 245447 (2013). doi:10.1103/PhysRevB.88.245447

B. Chakraborty, H.S.S.R. Matte, A.K. Sood, C.N.R. Rao, Layer-dependent resonant Raman scattering of a few layer MoS2. J. Raman Spectrosc. 44(1), 92–96 (2013). doi:10.1002/jrs.4147

Z.M. Wang, MoS2: Materials, Physics, and Devices (Springer, Ney work, 21, pp:1–291, 2014)

R. Frindt, Single crystals of MoS2 several molecular layers thick. J. Appl. Phys. 37(4), 1928–1929 (1966). doi:10.1063/1.1708627

Y.H. Lee, X.Q. Zhang, W. Zhang, M.T. Chang, C.T. Lin, K.D. Chang, Y.C. Yu, J.T.W. Wang, C.S. Chang, L.J. Li, T.W. Lin, Synthesis of large-area MoS2 atomic layers with chemical vapor deposition. Adv. Mater. 24(17), 2320–2325 (2012). doi:10.1002/adma.201104798

H. Pan, Y.W. Zhang, Tuning the electronic and magnetic properties of MoS2 nanoribbons by strain engineering. J. Phys. Chem. C 116(21), 11752–11757 (2012). doi:10.1021/jp3015782

Z. Zhou, Y. Lin, P. Zhang, E. Ashalley, M. Shafa, H. Li, J. Wu, Z. Wang, Hydrothermal fabrication of porous MoS2 and its visible light photocatalytic properties. Mater. Lett. 131, 122–124 (2014). doi:10.1016/j.matlet.2014.05.162

R. van Leeuwen, A. Castellanos-Gomez, G.A. Steele, H.S.J. van der Zant, W.J. Venstra, Time-domain response of atomically thin MoS2 nanomechanical resonators. Appl. Phys. Lett. 105(4), 041911 (2014). doi:10.1063/1.4892072

Z. Yin, H. Li, H. Li, L. Jiang, Y. Shi, Y. Sun, G. Lu, Q. Zhang, X. Chen, H. Zhang, Single-layer MoS2 phototransistors. ACS Nano 6(1), 74–80 (2012). doi:10.1021/nn2024557

F.K. Perkins, A.L. Friedman, E. Cobas, P.M. Campbell, G.G. Jernigan, B.T. Jonker, Chemical vapor sensing with monolayer MoS2. Nano Lett. 13(2), 668–673 (2013). doi:10.1021/nl3043079

O. Lopez-Sanchez, D. Lembke, M. Kayci, A. Radenovic, A. Kis, Ultrasensitive photodetectors based on monolayer MoS2. Nat. Nanotechnol. 8(7), 497–501 (2013). doi:10.1038/nnano.2013.100

B. Radisavljevic, M.B. Whitwick, A. Kis, Small-signal amplifier based on single-layer MoS2. Appl. Phys. Lett. 101(4), 043103 (2012). doi:10.1063/1.4738986

S. Ding, D. Zhang, J.S. Chen, X.W. Lou, Facile synthesis of hierarchical MoS2 microspheres composed of few-layered nanosheets and their lithium storage properties. Nanoscale 4(1), 95–98 (2012). doi:10.1039/c1nr11552a

K. Chang, W. Chen, L-cysteine-assisted synthesis of layered MoS2/graphene composites with excellent electrochemical performances for lithium ion batteries. ACS Nano 5(6), 4720–4728 (2011). doi:10.1021/nn200659w

K.F. Mak, K. He, J. Shan, T.F. Heinz, Control of valley polarization in monolayer MoS2 by optical helicity. Nat. Nanotechnol. 7(8), 494–498 (2012). doi:10.1038/nnano.2012.96

H. Zeng, J. Dai, W. Yao, D. Xiao, X. Cui, Valley polarization in MoS2 monolayers by optical pumping. Nat. Nanotechnol. 7(8), 490–493 (2012). doi:10.1038/nnano.2012.95

X. Huang, Z. Yin, S. Wu, X. Qi, Q. He, Q. Zhang, Q. Yan, F. Boey, H. Zhang, Graphene-based materials: synthesis, characterization, properties, and applications. Small 7(14), 1876–1902 (2011). doi:10.1002/smll.201002009

H.S. Lee, S.W. Min, Y.G. Chang, M.K. Park, T. Nam, H. Kim, J.H. Kim, S. Ryu, S. Im, MoS2 nanosheet phototransistors with thickness-modulated optical energy gap. Nano Lett. 12(7), 3695–3700 (2012). doi:10.1021/nl301485q

H. Liu, J.J. Gu, P.D. Ye, MoS2 nanoribbon transistors: transition from depletion mode to enhancement mode by channel-width trimming. IEEE Electr. Device L 33(9), 1273–1275 (2012). doi:10.1109/LED.2012.2202630

X. Wang, S. Yang, Q. Yue, F. Wu, J. Li, Response of MoS2 nanosheet field effect transistor under different gas environments and its long wavelength photoresponse characteristics. J. Alloy. Compd. 615, 989–993 (2014). doi:10.1016/j.jallcom.2014.07.016

G. Eda, H. Yamaguchi, D. Voiry, T. Fujita, M. Chen, M. Chhowalla, Photoluminescence from chemically exfoliated MoS2. Nano Lett. 11(12), 5111–5116 (2011). doi:10.1021/nl201874w

B. Radisavljevic, A. Radenovic, J. Brivio, V. Giacometti, A. Kis, Single-layer MoS2 transistors. Nat. Nanotechnol. 6(3), 147–150 (2011). doi:10.1038/nnano.2010.279

Y. Yoon, K. Ganapathi, S. Salahuddin, How good can monolayer MoS2 transistors Be? Nano Lett. 11(9), 3768–3773 (2011). doi:10.1021/nl2018178

F. Leonard, A.A. Talin, Electrical contacts to one- and two-dimensional nanomaterials. Nat. Nanotechnol. 6(12), 773–783 (2011). doi:10.1038/nnano.2011.196

Y. Du, L. Yang, H. Liu, P.D. Ye, Contact research strategy for emerging molybdenum disulfide and other two-dimensional field-effect transistors. Appl. Mater. 2(9), 092510 (2014). doi:10.1063/1.4894198

H. Liu, A.T. Neal, P.D. Ye, Channel length scaling of MoS2 MOSFETs. ACS Nano 6(10), 8563–8569 (2012). doi:10.1021/nn303513c

S. Das, H.Y. Chen, A.V. Penumatcha, J. Appenzeller, High performance multilayer MoS2 transistors with scandium contacts. Nano Lett. 13(1), 100–105 (2013). doi:10.1021/nl303583v

J.H. Kang, D. Sarkar, W. Liu, D. Jena, K. Banerjee, A computational study of metal-contacts to beyond-graphene 2D semiconductor materials. 2012 IEEE Int. Electr. Devices Meet. (IEDM) (2012). doi:10.1109/IEDM.2012.6479060

W. Liu, J.H. Kang, W. Cao, D. Sarkar, Y. Khatami, D. Jena, K. Banerjee, High-performance few-layer-MoS2 field-effect-transistor with record low contact-resistance, 2013 IEEE Int. Electr. Devices Meet. (IEDM) (2013). doi:10.1109/IEDM.2013.6724660

J. Kang, W. Liu, K. Banerjee, High-performance MoS2 transistors with low-resistance molybdenum contacts. Appl. Phys. Lett. 104(9), 093106 (2014). doi:10.1063/1.4866340

S. Kim, A. Konar, W.S. Hwang, J.H. Lee, J. Lee, J. Yang, C. Jung, H. Kim, J.B. Yoo, J.Y. Choi, Y.W. Jin, S.Y. Lee, D. Jena, W. Choi, K. Kim, High-mobility and low-power thin-film transistors based on multilayer MoS2 crystals. Nat. Commun. 3, 1011 (2012). doi:10.1038/ncomms2018

M. Fontana, T. Deppe, A.K. Boyd, M. Rinzan, A.Y. Liu, M. Paranjape, P. Barbara, Electron-hole transport and photovoltaic effect in gated MoS2 Schottky junctions. Sci. Rep-UK 3, 1634 (2013). doi:10.1038/srep01634

S. Chuang, C. Battaglia, A. Azcatl, S. McDonnell, J.S. Kang, X. Yin, M. Tosun, R. Kapadia, H. Fang, R.M. Wallace, A. Javey, MoS2 P-type transistors and diodes enabled by high work function moox contacts. Nano Lett. 14(3), 1337–1342 (2014). doi:10.1021/nl4043505

C. Battaglia, X. Yin, M. Zheng, I.D. Sharp, T. Chen, S. McDonnell, A. Azcatl, C. Carraro, B. Ma, R. Maboudian, R.M. Wallace, A. Javey, Hole selective MoOx contact for silicon solar cells. Nano Lett. 14(2), 967–971 (2014). doi:10.1021/nl404389u

I. Popov, G. Seifert, D. Tomanek, Designing electrical contacts to MoS2 monolayers: a computational study. Phy. Rev. Lett. 108(15), 156802 (2012). doi:10.1103/PhysRevLett.108.156802

J.-R. Chen, P.M. Odenthal, A.G. Swartz, G.C. Floyd, H. Wen, K.Y. Luo, R.K. Kawakami, Control of schottky barriers in single layer MoS2 transistors with ferromagnetic contacts. Nano Lett. 13(7), 3106–3110 (2013). doi:10.1021/nl4010157

A. Dankert, L. Langouche, M.V. Kamalakar, S.P. Dash, High-performance molybdenum disulfide field-effect transistors with spin tunnel contacts. ACS Nano 8(1), 476–482 (2014). doi:10.1021/nn404961e

N.R. Pradhan, D. Rhodes, Q. Zhang, S. Talapatra, M. Terrones, P.M. Ajayan, L. Balicas, Intrinsic carrier mobility of multi-layered MoS2 field-effect transistors on SiO2. Appl. Phys. Lett. 102(12), 123105 (2013). doi:10.1063/1.4799172

W. Bao, X. Cai, D. Kim, K. Sridhara, M.S. Fuhrer, High mobility ambipolar MoS2 field-effect transistors: substrate and dielectric effects. Appl. Phys. Lett. 102(4), 042104 (2013). doi:10.1063/1.4789365

B.W.H. Baugher, H.O.H. Churchill, Y. Yang, P. Jarillo-Herrero, Intrinsic electronic transport properties of high-quality monolayer and bilayer MoS2. Nano Lett. 13(9), 4212–4216 (2013). doi:10.1021/nl401916s

N.R. Pradhan, D. Rhodes, Y. Xin, S. Memaran, L. Bhaskaran, M. Siddiq, S. Hill, P.M. Ajayan, L. Balicas, Ambipolar molybdenum diselenide field-effect transistors: field-effect and hall mobilities. ACS Nano 8(8), 7923–7929 (2014). doi:10.1021/nn501693d

J. Yoon, W. Park, G.Y. Bae, Y. Kim, H.S. Jang, Y. Hyun, S.K. Lim, Y.H. Kahng, W.K. Hong, B.H. Lee, H.C. Ko, Highly flexible and transparent multilayer MoS2 transistors with graphene electrodes. Small 9(19), 3295–3300 (2013). doi:10.1002/smll.201300134

R. Kappera, D. Voiry, S.E. Yalcin, B. Branch, G. Gupta, A.D. Mohite, M. Chhowalla, Phase-engineered low-resistance contacts for ultrathin MoS2 transistors. Nat. Mater. 13(12), 1128–1134 (2014). doi:10.1038/nmat4080

M. Amani, M.L. Chin, A.G. Birdwell, T.P. O’Regan, S. Najmaei, Z. Liu, P.M. Ajayan, J. Lou, M. Dubey, Electrical performance of monolayer MoS2 field-effect transistors prepared by chemical vapor deposition. Appl. Phys. Lett. 102(19), 193107 (2013). doi:10.1063/1.4804546

H. Wang, L. Yu, Y.H. Lee, Y. Shi, A. Hsu, M.L. Chin, L.-J. Li, M. Dubey, J. Kong, T. Palacios, Integrated circuits based on bilayer MoS2 transistors. Nano Lett. 12(9), 4674–4680 (2012). doi:10.1021/nl302015v

L. Zeng, Z. Xin, S. Chen, G. Du, J. Kang, X. Liu, Remote phonon and impurity screening effect of substrate and gate dielectric on electron dynamics in single layer MoS2. Appl. Phys. Lett. 103(11), 113505 (2013). doi:10.1063/1.4821344

D. Jena, A. Konar, Enhancement of carrier mobility in semiconductor nanostructures by dielectric engineering. Phys. Rev. Lett. 98(13), 136805 (2007). doi:10.1103/PhysRevLett.98.136805

H. Liu, K. Xu, X. Zhang, P.D. Ye, The integration of high-k dielectric on two-dimensional crystals by atomic layer deposition. Appl. Phys. Lett. 100(15), 152115 (2012). doi:10.1063/1.3703595

J. Swerts, N. Peys, L. Nyns, A. Delabie, A. Franquet, J.W. Maes, S. Van Elshocht, S. De Gendt, Impact of precursor chemistry and process conditions on the scalability of ALD HfO2 gate dielectrics. J. Electrochem. Soc. 157(1), G26–G31 (2010). doi:10.1149/1.3258664

J. Yang, S. Kim, W. Choi, S.H. Park, Y. Jung, M.H. Cho, H. Kim, Improved growth behavior of atomic-layer-deposited high-k dielectrics on multilayer MoS2 by oxygen plasma pretreatment. ACS Appl. Mater. Inter. 5(11), 4739–4744 (2013). doi:10.1021/am303261c

A. Azcatl, S. McDonnell, K.C. Santosh, X. Peng, H. Dong, X. Qin, R. Addou, G.I. Mordi, N. Lu, J. Kim, M.J. Kim, K. Cho, R.M. Wallace, MoS2 functionalization for ultra-thin atomic layer deposited dielectrics. Appl. Phys. Lett. 104(11), 111601 (2014). doi:10.1063/1.4869149

L. Cheng, X. Qin, A.T. Lucero, A. Azcatl, J. Huang, R.M. Wallace, K. Cho, J. Kim, Atomic layer deposition of a high-k dielectric on MoS2 using trimethylaluminum and ozone. ACS Appl. Mater. Inter. 6(15), 11834–11838 (2014). doi:10.1021/am5032105

Y. Du, H. Liu, A.T. Neal, M. Si, P.D. Ye, Molecular doping of multilayer MoS2 field-effect transistors: reduction in sheet and contact resistances. IEEE Electr. Device L 34(10), 1328–1330 (2013). doi:10.1109/LED.2013.2277311

J.D. Lin, C. Han, F. Wang, R. Wang, D. Xiang, S. Qin, X.A. Zhang, L. Wang, H. Zhang, A.T.S. Wee, W. Chen, Electron-doping-enhanced trion formation in monolayer molybdenum disulfide functionalized with cesium carbonate. ACS Nano 8(5), 5323–5329 (2014). doi:10.1021/nn501580c

H. Fang, M. Tosun, G. Seol, T.C. Chang, K. Takei, J. Guo, A. Javey, Degenerate n-doping of few-layer transition metal dichalcogenides by potassium. Nano Lett. 13(5), 1991–1995 (2013). doi:10.1021/nl400044m

D. Kiriya, M. Tosun, P. Zhao, J.S. Kang, A. Javey, Air-stable surface charge transfer doping of MoS2 by benzyl viologen. JACS 136(22), 7853–7856 (2014). doi:10.1021/ja5033327

L. Yang, K. Majumdar, H. Liu, Y. Du, H. Wu, M. Hatzistergos, P.Y. Hung, R. Tieckelmann, W. Tsai, C. Hobbs, P.D. Ye, Chloride molecular doping technique on 2D materials: WS2 and MoS2. Nano Lett. 14(11), 6275–6280 (2014). doi:10.1021/nl502603d

Y. Wu, Y. Lin, A.A. Bol, K.A. Jenkins, F. Xia, D.B. Farmer, Y. Zhu, P. Avouris, High-frequency, scaled graphene transistors on diamond-like carbon. Nature 472(7341), 74–78 (2011). doi:10.1038/nature09979

J.B. Johnson, The Schottky effect in low frequency circuits. Phys. Rev. 26(1), 71 (1925). doi:10.1103/PhysRev.26.71

B.H. Calhoun, A. Wang, A. Chandrakasan, Device sizing for minimum energy operation in subthreshold circuits. (pp: 95–98, 3–6 Oct. 2004). doi:10.1109/CICC.2004.1358745

J.M. Chang, A.A. Abidi, C.R. Viswanathan, Flicker noise in CMOS transistors from subthreshold to strong inversion at various temperatures. IEEE Trans. Electron Devices 41(11), 1965–1971 (1994). doi:10.1109/16.333812

S. Ghatak, A.N. Pal, A. Ghosh, Nature of electronic states in atomically thin MoS2 field-effect transistors. ACS Nano 5(10), 7707–7712 (2011). doi:10.1021/nn202852j

B. Radisavljevic, M.B. Whitwick, A. Kis, Integrated circuits and logic operations based on single-layer MoS2. ACS Nano 5(12), 9934–9938 (2011). doi:10.1021/nn203715c

C. Kayis, J.H. Leach, C.Y. Zhu, M. Wu, X. Li, U. Oezguer, H. Morkoc, X. Yang, V. Misra, P.H. Handel, Low-frequency noise measurements of AlGaN/GaN metal-oxide-semiconductor heterostructure field-effect transistors with HfAlO gate dielectric. IEEE Electr. Device L. 31(9), 1041–1043 (2010). doi:10.1109/LED.2010.2055823

A.A. Balandin, Noise and Fluctuations Control in Electronic Devices (American Scientific Publishers, Los Angeles, pp.1–411, 2002)

E. Simoen, A. Mercha, C. Claeys, E. Young, Correlation between the 1/f noise parameters and the effective low-field mobility in HfO2 gate dielectric n-channel metal-oxide-semiconductor field-effect transistors. Appl. Phys. Lett. 85(6), 1057–1059 (2004). doi:10.1063/1.1779967

X. Xie, D. Sarkar, W. Liu, J. Kang, O. Marinov, M.J. Deen, K. Banerjee, Low-frequency noise in bilayer MoS2 transistor. ACS Nano 8(6), 5633–5640 (2014). doi:10.1021/nn4066473

V.K. Sangwan, H.N. Arnold, D. Jariwala, T.J. Marks, L.J. Lauhon, M.C. Hersam, Low-frequency electronic noise in single-layer MoS2 transistors. Nano Lett. 13(9), 4351–4355 (2013). doi:10.1021/nl402150r

H.-J. Kwon, H. Kang, J. Jang, S. Kim, C.P. Grigoropoulos, Analysis of flicker noise in two-dimensional multilayer MoS2 transistors. Appl. Phys. Lett. 104(8), 083110 (2014). doi:10.1063/1.4866785

J. Renteria, R. Samnakay, S.L. Rumyantsev, C. Jiang, P. Goli, M.S. Shur, A.A. Balandin, Low-frequency 1/f noise in MoS2 transistors: relative contributions of the channel and contacts. Appl. Phys. Lett. 104(15), 153104 (2014). doi:10.1063/1.4871374

S. Ghatak, S. Mukherjee, M. Jain, D.D. Sarma, A. Ghosh, Microscopic origin of low frequency noise in MoS2 field-effect transistors. Appl. Mater. 2(9), 092515 (2014). doi:10.1063/1.4895955

A.M. Jones, H. Yu, N.J. Ghimire, S. Wu, G. Aivazian, J.S. Ross, B. Zhao, J. Yan, D.G. Mandrus, D. Xiao, W. Yao, X. Xu, Optical generation of excitonic valley coherence in monolayer WSe2. Nat. Nanotechnol. 8(9), 634–638 (2013). doi:10.1038/nnano.2013.151

N.R. Pradhan, S. Memaran, D.R.Z. Lu, J. Ludwig, Q. Zhou, P. Ajayan, D. Smirnov, L. Balicas, Pronounced photovoltaic response from PN-junctions of multi-layered MoSe2 on h-BN. arXiv:1411.2086 (2014)

H.M. Li, D.Y. Lee, M.S. Choi, D. Qu, X. Liu, C.H. Ra, W.J. Yoo, Metal-semiconductor barrier modulation for high photoresponse in transition metal dichalcogenide field effect transistors. SCI Rep-UK 4, 4041 (2014). doi:10.1038/srep04041

M.F. Khan, M.W. Iqbal, M.Z. Iqbal, M.A. Shehzad, Y. Seo, J. Eom, Photocurrent response of MoS2 field-effect transistor by deep ultraviolet light in atmospheric and N2 gas environments. ACS Appl. Mater. Interface 6(23), 21645–21651 (2014). doi:10.1021/am506716a

K. Cho, T.Y. Kim, W. Park, J. Park, D. Kim, J. Jang, H. Jeong, S. Hong, T. Lee, Gate-bias stress-dependent photoconductive characteristics of multi-layer MoS2 field-effect transistors. Nanotechnology 25(15), 155201 (2014). doi:10.1088/0957-4484/25/15/155201

D.S. Tsai, D.H. Lien, M.L. Tsai, S.H. Su, K.M. Chen, J.J. Ke, Y.C. Yu, L.J. Li, J.H. He, Trilayered MoS2 metal-semiconductor-metal photodetectors: photogain and radiation resistance. IEEE J. Sel. Top. Quantum 20(1), 3800206 (2014). doi:10.1109/JSTQE.2013.2268383

A. Sobhani, A. Lauchner, S. Najmaei, C. Ayala-Orozco, F. Wen, J. Lou, N.J. Halas, Enhancing the photocurrent and photoluminescence of single crystal monolayer MoS2 with resonant plasmonic nanoshells. Appl. Phys. Lett. 104(3), 031112 (2014). doi:10.1063/1.4862745

X. Hong, J. Kim, S.F. Shi, Y. Zhang, C. Jin, Y. Sun, S. Tongay, J. Wu, Y. Zhang, F. Wang, Ultrafast charge transfer in atomically thin MoS2/WS2 heterostructures. Nat. Nanotechnol. 9(9), 682–686 (2014). doi:10.1038/nnano.2014.167

N. Huo, J. Kang, Z. Wei, S.S. Li, J. Li, S.H. Wei, Novel and enhanced optoelectronic performances of multilayer MoS2-WS2 heterostructure transistors. Adv. Funct. Mater. 24(44), 7025–7031 (2014). doi:10.1002/adfm.201401504

D. Sarkar, W. Liu, X. Xie, A.C. Anselmo, S. Mitragotri, K. Banerjee, MoS2 field-effect transistor for next-generation label-free biosensors. ACS Nano 8(4), 3992–4003 (2014). doi:10.1021/nn5009148

L. Wang, Y. Wang, J.I. Wong, T. Palacios, J. Kong, H.Y. Yang, Functionalized MoS2 nanosheet-based field-effect biosensor for label-free sensitive detection of cancer marker proteins in solution. Small 10(6), 1101–1105 (2014). doi:10.1002/smll.201302081

B. Liu, L. Chen, G. Liu, A.N. Abbas, M. Fathi, C. Zhou, High-performance chemical sensing using Schottky-contacted chemical vapor deposition grown mono layer MoS2 transistors. ACS Nano 8(5), 5304–5314 (2014). doi:10.1021/nn5015215

S. Najmaei, Z. Liu, W. Zhou, X. Zou, G. Shi, S. Lei, B.I. Yakobson, J.C. Idrobo, P.M. Ajayan, J. Lou, Vapour phase growth and grain boundary structure of molybdenum disulphide atomic layers. Nat. Mater. 12(8), 754–759 (2013). doi:10.1038/nmat3673

H. Li, Z. Yin, Q. He, H. Li, X. Huang, G. Lu, D.W.H. Fam, A.I.Y. Tok, Q. Zhang, H. Zhang, Fabrication of single-and multilayer MoS2 film-based field-effect transistors for sensing NO at room temperature. Small 8(1), 63–67 (2012). doi:10.1002/smll.201101016

D.J. Late, Y.K. Huang, B. Liu, J. Acharya, S.N. Shirodkar, J. Luo, A. Yan, D. Charles, U.V. Waghmare, V.P. Dravid, C.N.R. Rao, Sensing behavior of atomically thin-layered MoS2 transistors. ACS Nano 7(6), 4879–4891 (2013). doi:10.1021/nn400026u

A.L. Friedman, F.K. Perkins, E. Cobas, G.G. Jernigan, P.M. Campbell, A.T. Hanbicki, B.T. Jonker, Chemical vapor sensing of two-dimensional MoS2 field effect transistor devices. Solid State Electron. 101, 2–7 (2014). doi:10.1016/j.sse.2014.06.013

J. Lee, P. Dak, Y. Lee, H. Park, W. Choi, M.A. Alam, S. Kim, Two-dimensional layered MoS2 biosensors enable highly sensitive detection of biomolecules. Sci. Rep. 4, 7352 (2014). doi:10.1038/srep07352

Y. Guo, C. Di, S. Ye, X. Sun, J. Zheng, Y. Wen, W. Wu, G. Yu, Y. Liu, Multibit storage of organic thin-film field-effect transistors. Adv. Mater. 21(19), 1954–1959 (2009). doi:10.1002/adma.200802430

J.I. Sohn, S.S. Choi, S.M. Morris, J.S. Bendall, H.J. Coles, W.K. Hong, G. Jo, T. Lee, M.E. Welland, Novel nonvolatile memory with multibit storage based on a ZnO nanowire transistor. Nano Lett. 10(11), 4316–4320 (2010). doi:10.1021/nl1013713

T. Nirschl, J.B. Philipp, T.D. Flapp, G.W. Burr, B. Rajendran, M.H. Leeo, A. Schrott, M. Yang, M. Breitwisch, C.F. Chen, E. Joseph, M. Lamorey, R. Cheek, S.H. Chen, S. Zaidi, S. Raoux, Y.C. Chen, Y. Zhu, R. Bergmann, H.L. Lung, C. Lam, Write strategies for 2 and 4-bit multi-level phase-change memory. IEEE Electr. Devices Meet. (pp: 461–464, 10–12 Dec. 2007). doi:10.1109/IEDM.2007.4418973

M. Chen, H. Nam, S. Wi, G. Priessnitz, I.M. Gunawan, X. Liang, Multibit data storage states formed in plasma-treated MoS2 transistors. ACS Nano 8(4), 4023–4032 (2014). doi:10.1021/nn501181t

M. Kang, Y.A. Kim, J.M. Yun, D. Khim, J. Kim, Y.Y. Noh, K.J. Baeg, D.Y. Kim, Stable charge storing in two-dimensional MoS2 nanoflake floating gates for multilevel organic flash memory. Nanoscale 6(21), 12315–12323 (2014). doi:10.1039/C4NR03448A

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Tong, X., Ashalley, E., Lin, F. et al. Advances in MoS2-Based Field Effect Transistors (FETs). Nano-Micro Lett. 7, 203–218 (2015). https://doi.org/10.1007/s40820-015-0034-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40820-015-0034-8