Abstract

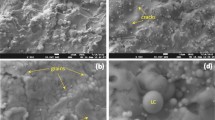

Understanding the evolution of target composition, hysteresis effect and coatings properties as a function of reactive gas and sputtering techniques in developing new thin film coatings is essential. This research investigation focuses on the influence of reactive nitrogen gas utilized at different flowrate on the hysteresis measurement and properties of TiAlN coatings doped with phosphorous, deposited using direct current magnetron sputtering (DcMS) and high power impulse magnetron sputtering (HiPIMS) techniques. The proportion of nitrogen content required for the transition from metallic to compound region varies with the deposition method as revealed from the hysteresis. The formation of stoichiometric coating was achieved at a lower flow rate of nitrogen in the HiPIMS coating. Dense and columnar structures were noticed in the cross-sectional morphology of the coatings. The XRD diffraction pattern revealed that the preferential orientation of the coatings depends on the nitrogen flow rate and the choice of the deposition techniques. The Raman spectra of the coatings show groups of bands in the acoustic and optical range, with a shift to higher Raman wavelength in the HiPIMS sputtered coatings. The maximum hardness of 28 GPa was found at 6 sccm of nitrogen flowrate of the HiPIMS coating. The optimal corrosion protection resistance for the HiPIMS sputtered coatings was noticed at 8 sccm of nitrogen flowrate. The coefficient of friction of the HiPIMS coating from the scratch test revealed that the CoF decreases with an increase in Nitrogen flowrate until 8 sccm, while the maximum critical load was noticed at 6 sccm.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Vepřek S, Reiprich S (1995) A concept for the design of novel superhard coatings. Thin Solid Films 268:64–71

Veprek S, Veprek-heijman M, Karvankova P, Prochazka J (2005) Different approaches to superhard coatings and nanocomposites. Thin Solid Flims 476:1–29. https://doi.org/10.1016/j.tsf.2004.10.053

Vieira T, Castanho J, Louro C (2006) Hard coatings based on metal nitrides, metal carbides and nanocomposite materials: PVD process and properties. Elsevier, Amsterdam, pp 537–572

Santecchia E, Hamouda AMS, Musharavati F et al (2015) Wear resistance investigation of titanium nitride-based coatings. Ceram Int 41:10349–10379

Ruppi S, Ho B, Huhtiranta M (1998) Wear characteristics of TiC, Ti (C, N), TiN and Al2O3 coatings in the turning of conventional and Ca-treated steels. Int J Refract Metal Hard Mater 16:353–368

Ghailane A, Oluwatosin AO, Larhlimi H et al (2021) Titanium nitride, TiXN (1−X), coatings deposited by HiPIMS for corrosion resistance and wear protection properties. Appl Surf Sci 574:151635

Su JF, Yu D, Nie X, Hu H (2011) Inclined impact–sliding wear tests of TiN/Al2O3/TiCN coatings on cemented carbide substrates. Surf Coat Technol 206:1998–2004. https://doi.org/10.1016/j.surfcoat.2011.09.067

Chauhan KV, Rawal SK (2014) A review paper on tribological and mechanical properties of ternary nitride based coatings. Proc Technol 14:430–437

Lungu MV (2020) An insight into TiN, TiAlN and AlTiN hard coatings for cutting tools. Mater Sci Res India 17:87–89

Uny F, Blanquet E, Schuster F, Sanchette F (2018) Ti–Al–N-based hard coatings: thermodynamical background, CVD deposition, and properties. A review. IntechOpen, London

Du H, Zhao H, Xiong J et al (2014) Effect of Ar/N2 flow ratio on oxidation resistance and properties of TiAl (La) N coatings. Int J Refract Metal Hard Mater 46:173–180

Koller CM, Hollerweger R, Sabitzer C et al (2014) Thermal stability and oxidation resistance of arc evaporated TiAlN, TaAlN, TiAlTaN, and TiAlN/TaAlN coatings. Surf Coat Technol 259:599–607

Liu H, Tang J-F, Wang X et al (2019) Effects of nitrogen-argon flow ratio on the microstructural and mechanical properties of TiAlSiN/CrN multilayer coatings prepared using high power impulse magnetron sputtering. J Vac Sci Technol A 37:51501

Rachbauer R, Blutmager A, Holec D, Mayrhofer PH (2012) Effect of Hf on structure and age hardening of Ti–Al-N thin films. Surf Coat Technol 206:2667–2672

Polcar T, Cavaleiro A (2014) High temperature behavior of nanolayered CrAlTiN coating: thermal stability, oxidation, and tribological properties. Surf Coat Technol 257:70–77

Braic V, Zoita CN, Balaceanu M et al (2010) TiAlN/TiAlZrN multilayered hard coatings for enhanced performance of HSS drilling tools. Surf Coat Technol 204:1925–1928

Park J-K, Cho J-Y, Jeon H-T, Baik Y-J (2009) Structure, hardness and thermal stability of TiAlBN coatings grown by alternating deposition of TiAlN and BN. Vacuum 84:483–487

Tillmann W, Momeni S, Hoffmann F (2013) A study of mechanical and tribological properties of self-lubricating TiAlVN coatings at elevated temperatures. Tribol Int 66:324–329

Yang K, Xian G, Zhao H et al (2015) Effect of Mo content on the structure and mechanical properties of TiAlMoN films deposited on WC–Co cemented carbide substrate by magnetron sputtering. Int J Refract Metal Hard Mater 52:29–35

Makha M, Ghailane A, Larhlimi H et al (2020) Phosphorus containing coatings: technologies and applications. ChemistrySelect 5:6570–6584

Lin B, LU J, (2014) Self-healing mechanism of composite coatings obtained by phosphating and silicate sol post-sealing. Trans Nonferrous Metals Soc China 24:2723–2728

Somisetti V, Narayan R, Kothapalli RVSN (2019) Multifunctional polyurethane coatings derived from phosphated cardanol and undecylenic acid based polyols. Progr Organ Coat 134:91–102. https://doi.org/10.1016/j.porgcoat.2019.04.077

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res 19:3–20

Strijckmans K, Schelfhout R, Depla D (2018) Tutorial: hysteresis during the reactive magnetron sputtering process. J Appl Phys 124:241101

Fekete M, Bernátová K, Klein P et al (2020) Influence of sputtered species ionisation on the hysteresis behaviour of reactive HiPIMS with oxygen admixture. Plasma Sources Sci Technol 29:25027

Aiempanakit M, Kubart T, Larsson P et al (2011) Hysteresis and process stability in reactive high power impulse magnetron sputtering of metal oxides. Thin Solid Films 519:7779–7784

Kubart T, Aiempanakit M, Andersson J et al (2011) Studies of hysteresis effect in reactive HiPIMS deposition of oxides. Surf Coat Technol 205:S303–S306

Audronis M, Bellido-Gonzalez V (2010) Hysteresis behaviour of reactive high power impulse magnetron sputtering. Thin Solid Films 518:1962–1965

Audronis M, Bellido-Gonzalez V, Daniel B (2010) Control of reactive high power impulse magnetron sputtering processes. Surf Coat Technol 204:2159–2164

Kadlec S, Čapek J (2017) Return of target material ions leads to a reduced hysteresis in reactive high power impulse magnetron sputtering: model. J Appl Phys 121:171910

Mirzaei S, Alishahi M, Souček P et al (2020) The effect of chemical composition on the structure, chemistry and mechanical properties of magnetron sputtered WBC coatings: modeling and experiments. Surf Coat Technol 383:125274

Shew B-Y, Huang J-L (1995) The effects of nitrogen flow on reactively sputtered Ti–Al–N films. Surf Coat Technol 71:30–36

Berg S, Nyberg T (2005) Fundamental understanding and modeling of reactive sputtering processes. Thin Solid Films 476:215–230

Mareš P, Dubau M, Polášek J et al (2021) High deposition rate films prepared by reactive HiPIMS. Vacuum 191:110329

Lundin D, Sarakinos K (2012) An introduction to thin film processing using high-power impulse magnetron sputtering. J Mater Res 27:780–792

Alami J (2005) Plasma characterization thin film growth and analysis in highly ionized magnetron sputtering

Alami J, Eklund P, Andersson JM et al (2007) Phase tailoring of Ta thin films by highly ionized pulsed magnetron sputtering. Thin Solid Films 515:3434–3438

Depla D, Strijckmans K, Dulmaa A et al (2019) Modeling reactive magnetron sputtering: opportunities and challenges. Thin Solid Films 688:137326

Strijckmans K, Depla D (2014) A time-dependent model for reactive sputter deposition. J Phys D Appl Phys 47:235302

Al-Mansoori M, Al-Shaibani S, Al-Jaeedi A et al (2017) Effects of gas flow rate on the structure and elemental composition of tin oxide thin films deposited by RF sputtering. AIP Adv 7:125105

Tien C-L, Lin H-Y, Chang C-K, Tang C-J (2018) Effect of oxygen flow rate on the optical, electrical, and mechanical properties of dc sputtering ITO thin films. Soft Matter Photon 11:1–9

Wüstefeld C, Rafaja D, Dopita M et al (2011) Decomposition kinetics in Ti1-xAlxN coatings as studied by in-situ X-ray diffraction during annealing. Surf Coat Technol 206:1727–1734

Goldfarb I, Pelleg J, Zevin L, Croitoru N (1991) Lattice distortion in thin films of IVB metal (Ti, Zr, Hr) nitrides. Thin Solid Films 200:117–127

Greene JE, Sundgren J, Hultman L et al (1995) Development of preferred orientation in polycrystalline TiN layers grown by ultrahigh vacuum reactive magnetron sputtering. Appl Phys Lett 67:2928–2930

Oh UC, Je JH (1993) Effects of strain energy on the preferred orientation of TiN thin films. J Appl Phys 74:1692–1696

Xi Y, Bai Y, Gao K et al (2018) Residual stress and microstructure effects on mechanical, tribological and electrical properties of TiN coatings on 304 stainless steel. Ceram Int 44:15851–15858

Hernandez LC, Ponce L, Fundora A, et al (2011) Nanohardness and residual stress in TiN coatings. Materials 4:929–940

Aissa KA, Achour A, Camus J et al (2014) Comparison of the structural properties and residual stress of AlN films deposited by dc magnetron sputtering and high power impulse magnetron sputtering at different working pressures. Thin Solid Films 550:264–267

Shulepov IA, Kashkarov EB, Stepanov IB et al (2017) The formation of composite Ti–Al–N coatings using filtered vacuum arc deposition with separate cathodes. Metals (Basel) 7:497

Barshilia HC, Rajam KS (2005) A Raman-scattering study on the interface structure of nanolayered Ti Al N∕Ti N and Ti N∕Nb N multilayer thin films grown by reactive dc magnetron sputtering. J Appl Phys 98:14311

Denisov VN, Mavrin BB, Vinogradov EA et al (2012) Structure of TiAlN reactive sputtered coatings. J Nano- Electron Phys 4:01021-1–1024

Ferrari AC, Robertson J (2000) Interpretation of Raman spectra of disordered and amorphous carbon. Phys Rev B 61:14095

Terrones H, del Corro E, Feng S et al (2014) New first order Raman-active modes in few layered transition metal dichalcogenides. Sci Rep 4:4215

Stoehr M, Shin C-S, Petrov I, Greene JE (2011) Raman scattering from TiNx (0.67≤ x≤ 1.00) single crystals grown on MgO (001). J Appl Phys 110:83503

Shin C-S, Gall D, Kim Y-W et al (2002) Development of preferred orientation in polycrystalline NaCl-structure δ-TaN layers grown by reactive magnetron sputtering: role of low-energy ion surface interactions. J Appl Phys 92:5084–5093

Wang X, Zhang K, Yue GH et al (2011) Investigation on the structure and properties of TiAlN coatings deposited by DC reactive magnetron sputtering. Trans Tech Publ, Geneva, pp 1639–1642

Anders A (2010) Deposition rates of high power impulse magnetron sputtering: physics and economics. J Vac Sci Technol A 28:783–790

Greczynski G, Lu J, Jensen J et al (2014) Strain-free, single-phase metastable Ti0.38Al0.62N alloys with high hardness: metal-ion energy vs. momentum effects during film growth by hybrid high-power pulsed/dc magnetron cosputtering. Thin Solid Films 556:87–98

Zhang S, Sun D, Fu Y, Du H (2005) Toughness measurement of thin films: a critical review. Surf Coat Technol 198:74–84

Leyland A, Matthews A (2000) On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear 246:1–11

Wang Z, Zhang D, Ke P et al (2015) Influence of substrate negative bias on structure and properties of TiN coatings prepared by hybrid HIPIMS method. J Mater Sci Technol 31:37–42. https://doi.org/10.1016/j.jmst.2014.06.002

Funding

The authors would like to acknowledge the financial contribution of OCP.SA Morocco.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abegunde, O.O., Makha, M., Machkih, K. et al. Comparative Study on the Influence of Reactive Gas Flow Rate on the Growth and Properties of P-doped TiAlN Coatings Prepared by DcMS and HiPIMS. J Bio Tribo Corros 8, 73 (2022). https://doi.org/10.1007/s40735-022-00672-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-022-00672-2