Abstract

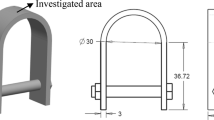

The localized material degradation and weakening induced by stress corrosion cracking (SCC) cause major effect on the service life of various machine components. The 300 series austenitic stainless steels are prone to SCC in chloride environment. Due to the complexity of SCC problem and its persistent attack, it is essential to study the problem with respect to various perspectives. In the present study, the effect of strain loadings on SCC susceptibility of 316L stainless steel in boiling magnesium chloride (MgCl2) solution was investigated. For this purpose, constant strain-based U-bend specimens were prepared to conduct the experiment. To attain the strain loading of 0.115, 0.2, 0.3, specimens were bent at three different curvature radii of 13 mm, 7.5 mm, 5 mm, respectively. Each sample was exposed to the boiling MgCl2 solution for 12 h and 24 h. Surface morphology and chemical composition were evaluated using optical microscope, field emission scanning electron microscope and energy dispersive X-ray spectroscopy, respectively. Preliminary results indicated no sign of SCC-induced cracks up to 24 h under all the proposed strain loadings. Although, SCC failure was observed after 07 days exposure in the same. Microscopic examination revealed the presence of multiple cracks, whereas both the major and minor cracks were intergranular in nature. The U-bend specimens under lower strain loading exhibit a higher degree of SCC attack in terms of weight loss, corrosion rate and surface roughness, where the size of plastic deformation could be the driving factor.

Similar content being viewed by others

Data Availability

The data and material generated during and/or analyzed during the current study are not publicly available due to all the datasets belong to the corresponding author’s PhD work.

References

Cigada A, Mazza B, Pedeferri P et al (1982) Strress corrosion cracking of cold-worked austenitic stainless steel. Corros Sci 22:559–578

Raja VS, Shoji T (2011) Stress corrosion cracking theory and practice. Woodhead Publishing Limited, Cambridge

Jones RH (1992) Stress corrosion cracking. ASM International, Ohio

Wang L, Seyeux A, Marcus P (2020) Thermal stability of the passive fi lm formed on 316L stainless steel surface studied by ToF-SIMS. Corros Sci 165:108395. https://doi.org/10.1016/j.corsci.2019.108395

Panda B, Sujata M, Madan M, Bhaumik SK (2014) Stress corrosion cracking in 316L stainless steel bellows of a pressure safety valve. Eng Fail Anal 36:379–389. https://doi.org/10.1016/j.engfailanal.2013.11.007

Hamzeh M, Karkehabadi MM, Jalali R (2017) Failure analysis of stress corrosion cracking of 316L structured packing in a distillation tower. Eng Fail Anal 79:431–440. https://doi.org/10.1016/j.engfailanal.2017.05.019

Rao MA, Babu RS, Kumar MVP (2018) Stress corrosion cracking failure of a SS 316L high pressure heater tube. Eng Fail Anal 90:14–22. https://doi.org/10.1016/j.engfailanal.2018.03.013

Juang HK, Altstetter C (1990) Effect of pH and chloride contents on stress corrosion cracking of austenitic stainless steels at room temperature. Corrosion 46:881–887. https://doi.org/10.5006/1.3580853

Zhong Y, Zhou C, Chen S, Wang R (2017) Effects of temperature and pressure on stress corrosion cracking behavior of 310s stainless steel in chloride solution. Chin J Mech Eng 30:200–206. https://doi.org/10.3901/CJME.2016.0420.056 (English Ed)

Du D, Chen K, Lu H et al (2016) Effects of chloride and oxygen on stress corrosion cracking of cold worked 316/316L austenitic stainless steel in high temperature water. Corros Sci 110:134–142. https://doi.org/10.1016/j.corsci.2016.04.035

Nishimura R (2007) Characterization and perspective of stress corrosion cracking of austenitic stainless steels (type 304 and type 316) in acid solutions using constant load method. Corros Sci 49:81–91

Yasir M, Danish M, Mia M et al (2021) Investigation into the surface quality and stress corrosion cracking resistance of AISI 316L stainless steel via precision end-milling operation. Int J Adv Manuf Technol 112:1065–1076. https://doi.org/10.1007/s00170-020-06413-4

He L, Yang J, Xiong Y, Song R (2021) Effect of solution pH on stress corrosion cracking behavior of modified AZ80 magnesium alloy in simulated body fluid. Mater Chem Phys 261:124232. https://doi.org/10.1016/j.matchemphys.2021.124232

Pal S, Bhadauria SS, Kumar P (2021) Studies on stress corrosion cracking of F304 stainless steel in boiling magnesium chloride solution. J Bio- Tribo-Corrosion 7:62. https://doi.org/10.1007/s40735-021-00498-4

Loto RT (2017) Electrochemical corrosion characteristics of 439 ferritic, 301 austenitic, S32101 duplex and 420 Martensitic stainless steel in sulfuric acid/NaCl solution. J Bio- Tribo-Corrosion 3:1–8. https://doi.org/10.1007/s40735-017-0084-1

Pal S, Bhadauria SS, Kumar P (2019) Pitting corrosion behavior of F304 stainless steel under the exposure of ferric chloride solution. J Bio- Tribo-Corrosion 5:1–13. https://doi.org/10.1007/s40735-019-0283-z

Pal S, Bhadauria SS, Kumar P (2021) Electrochemical corrosion behavior of type F304 stainless steel in different temperatures. J Bio- Tribo-Corrosion 7:43. https://doi.org/10.1007/s40735-021-00481-z

Totsuka N, Nishikawa Y, Kaneshima Y (2005) Effect of strain rate on primary water stress corrosion cracking fracture mode and crack growth rate of nickel alloy and austenitic stainless steel. Corrosion 61:219–229. https://doi.org/10.5006/1.3280631

Zhang W, Wu H, Wang S et al (2020) Investigation of stress corrosion cracking initiation in machined 304 austenitic stainless steel in magnesium chloride environment. J Mater Eng Perform 29:191–204. https://doi.org/10.1007/s11665-020-04558-7

Wu H, Li C, Fang K et al (2018) Effect of residual stress on the stress corrosion cracking in boiling magnesium chloride solution of austenite stainless steel. Mater Corros 69:1572–1583. https://doi.org/10.1002/maco.201810201

Leon A, Levy GK, Ron T et al (2020) The effect of strain rate on stress corrosion performance of Ti6Al4V alloy produced by additive manufacturing process. J Mater Res Technol 9:4097–4105. https://doi.org/10.1016/j.jmrt.2020.02.035

Eto S, Miura Y, Tani J, Fujii T (2014) Effect of residual stress induced by pulsed-laser irradiation on initiation of chloride stress corrosion cracking in stainless steel. Mater Sci Eng A 590:433–439. https://doi.org/10.1016/j.msea.2013.10.066

Ghosh S, Preet V, Rana S et al (2011) Role of residual stresses induced by industrial fabrication on stress corrosion cracking susceptibility of austenitic stainless steel. Mater Des 32:3823–3831. https://doi.org/10.1016/j.matdes.2011.03.012

Liu ZY, Li XG, Cheng YF (2011) Effect of strain rate on cathodic reaction during stress corrosion cracking of X70 pipeline steel in a near-neutral pH solution. J Mater Eng Perform 20:1242–1246. https://doi.org/10.1007/s11665-010-9770-6

Nishimura R, Maeda Y (2004) SCC evaluation of type 304 and 316 austenitic stainless steels in acidic chloride solutions using the slow strain rate technique. Corros Sci 46:769–785. https://doi.org/10.1016/j.corsci.2003.08.001

Hassani A, Habibolahzadeh A, Javadi AH, Hosseini SM (2013) Effect of strain rate on stress corrosion cracking of 316L austenitic stainless steel in boiling MgCl2 environment. J Mater Eng Perform 22:1783–1789. https://doi.org/10.1007/s11665-012-0461-3

Ben Rhouma A, Braham C, Fitzpatrick ME et al (2001) Effects of surface preparation on pitting resistance, residual stress, and stress corrosion cracking in austenitic stainless steels. J Mater Eng Perform 10:507–514. https://doi.org/10.1361/105994901770344638

Lu Z, Zhang H, Pan Y et al (2021) Effect of laser shock peening on stress corrosion sensitivity of 304 stainless steel C-ring weld specimens. Mater Res Express. https://doi.org/10.1088/2053-1591/abd73c

Lisenko N, Evans CD, Yao YL (2020) Effect of brass composition and phases on stress corrosion mitigation by laser shock peening. Manuf Lett 23:5–8. https://doi.org/10.1016/j.mfglet.2019.11.003

Yazdanpanah A, Biglari FR, Fallahi Arezoodar A, Dabalà M (2021) Role of grinding induced surface residual stress on probability of stress corrosion cracks initiation in 316L austenitic stainless steel in 3.5% sodium chloride aqueous solution. Corros Eng Sci Technol 56:81–92. https://doi.org/10.1080/1478422X.2020.1812818

Yazdanpanah A, Lago M, Gennari C, Dabalà M (2021) Stress corrosion cracking probability of selective laser melted 316l austenitic stainless steel under the effect of grinding induced residual stresses. Metals (Basel) 11:1–20. https://doi.org/10.3390/met11020327

Rajaguru J, Arunachalam N (2021) Effect of machined surface integrity on the stress corrosion cracking behaviour of super duplex stainless steel. Eng Fail Anal 125:105411. https://doi.org/10.1016/j.engfailanal.2021.105411

Li X, Xie F, Wang D et al (2018) Effect of residual and external stress on corrosion behaviour of X80 pipeline steel in sulphate-reducing bacteria environment. Eng Fail Anal 91:275–290. https://doi.org/10.1016/j.engfailanal.2018.04.016

Jinlong L, Tongxiang L, Wenli G (2015) Effect of strain on corrosion resistance of 316L stainless steel as bipolar plates in PEMFC environment. Int J Hydrogen Energy 40:10382–10389. https://doi.org/10.1016/j.ijhydene.2015.06.117

Cui Z, Liu Z, Wang L et al (2016) Effect of plastic deformation on the electrochemical and stress corrosion cracking behavior of X70 steel in near-neutral pH environment. Mater Sci Eng A 677:259–273. https://doi.org/10.1016/j.msea.2016.09.033

Du D, Song M, Chen K et al (2020) Effect of deformation level and orientation on SCC of 316L stainless steel in simulated light water environments. J Nucl Mater 531:152038. https://doi.org/10.1016/j.jnucmat.2020.152038

Shit G, Ningshen S (2020) The effect of severe plastic deformation on the corrosion resistance of AISI type 304L stainless steel. J Mater Eng Perform 29:5696–5709. https://doi.org/10.1007/s11665-020-05063-7

Salahi S, Kazemipour M, Nasiri A (2020) Effect of uniaxial tension-induced plastic strain on the microstructure and corrosion behavior of 13Cr martensitic stainless steel. Corrosion. https://doi.org/10.5006/3516

Despic AR, Raicheff RG, O’M Bockris J (1968) Mechanism of the acceleration of the electrodic dissolution of metals during yielding under stress. J Chem Phys 49:926–938. https://doi.org/10.1063/1.1670162

Nazarov A, Vivier V, Vucko F, Thierry D (2019) Effect of tensile stress on the passivity breakdown and repassivation of AISI 304 stainless steel: a scanning Kelvin probe and scanning electrochemical microscopy study. J Electrochem Soc 166:C3207–C3219. https://doi.org/10.1149/2.0251911jes

Khatak HS, Raj B (2002) Corrosion of austenitic stainless steels, first. Woodhead Publishing Limited, Cambridge

Kirsh Y, Yariv S, Shoval S (1986) Kinetic analysis of thermal dehydrationand hydrolysis of MgCl2.6H2O by DTA and TG. J Therm Anal 32:393–408

Huang Q, Lu G, Wang J, Yu J (2011) Thermal decomposition mechanisms of MgCl2·6H2O and MgCl2·H2O. J Anal Appl Pyrolysis 91:159–164. https://doi.org/10.1016/j.jaap.2011.02.005

Acknowledgements

We appreciate the technical support from MRC MNIT Jaipur and TCR Advanced Pvt Ltd Vadodara for FESEM-EDS analysis and SCC testing services, respectively.

Author information

Authors and Affiliations

Contributions

KK: Conceptualization, Methodology, Experimentation, Investigation, Writing—original draft, Visualization. SSB: Writing—review and editing, Supervision. APS: Writing—review and editing, Supervision.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, K., Bhadauria, S.S. & Singh, A.P. Effect of Strain Loading on Stress Corrosion Cracking Susceptibility of 316L Stainless Steel in Boiling MgCl2 Solution. J Bio Tribo Corros 7, 123 (2021). https://doi.org/10.1007/s40735-021-00561-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00561-0