Abstract

In this paper, a mesh-less approach for the simulation of a fluid with particle loading and the prediction of abrasive wear is presented. We are using the smoothed particle hydrodynamics (SPH) method for modeling the fluid and the discrete element method (DEM) for the solid particles, which represent the loading of the fluid. These Lagrangian methods are used to describe heavily sloshing fluids with their free surfaces as well as the interface between the fluid and the solid particles accurately. A Reynolds-averaged Navier–Stokes equations model is applied for handling turbulences. We are predicting abrasive wear on the boundary geometry with two different wear models taking cutting and deformation mechanisms into account. The boundary geometry is discretized with special DEM particles. In doing so, it is possible to use the same particle type for both the calculation of the boundary conditions for the SPH method as well as the DEM and for predicting the abrasive wear. After a brief introduction to the SPH method and the DEM, the handling of the boundary and the coupling of the fluid and the solid particles are discussed. Then, the applied wear models are presented and the simulation scenarios are described. The first numerical experiment is the simulation of a fluid with loading which is sloshing inside a tank. The second numerical experiment is the simulation of the impact of a free jet with loading to a simplified pelton bucket. We are especially investigating the wear patterns inside the tank and the bucket.

Similar content being viewed by others

1 Introduction

In this work simulating fluid-particle systems and the prediction of caused abrasive wear are the main interests. There are several crucial points, three of them are the accurate description of the interfaces of the fluid–particle system, the free surface of the fluid, and the modeling of wear at the boundary geometry. In this work a mesh-less approach for the simulation of a sloshing fluid with solid particle loading, which is causing abrasive wear at a boundary geometry, is presented.

In the past, many studies have dealt with the simulation of fluid–particle systems [51]. In these studies different combinations of mesh-less and mesh-based methods were proposed. There are different techniques for coupling the necessary simulation methods [50]. Here, only Lagrangian methods are applied. The main advantage of the Lagrangian methods is the natural description of the free surface and the fluid-solid interface. There is no additional computation necessary. The solid particles are modeled here with the discrete element method (DEM) and the fluid with the smoothed particle hydrodynamics (SPH) method. Several possibilities were proposed for coupling SPH and DEM, e.g. [40] or [20]. In this work we are using an approach based on ideas in [41], for which the SPH particles are larger than the DEM particles. In this way, it possible to simulate larger scenarios than with an approach which uses a penalty force between a large DEM and a small SPH particle.

Wear like cutting wear, sliding wear, cavitation, chemical wear, abrasive wear, etc. is caused by different mechanisms. In this work, we consider only abrasive wear, which can be defined as a combination of cutting, fatigue failure and material transfer [33]. There exist different approaches for predicting abrasive wear. For these approaches, different simulation methods are used for modeling the fluid, the abrasive particles and the abrasive wear. Depending on the application, there are approaches in which Eulerian and Lagrangian methods are coupled [18, 32], especially for the explicit simulation of hydraulic machines. For applications with a high level of detail only Lagrangian methods are used [22, 38] or only parts of the boundary geometry are described with a Lagrangian method [47]. One of the main differences, in relation to the prediction of abrasive wear, is the usage of a wear model with an undeformable shape of the geometry during the simulation, or the modeling of wear with a deformable boundary geometry. For the presented approach, we want to apply only Lagrangian methods without a high level of detail and, therefore, two wear models are applied with an undeformable shape of the geometry.

In this work first some basics of SPH and DEM are discussed. Then, the handling of the boundary as well as the fluid-solid interface are introduced. Besides, the wear models for predicting wear on the boundary are described. Next to this, the simulations for the sloshing of a fluid with loading inside a tank and the impact of a free jet with loading are presented. The free jet is shown in Fig. 1. The visualization of SPH particles is a crucial point which can be misleading, because we have there particles which represent an interpolation point and its smoothing length. In this work we are visualizing the SPH particle with a center point and a partially transparent sphere around it. The center point has the maximum opacity and the sphere with the radius of the smoothing length has a lower opacity.

The numerical experiments are chosen to demonstrate the ability of the proposed approach to handle both simple boundary geometries as well as very complex industrial relevant boundary geometries. At the end, a conclusion on the described methods and performed analyses is given.

The novel contribution of this work are the particles which are used for the prediction of the abrasive wear on the boundary geometry and for the calculation of the boundary conditions of the SPH method and the DEM. Also, the way of coupling of the SPH and the DEM particles in combination with modeling abrasive wear on the boundary has not been performed in that way before. The proposed approach can be applied for numerical experiments on wear analyses resulting from fluids with particle loading on large complex scenarios without additional preparations or computations.

2 Simulation method

2.1 Smoothed particle hydrodynamics

In classical Computational Fluid Dynamics simulations, mesh-based methods are applied. The motion of the fluid flow is modeled with the Navier–Stokes (N–S) equations. Here, these equations are solved with the SPH method. The description of the free surface and the complex interface between fluid and solid can be handled without any additional calculation steps due to the mesh-less character of the method.

In the very beginning the SPH method was simultaneously derived by two different groups [17, 30]. The method was used in several fields of application like fluid-solid interaction [7, 23], free surfaces [34, 35, 46], and multi-phase flow [8, 19]. An extensive review about different applications can be found in [28]. There are different variants of this method which are referred to as weakly compressible SPH formulation or the truly incompressible SPH formulation. One advantage of the truly incompressible SPH method is the more accurate description of the pressure field. But of course there are also disadvantages in contrast to the weakly compressible approach, as for example the higher computational costs.

The conservation of mass which is discretized with the SPH method is

and the conservation of the momentum is

In these equations, \(p\) is the pressure, \(\mathbf {f}\) are the body forces acting on the fluid, \(\mathbf {v}\) is the velocity, \(\rho \) the density, \(\mu \) the viscosity of the fluid and \(\mathbf {R}\) are the Reynolds turbulence stresses. Basically, there are two steps required to derive the SPH formulation of the N-S equations. These steps are the kernel approximation and the particle approximation [28]. Any quantity \(A\) at these particles, which are used to discretize the fluid, is described with the functions

In these functions \(\rho _b\) is the density, \(\mathbf {r}_b\) the position, \(m_b\) is the mass of a particle \(b\), \(\mathbf {r}_a\) the position of particle \(a\), \(\mathbf {r}_{ab}\) distance between particle \(a\) and \(b\), \(W\) the smoothing function, and \(h\) the smoothing length.

It is possible to use different kernel functions \(W\) in Eqs. (3) and (4) like e.g. a spline kernel [35]. In this project the often used Wendland kernel function [48]

with \(\alpha _D = 21/(16\pi h^3)\) is applied for the simulation.

The different terms in Equations (1) and (2) are mainly calculated as in [25]. The viscous term \(\mu \nabla ^2\mathbf {v} \) in Equation (2) is modeled as the well known artificial viscous term \(\varPi _{ab}\) described in [36]. In the following the pressure term, the Reynolds turbulence stresses term and the kernel correction term which are calculated different and are not so well known are discussed in more detail. After these terms we give some details about the handling of the boundary conditions.

The pressure gradient term \(\nabla p\) introduced in [10] is applied and the pressure is obtained from

where \(\mathbf {v}^*\) is the intermediate velocity in the Euler time stepping algorithm with the time \(t\), which is used for the performed simulation. In this work, a turbulence model is used to describe the flow which involves heavy sloshing accurately. The Reynolds turbulence stresses are

with \(\nu _t\) the turbulence eddy viscosity, \(k\) the turbulence kinetic energy, \(S_{ij}\) the components of the strain rate tensor and \(\delta _{ij}\) the Kronecker delta function [29]. It is proposed in [44] to use a viscosity which is 1000 times larger than the laminar value of water due to the turbulent character of a broken-dam flow to avoid instabilities. In this work, the artificial viscosity, which is not only valid for laminar flows, is applied to avoid instabilities.

Particles which are spraying back in the bulk fluid after a heavy impact of the fluid on a wall lead to a disordering of the particles inside the bulk. For avoiding instabilities which can occur due to disturbed particle distribution we are using different correction terms. We use the Shepard filter from [45] and the kernel correction

from [6]. For preventing instabilities at the free surface the approach of [42] for surface damping can be applied, but for the investigated numerical examples which are presented here this is not necessary.

An accurate description of the boundary is a crucial part in the SPH method. There are different approaches like repulsive forces [36], which are rarely used in recent studies because of their inaccuracies.

Other possibilities are dummy particles [25, 44] or mirror particles [27, 42]. Different studies are dealing with the boundary conditions and improving them successfully [26, 29].

In this work we are using an approach that is based on the mirror particles technique. The mirror axes are special triangle shaped DEM particles. We are using a bounding box based neighborhood search. This technique for searching adjacent particles can easily handle particles with different geometries [16]. The quantities at the mirror particles are calculated according to [10] to obtain Dirichlet and Neumann boundary conditions. The dummy approach and the mirror particle approach are shown in Fig. 2 for a 3D broken dam flow. The abrasive wear is also calculated with these special DEM particles. The loading of the fluid is modeled with the DEM.

2.2 Discrete element method

The DEM [11] is applied for modeling the particle loading of the fluid. Originally this method was used only for particles which are permanently interacting. In [13], free particles of bulk material without permanent contact like the particle loading of the fluid are modeled. With the extension of inner-particle bonds, which are used to form a multi-particle body, it is possible to model natural failure [14]. The idea behind this method is the description of the particle dynamics with the Newton–Euler equations [43] in combination with a contact law. The equations of motion for a single particle \(i\) are

In these equations, \(\mathbf {I}_\mathrm{i}\) is the inertia tensor, \(m_\mathrm{i}\) is the mass, \(\mathbf {f}_\mathrm{i}\) and \(\mathbf {l}_\mathrm{i}\) are applied forces and torques, \(\mathbf {a}_{i}\) is the translational acceleration and \(\varvec{\omega }_i\) is the angular velocity. The simulations presented in this work are performed only using the translational part in Eq. (9) and neglecting particle rotations.

Depending on the application there are different contact models [50]. For the calculation of the forces between two particles with contact, here a Hertzian penalty contact is applied [24]. The equations for calculating the forces between bodies \(i\) and \(j\) are

with the abbreviations

Here, \(E_\mathrm{j}\) is the Young’s modulus of the granular material, \(R_\mathrm{j}\) is the radius of a particle, \(\nu _\mathrm{j}\) the Poisson number, \(d\) a damping parameter and \(\delta _\mathrm{ij}\) the overlap of two particles.

2.3 DEM–SPH coupling

There are different possibilities for the description of the interface between the SPH method and the DEM. In the approach introduced in [40] the SPH particles are smaller than the DEM particles and the contact force is modeled with a penalty force, e.g., a spring damper combination. The disadvantage of this approach is that for large simulation scenarios a huge number of particles is required. This approach particularly is used when the influence of the solid particles on the flow cannot be neglected. Another approach proposed in [41] uses a force model which is taking the drag as well as the fluid forces buoyancy and shear stress into account. The SPH particles are much larger than the DEM particles in this approach.

The equation for the conservation of the momentum of the fluid and the equation of motion of a DEM particle are

The equation for the coupling force \(\mathbf {f}_c\) was introduced in [1] and reads

where \(V_i\) is the volume of a particle, \(\varvec{\tau }\) are the viscous stresses and \(\epsilon \) is the porosity. The first term for resolving the fluid forces, which are corrected with the Shepard filter, is calculated by

with the uncorrected fluid forces

The drag force \( \mathbf {f}_d \) is depending on the velocity difference \(\mathbf {u}_s\) between the fluid and the loading particles. For creeping flow, the force can be calculated with Stokes law to

with the diameter \( d \) of the particle. According to [21] for Reynolds numbers greater than \(10^{-2}\) the force is calculated as

with \(\rho _f\) the fluid density and \(Re_p = \rho _f |\mathbf {u}_s|d/\mu \) the particle Reynolds Number. The direction is given by the normal of the projected area of the particle in the plane perpendicular to its direction of motion. The SPH particles are here larger than the adjacent DEM particles and, therefore, the coupling force for a single SPH particle is calculated as weighted average of the fluid-particle coupling force of all adjacent DEM particles as

with

2.4 Wear model

There are different abrasive wear mechanisms which cause a damage to the surface of the boundary geometry, e.g. cutting or deformation. Therefore, different approaches are used depending on the desired level of detail. In [22, 37, 38] an approach for a high level of detail is proposed. The boundary is described with several layers of particles and also the solid particles inside the fluid consist of several particles. In this way it is possible to model chip building on the boundary geometry and also failure of the solid particles. The disadvantage is the huge number of particles which is required for large simulation scenarios.

In [12] the damage of the surface is described with a simplified wear model and not resolved in detail. The advantage is that large simulation scenarios can be described with an acceptable number of particles and, therefore, simulations over a long time scale can be performed. In several studies different wear models were developed, an overview is given in [9, 31].

There are three different types, i.e., single-particle, dense phase and dissipation models. The choice of the model is a crucial point and has to be done carefully according to the specific application. A comprehensive comparison of several models can be found in [33]. In this work we have chosen two different single-particle models. The first one is the Finnie model proposed in [15]

with

In this equation \(M\) is the amount of removed material, \(m\) is the mass of the particle, \(\alpha \) is the attack angle, \(k\) is the ratio of vertical to horizontal force components, \(\psi \) is the ratio of the depth of contact to the length of the swarf, \(V\) is the absolute velocity of the abrasive particle and \(p\) is the flow stress of the component material. This erosion model covers only cutting mechanisms under small impact angles.

The other model was introduced in [4, 5]. The removed material of the surface is calculated in the Bitter model to

where

and

Here, \(r_p\) is the radius, \(U_p\) the velocity, \(M_p\) the mass, \(q_p\) the Poisson ratio, \(E_p\) the Young’s modulus, \(\rho _p\) the density and \(R_f\) the roundness factor of the solid particle, \(\alpha \) is the impact angle, \(\rho _t\) the density, \(q_t\) the Poisson ratio, \(Y\) the yield stress and \(E_f\) is the Young’s modulus of the boundary, \(\sigma \) the plastic flow stress, \(E_f\) the deformation erosion factor and \(n\) the velocity exponent. This wear model is more complex as it covers cutting and deformation mechanisms. The values of used the parameters are listed in the result section.

2.5 Pasimodo

The simulation software Pasimodo is developed at the ITM for more than a decade [39] and used for several different studies, e.g., [3]. The basic idea behind this software package is the development of a flexible framework for general particle methods, which consists of a core and plugins. The complete software is written in C++. The core is independent of the used particle method. Its main task is to control the sequence of the three basic steps of particle methods.

These are the neighborhood search, in this step adjacent particles are detected, the interaction of adjacent particles, in this step the forces between particles are calculated, and the integration step, where the particles are moved and their state variables are updated.

A specific particle method like the DEM or the SPH method is implemented as plugin. A plugin is a shared library which is loaded before the simulation starts. The plugins can combined arbitrarily. The SPH plugin,e.g., contains the SPH particles, the interaction for the calculation of the forces between SPH particles, the interaction for SPH and DEM particles and the integrator for the SPH method.

3 Numerical experiments

After the introduction of our mesh-less approach for simulating a fluid with loading, we want to present different numerical experiments. We have chosen two different setups, the first one to illustrate the capability for predicting wear with the focus on the proposed mesh-less approach without distracting complex boundary geometry. The simulation scenario is therefore a rather simple one. We are simulating the sloshing of a fluid with loading inside a tank. We are using the setup for predicting wear at the right wall of the tank with two different wear models.

This experiment is inspired by an artificial dam break. The artificial dam break is an often used numerical example to demonstrate the capability of the SPH method for describing a heavily sloshing fluid with a free surface accurately without high computational effort. The accurate description of the free surface of the fluid is possible due to the mesh-less character of the SPH method.

The second simulation scenario is related to very complex industrial applications. The boundary geometry is a simplified pelton bucket. We are simulating the impact of a free jet with loading on this complex boundary geometry. A crucial point in this context is the simulation of the jet at the edge where it is divided. It is possible to handle this situation accurately with our developed boundary particles.

The motivation of this numerical experiment is the difficulty to measure abrasive wear in hydraulic machineries. Often optical access is not possible and therefore the investigation of abrasive wear is difficult. Here, the simulation of abrasive wear is a promising alternative.

3.1 Sloshing inside a tank

The accurate modeling of the free surface of a fluid is a challenging point. In contrast to classical fluid dynamics methods, the description with the SPH method is possible without additional modeling effort. A commonly used example for the demonstration of the simulation of a heavily sloshing fluid with a free surface is an artificial dam break.

The sloshing of a fluid with loading inside a tank is similar to the simulation of an artificial dam break. We use a simple geometry for the tank, for which we investigate the resulting wear pattern. We want to keep the focus on the proposed approach and therefore we use this rather simple geometry as benchmark.

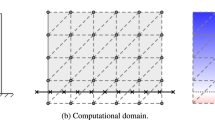

The setup for the simulation is a rectangular tank shown in Fig. 3. The length of the tank is \(l_2=0.245\,\hbox {m}\), the height is \(h_2=0.1\,\hbox {m}\), and the width is \( w_1=0.1\,\hbox {m}\). The wear pattern at the right wall is investigated in the numerical experiment. According to this, the discretization of the tank is done to avoid unnecessary calculations. The discretization of the right wall is shown in Fig. 3.

The considered fluid is water at \( 20^\circ C\) and is placed in the beginning of the simulation on the left side of the tank as shown in Fig. 3. The measures of volume of the fluid are \( w_1=0.1\,\hbox {m}\), \( h_1=0.1\,\hbox {m}\), and \( l_1=0.1\,\hbox {m}\). The initial distance of the SPH particles is \(0.005\,\hbox {m}\) resulting in 8000 particles and 1,136,000 interactions. We use a dry bed in this simulation.

The loading of the fluid is coarse sand. The parameters for the boundary geometry, the sand particles and the wear models are listed in Table 1. The parameters of the wear models aside of material parameters are results from different studies. The determination of their values is a crucial point [33]. The parameters which are used in this study are taken from [31, 33] and [49].

In the beginning, the fluid is at rest and then it sloshes from left to right and back again in the tank. In Fig. 4 six different stages of the fluid motion during the simulation are shown. In these figures, only the fluid particles are shown.

The loading is also at rest in the beginning. Then it is moving with the fluid inside the tank. In Fig. 5 on the left the loading of the fluid at two different stages during the simulation is shown. The size of the DEM particles is scaled up for a better visualization. On the right hand side in Fig. 5 the corresponding state of the fluid is shown. The particles are colored according to their absolute velocity and additionally the velocity directions of the DEM particles are shown.

The wear models cover different application scenarios. They are taking different mechanisms like cutting and deformation into account. Therefore, only the resulting wear patterns without the absolute values are compared. The wear pattern at \(t=0.203\,\hbox {s}\) is shown in Fig. 6 and in Fig. 7 the wear pattern for \(t=0.237\,\hbox {s}\). As expected, the wear patterns are somehow different, but quite similar. Close to the lower edge of the investigated wall of the tank, the DEM particles are lifted up to the top before they have contact with the wall. After they lifted up they are moving back to the left in tank.

3.2 Impact of a free jet

The impact of a free jet with loading on a complex boundary geometry is simulated in this numerical example. In Fig. 8, the free jet and the damaged boundary geometry are shown. We show here that it is possible to handle complex boundary geometries of industrial applications without additional preparations or computations with the newly developed approach. In this scenario, the boundary geometry is a simplified pelton bucket, whose surface can be damaged, among other things, by abrasive wear.

The damage of the surface of hydraulic machinery is caused by several different mechanisms. In many industrial applications the working fluid of hydraulic machinery transports small stiff abrasive particles which can cause abrasive wear. The damage can lead to a decrease of the efficiency of the hydraulic machinery. Therefore, it is necessary to analyze abrasive wear to reduce this decrease.

The parameters of the fluid and the loading are the same as in the first numerical example. The fluid is again water at \( 20\,^\circ \)C and the parameters for the boundary geometry, the sand particles and the wear models are listed in Table 1. In Fig. 9, four different states of the fluid flow are shown. After the impact of the free jet the fluid is sloshing heavily inside the bucket and of course some of the surface particles are spraying around. We removed these particles in Fig. 9 for a better visualization of the fluid flow.

The resulting wear patterns for the impact are shown in Figs. 10 and 11. The removed material of the surface is predicted, on the one hand, with the Bitter model equation (22) and, on the other hand, with the Finnie model equation (24). The color coding is equal as for the simulation of the tank.

The wear pattern is as expected slightly different. In both simulations the maximum removed material is in the middle of the bucket. The abrasive particles are deccelerated after the contact of the jet with the bucket and therefore their velocity and the removed material are decreasing. The surface damage predicted with the Bitter model is much greater than with the Finnie model for this case. The difference is due to the fact that fewer mechanisms are taken into account with the Finnie model and the accuracy of experimental model parameters is always critical.

An important point is the calculation of the forces between SPH particles at the upper edge where the jet is divided into two parts. The smoothing length of the SPH particles is larger than the wall thickness of the bucket at this edge. We are using the normal of the boundary geometry to avoid the calculation of forces of SPH particles which are physically separated by the thin wall of the bucket. The normal of the boundary is stored as additional entity for SPH particles which are adjacent to the boundary. We use the dot product of the normals of two adjacent SPH particles and decide if they are separated or not. If we wouldn’t take care of this, the separation of the jet would not be accurate enough. The wear patterns which are shown in Figs. 10 and 11 are very satisfying for this extremly complex simulation scenario. Here, we have simulated a single impact of a free jet. Further steps are the simulation of multiple impacts with different loadings. Of course always, the shape of the boundary geometry and many other parameters have to be taken into account for analyses of abrasive wear.

4 Conclusion

The simulation of abrasive wear with two different wear models is presented. The mesh-less approach works fine for modeling the fluid with turbulence, the abrasive particles and the boundary geometry. The transport of the loading and the prediction of wear can be simulated with this approach.

The interface between the fluid and the solid particles and also the free surface needs no additional preparation or computational effort. The choice of the parameters of the different wear models is a crucial point and needs to be further investigated in separate studies.

Two simulations scenarios, the sloshing of a fluid with loading inside a tank and the impact of a free jet with loading, were presented. The prediction of wear due to different effects is shown. The proposed approach is able to handle complex industrial boundary geometries as well as simpler geometries. The limitation of this approach is the maximum number of particles, because the rising computational effort with more particles. Thus, super computing can be applied for Pasimodo favourably [2].

The next step will be the application of different wear models and the investigation of the different model parameters in a more extensive comparison.

References

Anderson TB, Jackson R (1967) Fluid mechanical description of fluidized beds. Equations of motion. Ind Eng Chem Fundam 6(4):527–539

Beck F, Fleissner F, Eberhard P (2013) Lagrangian simulation of a fluid with solid particle loading performed on supercomputers. High Perform Comput Sci Eng 13:405–421

Beck F, Fleissner F, Eberhard P (2013) Simulation of a pendulum with fluid interaction and experimental validation. Comput Methods Marine Eng 2013:479–490

Bitter J (1963) A study of erosion phenomena: part I. Wear 6(1):5–21

Bitter J (1963) A study of erosion phenomena: part II. Wear 6(3):169–190

Bonet J, Lok TS (1999) Variational and momentum preservation aspects of smooth particle hydrodynamic formulations. Comput Methods Appl Mech Eng 180(1–2):97–115

Campbell J, Vignejevic R, Libersky L (2000) A contact algorithm for smoothed particle hydrodynamics. Comput Methods Appl Mech Eng 184:49–65

Colagrossi A, Landrini M (2003) Numerical simulation of interfacial flows by smoothed particle hydrodynamics. J Comput Phys 191:448–475

Crowe C (2006) Multiphase handbook. Taylor and Francis, London

Cummins SJ, Rudman M (1999) An SPH projection method. J Comput Phys 152(2):584–607

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 29(1):47–65

ElTobgy M, Ng E, Elbestawi M (2005) Finite element modeling of erosive wear. int j mach tools manuf 45(11):1337–1346

Ergenzinger C, Seifried R, Eberhard P (2011) A discrete element model to describe failure of strong rock in uniaxial compression. Granul Matter 13(4):341–364

Ergenzinger C, Seifried R, Eberhard P (2012) A discrete element approach to model breakable railway ballast. J Comput Nonlinear Dyn 7(4):041010-1–041010-8

Finnie I (1972) Some observations on the erosion of ductile metals. Wear 19:81–90

Fleissner F (2010) Parallel Object oriented simulation with lagrangian particle methods. Dissertation, Schriften aus dem Institut für Technische und Numerische Mechanik der Universität Stuttgart, Band 16. Shaker Verlag, Aachen

Gingold RA, Monaghan JJ (1977) Smoothed particle hydrodynamics: theory and application to non-spherical stars. Mon Not R Astron Soc 181:375–389

Hamed A, Tabakoff W, Rivir R, Das K, Arora P (2005) Turbine blade surface deterioration by erosion. J Turbomach 127:445– 452

Hu X, Adams N (2005) A multi-phase SPH method for macroscopic and mesoscopic flows. J Comput Phys 213:844–861

Huang J, Nydal O (2012) Coupling of discrete-element method and smoothed particle hydrodynamics for liquid-solid flows. Theo Appl Mech Lett 2(1):012002

Khan A, Richardson J (1987) The resistance to motion of a solid sphere in a fluid. Chem Eng Commun 62:135–150

Kristof P, Benes B, Krivanek J, Stava O (2009) Hydraulic erosion using smoothed particle hydrodynamics. In: Computer graphics forum proceedings of eurographics 2009, 28(2)

Kulasegaram S, Bonet J, Lewis RW, Profit M (2004) A variational formulation based contact algorithm for rigid boundaries in two-dimensional SPH applications. Comput Mech 33:316–325

Lankarani HM, Nikravesh PE (1990) A contact force model with hysteresis damping for impact analysis of multibody systems. J Mech Des 112:369–376

Lee ES, Moulinec C, Xu R, Violeau D, Laurence D, Stansby P (2008) Comparisons of weakly compressible and truly incompressible algorithms for the SPH mesh free particle method. J Comput Phys 227(18):8417–8436

Leroy A, Violeau D, Ferrand M, Kassiotis C (2014) Unified semi-analytical wall boundary conditions applied to 2-D incompressible SPH. J Comput Phys 261:106–129

Libersky L, Petschek A, Hipp T (1993) High strain Lagrangian hydrodynamics. J Comput Phys 109:67–75

Liu M, Liu G (2010) Smoothed particle hydrodynamics (SPH): an overview and recent developments. archives Computat Methods Eng 17:25–76

Liu X, Xu H, Shao S, Lin P (2013) An Improved incompressible SPH model for simulation of wave structure interaction. Comput Fluids 71:113–123

Lucy LB (1977) A numerical approach to the testing of the fission hypothesis. Astron J 82(12):1013–1024

Lyczkowski RW, Bouillard JX (2002) State-of-the-art review of erosion modeling in fluid/solids systems. Progress Energy Combustion Science 28(6):543–602

Mazur Z, Palacios L, Urquiza G (2004) Numerical modeling of gland seal erosion in a geothermal turbine. Geothermics 33:599–614

Meng H, Ludema K (1995) Wear models and predictive equations: their form and content. Wear 181–183, Part 2, 443–457

Monaghan JJ, Kocharyan A (1995) SPH simulation of multi-flow. Comput Phys Commun 87:225–235

Monaghan JJ (1994) Simulating free surface flows with SPH. J Comput Phys 110:399–406

Monaghan JJ (2005) Smoothed particle hydrodynamics. Rep Progress Phys 68:1703–1759

Nutto C, Bierwisch C, Lagger H, Moseler M (2012) Towards simulation of abrasive flow machining. In: Proceedings 7th international spheric workshop, pp 59–64

Nutto C, Bierwisch C, Lagger H, Moseler M (2013) Towards simulation of abrasive flow machining. In: Proceedings 8th international spheric workshop, pp 270–276

Pasimodo (2008) http://www.itm.uni-stuttgart.de/research/pasimodo/pasimodo_en.php. Accessed 4 Nov 2014

Potapov AV, Hunt ML, Campbell CS (2001) Liquid-solid flows using smoothed particle hydrodynamics and the discrete element method. Powder Technol 116(2–3):204–213

Robinson M, Ramaioli M, Luding S (2014) Fluid particle flow simulations using two-way-coupled mesoscale SPHDEM and validation. Int J Multiph Flow 59:121–134

Rui X (2009) An improved incompressible smoothed particle hydrodynamics method and its application in free-surface simulations. Ph.D. thesis, School of Mechanical, Aerospace and Civil Engineering, University of Manchester

Schiehlen W, Eberhard P (2014) Technische Dynamik (in German), 4th edn. Vieweg+Teubner, Wiesbaden

Shao S, Lo EY (2003) Incompressible SPH method for simulating newtonian and non-Newtonian flows with a free surface. Adv Water Resour 26(7):787–800

Shepard D (1968) A two-dimensional interpolation function for irregularly-spaced data. In: Proceedings of the 1968 23rd ACM national conference, pp 517–524

Takeda H, Miyama S, Sekiya M (1994) Numerical simulation of viscous flow by smoothed particle hydrodynamics. Progress Theo Phys 92(5):939–960

Wang Y, Yang Z (2009) A coupled finite element and meshfree analysis of erosive wear. Tribol Int 42(2):373–377

Wendland H (1995) Piecewise polynomial, positive definite and compactly supported radial functions of minimal degree. Adv Comput Math 4(1):389–396

Wood R, Jones T, Ganeshalingam J, Miles N (2004) Comparison of predicted and experimental erosion estimates in slurry ducts. Wear 256(9–10):937–947

Zhu H, Zhou Z, Yang R, Yu A (2007) Discrete particle simulation of particulate systems: theoretical developments. Chem Eng Sci 62(13):3378–3396

Zhu H, Zhou Z, Yang R, Yu A (2008) Discrete particle simulation of particulate systems: a review of major applications and findings. Chem Eng Sci 63(23):5728–5770

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beck, F., Eberhard, P. Predicting abrasive wear with coupled Lagrangian methods. Comp. Part. Mech. 2, 51–62 (2015). https://doi.org/10.1007/s40571-015-0034-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-015-0034-y