Abstract

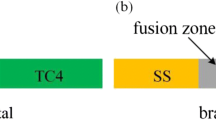

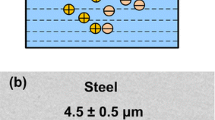

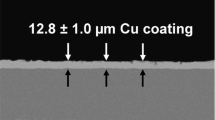

In this study, a pulsed Nd:YAG laser welding method is implemented to join Ti-G2 (1 mm thick) to AA3105-O (0.5 mm thick) via a ring of spots filled with AlScZr alloy (0.15 mm thick). The filler material improved the weld’s microstructure and mechanical properties by reducing the undesirable intermetallic compounds (IMCs) such as TiAl2 and TiAl3 in the aluminium re-solidified zone near the titanium/aluminium interface. The joints having AlScZr filler were mostly failed at Al heat affected zone (HAZ) during the tensile shear test. The addition of zirconium to binary Al–Sc system formed a substitutional solid-solution in which 50 wt% Zr+10 wt% Ti replaced Al3(Sc,Zr,Ti). Scandium had a strengthening effect by solid-solution and precipitation hardening effect due to the formation of Al3(Sc,Zr) particles. The joint strength rose from 86% (of the base Al strip) for autogenously laser weld to 102% with filler metal. Hardness increased steadily at the Ti/Al interaction zone, and the maximum hardness was reduced from 650 HV to 570 HV when filler metal was utilized.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Möller, F., Grden, M., Thomy, C., Vollertsen, F.: Combined laser beam welding and brazing process for aluminium titanium hybrid structures. Phys. Procedia. 12, 215–223 (2011). https://doi.org/10.1016/j.phpro.2011.03.028

Zhu, Z., Lee, K.Y., Wang, X.: Ultrasonic welding of dissimilar metals, AA6061 and Ti6Al4V. Int. J. Adv. Manuf. Technol. 59, 569–574 (2012). https://doi.org/10.1007/s00170-011-3534-9

Palanivel, R., Dinaharan, I., Laubscher, R.F.: A comparative study on microstructure and mechanical properties between friction and laser beam welded titanium tubes. Optik (Stuttg) 177, 102–111 (2019). https://doi.org/10.1016/j.ijleo.2018.09.022

Sohn, W.H., Bong, H.H., Hong, S.H.: Microstructure and bonding mechanism of Al/Ti bonded joint using Al–10Si–1Mg filler metal. Mater. Sci. Eng. A. 355, 231–240 (2003). https://doi.org/10.1016/S0921-5093(03)00070-4

Cao, R., Sun, J.H., Chen, J.H.: Mechanisms of joining aluminium A6061-T6 and titanium Ti–6Al–4V alloys by cold metal transfer technology. Sci. Technol. Weld. Join. 18, 425–433 (2013). https://doi.org/10.1179/1362171813Y.0000000118

Chen, Y., Ni, Q., Ke, L.: Interface characteristic of friction stir welding lap joints of Ti/Al dissimilar alloys. Trans. Nonferrous Met. Soc. China 22, 299–304 (2012). https://doi.org/10.1016/S1003-6326(11)61174-6

Baqer, Y.M., Ramesh, S., Yusof, F., Manladan, S.M.: Challenges and advances in laser welding of dissimilar light alloys: Al/Mg, Al/Ti, and Mg/Ti alloys. Int. J. Adv. Manuf. Technol. 95, 4353–4369 (2018). https://doi.org/10.1007/s00170-017-1565-6

Casalino, G., D’Ostuni, S., Guglielmi, P., Leo, P., Mortello, M., Palumbo, G., Piccininni, A.: Mechanical and microstructure analysis of AA6061 and Ti6Al4V fiber laser butt weld. Optik (Stuttg). 148, 151–156 (2017). https://doi.org/10.1016/j.ijleo.2017.08.138

Atabaki, M.M., Yazdian, N., Kovacevic, R.: Partial penetration laser-based welding of aluminum alloy (AA 5083-H32). Optik (Stuttg). 127, 6782–6804 (2016). https://doi.org/10.1016/j.ijleo.2016.05.007

Akbari, M., Saedodin, S., Panjehpour, A., Hassani, M., Afrand, M., Torkamany, M.J.: Numerical simulation and designing artificial neural network for estimating melt pool geometry and temperature distribution in laser welding of Ti6Al4V alloy. Optik (Stuttg). 127, 11161–11172 (2016). https://doi.org/10.1016/j.ijleo.2016.09.042

Chen, S., Li, L., Chen, Y., Huang, J.: Joining mechanism of Ti/Al dissimilar alloys during laser welding-brazing process. J. Alloys Compd. 509, 891–898 (2011). https://doi.org/10.1016/j.jallcom.2010.09.125

CHEN, S., LI, L., CHEN, Y., LIU, D.: Si diffusion behavior during laser welding-brazing of Al alloy and Ti alloy with Al-12Si filler wire. Trans. Nonferrous Met. Soc. China. 20, 64–70 (2010). https://doi.org/10.1016/S1003-6326(09)60098-4

Chen, Y., Chen, S., Li, L.: Effects of heat input on microstructure and mechanical property of Al/Ti joints by rectangular spot laser welding-brazing method. Int. J. Adv. Manuf. Technol. 44, 265–272 (2009). https://doi.org/10.1007/s00170-008-1837-2

Chen, Y., Chen, S., Li, L.: Influence of interfacial reaction layer morphologies on crack initiation and propagation in Ti/Al joint by laser welding–brazing. Mater. Des. 31, 227–233 (2010). https://doi.org/10.1016/j.matdes.2009.06.029

Tomashchuk, I., Sallamand, P., Cicala, E., Peyre, P., Grevey, D.: Direct keyhole laser welding of aluminum alloy AA5754 to titanium alloy Ti6Al4V. J. Mater. Process. Technol. 217, 96–104 (2015). https://doi.org/10.1016/j.jmatprotec.2014.10.025

Chen, S., Yang, D., Li, M., Zhang, Y., Huang, J., Yang, J., Zhao, X.: Laser penetration welding of an overlap titanium-on-aluminum configuration. Int. J. Adv. Manuf. Technol. 87, 3069–3079 (2016). https://doi.org/10.1007/s00170-016-8732-z

Chelladurai, A.M., Gopal, K.A., Murugan, S., Venugopal, S., Jayakumar, T.: Energy transfer modes in pulsed laser seam welding. Mater. Manuf. Process. 30, 162–168 (2015). https://doi.org/10.1080/10426914.2014.965829

Majumdar, B., Galun, R., Weisheit, A., Mordike, B.L.: Formation of a crack-free joint between Ti alloy and Al alloy by using a high-power CO2 laser. J. Mater. Sci. 32, 6191–6200 (1997). https://doi.org/10.1023/A:1018620723793

Vaidya, W.V., Horstmann, M., Ventzke, V., Petrovski, B., Koçak, M., Kocik, R., Tempus, G.: Improving interfacial properties of a laser beam welded dissimilar joint of aluminium AA6056 and titanium Ti6Al4V for aeronautical applications. J. Mater. Sci. 45, 6242–6254 (2010). https://doi.org/10.1007/s10853-010-4719-6

Sadrnezhaad, S.K., Shehab, A., Mahmoud, A., Torkamany, M.J., Kokabi, A.H., Fakouri Hasanabadi, M.: Pulsed Nd: YAG laser dissimilar welding of Ti/Al3105 alloys. Sci. Iran. B. 27, 1982–1994 (2020). https://doi.org/10.24200/sci.2019.52217.2600

Shehab, A.A., Sadrnezhaad, S.K., Torkamany, M.J., Fakouri Hasanabadi, M., Alali, M., Mahmoud, A.K., Abass, M.H., Kokabi, A.H.: Ring-like laser spot welding of Ti grade2 to AAl3105-O using AlSiMg filler metal. Optik (Stuttg). 206, 163630 (2020). https://doi.org/10.1016/j.ijleo.2019.163630

ASM: Handbook Volume 2: Properties and selection: nonferrous alloys and special-purpose materials. ASM International, Geauga County (1990)

Okamoto, H., Schlesinger, M.E., Mueller, E.M. (eds.): ASM Handbook Volume 3; Alloy phase diagrams. ASM International, Geauga County (1992)

Davydov, V., Rostova, T., Zakharov, V., Filatov, Y., Yelagin, V.: Scientific principles of making an alloying addition of scandium to aluminium alloys. Mater. Sci. Eng. A. 280, 30–36 (2000). https://doi.org/10.1016/S0921-5093(99)00652-8

Ahmad, Z.: The properties and application of scandium-reinforced aluminum. JOM. 55, 35–39 (2003). https://doi.org/10.1007/s11837-003-0224-6

Totten, G.E., MacKenzie, D.S.: Handbook of Aluminum: vol. 1: Physical Metallurgy and Processes. CRC Press, Boca Raton (2003)

Ion, J.C.: Laser processing of engineering materials: principles, procedure and industrial application. Elsevier, Oxford (2005)

Ready, J.F., Farson, D.F., Feeley, T.: LIA handbook of laser materials processing. Springer-Verlag, Berlin Heidelberg (2001)

Shehab, A.A., Nawi, S.A., Al-Rubaiy, A.A., Hammoudi, Z., Hafedh, S.A., Abass, M.H., Alali, M.S., Ali, S.D.: CO2 laser spot welding of thin sheets AISI 321 austenitic stainless steel. Arch. Mater. Sci. Eng. 2, 68–77 (2020). https://doi.org/10.5604/01.3001.0014.6974

Acknowledgements

Support from the Iran National Centre for Laser Science and Technology, Sharif University of Technology, Iran, Iran National Science Foundation, and Institute of Laser for Postgraduate Studies, University of Baghdad, Iraq is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shehab, A.A., Sadrnezhaad, S.K., Alali, M. et al. Laser Welding of Titanium Grade 2 and Aluminium AA 3105-O Using a New AlScZr Filler Metal. Lasers Manuf. Mater. Process. 9, 37–55 (2022). https://doi.org/10.1007/s40516-021-00159-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-021-00159-x