Abstract

Purpose

To probe the thermal and structural properties of gluten proteins using ultrasound.

Methods

A new ultrasonic approach for characterizing the quality of wheat gluten proteins is described. Low frequency (50 kHz) longitudinal ultrasonic velocity, v L, measurements were performed on gluten samples extracted from three wheat flours differing in protein content and in wheat endosperm hardness.

Results

At room temperature, v L for gluten extracted from soft flowers (Fielder) was found to be (870 ± 92) m/s, while for gluten extracted from extra strong flours (Glenlea) it was found to be (1,940 ± 90) m/s. In the second set of experiments, which aimed at probing thermal properties of gluten proteins, the variation in the numerical value of v L propagating in the wet gluten was found to be substantial (about 1,000 m/s) when the temperature of the gluten was raised from 20 to 90 °C, and also when gluten from different flour types was investigated. A continuous structural phase transition was observed, which was different for glutens extracted from different flours. Upon cooling, the velocity also varied depending on wheat type.

Conclusions

These experiments demonstrate that ultrasonic velocity measurements can be used as a selection tool and study changes in properties of wheat proteins, particularly the thermal transitions that are critical to the quality of end products such as noodles, pasta, and bread. It was also shown that v L is sensitive to gluten class (strength or protein content), showing the potential of such measurements as an early-generation selection tool in wheat breeding programs.

Riassunto

Obiettivo

Sondare le proprietà termiche e strutturali di proteine di glutine che usano l’ultrasuono.

Materiali e Metodi

Un nuovo approccio ultrasonico per caratterizzare la qualità di proteine di glutine di frumento è descritta. La frequenza bassa (50 kHz) la velocità longitudinale ultrasonica, il v L, le misure sono state eseguite sui campioni di glutine estratti da tre farine di frumento che differisce nel contenuto di proteina e nella durezza di endosperm di frumento.

Risultati

Alla temperatura ambiente, il v L per il glutine estratto dai fiori morbidi (l’Esterno) è stato trovato per essere (870 ± 92) il m/s, mentre per il glutine estratto dalle farine extra forti (Glenlea) è stato trovato per essere (1940 ± 90) il m/s. Nella seconda serie di esperimenti, che ha mirato a sondare le proprietà termiche di proteine di glutine, la variazione nel valore numerico di v L che propaga nel glutine bagnato è stata trovata per essere sostanzioso (circa 1000 m/s) quando la temperatura del glutine è stata alzata da 20 a 90 °C ed anche quando il glutine dai tipi di farina diversi sono stati investigati. Una transizione di fase continua strutturale è stata osservata, che era diverso per i glutini estratti dalle farine diverse. Sul raffreddamento, la velocità il tipo di frumento di dipendere da anche vario.

Conclusioni

Questi esperimenti dimostrano che le misure di velocità ultrasoniche possono essere usate come uni cambiamenti di attrezzo di selezione e studio nelle proprietà di proteine di frumento, particolarmente le transizioni termiche che sono critico alla qualità di prodotti finiti come i sempliciotti, la pasta ed il pane. È stato anche mostrato che il v L è sensibile alla classe di glutine (il contenuto di forza o proteina), mostrando il potenziale di tali misure come un attrezzo di selezione di prima-generazione nei programmi di allevare di frumento.

Similar content being viewed by others

References

Du Cros DL (1987) Glutenin proteins and gluten strength in durum wheat. J Cereal Sci 5:3–12

Shewry PR, Tatham AS, Forde J, Kreis M, Miflin BJ (1986) The classification and nomenclature of wheat gluten proteins: a reassessment. J Cereal Sci 4:97–106

Shewry PR, Halford NG, Belton PS, Tatham AS (2002) The structure and properties of gluten: an elastic protein from wheat grain. Philos Trans R Soc Lond B Biol Sci 357:133–142

Payne PI, Nightingale MA, Krattiger AF, Holt LM (1987) The relationship between HMW glutenin subunit composition and the breadmaking quality of British-grown wheat varieties. J Sci Food Agriculture 40:51–65

Shewry PR, Halford NG, Tatham AS (1992) The high molecular weight subunits of wheat glutenin. J Cereal Sci 15:105–120

Kovacs MIP, Dahlke G, Noll JS (1994) Gluten viscoelasticity: its usefulness in the Canadian durum wheat breeding program. J Cereal Sci 19:251–257

Kovacs MIP, Poste LM, Butler G, Woods SM, Leisle D, Noll JS et al (1997) Durum wheat quality: comparison of chemical and rheological screening tests with sensory analysis. J Cereal Sci 25:65–75

Wang C, Kovacs MIP (2002) Swelling index of glutenin test. I. Method and comparison with sedimentation, gel-protein, and insoluble glutenin tests. Cereal Chem 79:183–189

Wang C, Kovacs MIP (2002) Swelling index of glutenin test. II. Application in prediction of dough properties and end-use quality. Cereal Chem 79:190–196

Uthayakumaran S, Newberry M, Phan-Tien N, Tanner R (2002) Small and large strain rheology of wheat gluten. Rheol Acta 41:162–172

Povey MJW (1997) Ultrasonic techniques for fluid characterization. Academic Press, San Diego

Létang C, Piau M, Verdier C, Lefebvre L (2001) Characterization of wheat-flour-water doughs: a new method using ultrasound. Ultrasonics 39:133–141

Elmehdi HM, Page JH, Scanlon MG (2004) Ultrasonic investigation of the effect of mixing under reduced pressure on the mechanical properties of bread dough. Cereal Chem 81:504–510

Beuerlein J (2001) Classes and Uses of Wheat Fact Sheet. http://ohioline.osu.edu/agf-fact/0146.html

WholeHealthMD. http://www.wholehealthmd.com/ME2/Default.asp

US Wheat Associates (2005) Wheat Classes. http://www.uswheat.org/uswPublic2009.nsf/index?OpenPage

Elmehdi HM (2001) An ultrasonic investigation of the effect of voids on the mechanical properties of bread dough and the role of gas cells in determining the cellular structure of freeze-dried breadcrumb, Ph.D. Thesis. University of Manitoba, Canada

Elmehdi HM, Page JH, Scanlon MG (2003) Monitoring dough fermentation using acoustic waves. Trans Inst Chem Eng Part C 81:217–223

Scanlon MG, Elmehdi HM, Page JH (2002) Probing gluten interactions with low-intensity ultrasound. In: Wheat Quality Elucidation, the Bushuk Legacy. AACC Press, St Paul, pp 170–182

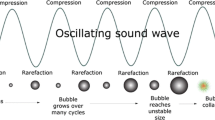

Ensminger D (1988) Ultrasonics: Fundamentals, Technology and Applications.Taylor & Francis Group, CRC Press, FL

Liley D. The Physics of Ultrasound. http://opax.swin.edu.au/~dliley/lectures/het408/ultrasound.pdf

Kidmose U, Pedersen L, Nielsen M (2001) Ultrasonics in evaluating rheological properties of dough from different wheat varieties and during aging. J Texture Studies 32:321–334

Gontard N, Ring S (1996) Edible wheat gluten film: influence of water content on glass transition temperature. J Agric Food Chem 44:3474–3478

Kovacs MIP (1985) An improved sodium dodecyl sulfate-sedimentation test for early generation screening of durum wheat quality. Sciences des Aliments 5:123–131

Mirsky AE (1941) Sulfhydryl groups of egg albumin in different denaturing agents. J Gen Physiol 24:709–723

Langmuir I (1938) Protein denaturation. Cold Spring Harb Symp Quant Biol 6:159

Neurath H, Greenstein JP, Putnam FW, Erickson JO (1944) The chemistry of protein denaturation. Chem Rev 34:157–265

Lumry R, Eyring H (1954) Conformation changes of proteins. J Phys Chem 58:110–120

Bull BH, Breese K (1973) Thermal transitions in proteins. Arch Biochem Biophys 156:604–612

Stellwagen E, Wilgus H (1978) Relationship of protein thermostability to accessible surface area. Nature 275:342–343

Wu YV, Inglett GE (1974) Denaturation of plant proteins. Related to functionality and food applications: a review. J Food Sci 39:218–225

Wolf WJ, Briggs DR (1958) Studies on the cold-insoluble fraction of the water-extractable soybean proteins. II. Factors influencing conformation changes in the 11 S component. Arch Biochem Biophys 76:377–393

Hinrichs J, Rademacher B (2004) High-pressure thermal denaturation kinetics of whey proteins. J Dairy Res 71:480–488

Kovacs MIP, Fu BX, Woods SM, Khan K (2004) Thermal stability of thermal gluten proteins: its effect on dough properties and noodle texture. J Cereal Sci 39:9–19

Hayta M, Schofield J (2004) Heat and additive induced biochemical transitions in gluten from good and poor breadmaking quality wheats. J Cereal Sci 40:245–256

Naeem HA, MacRitchie F (2003) Heat stress effects on wheat proteins during grain development. In: Proceedings of the tenth international wheat genetics symposium, vol 1, pp 455–458

Singh H, MacRitchie F (2004) Changes in proteins induced by heating gluten dispersions at high temperature. J Cereal Sci 39:297–301

Georget DMR, Belton PS (2006) Effects of temperature and water content on the secondary structure of wheat gluten studied by FTIR spectroscopy. Biomacromolecules 7:469–475

Stathopoulos CE, Tsiami AA, Dobraszczyk BJ, Schofield JD (2006) Effect of heat on rheology of gluten fractions from flours with different bread-making quality. J Cereal Sci 43:322–330

Campbell GM, Rielly CD, Fryer PJ, Sadd PA (1998) Aeration of bread dough during mixing: effect of mixing dough at reduced pressure. Cereal Food World 43:163–167

Gaunaurd GC, Uberall H (1981) Resonance theory of bubbly liquids. J Acoust Soc Am 69:362–370

Fairley P, McClements DJ, Povey MJW (1991) Ultrasonic characterization of some aerated foodstuffs. Proc Inst Acoustics 13:63–70

Leighton TG (1994) The acoustical bubble. Academic Press, London

Scanlon MG, Elmehdi HM, Leroy V, Page JH (2008) Using ultrasound to probe nucleation and growth of bubbles in bread dough and to examine the resulting cellular structure of bread crumb. In: Campbell GM, Scanlon, MG, Pyle DL (eds). Bubbles in Foods 2: Novelty, Health and Luxury. AACC Press, St Paul, pp 217–230

Acknowledgments

The authors are grateful to the Natural Sciences and Engineering Research Council of Canada (NSERC), the Cereal Research Centre of Agriculture & Agri-Food Canada and the College of Graduate Studies and Scientific Research at the University of Sharjah, for providing funds for this research.

Conflict of interest

Hussein Mohamed Elmehdi, Martin G. Scanlon, John H. Page, and Miklos I. P. Kovacs declare that they have no conflict of interest.

Informed consent

No patient information was included in this study.

Human and animal studies

The study described in this article did not include any procedures involving humans or animals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elmehdi, H.M., Scanlon, M.G., Page, J.H. et al. Probing thermal transitions and structural properties of gluten proteins using ultrasound. J Ultrasound 16, 101–110 (2013). https://doi.org/10.1007/s40477-013-0022-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40477-013-0022-0