Abstract

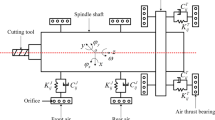

The dynamic characteristics of the gas film of an aerostatic spindle primary affect workpiece waviness in ultra-precision machining. To improve the machining accuracy of the machine tool and provide a firm theoretical basis for the design of an aerostatic spindle, a simulation model combining transient computational fluid dynamics (CFD) analysis and transient dynamic analysis is established in this study to investigate the dynamic characteristics of the spindle under unstable operating conditions. Based on a large eddy simulation, a three-dimensional flow model of an air film in an aerostatic spindle is established. The simulation results show that the gas flow in the throttle chamber is turbulent, and that complex vortices are formed. Using dynamic grid modeling technology, a CFD numerical model for the unsteady calculation of the spindle is established, and the dynamic characteristics of the gas film are obtained. A transient dynamic simulation model of an aerostatic spindle is established, and the effect of the nonlinear dynamic characteristics of the gas film on the spindle displacement response is investigated. Subsequently, a surface morphology prediction model is established. Results show that film fluctuation significantly affects the dynamic characteristics of the spindle and subsequently affects the generation of surface ripples on the workpiece.

Similar content being viewed by others

References

Chen D, Huo C, Cui X et al (2018) Investigation the gas film in micro scale induced error on the performance of the aerostatic spindle in ultra-precision machining. Mech Syst Signal Pr 105:488–501

Cui H, Lei D, Zhang X et al (2019) Measurement and analysis of the radial motion error of aerostatic ultra-precision spindle. Measurement 137:624–635

Cai T, Zhang M, Zhu Y et al (2011) Error modeling and analysis of an ultra-precision stage with an aerostatic bearing. J Tsinghua Univ (Sci & Tech) 51(6):857–861

Zhang SJ, To S, Wang HT (2013) A theoretical and experimental investigation into five-DOF dynamic characteristics of an aerostatic bearing spindle in ultra-precision diamond turning. Int J Mach Tool Manu 71(8):1–10

Chen D, Cui X, Pan R et al (2018) A prediction model of the surface topography due to the unbalance of the spindle system in ultra-precision fly-cutting machining. Adv Mech Eng 10(1):1–11

An C, Deng C, Miao J et al (2018) Investigation on the generation of the waviness errors along feed-direction on flycutting surfaces. Int J Adv Manuf Tech 8:1–9

Lozano-Duran A, Bae HJ (2019) Error scaling of large-eddy simulation in the outer region of wall-bounded turbulence. J Comput Phys 392:532–555

Chen X, Han C, Zhu J et al (2015) Vortex suppression and nano-vibration reduction of aerostatic bearings by arrayed micro-hole restrictors. J Vib Control 32(1):77–78

Zhu J, Chen H, Chen X (2013) Large eddy simulation of vortex shedding and pressure fluctuation in aerostatic bearings. J Fluid Struct 40(7):42–51

Salkhordeh S, Kimber ML (2019) Full-field dependence on inlet modeling of non-isothermal turbulent jets using validated large eddy simulations. J Fluid Eng-T ASME 141(8).

Abbà A, Bonaventura L, Nini M et al (2015) Dynamic models for large eddy simulation of compressible flows with a high order DG method. Comput Fluids 122:209–222

Du J, Zhang G, Liu T et al (2014) Improvement on load performance of externally pressurized gas journal bearings by opening pressure-equalizing grooves. Tribol Int 73(5):156–166

Munoa J, Beudaert X, Dombovari Z et al (2016) Chatter suppression techniques in metal cutting. CIRP Ann-Manuf Techn 65(2):785–808

Uddin MS, Seah KHW, Li XP et al (2004) Effect of crystallographic orientation on wear of diamond tools for nano-scale ductile cutting of silicon. Wear 257(7):751–759

Wang SJ, To S, Cheung CF (2013) An investigation into material-induced surface roughness in ultra-precision milling. Int J Adv Manuf Tech 68(1/4):607–616

Zhang SJ, To S (2013) A theoretical and experimental study of surface generation under spindle vibration in ultra-precision raster milling. Int J Mach Tool Manu 75(12):36–45

Chi FC, Lee WB (2000) A multi-spectrum analysis of surface roughness formation in ultra-precision machining. Precis Eng 24(1):77–87

Chen G, Sun Y, An C et al (2018) Measurement and analysis for frequency domain error of ultra-precision spindle in a flycutting machine tool. P I Mech Eng B-J Eng 232(9):1501–1507

An CH, Zhang Y, Xu Q et al (2010) Modeling of dynamic characteristic of the aerostatic bearing spindle in an ultra-precision fly cutting machine. Int J Mach Tools Manuf 50:374–385

Zhang SJ, To S (2013) A theoretical and experimental investigation into multimode tool vibration with surface generation in ultra-precision diamond turning. Int J Mach Tool Manu 72(18):32–36

Baek DK, Ko TJ, Kim HS (2001) Optimization of feed rate in a face milling operation using a surface roughness model. Int J Mach Tool Manu 41(3):451–462

Cheung CF, Lee WB (2001) Characterisation of nanosurface generation in single-point diamond turning. Int J Mach Tool Manu 41(6):851–875

Chen W, Lu L, Yang K et al (2015) An experimental and theoretical investigation into multimode machine tool vibration with surface generation in flycutting. Proc I Mech E Part B: J Eng Manuf 230:1–6

Boersma BJ, Lele SK (1999) Large eddy simulation of compressible turbulent jets. In: Center for Turbulence Research, Annual Research Briefs, Stanford University, pp 365–377

Yoshimoto S, Suganuma N, Yagi K et al (2007) Numerical calculations of pressure distribution in the bearing clearance of circular aerostatic thrust bearings with a single air supply inlet. J Tribol 129(2):384–390

Chen XD, Zhu JC, Han CS (2013) Dynamic characteristics of ultra-precision aerostatic bearings. Adv Manuf 1(1):82–86

Khajehzadeh M, Razfar MR (2015) FEM and experimental investigation of cutting force during UAT using multicoated inserts. Adv Manuf Processes 30(7):858–867

Acknowledgements

This study was funded by the National Natural Science Foundation of China (Grant Nos. 51875005 and 51475010), and the National Science and Technology Major Project of China (Grant No. 2016ZX04003001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, DJ., Li, SP., Zhang, X. et al. Relationship between dynamic characteristics of air film of aerostatic spindle and mid-frequency of surface topography. Adv. Manuf. 10, 428–442 (2022). https://doi.org/10.1007/s40436-022-00391-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-022-00391-4