Abstract

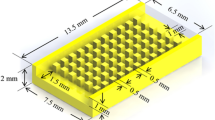

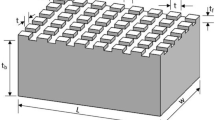

Flow boiling in micro-pin fin structured heat sinks is an up-to-date thermal management technique. However, due to micro-sized flow passages, bubble blockage is a problem for this type of heat sinks, too. In addition, mixing and bubble breakup are important phenomena for enhancement of heat transfer. Taking more advantages of potential of this unique technique depends on removing of relevant shortcomings and supporting influential mechanisms; therefore, new geometries being designed based on bubble-dynamic characteristics should be developed, and relevant thermo-hydrodynamic characteristics should be analyzed. Therefore, the present paper experimentally analyzes boiling performance of water flow in a micro-pin fin heat sink having a new type of geometry. The heat sink has four sections, and in each section, the micro-fins are positioned in staggered form according to previous sections, also the number of fins in each section is fewer than the one of the former sections. In this paper, for the first time in the literature, combined influence of regional staggered pin fin arrangement and regional cross-sectional enlargement on thermo-hydrodynamic characteristics of flow boiling in micro-pin fin heat sinks is investigated. The new type of heat sink (NT) is compared with conventional type (CT) in which the micro-pin fins are uniformly located throughout the heat sink. Saturated flow boiling experiments are conducted at a heat flux range of 132–272 kW m−2 (90 W to 180 W with 10 W increments), and at a constant mass velocity of 174 kg m−2 s−1 for constant inlet temperature of 75 °C. It is concluded that staggered pin fins with decreasing number significantly boost thermal and flow characteristics. Compared to the conventional type, two-phase heat transfer coefficient increases up to 94.5%, and pressure drop decreases up to 18.3% via NT. The wall superheat for NT is lower than those obtained for CT for the whole database, which physically means that NT keeps the heating surface at lower temperature for the same heat load. Prevention of bubble blockage problem, suppression of flow reversal, enhancement of bubble disjunction, decrease of vapor-waiting time on heat transfer surface, and more effective convective boiling characteristics are the main underlying reasons of performance enhancement.

Similar content being viewed by others

Abbreviations

- \({\text{CT}}\) :

-

Conventional micro-pin fin heat sink

- \({\text{NT}}\) :

-

Novel type micro-pin fin heat sink

- \(A_{{{\text{fn}}}}\) :

-

Wetted area of a single fin, m2

- \(A_{{{\text{hw}}}}\) :

-

Total heat transfer area, m2

- \(A_{{{\text{nf}}}}\) :

-

Area without fins at bottom of channels, m2

- \(A_{{{\text{pt}}}}\) :

-

Top platform area of heating piece, m2

- \(d_{L}\) :

-

Distance from inlet of the channels to any desired location, m

- \(L_{h}\) :

-

Heating length, m

- \(q_{{{\text{hl}}}}\) :

-

Heat loss, W

- \(q_{{{\text{hp}}}}\) :

-

Heating power, W

- \(T\) :

-

Temperature, K

- \(T_{{{\text{em}}}}\) :

-

Mean temperature of heat sink, K

- \(W_{h}\) :

-

Heating width, m

- \(a\) :

-

Ambient

- \({\text{ch}}\) :

-

Channel

- \({\text{cl}}\) :

-

Constriction

- \({\text{er}}\) :

-

Expansion

References

Karayiannis TG, Mahmoud MM (2017) Flow boiling in microchannels: fundamentals and applications. Appl Therm Eng 115:1372–1397. https://doi.org/10.1016/j.applthermaleng.2016.08.063

Markal B, Aydin O, Avci M (2012) Exergy analysis of a counter-flow Ranque-Hilsch vortex tube having different helical vortex generators. Int J Exergy 10:228–238. https://doi.org/10.1504/IJEX.2012.045867

Nuntadusit C, Wae-hayee M, Kaewchoothong N (2018) Heat transfer enhancement on a surface of impinging jet by increasing entrainment using air-augmented duct. Int J Heat Mass Transf 127:751–767. https://doi.org/10.1016/j.ijheatmasstransfer.2018.06.130

Markal B (2019) The effect of total flowrate on the cooling performance of swirling coaxial impinging jets. Heat Mass Transf und Stoffuebertragung 55:3275–3288. https://doi.org/10.1007/s00231-019-02653-7

Gupta NK, Sharma A, Rathore PKS, Verma SK (2020) Thermal performance optimization of heat pipe using nanofluid: response surface methodology. J Braz Soc Mech Sci Eng 42:590. https://doi.org/10.1007/s40430-020-02668-w

Domiciano KG, Krambeck L, Flórez JPM, Mantelli MBH (2022) Thin diffusion bonded flat loop heat pipes for electronics: fabrication, modelling and testing. Energy Convers Manag. https://doi.org/10.1016/j.enconman.2022.115329

Lee PC, Pan C (2008) Boiling heat transfer and two-phase flow of water in a single shallow microchannel with a uniform or diverging cross section. J Micromech Microeng. https://doi.org/10.1088/0960-1317/18/2/025005

Lu CT, Pan C (2008) Stabilization of flow boiling in microchannel heat sinks with a diverging cross-section design. J Micromech Microeng. https://doi.org/10.1088/0960-1317/18/7/075035

Lu CT, Pan C (2011) Convective boiling in a parallel microchannel heat sink with a diverging cross section and artificial nucleation sites. Exp Therm Fluid Sci 35:810–815. https://doi.org/10.1016/j.expthermflusci.2010.08.018

Fu BR, Tsou MS, Pan C (2012) Boiling heat transfer and critical heat flux of ethanol-water mixtures flowing through a diverging microchannel with artificial cavities. Int J Heat Mass Transf 55:1807–1814. https://doi.org/10.1016/j.ijheatmasstransfer.2011.11.051

Fu BR, Lin PH, Tsou MS, Pan C (2012) Flow pattern maps and transition criteria for flow boiling of binary mixtures in a diverging microchannel. Int J Heat Mass Transf 55:1754–1763. https://doi.org/10.1016/j.ijheatmasstransfer.2011.11.030

Wan W, Deng D, Huang Q et al (2017) Experimental study and optimization of pin fin shapes in flow boiling of micro pin fin heat sinks. Appl Therm Eng 114:436–449. https://doi.org/10.1016/j.applthermaleng.2016.11.182

Deng D, Zeng L, Sun W et al (2021) Experimental study of flow boiling performance of open-ring pin fin microchannels. Int J Heat Mass Transf 167:120829. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120829

Lie YM, Ke JH, Chang WR et al (2007) Saturated flow boiling heat transfer and associated bubble characteristics of FC-72 on a heated micro-pin-finned silicon chip. Int J Heat Mass Transf 50:3862–3876. https://doi.org/10.1016/j.ijheatmasstransfer.2007.02.010

Krishnamurthy S, Peles Y (2008) Flow boiling of water in a circular staggered micro-pin fin heat sink. Int J Heat Mass Transf 51:1349–1364. https://doi.org/10.1016/j.ijheatmasstransfer.2007.11.026

Ma A, Wei J, Yuan M, Fang J (2009) Enhanced flow boiling heat transfer of FC-72 on micro-pin-finned surfaces. Int J Heat Mass Transf 52:2925–2931. https://doi.org/10.1016/j.ijheatmasstransfer.2009.02.031

Qu W, Siu-Ho A (2009) Experimental study of saturated flow boiling heat transfer in an array of staggered micro-pin-fins. Int J Heat Mass Transf 52:1853–1863. https://doi.org/10.1016/j.ijheatmasstransfer.2008.10.008

Law M, Lee PS (2015) A comparative study of experimental flow boiling heat transfer and pressure characteristics in straight- and oblique-finned microchannels. Int J Heat Mass Transf 85:797–810. https://doi.org/10.1016/j.ijheatmasstransfer.2015.01.137

Law M, Lee PS (2016) Effects of varying secondary channel widths on flow boiling heat transfer and pressure characteristics in oblique-finned microchannels. Int J Heat Mass Transf 101:313–326. https://doi.org/10.1016/j.ijheatmasstransfer.2016.05.055

Deng D, Chen L, Wan W et al (2019) Flow boiling performance in pin fin- interconnected reentrant microchannels heat sink in different operational conditions. Appl Therm Eng 150:1260–1272. https://doi.org/10.1016/j.applthermaleng.2019.01.092

Chien LH, Liao WR, Ghalambaz M, Yan WM (2019) Experimental study on convective boiling of micro-pin-finned channels with parallel arrangement fins for FC-72 dielectric fluid. Int J Heat Mass Transf 138:390–400. https://doi.org/10.1016/j.ijheatmasstransfer.2019.04.072

Qin L, Li S, Zhao X, Zhang X (2021) Experimental research on flow boiling characteristics of micro pin-fin arrays with different hydrophobic coatings. Int Commun Heat Mass Transf 126:105456. https://doi.org/10.1016/j.icheatmasstransfer.2021.105456

Lee PS, Garimella SV (2008) Saturated flow boiling heat transfer and pressure drop in silicon microchannel arrays. Int J Heat Mass Transf 51:789–806. https://doi.org/10.1016/j.ijheatmasstransfer.2007.04.019

Cui P, Liu Z (2023) Experimental study on flow boiling in ultrahigh-aspect-ratio copper microchannel heat sink. Appl Therm Eng 223:119975. https://doi.org/10.1016/j.applthermaleng.2023.119975

Balasubramanian K, Lee PS, Teo CJ, Chou SK (2013) Flow boiling heat transfer and pressure drop in stepped fin microchannels. Int J Heat Mass Transf 67:234–252. https://doi.org/10.1016/j.ijheatmasstransfer.2013.08.023

Law M, Lee PS, Balasubramanian K (2014) Experimental investigation of flow boiling heat transfer in novel oblique-finned microchannels. Int J Heat Mass Transf 76:419–431. https://doi.org/10.1016/j.ijheatmasstransfer.2014.04.045

Mirmanto M (2014) Heat transfer coefficient calculated using a linear pressure gradient assumption and measurement for flow boiling in microchannels. Int J Heat Mass Transf 79:269–278. https://doi.org/10.1016/j.ijheatmasstransfer.2014.08.022

Deng D, Tang Y, Liang D et al (2014) Flow boiling characteristics in porous heat sink with reentrant microchannels. Int J Heat Mass Transf 70:463–477. https://doi.org/10.1016/j.ijheatmasstransfer.2013.10.057

Qu W, Mudawar I (2003) Measurement and prediction of pressure drop in two-phase micro-channel heat sinks. Int J Heat Mass Transf 46:2737–2753. https://doi.org/10.1016/S0017-9310(03)00044-9

Markal B, Kul B (2022) Combined influence of artificial nucleation site and expanding cross section on flow boiling performance of micro pin fins. Int Commun Heat Mass Transf 135:106081. https://doi.org/10.1016/j.icheatmasstransfer.2022.106081

Markal B, Kul B, Avci M, Varol R (2022) Effect of gradually expanding flow passages on flow boiling of micro pin fin heat sinks. Int J Heat Mass Transf 197:123355. https://doi.org/10.1016/j.ijheatmasstransfer.2022.123355

Kline SJ, McClintock FA (1953) Describing uncertainties in single-sample experiments. Mech Eng 75:3–8

Kandlikar SG (2004) Heat transfer mechanisms during flow boiling in microchannels. J Heat Transfer 126:8–16. https://doi.org/10.1115/1.1643090

Lee HJ, Liu DY, Yao SC (2010) Flow instability of evaporative micro-channels. Int J Heat Mass Transf 53:1740–1749. https://doi.org/10.1016/j.ijheatmasstransfer.2010.01.016

Acknowledgements

This study was conducted with the support of The Scientific and Technological Research Council of Turkey (TUBITAK). Number of the project is 219M142. Therefore, thanks to TUBITAK.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest. All authors of present paper declared this statement.

Additional information

Technical Editor: Guilherme Ribeiro.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Markal, B., Kul, B. Effect of a new type staggered pin fin configuration on flow boiling characteristics of micro-heat sinks. J Braz. Soc. Mech. Sci. Eng. 45, 552 (2023). https://doi.org/10.1007/s40430-023-04483-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04483-5