Abstract

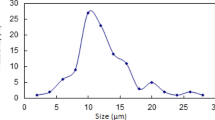

Progress in composite materials is leading to new research lines in this field, creating analytical models to study their mechanical behaviour, improving manufacturing procedures or trying to improve the problems that appear at the matrix-particle interface. The material to be studied consists of a nickel alloy-based metal matrix reinforced with Silicon Nitride particles (Si3N4). According to the manufacturer's data, the particle fraction is 12% of the total volume of the material. The data used are the results of a microscopic analysis carried out on a series of specimens to establish the following concepts: mean size, size distribution and generic dimensions of the particles; distribution, orientation and orientation trends of the particles in the matrix; existence or not of clusters and probability of breakage, among others. The main objective of the research, to determine the influence of the geometry of the reinforcement particles on the mechanical behaviour of a composite material. It is concluded that the slenderness of the reinforcement particles influences the material properties by making these particles break more easily. In addition, the stress–strain graphs also show that their slenderness influences the stress and strain field, the elongated shape means that the reinforcement is located closer to the point of load application and, consequently, is subject to higher stresses due to the smaller amount of matrix it possesses.

Similar content being viewed by others

References

Gan YX (2009) Effect of interface structure on mechanical properties of advanced composite materials. Int J Mol Sci. https://doi.org/10.3390/ijms10125115

Ye S, Li B, Li Q, Zhao HP, Feng XQ (2019) Deep neural network method for predicting the mechanical properties of composites. Appl Phys Lett. https://doi.org/10.1063/1.5124529

Kumar K, Davim JP (2018) Composites and advanced materials for industrial applications. In: Kumar K, Davim JP (eds) Composites and advanced materials for industrial applications. IGI Global, Hershey, pp 1–402. https://doi.org/10.4018/978-1-5225-5216-1

Miracle DB (2005) Metal matrix composites—from science to technological significance. Compos Sci Technol 65(15–16):2526–2540. https://doi.org/10.1016/j.compscitech.2005.05.027

Yamamoto K, Hirayama T, Tanji T (2013) Development of advanced electron holographic techniques and application to industrial materials and devices. J Electron Microsc. https://doi.org/10.1093/jmicro/dft006

Sharma V, Ghose J, Kumar S (2012) Compressive and acoustic behavioural analysis of AL-MMC foam for industrial applications. J Inst Eng (India) Ser C 93(1):33–40. https://doi.org/10.1007/s40032-011-0008-7

Magri M, Adam L, Segurado J (2022) Particle size effects in ductile composites: an FFT homogenization study. J Mech Phys Sol. https://doi.org/10.1016/j.jmps.2021.104759

González-Lezcano RA, Del Río JM (2015) Numerical analysis of the influence of the damping rings’ dimensions on interrupted dynamic tension experiment results. J Strain Anal Eng Des 50(8):594–613. https://doi.org/10.1177/0309324715601550

Saleem M, Toubal L, Zitoune R, Bougherara H (2013) Investigating the effect of machining processes on the mechanical behavior of composite plates with circular holes. Compos A Appl Sci Manuf 55:169–177. https://doi.org/10.1016/j.compositesa.2013.09.002

Hsissou R, Seghiri R, Benzekri Z, Hilali M, Rafik M, Elharfi A (2021) Polymer composite materials: a comprehensive review. Compos Struct. https://doi.org/10.1016/j.compstruct.2021.113640

Peter PI, Oki M, Adekunle AA (2020) A review of ceramic/bio-based hybrid reinforced aluminium matrix composites. Cogent Eng. https://doi.org/10.1080/23311916.2020.1727167

Andrew JJ, Srinivasan SM, Arockiarajan A, Dhakal HN (2019) Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: a critical review. Compos Struct. https://doi.org/10.1016/j.compstruct.2019.111007

Vassilopoulos AP (2020) The history of fiber-reinforced polymer composite laminate fatigue. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2020.105512

Ghazlan A, Ngo TD, Tran P (2018) Influence of geometric and material parameters on the behavior of nacreous composites under quasi-static loading. Compos Struct 183(1):457–482. https://doi.org/10.1016/j.compstruct.2017.05.015

González-Lezcano RA, López-Fernández E, Cesteros-García S, Sanglier-Contreras G (2020) Influence of the fastening between thread–test samples in the stress–strain curves in tensile dynamic tests. J Braz Soc Mech Sci Eng. https://doi.org/10.1007/s40430-019-2131-y

Kurganova YA, Shcherbakov SP, Chen Y, Lopatina YA (2020) Evaluation of the behavior of promising aluminum-matrix composite materials under impact loading conditions. Met Sci Heat Treat 62(1–2):174–178. https://doi.org/10.1007/s11041-020-00531-2

Raju K, Tay TE, Tan VBC (2021) A review of the FE2 method for composites. Multiscale Multidiscip Model Exp Des. https://doi.org/10.1007/s41939-020-00087-x

Monteleone A, Rodonò G, Gagliano A, Sapienza V (2021) SLICE: an innovative photovoltaic solution for adaptive envelope prototyping and testing in a relevant environment. Sustainability. https://doi.org/10.3390/su13168701

Tao R, Rice KD, Djakeu AS, Mrozek RA, Cole ST, Freeney RM, Forster AM (2019) Rheological characterization of next-generation ballistic witness materials for body armor testing. Polymers. https://doi.org/10.3390/polym11030447

Erkan Ö, Işık B, Çiçek A, Kara F (2013) Prediction of damage factor in end milling of glass fibre reinforced plastic composites using artificial neural network. Appl Compos Mater 20(4):517–536. https://doi.org/10.1007/s10443-012-9286-3

Lonkar K, Chang FK (2014) Modeling of piezo-induced ultrasonic wave propagation in composite structures using layered solid spectral element. Struct Health Monit 13(1):50–67. https://doi.org/10.1177/1475921713500514

Doomra VK, Debnath K, Singh I (2015) Drilling of metal matrix composites: experimental and finite element analysis. Proc Inst Mech Eng Part J Eng Manuf 229(5):886–890. https://doi.org/10.1177/0954405414534227

Balasivanandha Prabu S, Karunamoorthy L (2008) Microstructure-based finite element analysis of failure prediction in particle-reinforced metal-matrix composite. J Mater Process Technol 207(1–3):53–62. https://doi.org/10.1016/j.jmatprotec.2007.12.077

Qing H (2014) Finite element analysis of the microstructure-strength relationships of metal matrix composites. Acta Metall Sinica 27(5):844–852. https://doi.org/10.1007/s40195-014-0089-4

Prabu SB, Karunamoorthy L, Kandasami GS (2004) A finite element analysis study of micromechanical interfacial characteristics of metal matrix composites. J Mater Process Technol 153–154(1–3):992–997. https://doi.org/10.1016/j.jmatprotec.2004.04.157

González-Lezcano RA, Del Río Campos JM (2019) Numerical analysis of the influence of the damping rings’ thickness on interrupted dynamic tension results using SiC-reinforced ZC71 magnesium alloy specimens. Mech Sci 10(1):169–186. https://doi.org/10.5194/ms-10-169-2019

Kolsky H (1949) An investigation of the mechanical properties of materials at very high rates of loading. Proc Phys Soc Sect B 62(11):676–700. https://doi.org/10.1088/0370-1301/62/11/302

Lloyd DJ (1994) Particle reinforced aluminium and magnesium matrix composites. Int Mater Rev 39(1):1–23. https://doi.org/10.1179/imr.1994.39.1.1

Field JE, Walley SM, Proud WG, Goldrein HT, Siviour CR (2004) Review of experimental techniques for high rate deformation and shock studies. Int J Impact Eng 30:725–775. https://doi.org/10.1016/j.ijimpeng.2004.03.005

Malaki M, Tehrani AF, Niroumand B, Gupta M (2021) Wettability in metal matrix composites. Metals MDPI AG. https://doi.org/10.3390/met11071034

Hashim J, Looney L, Hashmi MSJ (1999) Metal matrix composites: production by the stir casting method. J Mater Process Technol 92–93:1–7. https://doi.org/10.1016/S0924-0136(99)00118-1

Li N, Liu W, Wang Y, Zhao Z, Yan T, Zhang G, Xiong H (2021) Laser additive manufacturing on metal matrix composites: a review. Chin J Mech Eng. https://doi.org/10.1186/s10033-021-00554-7

Shirvanimoghaddam K, Hamim SU, Akbari MK, Fakhrhoseini SM, Khayyam H, Pakseresht AH, Ghasali E, Zabet M, Munir KS, Jia S, Davim JP (2017) Carbon fiber reinforced metal matrix composites: fabrication processes and properties. Compos Part A Appl Sci Manuf 92:70–96

Yashpal S, Jawalkar CS, Verma AS, Suri NM (2017) Fabrication of aluminium metal matrix composites with particulate reinforcement: a review. Mater Today Proc 4:2927–2936. https://doi.org/10.1016/j.matpr.2017.02.174

Lezcano RG, del Río J (2017) Influence of damping ring material on dynamic tensile tests. Int J Eng Technol 9(2):1107–1120. https://doi.org/10.21817/ijet/2017/v9i2/170902253

Jacquemoud C, Bruyere-Garnier K, Coret M (2007) Methodology to determine failure characteristics of planar soft tissues using a dynamic tensile test. J Biomech 40(2):468–475. https://doi.org/10.1016/j.jbiomech.2005.12.010

Cantı E, Aydın M (2018) Effects of micro particle reinforcement on mechanical properties of 3D printed parts. Rapid Prototyp J 24(1):171–176. https://doi.org/10.1108/RPJ-06-2016-0095

González Lezcano R, Essa YE, Pérez-Castellanos JL (2003) Numerical analysis of interruption process of dynamic tensile tests using a Hopkinson bar. J Phys IV JP 110:565–570. https://doi.org/10.1051/jp4:20020753

Yuan MN, Yang YQ, Li C, Heng PY, Li LZ (2012) Numerical analysis of the stress-strain distributions in the particle reinforced metal matrix composite SiC/6064Al. Mater Des 38:1–6. https://doi.org/10.1016/j.matdes.2011.12.043

Liu Q, Qi FG, Ding HM, Fan XL, Yue Y (2018) Distribution of stress and strain between adjacent particles in particulate reinforced metal matrix composites. Trans Nonferr Metals Soc China 28(11):2314–2323. https://doi.org/10.1016/S1003-6326(18)64876-9

Segurado J, González C, LLorca C (2003) A numerical investigation of the effect of particle clustering on the mechanical properties of composites. Acta Mater 51(8):2355–2369. https://doi.org/10.1016/S1359-6454(03)00043-0

González-Lezcano RA, del Río-Campos JM, Awad Parada T (2023) Influence of thermal residual stresses on the behaviour of metal matrix composite materials. Iran J Sci Technol Trans Mech Eng. https://doi.org/10.1007/s40997-023-00601-9

Acknowledgements

The authors wish to thank the ARIE research group of the

Universidad CEU San Pablo (Madrid, Spain) for facilities and resources provided. The

authors would like to express their gratitude to Carlos III de Madrid Engineering

Department.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None of the authors have conflict of interest associated with this study to report.

Additional information

Technical Editor: Aurelio Araujo.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

González-Lezcano, R.A., del Río-Campos, J.M. & Melero-Tur, S. The influence of particle population geometry and slenderness on the mechanical behaviour of a metal-matrix composite material. J Braz. Soc. Mech. Sci. Eng. 45, 349 (2023). https://doi.org/10.1007/s40430-023-04269-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04269-9