Abstract

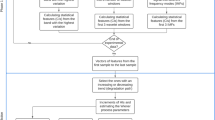

Within the framework of Prognostic and Health Management, an attempt has been made to enhance prediction accuracy of the bearing remaining useful life (RUL) using the adaptive-network-based fuzzy inference system. First, the gray relational analysis has been employed to select the optimal bearing health indicators from 30 vibration features of time, frequency, and time–frequency domains. The selection was based on four criteria, namely correlation, monotonicity, average increase rate, and robustness. This allowed ranking the candidate features in terms of sensitivity to the bearing degradation evolution. The effectiveness of the proposed approach was evaluated on bearing run-to-failure test carried out on a wind turbine. The results of RUL prediction, based on the average of the present and the two previous values of the optimal feature, were very satisfactory, which can effectively optimize the maintenance costs of such equipment.

Similar content being viewed by others

References

Ericsson S, Grip N, Johansson E, Persson L-E, Sjöberg R, Strömberg J-O (2005) Towards automatic detection of local bearing defects in rotating machines. Mech Syst Signal Process 19(3):509–535

Huang R, Xi L, Li X, Liu CR, Qiu H, Lee J (2007) Residual life predictions for ball bearings based on self-organizing map and back propagation neural network methods. Mech Syst Signal Process 21(1):193–207

Liao H, Zhao W, Guo H Predicting remaining useful life of an individual unit using proportional hazards model and logistic regression model. In: RAMS'06. Annual Reliability and Maintainability Symposium, 2006., 2006. IEEE, pp 127–132

Rai A, Upadhyay SH (2018) Intelligent bearing performance degradation assessment and remaining useful life prediction based on self-organising map and support vector regression. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 232 (6):1118-1132

Mahamad AK, Saon S, Hiyama T (2010) Predicting remaining useful life of rotating machinery based artificial neural network. Comput Math Appl 60(4):1078–1087

Medjaher K, Tobon-Mejia DA, Zerhouni N (2012) Remaining useful life estimation of critical components with application to bearings. IEEE Trans Reliab 61(2):292–302

Soualhi A, Clerc G, Razik H, Rivas F Long-term prediction of bearing condition by the neo-fuzzy neuron. In: 2013 9th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), 2013. IEEE, pp 586–591

Ertunc HM, Ocak H, Aliustaoglu C (2013) ANN-and ANFIS-based multi-staged decision algorithm for the detection and diagnosis of bearing faults. Neural Comput Appl 22(1):435–446

Ali JB, Chebel-Morello B, Saidi L, Malinowski S, Fnaiech F (2015) Accurate bearing remaining useful life prediction based on Weibull distribution and artificial neural network. Mech Syst Signal Process 56:150–172

Gougam F, Rahmoune C, Benazzouz D, Varnier C, Nicod J health monitoring approach of bearing : application of adaptive neuro fuzzy inference system (ANFIS) for RUL-estimation and autogram analysis for Fault-Localization. In: 2020 Prognostics and Health Management Conference (PHM-Besançon), 4–7 May 2020 2020. pp 200–206. doi:https://doi.org/10.1109/PHM-Besancon49106.2020.00040

Ahmad W, Khan SA, Islam MM, Kim J-M (2019) A reliable technique for remaining useful life estimation of rolling element bearings using dynamic regression models. Reliab Eng Syst Saf 184:67–76

Chen Y, Peng G, Zhu Z, Li S (2020) A novel deep learning method based on attention mechanism for bearing remaining useful life prediction. Appl Soft Comput 86:105919

Gordon NJ, Salmond DJ, Smith AF Novel approach to nonlinear/non-Gaussian Bayesian state estimation. In: IEE proceedings F (radar and signal processing), 1993. IET, pp 107–113

Qian Y, Yan R (2015) Remaining useful life prediction of rolling bearings using an enhanced particle filter. IEEE Trans Instrum Meas 64(10):2696–2707

Li N, Lei Y, Lin J, Ding SX (2015) An improved exponential model for predicting remaining useful life of rolling element bearings. IEEE Trans Industr Electron 62(12):7762–7773

Yu J (2011) A hybrid feature selection scheme and self-organizing map model for machine health assessment. Appl Soft Comput 11(5):4041–4054

Hu J, Zhang L, Liang W (2013) Dynamic degradation observer for bearing fault by MTS–SOM system. Mech Syst Signal Process 36(2):385–400

Liu Y, He B, Liu F, Lu S, Zhao Y, Zhao J (2016) Remaining useful life prediction of rolling bearings using PSR, JADE, and extreme learning machine. Math Probl Eng 2016:8623530. https://doi.org/10.1155/2016/8623530

Zhang B, Zhang L, Xu J (2016) Degradation feature selection for remaining useful life prediction of rolling element bearings. Qual Reliab Eng Int 32(2):547–554

Guo L, Li N, Jia F, Lei Y, Lin J (2017) A recurrent neural network based health indicator for remaining useful life prediction of bearings. Neurocomputing 240:98–109

Ali JB, Saidi L, Harrath S, Bechhoefer E, Benbouzid M (2018) Online automatic diagnosis of wind turbine bearings progressive degradations under real experimental conditions based on unsupervised machine learning. Appl Acoust 132:167–181

Bechhoefer E High speed bearing data. http://data-acoustics.com/measurements/bearing-faults/bearing-3/

Gopalsamy BM, Mondal B, Ghosh S (2009) Optimisation of machining parameters for hard machining: grey relational theory approach and ANOVA. Int J Adv Manuf Technol 45(11–12):1068

Jang J-S (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern 23(3):665–685

Yan M, Wang X, Wang B, Chang M, Muhammad I (2020) Bearing remaining useful life prediction using support vector machine and hybrid degradation tracking model. ISA Trans 98:471–482

Matlab 7.8 R2009a user manual AtC-TMW, Inc.

Saidi L, Ben Ali J, Benbouzid M, Bechhofer E (2018) An integrated wind turbine failures prognostic approach implementing Kalman smoother with confidence bounds. Appl Acoust 138:199–208. https://doi.org/10.1016/j.apacoust.2018.04.005

Jiang W, Zhou J, Xu Y, Liu J, Shan Y (2019) Multistep degradation tendency prediction for aircraft engines based on CEEMDAN permutation entropy and improved Grey–Markov model. Complexity 2019:1576817. https://doi.org/10.1155/2019/1576817

Meng Z, Li J, Yin N, Pan Z (2020) Remaining useful life prediction of rolling bearing using fractal theory. Measurement 156:107572. https://doi.org/10.1016/j.measurement.2020.107572

Acknowledgements

This work was carried out at the University's LMS laboratory on May 8, 1945, Guelma, Algeria by the team (Coupe des Métaux) as part of a PRFU research project, Code: A11N01UN240120190001. The authors thank the Directorate General of Scientific Research and Technological Development (DGRSDT) of (MESRS) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Technical Editor: Samuel da Silva, Dr.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meddour, I., Messekher, S.E., Younes, R. et al. Selection of bearing health indicator by GRA for ANFIS-based forecasting of remaining useful life. J Braz. Soc. Mech. Sci. Eng. 43, 144 (2021). https://doi.org/10.1007/s40430-021-02878-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-02878-w