Abstract

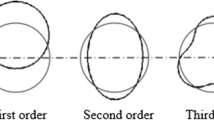

The deformation of cylinder liner directly affects the sealing performance of the friction components in internal combustion engines, resulting in high oil consumption, engine power loss, and high-particulate matter emissions. Previous research works focused more on deformation of the wet vehicular cylinder liners, however, the effects of different loads on the dry liner deformation is not clear yet. A non-road high-pressure common-rail diesel engine was selected as the research object, and a coupled model of the engine was developed based on fluid–solid coupled heat transfer theory. After the accuracy of the model was verified by temperature measurement of the cylinder head and cylinder liner, deformation of the dry cylinder liner was studied. The results show that the axial and radial deformations of the cylinder liner are not uniform under the bolt preload condition. Large deformation occurs at the first liner and fourth liner, with the maximum deformation occurring at the top of fourth liner for 10.14 μm. Under the condition of thermal load, the temperature of cylinder liner exhibits a distribution of three-segments from the top to bottom. The liner deformation is not uniform, and the maximum deformation occurs at the top of the fourth liner for 304 μm. The radial deformations of all four cylinder liners present a symmetrical structure of a “heart” shape with respect to the centerline of the second and third cylinders. The axial deformation of each liner exhibits a “barrel” shape which is convex in the middle and narrow at the two ends.

Similar content being viewed by others

References

Xin Q (2011) Diesel engine system design. Woodhead, Cambridge

Bi Y et al (2013) Study on cylinder liner pretightening deformation and influence of structure factors on it. Chin Intern Combust Engine Eng 34:62–68. https://doi.org/10.13949/j.cnki.nrjgc.2013.05.015

Green GW, Engelstad RL (1993) A Technique for the analysis of cylinder liner vibrations and cavitation. SAE Technical Paper, No. 930582, https://doi.org/10.4271/930582

Alshwawra A et al (2020) Enhancing the geometrical performance using initially conical cylinder liner in internal combustion engines-a numerical study. Appl Sci Basel. https://doi.org/10.3390/app10113705

Lu SL et al (2014) Simulation study on the centrifugal casting wet-type cylinder liner based on ProCAST. Appl Therm Eng 73:512–521. https://doi.org/10.1016/j.applthermaleng.2014.07.073

Kumar V, Sinha SK, Agarwal AK (2019) Wear evaluation of engine piston rings coated with dual layer hard and soft coatings. J Tribol Trans ASME. https://doi.org/10.1115/1.4041762

Özkan D, Sulukan E (2018) The anti-wear efficiency of boron succinimide on engine cylinder liner and piston ring surfaces. J Braz Soc Mech Sci Eng. https://doi.org/10.1007/s40430-018-1014-y

Wang X et al (2020) Study on the coolant pressure of internal combustion engines through vibro-acoustical analysis of a real cylinder block structure. J Braz Soc Mech Sci Eng. https://doi.org/10.1007/s40430-020-2204-y

Suzuki T, Yaguchi H (2019) Study on ring conformability under bore deformation. SAE Technical Paper 2019-01-2334. https://doi.org/10.4271/2019-01-2334

Fernandes W, et al (2020) Effect of aged oils on ring-liner wear. SAE Technical Paper 04-13-02-0010. https://doi.org/10.4271/04-13-02-0010

Wang TJ, Kim DS, Ahn TS (2017) Simulation study on improving the selective catalytic reduction efficiency by using the temperature rise in a non-road transient cycle. Proc Inst Mech Eng Part D J Autom Eng. https://doi.org/10.1177/0954407016664620

Barbieri SG, et al (2019) A simplified methodology for the analysis of the cylinder liner bore distortion: finite element analyses and experimental validations. SAE Technical Paper 2019-24-0164. https://doi.org/10.4271/2019-24-0164

Jiang YK et al (2015) 3d EHD lubrication and wear for piston ring-cylinder liner on diesel engines. Int J Autom Technol 16:1–15. https://doi.org/10.1007/s12239-015-0001-x

Grabon W et al (2013) Improving tribological behaviour of piston ring-cylinder liner frictional pair by liner surface texturing. Tribol Int 61:102–108. https://doi.org/10.1016/j.triboint.2012.11.027

Johansson S et al (2008) New cylinder liner surfaces for low oil consumption. Tribol Int 41:854–859. https://doi.org/10.1016/j.triboint.2008.02.012

Lan L, Xiang J, He L (2015) Deformation characteristics of diesel engine cylinder liner under pre-tightening condition. Trans CSICE 33:555–561. https://doi.org/10.16236/j.cnki.nrjxb.201506079

Ghasemi A (2012) CAE simulations for engine block bore distortion. SAE Technical Paper 2012-01-1320. https://doi.org/10.4271/2012-01-1320

Mohammed UA, et al (2015) Analysis of parameters affecting liner bore distortion in DI diesel engines. SAE Technical Paper, No. 2015-26-0178. https://doi.org/10.4271/2015-26-0178

Usman A, Cheema TA, Park CW (2015) Tribological performance evaluation and sensitivity analysis of piston ring lubricating film with deformed cylinder liner. Proc Inst Mech Engineers Part J J Eng Tribol 229:1455–1468. https://doi.org/10.1177/1350650115581029

Patwardhan M, et al (2015) Use of non linear analysis in powertrain design for prediction of cylinder bore distortion, design changes for reduction along with experimental validation. SAE Technical Paper, No. 2015-26-0202. https://doi.org/10.4271/2015-26-0202

Cheng J et al (2016) Blow-by and tribological performance of piston ring pack during cold start and warm idle operations. Sci China Tech Sci. https://doi.org/10.1007/s11431-016-6021-6

Bi Y et al (2014) Study on cylinder liner hot deformation of turbocharged inter-cooled diesel engine. Trans Chin Soc Agric Eng 30:34–41. https://doi.org/10.3969/j.issn.1002-6819.2014.07.005

Guan L et al (2013) Simulation and test comparison for internal combustion engine cylinder liner deformation. Trans CSICE 31:473–479. https://doi.org/10.16236/j.cnki.nrjxb.2013.05.015

Yang Z, Li B, Yu T (2016) Distortion optimization of engine cylinder liner using spectrum characterization and parametric analysis. Math Probl Eng. https://doi.org/10.1155/2016/9212613

Marathe AV, Venkatachalam G, Marathe NV (2018) Cylinder head bolt tightening strategies in case of multi-cylinder engines and its effect on gasket sealing performance, bore deformation and piston ring conformability. Aust J Mech Eng. https://doi.org/10.1080/14484846.2018.1523292

Liang X, et al (2017) Investigation on cylinder bore deformation under static condition based on fourier decomposition. SAE Technical Paper, No. 2017-01-0366. https://doi.org/10.4271/2017-01-0366

Bi Y et al (2015) Study on deformation of diesel engine cylinder liner under different loads. Chin Intern Combus Engine Eng 36:130–139. https://doi.org/10.13949/j.cnki.nrjgc.2015.03.022

Ruan D, Xu J, Gao X (2015) Effects of piston elastic deformation on piston secondary motion and skirt lubrication characteristics. Trans Chin Soc Agric Eng 31:63–68. https://doi.org/10.3969/j.issn.1002-6819.2015.04.009

Lu X et al (2018) Analysis of lubrication model between piston rings and cylinder liner considering structural dynamic deformation. Lubr Eng 43:70–75. https://doi.org/10.3969/j.issn.0254-0150.2018.05.012

Lu Y et al (2018) Evaluation on the tribological performance of ring/liner system under cylinder deactivation with consideration of cylinder liner deformation and oil supply. PLoS ONE 13(9):e0204179. https://doi.org/10.1371/journal

Siemens Industry Software Inc., Siemens NX, 2013, User Guide

Altair Engineering, Inc., HyperWorks, 2014, Desktop User Guides

ANSYS, Inc., ANSYS, 2017, Users Guide

Xiang R et al (2015) Study on influencing factors to the cylinder liner pre-tightening deformation of turbocharged inter-cooled diesel engine. J Mech Strength 37:682–688. https://doi.org/10.16579/j.issn.1001.9669.2015.04.033

Mikami S, Ogino K, Sorazawa M (2010) Development of evaluation method for low-cycle fatigue breakdown on HSDI diesel cylinder head. SAE Technical Paper, No. 2010-01-0695. https://doi.org/10.4271/2010-01-0695

Gamma Technologies, LLC., GT-SUITE, 2016, Tutorials

Bi Y (2012) Research on mechanical characteristics and deformation of diesel engine cylinder liner. Kunming University of Science and Technology Technical Report

Acknowledgements

The authors are grateful for the support given by the National Natural Science Foundation of China (51765025), Yunnan Province Key Project of Fundamental Research (2018FA030), and Yunnan Province Innovation Team.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bi, Y., Wang, P., Luo, L. et al. Analysis of out-of-round deformation of a dry cylinder liner of a non-road high-pressure common-rail diesel engine based on multi-field coupling. J Braz. Soc. Mech. Sci. Eng. 43, 50 (2021). https://doi.org/10.1007/s40430-020-02737-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02737-0