Abstract

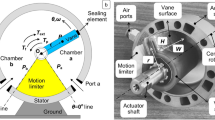

In this paper, the problem of modeling a pneumatic semi-rotary actuator for precise control in the presence of friction for future robotic manipulator applications is addressed. Precise commercial pneumatic components have become increasingly available and are widely applied in the processes and manufacturing industry. The robustness of pneumatic actuator solutions is limited by the precision of the system controller positioning, which depends on sophisticated algorithms that must deal with the highly nonlinear nature of the pneumatic system operation by means of the use of controllers that require suitable system knowledge. In this study, aiming at obtaining such a suitable model for a class of pneumatic semi-rotary actuator, the pressure dynamics in its chambers is modeled. The overall modeling task involves a detailed experimental identification of the curves of the mass flow rate related to the control voltage of the servovalve and its relationship with the pressures in the piston chambers. Moreover, friction was formulated with the LuGre model on account of its ability to represent different effects that comprise friction phenomena, including Coulomb, viscous and static friction effects, resulting in a comprehensive mathematical model for supporting future development of a nonlinear controller. Finally, validation in open loop was performed with comparisons between experimental and simulation results.

Adapted from Festo Corporation [33]

Adapted from Festo Corporation [33]

Similar content being viewed by others

References

Beater P (2007) Pneumatic drives. Springer, Berlin

Abry F, Brun X, Sesmat S, Bideaux E (2013) Non-linear position control of a pneumatic actuator with closed-loop stiffness and damping tuning. In: 2013 European control conference (ECC), pp 1089–1094. IEEE

Cukla AR (2012). Arquitetura Microcontrolada Programável Aplicada ao Controle de um Servoposicionador Pneumático. Dissertation (Master’s Degree in Mechanical Engineering), Post-Graduate Program in Mechanical Engineering, UFRGS (in Portuguese)

Mao XT, Yang QJ, Wu JJ, Bao G (2009) Control strategy for pneumatic rotary position servo systems based on feed forward compensation pole-placement self-tuning method. J Cent South Univ Technol 16(4):608–613

Perondi EA (2002) Controle Não-Linear em Cascata de um Servoposicionador Pneumático com Compensação do Atrito. Thesis (PhD in Mechanical Engineering), Technological Center, Federal University of Santa Catarina, Florianópolis—SC (in Portuguese)

Perondi EA, Guenther R (2003) Modelagem de um servoposicionador pneumático com atrito. Science & Engineering. Uberlândia 12(1):43–52 (in Portuguese)

Sarmanho CAC (2014) Desenvolvimento de um Robô Pneumático de 5 Graus de Liberdade com Controlador Não Linear com Compensação de Atrito. PhD Thesis, Federal University of Rio Grande do Sul—UFRGS (in Portuguese)

Sobczyk SMR (2009) Controle em cascata e a estrutura variável com adaptação de parâmetros e compensação de atrito de um servoposicionador pneumático. Thesis (PhD in Mechanical Engineering)—UFRGS—Post-Graduation Program in Mechanical Engineering (in Portuguese)

Pandian, SR, Takemura, F, Hayakawa, Y, Kawamura S (1999) Control performance of an air motor: can air motors replace electric motors? In: Conferences on robotics and automation. IEEE, vol 1, pp 518–524

Bobrow JE, McDonell BWM (1998) Modeling, identification, and control of a pneumatically actuated, force controllable robot. IEEE Trans Robot Autom 14:732–742

Guenther R, Perondi EA (2001) The cascade control of a pneumatic positioning system. In: Proceedings of the 16th Brazilian congress of mechanical engineering—COBEM2001. Uberlândia, MG, Brazil

McDonell, BW (1996) Modeling, identification, and control of a pneumatically actuated robotic manipulator. PhD. Thesis, University of California, Irvine

Endler L, De Negri VJ (2013) A scheme for compressed air saving in pneumatic positioning systems for high loads. In: 13th Scandinavian international conference on fluid power; June 3–5; 2013; Linköping; Sweden (No 092, pp 485–494). Linköping University Electronic Press

Merritt HE (1967) Hydraulic control systems. Wiley, New York

Papoutsidakis M, Tseles D, Malatestas P (2015) A comparative study of controlling a pneumatic conveying system with a multifunctional interface and simulation. Int J Sustain Energ Dev 4(1). https://doi.org/10.20533/ijsed.2046.3707.2015.0026

Marumo R, Tokhi MO (2003) Modelling and control of a pneumatic motor using neural networks. In: Proceedings of the 2003. The first African Control Conference

Wang J, Yang L, Luo X, Mangan S, Derby JW (2011) Mathematical modeling study of scroll air motors and energy efficiency analysis—part I. IEEE/ASME Trans Mechatron 16(1):112–121

Wang J, Luo X, Yang L, Shpanin LM, Jia N, Mangan S, Derby JW (2011) Mathematical modeling study of scroll air motors and energy efficiency analysis—part II. IEEE/ASME Trans Mechatron 16(1):122–132

Wang J, Pu J, Moore PR, Zhang Z (1998) Modelling study and servo-control air motor systems. Int J Control 17:459–476

Cabral ELL, Hunold MC (1999) Mathematical model of an air vane pneumatic motor. COBEM—XV Brazilian congress of mechanical engineering, São Paulo

Hunold MC, Cabral ELL (2001) Control design of a rotating pneumatic positioning system. COBEM—16th Brazilian congress of mechanical engineering, São Paulo

Blagojevic VA, Jankovic PL (2016) Advantages of restoring energy in the execution part of pneumatic system with semi-rotary actuator. Therm Sci 20

Richard E, Scavarda S (1996) Comparison between linear and nonlinear control of an electropneumatic servodrive. ASME J Dyn Syst Meas Control 118(2):245–252

Belgharbi M, Sesmat S, Scavarda S, Thomasset D (1999) Analytical model of the flow stage of a pneumatic servo-distributor for simulation an nonlinear control. In: SICFP, vol 2, pp 847–860

Thomasset D, Bouri M (2001) Sliding control of an electropneumatic actuator using an integral switching surface. IEEE Trans Control Syst Technol 9(2):368–375

Guenther R, Perondi, EA, Pieri, E R Di, Valdiero, AC (2006). Cascade controlled pneumatic positioning system with Lugre model based friction compensation. J Braz Soc Mech Eng Rio de Janeiro Brazil XXVIII(1):48–57

Suzuki RM (2010) Controle baseado em linearização por realimentação dos estados aplicado a um servoposicionador pneumático. Dissertation (Master’s degree in mechanical engineering)—UFRGS—Post-Graduate Program in Mechanical Engineering. (in Portuguese)

Belforte G, Raparelli T (1997) Friction analysis of pneumatic semi-rotary actuators. Tribol Trans 40(1):57–62

Canudas de Wit C, Olsson H, Astrom KJ, Lischinsky P (1995) New model for control systems with friction. IEEE Trans Autom Control 40:419–425

Lischinsky P, Canudas de Wit C, Morel G (1999) Friction compensation for an industrial hydraulic robot. IEEE Control Systems, February, 25–32

Valdiero AC, Ritter CS, Rios CF, Rafikov M (2011) Nonlinear mathematical modeling in pneumatic servo position applications. Math Probl Eng. https://doi.org/10.1155/2011/472903

Falcão Carneiro J, Gomes de Almeida F (2014) Accurate motion control of a servopneumatic system using integral sliding mode control. Int J Adv Manuf Technol 77(9):1533–1548

Festo Corporation (2017) Festo electronic catalog 2015. Worldwide version 9.08. www.festo.com. Accessed April

Frasson M (2007) Projeto de um Robô Cartesiano com Acionamento Pneumático. Post-Graduation Program in Mechanical Engineering, Dissertation (Master in Mechanical Engineering)—UFRGS. (in Portuguese)

Andersen BW (1967) The analysis and design of pneumatic systems. Wiley, New York

Fox RW, McDonald AT (1998) Introduction to fluid mechanics. Wiley, New York

Virvalo T (1995) Modeling and design of a pneumatic position servo system realized with commercial components. PhD Thesis, Tempere, Finland

Göettert M, Neumann R (1999). Nichtlineare Regelungskonzepte für Servopneumatische Roboter. In Deutsch-Polnisches Seminar Inovation und Fortschritt in der Fluidtechnik, Zakopane, Poland

Brun X, Thomasset D (2000). Choice of control law in electropneumatics. Expertise using an industrial benchmark and some new trends. In: Proceedings of the 39th IEEE conference on decision and control, 2000, vol 2, pp 1323–1328. IEEE

Chang H, Lan CW, Chen CH, Tsung TT, Guo JB (2012) Measurement of frictional force characteristics of pneumatic cylinders under dry and lubricated conditions. Przegląd Elektrotechniczny 88:261–264

Streeter VL (1981) Fluid mechanics. McGraw-Hill, São Paulo

Barabanov N, Ortega R (2000) Necessary and sufficient conditions for passivity of the LuGre friction model. IEEE Trans Autom Control 45:830–832

Carneiro JF, Almeida FG (2006) Reduced order thermodynamic models for servopneumatic actuator chambers. Proc Inst Mech Eng Part I J Syst Control Eng 220(4):301–314

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Victor Juliano De Negri, D.Eng.

Rights and permissions

About this article

Cite this article

Schlüter, M.S., Perondi, E.A. Mathematical modeling of pneumatic semi-rotary actuator with friction. J Braz. Soc. Mech. Sci. Eng. 40, 523 (2018). https://doi.org/10.1007/s40430-018-1434-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1434-8