Abstract

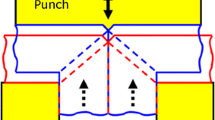

The AZ80 magnesium (Mg) alloy cabin component with high strength and excellent ductility was developed by W-shaped channel extrusion (WCE) at 350 °C and subsequent T6 heat treatment. The effect of WCE process on the microstructure and mechanical properties of the alloy was experimentally investigated, and the age-hardening behavior with microstructure evolution during heat treatment was revealed. Due to the introduction of multi-stage asymmetric extrusion and severe shear deformation along the annular channel, the average grain size of the WCE extruded alloy could be effectively refined to 4.7 μm. Besides, the β phase particles were dynamically precipitated from the fine grain boundaries during extrusion, which hindered the grain growth, but worsen the material plasticity. After T6 treatment, the properties of component were eventually improved to a yield strength (YS) of 218 MPa and ultimate tensile strength (UTS) of 344 MPa with elongation (EL) of 14.5%. It was revealed that the rod/lath- and needle-shaped continuous β phase (CP) with finer size precipitated after T6 treatment was more effective in hindering the movement of dislocations and strengthened the alloy than lamellar discontinuous β phase (DP). The dispersed phase precipitated in the grains, the annihilation of dislocations, the uniformly distributed grains and the re-dissolution of β phase particles at initial grain boundaries after T6 treatment greatly contributed to the ductility of alloy. Moreover, the T6 treatment also promoted the basal plane of most grains which were re-arranged to the extrusion direction, which promoted the possibility of non-basal slip activation and further improved the elongation of the alloy. As a result, the UTS and YS of the final component increased by 10% and the EL increased by 7%, respectively.

Similar content being viewed by others

References

R.G. Li, F. Asghar, J.H. Zhang, G.Y. Fu, Q. Liu, B.T. Guo, Y.M. Yu, S.G. Guo, Y. Su, X.J. Chen, L. Zong, Acta Metall. Sin. -Engl. Lett. 32, 245 (2018)

Y.H. Zou, J. Wang, L.Y. Cui, R.C. Zeng, Q.Z. Wang, Q.X. Han, J. Qiu, X.B. Chen, D.C. Chen, S.K. Guan, Y.F. Zheng, Acta Biomater. 98, 196 (2019)

P.J. Scott, C.R. Kasprzak, K.D. Feller, V. Meenakshisundaram, C.B. Williams, T.E. Long, Polym. Chem. 11, 3498 (2020)

T.L. Zhu, C.L. Cui, T.L. Zhang, R.Z. Wu, S. Betsofen, Z. Leng, J.H. Zhang, M.L. Zhang, Mater. Des. 57, 245 (2014)

K.K. Alaneme, E.A. Okotete, J. Magnes. Alloy. 5, 460 (2017)

S. You, Y. Huang, K.U. Kainer, N. Hort, J. Magnes. Alloy. 5, 239 (2017)

D. Wang, S.J. Liu, R.Z. Wu, S. Zhang, Y. Wang, H.J. Wu, J.H. Zhang, L.G. Hou, J. Alloys Compd. 881, 160663 (2021)

J.H. He, L. Jin, F.H. Wang, S. Dong, J. Dong, J. Magnes. Alloy. 5, 423 (2017)

M. Zhou, Y. Morisada, H. Fujii, J. Magnes. Alloy. 8, 91 (2020)

H.C. Pan, R. Kang, J.R. Li, H.B. Xie, Z.R. Zeng, Q.Y. Huang, C.L. Yang, Y.P. Ren, G.W. Qin, Acta Mater. 186, 278 (2020)

W.L. Cheng, H.S. Kim, B.S. You, B.H. Koo, S.S. Park, Mater. Lett. 65, 1525 (2011)

T.T. Sasaki, K. Yamamoto, T. Honma, S. Kamado, K. Hono, Scr. Mater. 59, 1111 (2008)

F.R. Elsayed, T.T. Sasaki, T. Ohkubo, H. Takahashi, S.W. Xu, S. Kamado, K. Hono, Mater. Sci. Eng. A 588, 318 (2013)

S.S. Park, B.S. You, Scr. Mater. 65, 202 (2011)

S.M. Razavi, D.C. Foley, I. Karaman, K.T. Hartwig, O. Duygulu, L.J. Kecskes, S.N. Mathaudhu, V.H. Hammond, Scr. Mater. 67, 439 (2012)

A. Yamashita, Z. Horita, T.G. Langdon, Mater. Sci. Eng. A 300, 142 (2001)

B.Q. Xu, J.P. Sun, Z.Q. Yang, L.R. Xiao, H. Zhou, J. Han, H. Liu, Y.N. Wu, Y.C. Yuan, X.R. Zhuo, D. Song, J.H. Jiang, A.B. Ma, Mater. Sci. Eng. A 780, 139191 (2020)

J.B. Lin, Q.D. Wang, Y.J. Chen, M.P. Liu, H.J. Roven, Trans. Nonferrous Met. Soc. China 20, 2081 (2010)

R. Wadsack, R. Pippan, B. Schedler, Fusion Eng. Des. 66–68, 265 (2003)

R.K. Islamgaliev, N.F. Yunusova, I.N. Sabirov, A.V. Sergueeva, R.Z. Valiev, Mater. Sci. Eng. A 319–321, 877 (2001)

A.A. Popov, I.Y. Pyshmintsev, S.L. Demakov, A.G. Illarionov, T.C. Lowe, A.V. Sergeyeva, R.Z. Valiev, Scr. Mater. 37, 1089 (1997)

S.M. Fatemi-Varzaneh, A. Zarei-Hanzaki, S. Izadi, J. Mater. Sci. 46, 1937 (2010)

V. Shatermashhadi, B. Manafi, K. Abrinia, G. Faraji, M. Sanei, Mater. Des. 62, 361 (2014)

H. Li, Y. Xue, X. Zhao, Z.M. Zhang, Forg. Stamp. Technol. 41, 34 (2016)

X. Zhao, H. Li, Y. Xue, M.Z. Zhang, L. Wang, Hot Work. Technol. 45, 152 (2016)

X. Zhao, S.C. Li, Z.M. Zhang, P.C. Gao, S.L. Kan, F.F. Yan, J. Magnes. Alloy. 8, 624 (2020)

X. Zhao, S.L. Kan, Y. Yin, P.C. Gao, L.F. Guo, Ordnance. Mater. Sci. Eng. 43, 16 (2020)

H. Watanabe, H. Tsutsui, T. Mukai, K. Ishikawa, Y. Okanda, M. Kohzu, K. Higashi, Mater. Trans. 42, 1200 (2001)

S.Y. Jin, H.Y. Liu, R.Z. Wu, F. Zhong, L.G. Hou, J.H. Zhang, Mater. Sci. Eng. A 788, 139611 (2020)

J.H. Zhang, L. Zhang, Z. Leng, S.J. Liu, R.Z. Wu, M.L. Zhang, Scr. Mater. 68, 675 (2013)

D.G. Zhao, Z.Q. Wang, M. Zuo, H.R. Geng, Mater. Des. 56, 589 (2014)

P. Palai, N. Prabhu, P.D. Hodgson, B.P. Kashyap, J. Mater. Eng. Perform. 23, 77 (2013)

X. Zhao, F.F. Yan, Z.M. Zhang, P.C. Gao, S.C. Li, Acta Metall. Sin. -Engl. Lett. 34, 54 (2020)

X.J. Zhou, J. Zhang, X.M. Chen, X. Zhang, M.J. Li, J. Alloys Compd. 787, 551 (2019)

Y.C. Zhang, Y.R. Yang, J.W. Li, J.F. Zhang, Z.Y. Wu, H.G. Zhu, Mater. Sci. 11, 185 (2021)

M. Soucail, R. Messina, A. Cosnuau, L.P. Kubin, Mater. Sci. Eng. A 271, 1 (1999)

S.C. Li, Y.S. Zheng, F.F. Yan, W.M. Guo, S.Q. Zheng, X. Zhao, Y. Yin, N.A. Mater, Sci. Eng. 44, 43 (2021)

S. Yu, Y. Gao, C. Liu, X. Han, J. Alloys Compd. 646, 431 (2015)

M. Chandrasekaran, Y.M.S. John, Mater. Sci. Eng. A 381, 308 (2004)

W.T. Yu, Q.T. Hao, Q. Wang, Trans. Nonferrous Met. Soc. China 28, 1913 (2018)

G.L. Shi, D.F. Zhang, H.J. Zhang, X.B. Zhao, F.G. Qi, K. Zhang, Trans. Nonferrous Met. Soc. China 23, 586 (2013)

S.H. Kim, J.U. Lee, Y.J. Kim, J.H. Bae, B.S. You, S.H. Park, J. Mater. Sci. Technol. 34, 265 (2018)

F.Y. Liu, R.L. Xin, C.P. Wang, B. Song, Q. Liu, Scr. Mater. 158, 131 (2019)

S.W. Lee, J.W. Yeh, Y.S. Liao, Adv. Eng. Mater. 6, 936 (2004)

C. Xu, M. Furukawa, Z. Horita, T.G. Langdon, Mater. Sci. Eng. A 398, 66 (2005)

J.W. Kang, X.F. Sun, K.K. Deng, F.J. Xu, X. Zhang, Y. Bai, Mater. Sci. Eng. A 697, 211 (2017)

F. Guo, D.F. Zhang, X.S. Yang, L.Y. Jiang, F.S. Pan, Mater. Sci. Eng. A 636, 516 (2015)

M.H. Maghsoudi, A. Zarei-Hanzaki, H.R. Abedi, Mater. Sci. Eng. A 595, 99 (2014)

B.J. Wang, D.K. Xu, L.Y. Sheng, E.H. Han, J. Sun, J. Mater. Sci. Technol. 35, 2423 (2019)

B.L. Xiao, Q. Yang, J. Yang, W.G. Wang, G.M. Xie, Z.Y. Ma, J. Alloys Compd. 509, 2879 (2011)

J. Koike, Metall. Mater. Trans. A 36, 1689 (2005)

X. Zhao, S.C. Li, Y.S. Zheng, Z.R. Liu, K. Chen, J.M. Yu, Z.M. Zhang, S.Q. Zheng, J. Alloys Compd. 883, 160871 (2021)

Acknowledgements

This work was financially supported by the Shanxi Provincial Science and Technology Cooperation and Exchange Project (No. 202104041101033); the special fund for Science and Technology Innovation Teams of Shanxi Province; the Shanxi Province's Key Core Technology and Common Technology Research and Development Special Project (No. 2020XXX015); and the Ningbo Natural Science Foundation (Project 2021J231 and 2021J232 ).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Wang, Z., Li, S. et al. High Strength and Excellent Ductility of AZ80 Magnesium Alloy Cabin Component Developed by W-Shaped Channel Extrusion and Subsequent T6 Heat Treatment. Acta Metall. Sin. (Engl. Lett.) 36, 839–856 (2023). https://doi.org/10.1007/s40195-023-01525-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-023-01525-8