Abstract

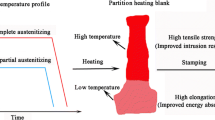

The effects of forming temperature on the formability and product properties of hot-stamping boron steel B1500HS were investigated. Based on the fractional cooling strategy, boron steel sheets were heated to achieve full austenitization before they were removed from the furnace and cooled to the forming temperature using different cooling methods. Subsequently, they were simultaneously press-formed and quenched inside the tool until the martensitic transformation was finished. A series of thermal tensile tests were conducted to study the effects of forming temperatures on the stamping performance indices, including elongation, yield ratio, and hardening exponent. Then, the mechanical properties and microstructures of the hot-stamped products were characterized. Finally, an irregular part was formed using different fractional cooling strategies, while its formability and springback phenomena were discussed. The results show that using a fast-cooling method to reach 650 °C as the forming temperature optimizes the formability of the tested B1500HS boron steel. The best mechanical properties and smallest springback values were achieved using this optimal strategy.

Similar content being viewed by others

References

W.J. Liu, Acta Metall. Sin. (Engl. Lett.) 27, 373 (2014)

H. Karbasian, A.E. Tekkaya, J. Mater. Process. Technol. 210, 2103 (2010)

P. Hu, N. Ma, L. Liu, Y. Zhu, Theories, Methods and Numerical Technology of Sheet Metal Cold and Hot Forming (Springer, London, 2013)

K. Mori, P.F. Bariani, B.A. Behrens, A. Brosius, S. Bruschi, T. Maeno, M. Merklein, J. Yanagimoto, CIRP Ann. Manuf. Technol. 66, 755 (2017)

H.S. Liu, Z.W. Xing, C.X. Lei, Trans. Nonferrous Met. Soc. China (Eng. Ed.) 22, s542 (2012)

J. Cui, G. Sun, J. Xu, X. Huang, G. Li, Mater. Design 77, 95 (2015)

S.L. Rong, Y.K. Lin, T.W. Chien, in 11th International Conference on Technology of Plasticity, Nagoya, October 2014. Experimental and Theoretical Studies on Formability of 22MnB5 at Elevated Temperatures by Gleeble Simulator, vol 81 (Springer, Heidelberg, 2014), pp. 1682–1688

Miklós, Zsolt, Lukács, Acta Metall. Sin. (Engl. Lett.) 28, 1471 (2015)

B. He, L. Ying, P. Hu, Y. Yu, X. Zhao, L.W. Zhang, Adv. Mater. Res. 1063, 186 (2014)

M. Naderi, M. Ketabchi, M. Abbasi, W. Bleck, J. Mater. Process. Technol. 211, 1117 (2011)

T. Nishibata, N. Kojima, J. Alloys Compd. 577, S549 (2013)

T. Maeno, K.I. Mori, T. Nagai, CIRP Ann. Manuf. Technol. 63, 301 (2014)

T. Maeno, K.I. Mori, M. Fujimoto, CIRP Ann. Manuf. Technol. 64, 281 (2015)

K. Zhao, Y. Chang, P. Hu, Y. Wu, J. Mater. Process. Technol. 228, 68 (2016)

M. Ganapathy, N. Li, J. Lin, D. Bhattacharjee, in International Conference on the Technology of Plasticity, Cambridge, September 2017. Investigation of a new hot stamping process with improved formability and productivity, vol 207 (Springer, Heidelberg, 2017), pp. 771–776

X. Han, K. Yang, S. Chen, J. Chen, J. Mater. Eng. Perf. 24, 3845 (2015)

B. Tang, Q. Wang, Z. Wang, W. Zheng, Int. J. Mater. Prod. Tech. 46, 255 (2013)

Y. Mu, J. Zhou, B. Wang, Q. Wang, A. Ghiotti, S. Bruschi, Finite Elem. Anal. Des. 147, 34 (2018)

J. Zhou, Y. Mu, B. Wang, J. Zhou, Y. Mu, B. Wang, Int. J. Mech. Sci. (2017). https://doi.org/10.1016/j.ijmecsci.2017.09.006

P. Hu, N. Ma, Adv. Mater. Res. 156–157, 582 (2011)

N. Li, J. Lin, D.S. Balint, T.A. Dean, J. Mater. Process. Technol. 231, 254 (2016)

K. Liu, B. Chi, Z.M. Shi, J.B. Liu, L. Jian, Adv. Mater. Res. 798, 280 (2013)

G. Venturato, M. Novella, S. Bruschi, A. Ghiotti, R. Shivpuri, in 17th International Conference on Sheet Metal, SHEMET 17, Effects of Phase Transformation in Hot Stamping of 22MnB5 High Strength Steel, vol 183 (Springer, Heidelberg, 2017), pp. 316–321

Y.D. Guo, Key Eng. Mater. 499, 96 (2012)

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grants 51775336 and U1564203, and the Shanghai Pujiang Program under Grant No. 17PJD019.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Han, XH., Wang, CL., Chen, SS. et al. Fractional Cooling Strategy of the Hot-Stamping Process and Its Influence on Formability and Mechanical Properties of Ultra-High-Strength Steel Parts. Acta Metall. Sin. (Engl. Lett.) 32, 343–351 (2019). https://doi.org/10.1007/s40195-018-0832-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0832-3