Abstract

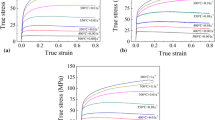

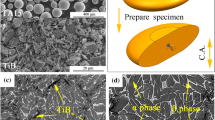

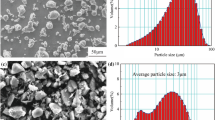

The hot deformation behavior of (3 vol% SiCp + 3 vol% Mg2B2O5w)/6061 Al (W3P3) hybrid composite and 6 vol% SiCp/6061 Al (P6) composite have been characterized in the temperature range of 300–450 °C and strain rate range of 0.0001–0.1 s−1 using isothermal constant true strain rate tests. The flow behavior and processing maps have been investigated using the corrected data to eliminate the effect of friction. Under the same deformation conditions, the compressive resistance of the singular composite remains superior to that of the hybrid composites. The processing map of W3P3 hybrid composite exhibits a single hot working domain at the temperature between 350 and 450 °C with strain rate between 0.0001 and 0.003 s−1 (domain A). Two hot working domains exist for P6 composite: (i) 300–400 °C/0.0001–0.003 s−1 (domain B1); (ii) 380–450 °C/0.01–0.1 s−1 (domain B2). The processing maps also reveal the flow instability of the two composites, which is associated with whiskers breakage, whisker/matrix interfacial debonding, SiCp/matrix interfacial decohesion, adiabatic shear bands or flow localization, and wedge cracking in the corresponding regions. The estimated apparent activation energies are about 224 kJ mol−1 in domain A for W3P3 hybrid composite, 177 kJ mol−1 in domain B1 and 263 kJ mol−1 in domain B2 for P6 composite, respectively. These values are higher than that for self-diffusion in Al (142 kJ mol−1), suggesting that there is a significant contribution from the back stress caused by the presence of particles and/or whiskers in the matrix. The deformation mechanisms corresponding to domain B1 and domain B2 are dislocation climb controlled creep and cross-slip for P6 composite, respectively. For W3P3 hybrid composite, the deformation mechanisms contain dislocation climb controlled creep and grain boundary sliding caused by DRX in domain A.

Similar content being viewed by others

References

D.P. Mondal, S. Das, K.S. Suresh, N. Ramakrishnan, Mater. Sci. Eng. A 460–461, 550 (2007)

T.S. Srivatsan, M. Al-Hajri, C. Smith, M. Petraroli, Mater. Sci. Eng. A 346, 91 (2003)

B. Inem, Mater. Sci. Eng. A 197, 91 (1995)

Q.G. Zhang, M.Y. Gu, Mater. Sci. Eng. A 419, 86 (2006)

P. Jin, B.L. Xiao, Q.Z. Wang, Z.Y. Ma, Y. Liu, S. Li, Mater. Sci. Eng. A 528, 1504 (2011)

Y.V.R.K. Prasad, K.P. Rao, M. Gupta, Compos. Sci. Technol. 69, 1070 (2009)

I.C. Stone, P. Tsakiropoulos, Mater. Sci. Eng. A 241, 19 (1998)

J.K.M. Kwok, S.C. Lim, Compos. Sci. Technol. 59, 55 (1999)

C.Y. Wang, K. Wu, M.Y. Zheng, Mater. Sci. Eng. A 487, 495 (2008)

Z.J. Li, L.D. Wang, W.D. Fei, Mater. Sci. Eng. A 447, 314 (2007)

K. Euh, S.B. Kang, Mater. Sci. Eng. A 395, 47 (2005)

V.C. Srivastava, A. Schneider, V. Uhlenwinkel, K. Bauckhage, Mater. Sci. Eng. A 412, 19 (2005)

Y.C. Feng, L. Geng, P.Q. Zheng, Z.Z. Zheng, G.S. Wang, Mater. Des. 29, 2023 (2008)

J.S.S. Babu, C.G. Kang, H.H. Kim, Mater. Des. 32, 3920 (2011)

B.C. Ko, Y.C. Yoo, Compos. Sci. Technol. 59, 775 (1999)

X.N. Zhang, L. Geng, B. Xu, Mater. Chem. Phys. 101, 242 (2007)

X.N. Zhang, L. Geng, G.S. Wang, J. Mater. Process. Technol. 176, 146 (2006)

B.C. Ko, Y.C. Yoo, Compos. Sci. Technol. 58, 479 (1998)

X. Ma, W.D. Zeng, B. Xu, Y. Sun, C. Xue, Y.F. Han, Intermetallics 20, 1 (2012)

Y.V.R.K. Prasad, K.P. Rao, Mater. Sci. Eng. A 391, 141 (2005)

O. Sivakesavam, Y.V.R.K. Prasad, Mater. Sci. Eng. A 362, 118 (2003)

E. Cerri, S. Spigarelli, E. Evangelista, P. Cavaliere, Mater. Sci. Eng. A 324, 157 (2002)

Y.V.R.K. Prasad, K.P. Rao, Mater. Lett. 60, 2786 (2006)

Y.V.R.K. Prasad, Indian J. Technol. 28, 435 (1990)

S. Anbu Selvan, S. Ramanathan, Trans. Nonferrous Metal. Soc. 21, 257 (2011)

H.Z. Li, H.J. Wang, M. Zeng, X.P. Liang, H.T. Liu, Compos. Sci. Technol. 71, 925 (2011)

Y.C. Lin, L.T. Li, Y.C. Xia, Y.Q. Jiang, J. Alloys Compd. 550, 438 (2013)

X.J. Wang, X.S. Hu, K. Wu, K.K. Deng, W.M. Gan, C.Y. Wang, M.Y. Zheng, Mater. Sci. Eng. A 492, 481 (2008)

X.J. Wang, K. Wu, W.X. Huang, H.F. Zhang, M.Y. Zheng, D.L. Peng, Compos. Sci. Technol. 67, 2253 (2007)

P. Wanjara, M. Jahazi, H. Monajati, S. Yue, J.P. Immarigeon, Mater. Sci. Eng. A 396, 50 (2005)

R. Ebrahimi, A. Najafizadeh, J. Mater. Process. Technol. 152, 136 (2004)

A.B. Li, L. Geng, J. Zhang, H.Y. Xu, Z.Z. Zheng, C.K. Yao, Mater. Chem. Phys. 84, 29 (2004)

A. Patel, S. Das, B.K. Prasad, Mater. Sci. Eng. A 530, 225 (2011)

K.P. Rao, Y.V.R.K. Prasad, K. Suresh, N. Hort, K.U. Kainer, Mater. Sci. Eng. A 552, 444 (2012)

R. Raj, Metall. Trans. A 12, 1089 (1981)

R. Zauter, F. Petry, H.J. Christ, H. Mugrabi, Mater. Sci. Eng. A 124, 125 (1990)

C.M. Sellars, W.J. Tegart, Int. Metall. Rev. 17, 1 (1972)

R. Kaibyshev, O. Sitdikov, I. Mazurina, D.R. Lesuer, Mater. Sci. Eng. A 334, 104 (2002)

R. Mahmudi, R. Roumina, B. Raeisinia, Mater. Sci. Eng. A 382, 15 (2004)

V.C. Srivastava, V. Jindal, V. Uhlenwinkel, K. Bauckhage, Mater. Sci. Eng. A 447, 86 (2008)

T.G. Nieh, J.L. Wadsworth, O.D. Sherby, Superplasticity in Metals and Ceramics (Cambidge University, Cambridge, 1997), p. 33

Y. Li, T.G. Langdon, Acta Mater. 47, 3395 (1999)

S. Spigareli, E. Evangelista, E. Cerri, T.G. Longdon, Mater. Sci. Eng. A 319–321, 721 (2001)

J.R. Morris, J. Scharff, K.M. Ho, D.E. Turner, Y.Y. Ye, M.H. Yoo, Philos. Mag. A 76, 1065 (1997)

J. Koike, T. Kobahashi, T. Mukai, H. Watanabe, M. Suzuki, K. Maruyama, K. Higashi, Acta Mater. 51, 2055 (2003)

Acknowledgments

The authors would like to express their sincere thanks to Dr. Tianping Zhu, research associate of The University of Auckland for his helpful discussions. This work was financially supported by the National Basic Research Program of China (No. 2011CB612200).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Wang, M., Jin, P., Wang, J. et al. Hot Deformation Behavior and Workability of (SiCp + Mg2B2O5w)/6061 Al Hybrid and SiCp/6061 Al Composites. Acta Metall. Sin. (Engl. Lett.) 27, 63–74 (2014). https://doi.org/10.1007/s40195-014-0023-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-014-0023-9