Abstract

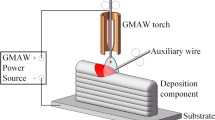

During gas tungsten arc–based additive manufacturing (GTA-AM), the arc is burning between a tungsten electrode and a deposited wall. With the increases in the built height, the arc behaviour becomes much different from that in gas tungsten arc welding (GTAW), in which the workpiece is keeps flat relatively. In present research, the arc properties in GTA-AM process were investigated via a numerical model including the effect of the surrounding air; the arc properties and the air transport and distribution were exhibited; the effect of the arc current on the arc properties and the air diffusion were examined. It is found that the arc is burning astride the deposited wall, altering the arc shape and peripheries significantly. A backward flow forms near the side surface of the build due to the abrupt drop of the deposited wall surface; such flow results in the air transport from the surrounding region to the inner part of the arc. Consequently, a relatively high concentration of the air occurs adjacent to the built wall, which, to a large extent, is an important reason for the oxidation and the shielding effect degradation of the layer during WAAM. In addition, the coverage of the arc plasma over the wall extends with the increased arc current surveyed, while the air diffusion towards the wall becomes intensified and its concentration presents a huge surge in this region, implying an aggravated oxidation and worsen shielding of the wall. The numerical results were in fair agreement with the experimental ones obtained by shadowgraphy technique.

Similar content being viewed by others

Data Availability

The datasets generated and supporting the findings of this article are obtainable from the corresponding author upon reasonable request.

References

Williams SW, Martina FA, Ding AC, Pardal JG, Colegrove P (2016) Wire + arc additive manufacturing. Mater Sci Tech 32:641–647. https://doi.org/10.1179/1743284715Y.0000000073

Norrish J, Polden J, Richardson I (2021) A review of wire arc additive manufacturing: development, principles, process physics, implementation and current status. J Phys D Appl Phys 54(29):473001. https://doi.org/10.1088/1361-6463/ac1e4a

Tanaka M, Lowke J (2007) Predictions of weld pool profiles using plasma physics. J Phys D Appl Phys 40:R1-23. https://doi.org/10.1088/0022-3727/40/1/R01.10.1088/0022-3727/40/1/R01

Cunningham CR, Flynn JM, Shokrani A, Dhokia V, Newman ST (2018) Strategies and processes for high quality wire arc additive manufacturing. Add Manuf 22:672–686. https://doi.org/10.1016/j.addma.2018.06.020

Schnick M, Dreher M, Zschetzsche J, Fuessel U, Spille-Kohoff A (2012) visualization and optimization of shielding gas flows in arc welding. Weld World 56:55–61. https://doi.org/10.1007/BF03321146

Dreher FU, Rose S, Häßler M, Hertel M, Schnick M (2013) Methods and results concerning the shielding gas flow in GMAW. Weld World 57:391–410. https://doi.org/10.1007/s40194-013-0038-2

Beyer V, Campbell SW, Ramsey GM, Galloway AM, Moore AJ, McPherson NA (2013) Systematic study of effect of cross-drafts and nozzle diameter on shield gas coverage in MIG welding. Sci Tech Weld Join 18:652–660. https://doi.org/10.1179/1362171813Y.0000000143

Bitharas I, McPherson NA, McGhie W, Roy D, Moore AJ (2018) Visualisation and optimisation of shielding gas coverage during gas metal arc welding. J Mate Process Tech 255:451–462. https://doi.org/10.1016/j.jmatprotec.2017.11.048

Bitharas I (2018) Visualisation of shielding gas flows during high-value manufacture, Eng D Thesis, Heriot-Watt University. https://www.ros.hw.ac.uk/handle/10399/3992. Accessed 17 Dec 2022

Xu X, Ding J, Ganguly S, Diao C, Williams S (2018) Oxide accumulation effects on wire + arc layer-by-layer additive manufacture process. J Mater Process Techn 252:739–750. https://doi.org/10.1016/j.jmatprotec.2017.10.030

Elmer JW, Gibbs G (2019) The effect of atmosphere on the composition of wire arc additive manufactured metal components. Sci Techn Weld Join 24:367–374. https://doi.org/10.1080/13621718.2019.1605473

Hauser T, Reisch RT, Breese P, Nalam Y, Joshi KS, Bela K, Kamps T, Volpp J, Kaplan AFH (2021) Oxidation in wire arc additive manufacturing of aluminium alloys. Add Manuf 41(11):101958. https://doi.org/10.1016/j.addma.2021.101958

Wang X, Chi L, Wu G, Li FD (2019) Numerical simulation of mixture gas arc of Ar-O2. Acta Phys Sin 68(10):178102. https://doi.org/10.7498/aps.68.20190416

Wang X, Luo Y, Chi L, Fan D (2020) Numerical investigation of transport phenomena of arc plasma in argon-oxygen gas mixture. Int J Heat Mass Transfer 154(11):11970. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119708

Murphy AB (1995) Transport coefficients of air, argon-air, nitrogen-air, and oxygen-air plasmas. Plasma Chem Plasma Process 15:279–307. https://doi.org/10.1007/BF01459700

Murphy AB (1993) Diffusion in equilibrium mixtures of ionized gases. Phys Rev E 48:3594–3603. https://doi.org/10.1103/PhysRevE.48.3594

Murphy AB (1997) Demixing in free-burning arcs. Phys Rev E 55:7473–7494. https://doi.org/10.1103/PhysRevE.55.7473

Murphy AB (1998) Cataphoresis in electric arcs. J Phys D Appl Phys 31:3383–3390. https://doi.org/10.1088/0022-3727/31/23/012

Murphy AB, Tanaka M, Yamamoto K, Tashiro S, Sato T, Lowke J (2009) Modelling of thermal plasmas for arc welding: the role of the shielding gas properties and of metal vapour. J Phys D Appl Phys 42(20):194006. https://doi.org/10.1088/0022-3727/42/19/194006

Tanaka M, Yamamoto K, Tashiro S, Nakata K, Ushio M, Yamazaki K, Yamamoto E, Suzuki K, Murphy AB, Lowke J (2008) Metal vapor behavior in gas tungsten arc thermal plasma during welding. Weld World 52:82–88. https://doi.org/10.1007/BF03266686

Wang X, Luo Y, Wu G, Chi L, Fan D (2018) Numerical simulation of metal vapour behavior in double electrodes TIG welding. Plasma Chem Plasma Process 38:1095–1114. https://doi.org/10.1007/s11090-018-9904-4

Murphy AB, Tam E (2014) Thermodynamic properties and transport coefficients of arc lamp plasmas: argon, krypton and xenon. J Phys D Appl Phys 47(10):295202. https://doi.org/10.1088/0022-3727/47/29/295202

Murphy AB (2012) Transport coefficients of plasmas in mixtures of nitrogen and hydrogen. Chem Phys 398:64–72. https://doi.org/10.1016/j.chemphys.2011.06.017

Park H, Trautmann M, Tanaka K, Tanaka M, Murphy AB (2017) Mixing of multiple metal vapours into an arc plasma in gas tungsten arc welding of stainless steel. J Phys D Appl Phys 43(7):43LT03. https://doi.org/10.1088/1361-6463/aa8b06

Hsu KC, Etemadi K, Pfender E (1983) Study of the freeburning high intensity argon arc. J Appl Phys 54:1293–1301. https://doi.org/10.1063/1.332195

Lancaster J F (1986) The physics of welding, second ed, Oxford Pergamon

Elmer JW, Gibbs G (2019) The effect of atmosphere on the composition of wire arc additive manufactured metal components. Sci Techno Weld Join 24:367–374. https://doi.org/10.1080/13621718.2019.1605473

Mundra K, DebRoy T (1995) A general model for partitioning of gases between a metal and its plasma environment. Sci Tech Weld Join 26:149–157. https://doi.org/10.1007/BF02648987

Okada T, Yamamoto H, Harada S (1980) Observation of the shielding gas flow pattern during arcing by the use of a laser light source. Arc Phys Weld Pool Behav 1:203–213

Tashiro S, Trinh NQ, Suga T, Matsuda N, Tsurumaru N, Maeda T, Tanaka R, Nakatsu S, Tsujii G, Bui HV, Tanaka M (2021) Influence of cross-wind on CO2 arc welding of carbon steel. Metal 11:1677. https://doi.org/10.3390/met11111677

Tanaka M, Yamada T, Shigeta M, Komen H, Fukahori M, Saito N (2021) Experimental study on effects of gas-shielding in lap-fillet arc welding. Weld Int 35(10–12):492–507. https://doi.org/10.1080/09507116.2021.1980296

Schwedersky MB, Rosa ÁF, Okuyama MP, Silva RHG (2021) Limitations of the Schlieren technique for shielding gas flow visualization in arc welding processes. Weld World 65:1097–1105. https://doi.org/10.1007/s40194-021-01092-5

Acknowledgements

The authors are grateful to Dr. A B Murphy of CSIRO Manufacturing for providing thermophysical properties of arc plasma in gas mixture of Ar-air.

Funding

This work is supported by the China Scholarship Council (Grant no. 202108500099), National Natural Science Foundation of China (NO.51705054), and Scientific and Technological Research Program of Chongqing Municipal Education Commission (NO. KJQN202101135), and performed under the Joint Usage/Research Center on Joining and Welding, Osaka University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The paper (DOC. XII-2526–2022) was recommended for submitting to the Welding in the World for publication in IIW 2022.

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Zhang, J., Deng, Y. et al. Numerical investigation of the arc properties in gas tungsten arc–based additive manufacturing. Weld World 67, 945–954 (2023). https://doi.org/10.1007/s40194-023-01473-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-023-01473-y