Abstract

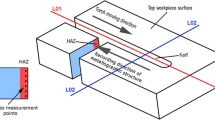

This research paper exhibits an experimental investigation of plasma arc cutting of hardox-400 using different types of plasma gases. Nature and behavior of the plasma arc were studied and described the effect of plasma gas on the workpiece. The experiments were performed on 10 mm hardox-400 using CNC plasma cutting machine. The selected workpiece material has very good mechanical properties like high toughness, good bendability, and good weldability. This special abrasion resistance steel is used in part manufacturing of front loaders, buckets, barges, and various mining equipment. Four different plasma gases were chosen for this experiment, i.e., air, argon, oxygen, and nitrogen. Thermophysical properties of plasma gases, properties of generated arc, cutting performance, and energy balance are explained for different plasma gases used. The kerf shape and material removal rate (MRR) due to the generated arc were measured and analyzed the effect. This paper clarifies the potential of cutting process by varying the flow rate and chemical composition of the plasma gas.

Similar content being viewed by others

References

Gariboldi E, Previtali B (2005) High tolerance plasma arc cutting of commercially pure titanium. J Mater Process Technol 160(1):77–89

Nemchinsky VA, Severance W (2006) What we know and what we do not know about plasma arc cutting. J Phys D Appl Phys 39(22):R423

Maity KP, Bagal DK (2015) Effect of process parameters on cut quality of stainless steel of plasma arc cutting using hybrid approach. Int J Adv Manuf Technol 78(1–4):161–175

Girard L et al (2006) Experimental study of an oxygen plasma cutting torch: I. Spectroscopic analysis of the plasma jet. J Phys D Appl Phys 39(8):1543

Fernicola RC (1994) New oxygen plasma process rivals laser cutting methods. Welding Journal 73(6):65–69

Naik DK, Khan A, Majumder H, Garg RK (2019) Experimental investigation of the PMEDM of nickel free austenitic stainless steel: a promising coronary stent material. Silicon 11(2):899–907

Naik DK, Maity K (2018) Application of desirability function based response surface methodology (DRSM) for investigating the plasma arc cutting process of sailhard steel. World Journal of Engineering 15(4):505–512

Naik DK, Maity K (2019) Temperature analysis by moving heat source during plasma arc cutting process: an analytical approach. World Journal of Engineering 16(4):569–572

Naik DK, Maity K (2018) Optimization of dimensional accuracy in plasma arc cutting process employing parametric modelling approach. IOP Conference Series: Materials Science and Engineering 338:1–6

Naik DK, Maity K (2018) An optimization and experimental analysis of plasma arc cutting of Hardox-400 using Taguchi based desirability analysis. Materials Today: Proceedings 5(5):13157–13165

Kavka T et al (2013) Experimental study of the effect of gas nature on plasma arc cutting of mild steel. J Phys D Appl Phys 46(22):224011

Ramakrishnan S et al (1997) Plasma generation for the plasma cutting process. IEEE Transactions on plasma science 25(5):937–946

Ramakrishnan S, Rogozinski M (1997) Properties of electric arc plasma for metal cutting. J Phys D Appl Phys 30(4):636

Freton P et al (2001) Numerical and experimental study of a plasma cutting torch. J Phys D Appl Phys 35(2):115

Peters J et al (2008) Relating spectroscopic measurements in a plasma cutting torch to cutting performance. Plasma Chem Plasma Process 28(3):331–352

Colombo V et al (2012) Advances in plasma arc cutting technology: the experimental part of an integrated approach. Plasma Chem Plasma Process 32(3):411–426

Nemchinsky VA, Severance W (2009) Plasma arc cutting: speed and cut quality. J Phys D Appl Phys 42(19):195204

Gonzalez J, Freton P, Masquère M (2007) Experimental quantification in thermal plasma medium of the heat flux transferred to an anode material. J Phys D Appl Phys 40(18):5602

Long NP et al (2012) Cathode diameter and operating parameter effects on hafnium cathode evaporation for oxygen plasma cutting arc. J Phys D Appl Phys 45(43):435203

Ramakrishnan S et al (2000) Influence of gas composition on plasma arc cutting of mild steel. J Phys D Appl Phys 33(18):2288

Adamiak M, Górka J, Kik T (2009) Comparison of abrasion resistance of selected constructional materials. Journal of Achievements in Materials and Manufacturing Engineering 37(2):375–380

Camaioni DM, Schwerdtfeger CA (2005) Comment on “accurate experimental values for the free energies of hydration of H+, OH-, and H3O+”. J Phys Chem A 109(47):10795–10797

Jones G, Fang M (1980) The physics of high-power arcs. Rep Prog Phys 43(12):1415

Hrabovsky M (1998) Water-stabilized plasma generators. Pure Appl Chem 70(6):1157–1162

Aubrecht V, Bartlova M (2009) Net emission coefficients of radiation in air and SF6 thermal plasmas. Plasma Chem Plasma P 29(2):131–147

Bini R et al (2008) Experimental study of the features of the kerf generated by a 200A high tolerance plasma arc cutting system. J Mater Process Tech 196(1):345–355

Naghizadeh-Kashani Y, Cressault Y, Gleizes A (2002) Net emission coefficient of air thermal plasmas. J Phys D Appl Phys 35(22):2925

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for Publication by Commission I - Additive Manufacturing, Surfacing, and Thermal Cutting

Rights and permissions

About this article

Cite this article

Naik, D.K., Maity, K. Experimental analysis of the effect of gas flow rate and nature on plasma arc cutting of hardox-400. Weld World 64, 345–352 (2020). https://doi.org/10.1007/s40194-019-00836-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00836-8