Abstract

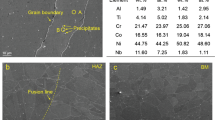

The hardness response of Alloy 625 weld overlay on low alloy steel was evaluated under a range of aging conditions to determine how the properties of the overlay change during postweld heat treatment (PWHT). It was presumed that the hardening compared to the as-welded condition occurs due to the precipitation of gamma double-prime (γ″). To confirm this assumption, an investigation was conducted on weld overlay samples under different aging conditions, using Vickers hardness testing, SEM microstructure characterization, SEM/EDAX analysis, and nanoindentation. The Alloy 625 weld overlay hardness values initially increased but eventually decreased with increasing aging temperature. γ″ precipitation was found in the interdendritic regions of the weld overlay samples. In the overaged condition, dissolution and coarsening of γ″ precipitates occurred. Delta (δ) phase also formed in the interdendritic regions, generally at higher temperatures than for γ″ precipitation. Nanoindentation revealed that the precipitation of γ″ is responsible for the hardening in the interdendritic regions of Alloy 625 weld overlay. The time-temperature-precipitation curves of interdendritic regions are altered from that of wrought Alloy 625 due to higher Nb, Ti, and Mo contents and lower dislocation density. The peak temperatures achieved in service for heating coke drum may result in interdendritic γ″ precipitation which can cause significant hardening of the overlay and promote cracking.

Similar content being viewed by others

References

Shoemaker, L., Alloys 625 and 725: trends in properties and applications, in Superalloys 718, 625, 706 and Derivatives, TMS (The Minerals, Metals & Materials Society), 2005, pp. 409–418

Dai T, Lippold JC (2017) Tempering behavior of the fusion boundary region of an F22/625 weld overlay. Weld J 96:467–480

Dai T, Lippold JC (2018) The effect of postweld heat treatment on hydrogen-assisted cracking of F22/625 overlays. Weld J 97:75–90

Dai T, Lippold JC (2018) Tempering effect on the fusion boundary region of alloy 625 weld overlay on 8630 steel. Welding in the World 62(3):535–550

Dai T, Lippold JC (2018) The effect of postweld heat treatment on hydrogen-assisted cracking of 8630/alloy 625 overlay. Welding in the World 62(3):581–599

Lippold, J. C. and Wheeling, R. A.,2017 An investigation of alloy 625 weld overlay microstructure from a coke drum that experienced service cracking, unpublished

Brown EE, Muzyka DR (1987) Nickel-iron alloys. In: The Superalloys II. John Wiley, New York, pp 165–187

Sundararaman, M., Mukhopadhyay, P. and Banerjee, S.,1994 Some aspects of the heterogeneous precipitation of the metastable γ″ phase in alloy 625, in Superalloys 718, 625, 706 and Various Derivatives, E. A. Loria, Ed., Warrendale, PA, TMS, , pp. 405–418

Floreen, S., Fuchs, G. E. and Yang, W. J.,1994 The metallurgy of alloy 625, in Superalloys 718, 625, 706 and Various Derivatives, E. A. Loria, Ed., Warrendale, PA, TMS, pp. 13–38

Petrzak P, Kowalski K, Blicharski M (2016) Analysis of phase transformations in Inconel 625 alloy during annealing. Acta Phys Pol A 130(4):1041–1044

Shaikh MA, Ahmad M, Shoaib KA, Akhter JI, Iqbal M (2000) Precipitation hardening in Inconel* 625. Mater Sci Technol 16(2):129–132

Suave LM, Cormier J, Villechaise P, Soula A, Hervier Z, Bertheau D, Laigo J (2014) Microstructural evolutions during thermal aging of Alloy 625: impact of temperature and forming process. Metall Mater Trans A 45(7):2963–2982

Malej S, Medved J, Batic BS, Tehovnik F, Godec M (2017) Microstructural evolution of Inconel 625 during thermal aging. Metalurgija 56(3–4):319–322

Mathew MD, Parameswaran P, Bhanu Sankara Rao K (2008) Microstructural changes in alloy 625 during high temperature creep. Mater Charact 59:508–513

Garzarotli F, Gerscha A, Francke FP (1969) Untersuchungen uber das Ausscheidungsverhalten und die mechanischen Eigenschaften der Legierung Inconel 625. Z Metallkunde 60:643–652

Silva CC, Miranda HC, Motta MF, Farias JP, Afonso CRM, Ramirez AJ (2013) New insight on the solidification path of an alloy 625 weld overlay. J Mater Res Technol 2(3):228–237

Inconel alloy 625 - special metals, [Online]. Available: http://www.specialmetals.com/assets/smc/documents/alloys/inconel/inconel-alloy-625.pdf

Bleck W (2007) Materials science of steel. RWTH Aachen University, Aachen, Germany, pp 270–271

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Dai, T., Wheeling, R.A., Hartman-Vaeth, K. et al. Precipitation behavior and hardness response of Alloy 625 weld overlay under different aging conditions. Weld World 63, 1087–1100 (2019). https://doi.org/10.1007/s40194-019-00724-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00724-1