Abstract

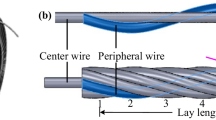

Cable-type welding wire (CWW) electrogas welding (EGW) is an innovative process in which CWW is used as the consumable electrode. Seven wires can be melted simultaneously with only one welding power source, one wire feeder, and one welding torch. This paper reports a study of the sidewall penetration of CWW EGW. The results showed that all the mechanical properties of CWW EGW welded joints met the standards of the China Classification Society (CCS). The arc heating area of CWW EGW was large and that the unique rotating arc of CWW EGW had a strong stirring effect, enhancing convective motion of the molten pool and accelerating heat transfer between the superheated molten pool and the sidewall. The droplet of the CWW EGW appeared to be non-axial transfer due to the rotating force. The superheated droplet transferred to the sidewall or the molten pool near the sidewall directly, promoting the heating and melting of the base metal.

Similar content being viewed by others

References

Park CS, Yun JO, Kim BJ et al (2007) A study of electro gas welding process for vertical welding joint in the shipbuilding. Welding in the world 51:605–614

von Bush M, Engel D (2007) Electro gas welding in shipbuilding. Electric Welding Machine 6:4–10

Li JB, Wang G, Sha YZ (2006) Study of technology and equipment of electrogas welding of high efficiency in thick plate of ship. Electric Welding Machine 34(2):14–15 (in Chinese)

Kim NI, Jeong SH, Lee JS et al (2009) Effects of Mn and heat-input on the mechanical properties of EGW welds. Journal of the Korean institute of metals and materials 47(3):195–201

Hashiba Y, Sasaki K, Kasuya T et al (2010) Development of welding materials for high heat input welding compatible with thick steel plates of 460MPa yield point class for very large container ship. Welding in the World 54(1–2):35–41

Bae SD, Kim DJ, Kim YP et al (2009) A study on the electro gas welding with an additional solid wire. Welding in the World 53:437–442

Sasaki K, Kazutoshi Suda, Motomatsu RI et al (2004) Development of two-electrode electro gas arc welding process. Nippon Steel Technical Report 90:67–74

Hwang SY, Kim Y, Lee JH (2016) Finite element analysis of residual stress distribution in a thick plate joined using two-pole tandem electro-gas welding. J Mater Process Technol 229:349–360

Zhang YM, Jiang M, Lu W (2004) Double electrodes GMAW improve heat input control. Weld J 83(11):39–41

Li KH, Zhang YM, Xu P et al (2008) High-strength steel welding with consumable double-electrode gas metal arc welding. Weld J 87(3):57–64

Li KH, Zhang YM (2010) Interval model control of consumable double-electrode gas metal arc welding process. IEEE Trans Autom Sci Eng 7(4):826–839

Zhang CY, Ma GH, Nie J (2015) Numerical simulation of AZ31B magnesium alloy in DE-GMAW welding process. Int J Adv Manuf Technol 78:5–8

Ma GH, Zhang YM (2012) A novel DE-GMAW method to weld steel tubes on simplified condition. Int J Adv Manuf Technol 63:1–4

Qiu G, Geng Z, Wang W (2012) Double wire vertical electrogas welding system and welding method. Chinese Patent, CN102581449A (in Chinese)

Wang G, Li JB, Sha YZ (2002) Study on the penetration of electrogas welding. Welding technology 5:8–9 (in Chinese)

Hirohira A (1985) The phenomenon of welding arc. China machine press, Beijing (in Chinese)

Zheng SM, Gao HM, Liu X (2011) Metal transfer characteristics of GMAW with strip electrode. Sci Technol Weld Join 16(7):586–591

Liu HY, Li ZX, Li H, Shi YW (2008) Study on metal transfer modes and welding spatter characteristics of self-shielded flux cored wire. Sci Technol Weld Join 13(8):777–780

Yang CL, Guo N, Lin SB, Fan CL, Zhang YQ (2009) Application of rotating arc system to horizontal narrow gap welding. Sci Technol Weld Join 14(2):172–177

Guo N, Lin SB, Gao C, Fan CL, Yang CL (2009) Study on elimination of interlayer defects in horizontal joints made by rotating arc narrow gap welding. Sci Technol Weld Join 14(6):584–588

Guo N, Lin SB, Zhang L, Yang CL (2009) Metal transfer characteristics of rotating arc narrow gap horizontal GMAW. Sci Technol Weld Join 14(8):760–764

Cai XY, Lin SB, Fan CL, Yang CL, Zhang W, Wang YW (2016) Molten pool behavior and weld forming mechanism of tandem narrow gap vertical GMAW. Sci Technol Weld Join 21(2):124–130

Acknowledgements

The authors are grateful for the financial support for this research from the National Natural Science Foundation of China (grant nos. 51575250 and 51275224), Prospective Joint Research Project of Jiangsu Province of China (grant no. BY2015065-06), Collaborative Innovation Center of Ship Technology of China (grant no. HZ20160020), and Priority Academic Program Development of Jiangsu Higher Education Institutions of China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

About this article

Cite this article

Chen, Y., Fang, C., Yang, Z. et al. A study on sidewall penetration of cable-type welding wire electrogas welding. Weld World 61, 979–986 (2017). https://doi.org/10.1007/s40194-017-0479-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-017-0479-0