Abstract

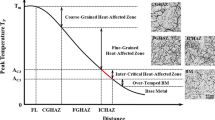

A factor of four decreases from 16.0 × 10−4 to 4.1 × 10−4 %/h in steady state creep rate was observed in the fine-grained heat-affected zone (FGHAZ) of a Cr-Mo steel weld, by reducing the pre-weld tempering temperature from 760 to 650 °C. The current study used electron backscatter diffraction and synchrotron x-ray diffraction techniques to characterize the microstructure in the FGHAZ of the two tempering temperature conditions. The results showed carbide-free ferrite that formed in the FGHAZ of weldments that were pre-weld tempered at 760 °C, contributed to void formation resulting in lower creep strength. It is proposed that the formation of ferrite in the FGHAZ is due to the incomplete dissolution of Cr23C6 carbide at heating process during welding, which results in Cr enrichment adjacent to the undissolved Cr23C6 carbide. Dictra simulation confirmed ferrite formation at the carbide/austenite boundaries during Cr23C6 carbide dissolution.

Similar content being viewed by others

References

Bhadeshia HKDH (2001) ISIJ Int 41:626

Henry JF (2005) Combined Cycle J 8

I.A. Shibli, K. Coleman, www.ommi.co.uk/etd/ETD-EPRI-%20P91%20Failures.pdf

Berte FJ (2007) Combined Cycle J 52

Francis JA, Mazur W, Bhadeshia HKDH (2006) Mater Sci Technol 22:1387

Abe F, Tabuchi M (2004) Mater Sci Technol 9:22

Hirata H, Ogawa K (2005) Weld Int 19:37

Hirata H, Ogawa K (2005) Weld Int 19:118

Albert SK, Matsui M, Watanabe T, Hongo H, Kubo K, Tabuchi M (2003) Int J Press Vessel Pip 80:405

Li D, Shinozaki K, Kuroki H (2003) Mater Sci Technol 19:1253

Otoguro Y, Matsubara M, Itoh I, Nakazawa T (2000) Nucl Eng Des 196:51

Yu X, Babu SS, Terasaki H, Komizo Y, Yamamoto Y, Santella ML (2013) Acta Mater 61:2194

Yu X, Santella ML, Yamamoto Y, Terasaki H, Komizo Y, Babu SS (2014) In situ phase transformation study in fine grained heat affected zone of grade 91 steels. In in situ Studies with photons, neutrons and electrons scattering II. Springer International Publishing, Switzerland, pp 29–49

Yu X, Babu SS, Terasaki H, Komizo Y, Yamamoto Y, Santella ML (2013) Correlation of precipitate stability to increased creep resistance of Cr–Mo steel welds. Acta Mater 61(6):2194–2206

Letofsky E, Cerjak H (2004) Metallography of 9Cr steel power plant weld microstructures. Sci Technol Weld Join 9(1):31–36

Li D, Shinozaki K, Kuroki H (2003) Stress–strain analysis of creep deterioration in heat affected weld zone in high Cr ferritic heat resistant steel. Mater Sci Technol 19(9):1253–1260

Kimmins ST, Smith DJ (1998) On the relaxation of interface stresses during creep of ferritic steel weldments. J Strain Analysis Eng Des 33(3):195–206

Elmer JW, Wong J, Ressler T (2000) Scripta Mater 43:751

Babu SS, Elmer JW, Vitek JM, David JM (2002) Acta Mater 50:4763

Wong J, Ressler JW, Elmer J (2003) Synchrotron Radiat 10:154

Babu SS, Specht ED, David SA, Karapetrova E, Zschack P, Peet M, Bhadeshia HKDH (2005) Metall Mater Trans A 36A:3281

Stone HJ, Peet MJ, Bhadeshia HKDH, Withers PJ, Babu SS, Specht ED (2009) Proc Roy Soc A 464:1009

Offerman SE, van Dijk NH, Sietsma J, Grigull S, Lauridsen EM, Margulies L, Poulsen HF, Rekveldt MT, vander Zwaag S (2002) Science 298:1003

Terasaki H, Komizo Y (2011) Scripta Mater 64:29

Rozenak P, Eliezer D (1986) J Mater Sci 21:3065

Lai JKL, Galbraith IF (1980) J Mater Sci 15:1297

Terao N, Sasmal B (1980) Metallography 13:117

Parish C, Watkins T, Rios O, Mackiewicz-Ludtka G, Ludtka G, Cavin O (2011) Microsc Microanal 17:410

Beneteaua A, Weisbeckera P, Geandierb G, Aeby-Gautiera E, Appolaire B (2005) Mater Sci Eng A 393:63

Yonemura M, Osuki T, Hirata H, Ogawa K (2008) Metall Mater Trans A 39A:113

Zhang XF (2012) Scripta Mater. doi:10.1016/j.scriptamat.2012.04.019

Stevens RA, Lonsdale D (1985) J Mater Sci 20:3631

Mitchell DRG, Ball CJ (2001) Mater Charact 47:17

ASTM Specification A139-06 (2008) Section II, part A

Broennimann C, Eikenberry EF, Henrichn B, Horisberger R, Huelsen G, Pohl E, Schmitt B, Schulze-Briese C, Suzuki M, Tomizaki T, Toyokawa H, Wagner A (2006) The PILATUS 1M detector. J Synchrotron Radiat 13:120–130

Hammersley AP, Svensson SO, Hanfland M, Fitch AN, Hausermann D (1996) High Press Res 14:235

Hammersley AP (1997) ESRF Internal Report No. ESRF97HA02A. ESRF, Grenoble, Cedex, France

Yamamoto Y, Yu X, Babu SS (2014) Proceedings of the ASME Symposium on Elevated Temperature Application of Materials for Fossil, Nuclear, and Petrochemical Industries ASME (2014), S2-1 ETS 2014–1009

Evans M (2008) J Mater Sci 43:6070

Hasegawa Y, Muraki T, Ohgami M (2004) Metallurgical investigation of a type IV damage at the heat affected zone of weld for tungsten containing martensitic heat resistant steels’, in International Conference Experience with Creep-Strength Enhanced Ferritic Steels and New and Emerging Computational Methods, ASME, San Diego

Masuyama F (2001) ISIJ Int 41:612–625

Tsuchida Y, Tokuno K, Hashimoto K (1993) Nippon Steel Technical Report No 58:27–35

Acknowledgments

This research was conducted as part of the Fossil Energy Advanced Research Materials Program, which is sponsored by the Crosscutting Research Program, Office of Fossil Energy, U.S. Department of Energy. The author would like to thank Dr. Yukinori Yamamoto and Dr. Mike Santella from Oak Ridge National Lab (ORNL) for the mentoring and discussion. Dr. Terasaki and Dr. Komizo from Osaka University are thanked for their help and discussion on the synchrotron experiments. Mr. Thomas Muth from ORNL is thanked for technically reviewing the manuscript. The synchrotron radiation experiments were performed at the BL46XU of SPring-8 as the Priority Research Proposal (priority filed: industrial application) with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) (proposal no. 2011B1968).

Author information

Authors and Affiliations

Corresponding author

Additional information

The research work was supervised by Professor Sudarsanam Suresh Babu at The Ohio State University, Columbus, OH. This submission was sponsored by a contractor of the United States Government under contract DE-AC05-00OR22725 with the United States Department of Energy. The United States Government retains, and the publisher, by accepting this submission for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, and worldwide license to publish or reproduce the published form of this submission, or allow others to do so, for the United States Government purposes.

Doc. IIW-2512, recommended for publication by Commission IX “Behaviour of Metals Subjected to Welding.”

Rights and permissions

About this article

Cite this article

Yu, X. Correlation of ferrite formation to creep properties of Cr-Mo steel welds. Weld World 59, 251–259 (2015). https://doi.org/10.1007/s40194-014-0200-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-014-0200-5