Abstract

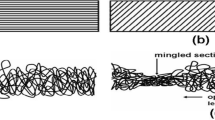

For moisture regulation, careful selection of fibre, fibre packing in yarns and fabric structure are necessary. Introducing selective porosity in yarn can significantly influence moisture transport properties in fabrics made out of profiled fibre yarn. The arrangement of fibres in the yarn and that of yarn in fabric provide wide variability in the size and shape of the passage of liquid to flow. A change in the cross sectional diameter of the capillary leads to a change in interfacial speed for liquid. The mechanism of liquid transmission in fabric is expected to be different from that in yarn in isolated state. Generally, openness in fabric offers least resistance to flow. However, at each cross over points of threads the pressure exerted by one set of yarn on another can influence the capillary geometry affecting flow of liquid. The present work reports on the investigation made to study the wicking performance of five sets of fabrics made out of five homogeneous profiled fibre yarns as weft and respective double yarns as warp. It was observed that the wicking time and height in the weft direction were different than that in the corresponding yarns. Interestingly, wicking height attained in warp direction and individual yarn in isolation does not show any significant difference. It was observed that the points of interlacements between warps and wefts were constantly splitting the fluid flow both in horizontal and vertical directions.

Similar content being viewed by others

References

S. Mhetre, R. Parachuru, J. Text. Inst. 101, 621–626 (2010)

K. Erik, Text. Res. J. 66, 660 (1996)

D. Lukas, V. Soukupova, P. Ning, D.V. Parikh, Simulation 80, 547 (2004)

R.K. Marcus, W.C. Davis, B.C. Knippel, L. LaMotte, T.A. Hill, D. Perahia, J.D. Jenkins, J. Chromatogr. A 986, 17 (2003)

S. Amico, C. Lekakou, Compos. A 31, 1331–1344 (2000)

S.C. Van der Marck, T. Matsuura, J. Glas, Phys. Rev. E 56(5), 5675–5687 (1997)

S.C. Amico, C. Lekakou, European Conference on Composite Materials, ECCM-8, Naples, Italy, 3–6 June 1998, pp. 487–494

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Datta Roy, M., Chattopadhyay, R. & Sinha, S.K. Wicking Performance of Profiled Fibre Part B: Assessment of Fabric. J. Inst. Eng. India Ser. E 99, 1–8 (2018). https://doi.org/10.1007/s40034-017-0103-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40034-017-0103-2