Abstract

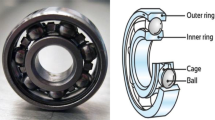

Bearing plays vital role in dynamic characteristic of any rotating machine. Vibration study of rolling element bearings in the presence of either local defect or distributed defect have been carried out by many researchers. In the present study experimental vibration studies of bearing in the presence of local defect on one of the bearing race and waviness on another race have been carried out. Moreover, the effects of local defect width, waviness order, radial load, rotational speed, presence of lubricant on vibration amplitude in the presence of local defect and race waviness have also been analyzed. Frequency peaks at both characteristic defect frequencies, based on location and type of defect have been observed in the presence of combined defects. The local defect frequency amplitude of inner race/outer race is affected by presence of distributed defect on outer race/inner race and vice versa. However, the waviness frequency amplitude found dominant as compared to local defect frequency amplitude. This study will be helpful to practicing engineers in analyzing the complex vibrations generated by defective rolling elements bearings.

Similar content being viewed by others

References

N. Tandon, A. Choudhury, A review of vibration and acoustic measurement methods for the detection of defects in rolling element bearings. Tribol. Int. 32(8), 469–480 (1999)

D.S. Shah, V.N. Patel, A review of dynamic modeling and fault identifications methods for rolling element bearing. Procedia Technol. 14, 447–456 (2014)

M.S. Patil, J. Mathew, P.K. RajendraKumar, Bearing signature analysis as a medium for fault detection: a review. J. Tribol. 130(1), 014001–014007 (2007)

S. Singh, C.Q. Howard, C.H. Hansen, An extensive review of vibration modelling of rolling element bearings with localised and extended defects. J. Sound Vib. 357, 300–330 (2015)

M.S. Patil, J. Mathew, P.K. RajendraKumar, Experimental studies using Response Surface Methodology for condition monitoring of ball bearings. J. Tribol. 132(4), 044505-1–044505-6 (2010)

V.N. Patel, D. Prajapati, Experimental study of vibrations generated by defective deep groove ball bearing. Int. J. Des. Eng. 6(4), 309–325 (2016)

V.N. Patel, N. Tandon, R.K. Pandey, A dynamic model for vibration studies of deep groove ball bearings considering single and multiple defects in races. J. Tribol. 132(4), 041101-1–041101-10 (2010)

A. Utpat, Vibration Signature analysis of defective deep groove ball bearings by Numerical and Experimental approach. Int. J. Sci. Eng. Res. 4(6), 592–598 (2013)

A. Moazen Ahmadi, C.Q. Howard, D. Petersen, The path of rolling elements in defective bearings: observations, analysis and methods to estimate spall size. J. Sound Vib. 366(Supplement C), 277–292 (2016)

S. Khanam, J.K. Dutt, N. Tandon, Impact force based model for bearing local fault identification. J. Vib. Acoust. 137(5), 0510021–05100213 (2015)

S. Khanam, N. Tandon, J.K. Dutt, Multi-event excitation force model for inner race defect in a rolling element bearing. J. Tribol. 138(1), 011106-1–011106-15 (2015)

P.K. Kankar, S.C. Sharma, S.P. Harsha, Fault diagnosis of high speed rolling element bearings due to localized defects using response surface method. J. Dyn. Syst. Meas. Contr. 133(3), 0310071–03100714 (2011)

C. Mishra, A.K. Samantaray, G. Chakraborty, Ball bearing defect models: a study of simulated and experimental fault signatures. J. Sound Vib. 400, 86–112 (2017)

F.P. Wardle, Vibration forces produced by waviness of the rolling surfaces of thrust loaded ball bearings Part 2: Experimental validation. Proc lnstn Mech Engrs 202(C5), 313–319 (1998)

H. Ohta, N. Sugimoto, Vibration characteristics of tapered roller bearings. J. Sound Vib. 190(2), 137–147 (1996)

P.K. Kankar, Fault diagnosis of a rotor bearing system using response surface method. Eur. J. Mech. A/Solids 28(4), 841–857 (2009)

C.K. Babu, N. Tandon, R.K. Pandey, Vibration modeling of a rigid rotor supported on the lubricated angular contact ball bearings considering six degrees of freedom and waviness on balls and races. J. Vib. Acoust. 134(1), 011006–0110012 (2011)

C.K. Babu, N. Tandon, R.K. Pandey, Nonlinear vibration analysis of an elastic rotor supported on angular contact ball bearings considering six degrees of freedom and waviness on balls and races. J. Vib. Acoust. 136, 044503-1 (2014)

D.S. Shah, V.N. Patel, Theoretical and experimental vibration studies of lubricated deep groove ball bearings having surface waviness on its races. Measurement 129, 405–423 (2018)

B. Dolenc, B. Pavle, J. Dani, Distributed bearing fault diagnosis based on vibration analysis. Mech. Syst. Signal Process. 66, 521–532 (2016)

U.A. Patel, S.H. Upadhyay, Nonlinear dynamic response of cylindrical roller bearing-rotor system with 9 degree of freedom model having a combined localized defect at inner-outer races of bearing. Tribol. Trans. 60(2), 284–299 (2017)

MATLAB R2016a. The MathWorks Inc., Natick (2016)

N. Tandon, A. Choudhury, An analytical model for the prediction of the vibration response of rolling element bearings due to a localized defect. J. Sound Vib. 205(3), 275–292 (1997)

A. Choudhury, N. Tandon, Vibration response of rolling element bearings in a rotor bearing system to a local defect under radial load. J. Tribol. 128(2), 252–261 (2005)

F.P. Wardle, Vibration forces produced by waviness of the rolling surfaces of thrust loaded ball bearings Part 1: theory. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 202(5), 305–312 (1988)

M. Sarangi, B.C. Majumdar, A.S. Sekhar, On the dynamics of elastohydrodynamic mixed lubricated ball bearings. Part I: Formulation of stiffness and damping coefficients. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 219, 411–421 (2005)

J. Kraus, J.J. Blech, S.G. Braun, In situ determination of rolling bearing stiffness and damping by modal analysis. J. Vib. Acoust. Stress Reliab. Des. 109(7), 235–240 (1987)

H. Saruhan, S. Sardemir, A. Cicek, I. Uygur, Vibration analysis of rolling element bearings defects. J. Appl. Res. Technol. 12(3), 384–395 (2014)

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The following general guidelines will be helpful to the practicing engineers for vibration analysis of defective bearing in the absence of misalignment and unbalanced shaft-bearing system:

Frequency peaks only at shaft rotational frequency (fs) and cage frequency with their harmonics can be observed in spectra of healthy (defect free) bearings.

In addition to shaft rotation frequency, peaks at ball pass frequency of outer race (BPFO) and its harmonics can also be observed for bearings having defects on its outer race.

The frequency peaks at ball pass frequency of inner race (BPFI) can be noticed for bearings having defects on its inner race. Moreover, the sidebands at shaft rotational frequency can also be observed due to rotation of inner race defect.

The vibration amplitudes enhance in the presence of outer race local defect as compared to same size inner race local defect.

The vibration amplitude at bearing characteristics defect frequency increases with increase in local defect width on either of races in the presence or absence of lubricant.

In case of distributed defects, the dominant frequency peaks are governed by waviness order and waviness location.

The waviness peak amplitude at wave passage frequency (WPF) = Nb × (fs − fc) can be observed for waviness order (Nw) = q × Nb, while the side band frequencies at Nb × (fs − fc) ± fs have been noticed for waviness order of Nw = q × Nb ± 1.

More complicated vibration patterns can be found for higher waviness order.

In case of outer race waviness peak amplitude at ball pass frequency Nb × fc and its harmonics can be observed irrespective of waviness order.

Severe vibration amplitudes at wave passage frequency can be noticed for inner race waviness order equal to number of balls.

The amplitude of characteristic local defect frequency (either BPFO or BPFI) increases in the presence of waviness on alternative/another race.

The dominant peak at waviness defect frequency can be observed even in the presence of local defect and distributed defect on bearing races.

Amplitude of characteristic distributed defect (wave passage frequency and side bands) increases in the presence of local defect on alternative/another race.

In general, bearing defect frequency amplitudes are also affected by magnitude of radial load, shaft rotational speed, location and size of defect, waviness order and presence of lubricant.

Rights and permissions

About this article

Cite this article

Shah, D.S., Patel, V.N. & Darji, P.H. Experimental Vibration Studies of Deep Groove Ball Bearings Having Damaged Surfaces. J. Inst. Eng. India Ser. C 100, 919–935 (2019). https://doi.org/10.1007/s40032-018-0497-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-018-0497-8