Abstract

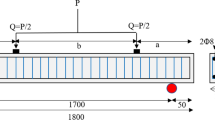

A series of experiments were conducted to study the structural behavior of conventionally reinforced (GR-GPC), steel fiber-reinforced (SFR-GPC), and post-tensioned (PS-GPC) geopolymer concrete beams with geometrical similarities. The geopolymer concrete mixtures were prepared by using fly ash (FA) as a precursor. A mixture of sodium hydroxide and sodium silicate solution was used as an alkaline activator to prepare geopolymer specimens. All concrete specimens were cured at 65 °C in a specially fabricated hot air curing chamber that is an alternative to the conventional oven. The final mix for the beams was selected based on the substantial trial mix studies conducted by varying FA content and steel fiber volume fractions. The experimental investigations are confined to studying the flexural behavior under the two-point load testing. The investigated structural parameters are cracking load, ultimate load, deflections, stiffness, ductility ratio, and failure patterns of these beams. Few important conclusions were drawn based on the discussion and comparison of results. The performance of SFR-GPC and PS-GPC was found to be superior compared to conventionally reinforced GPC beams in all structural parameters investigated.

Similar content being viewed by others

Availability of Data and Materials

The data and material are available within the manuscript.

References

M. Nodehi, F. Aguayo, Ultra high performance and high strength geopolymer concrete. J. Build. Pathol. Rehabil. 6, 1–29 (2021). https://doi.org/10.1007/s41024-021-00130-5

J. Davidovits, Geopolymers—inorganic polymeric new materials. J. Therm. Anal. 37, 1633–1656 (1991). https://doi.org/10.1007/BF01912193

M.C. Nataraja, G. Bhat, M. Manoj, S. Mallya, Investigation on concrete with crushed vitrified tiles as coarse aggregates. J. Build. Pathol. Rehabil. 7, 1–14 (2022). https://doi.org/10.1007/s41024-022-00245-3

N. Lloyd, V. Rangan, Geopolymer concrete with fly ash, in: Second International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, UWM Center for By-Products Utilization (2010), pp. 1493–1504

P. Duxson, A. Fernández-Jiménez, J.L. Provis, G.C. Lukey, A. Palomo, J.S.J. van Deventer, Geopolymer technology: the current state of the art. J. Mater. Sci. 42, 2917–2933 (2015). https://doi.org/10.1007/s10853-006-0637-z.

F. Pacheco-Torgal, J. Castro-Gomes, S. Jalali, Alkali-activated binders: a review. Part 1. Historical background, terminology, reaction mechanisms and hydration products. Constr. Build. Mater. 22, 1305–1314 (2008). https://doi.org/10.1016/j.conbuildmat.2007.10.015

A. Ojha, P. Aggarwal, Development of mix design guidelines for low calcium fly ash-based geopolymer concrete—a quantitative approach. SILICON (2023). https://doi.org/10.1007/s12633-023-02299-5

A. Jan, Z. Pu, K.A. Khan, I. Ahmad, A.J. Shaukat, Z. Hao, I. Khan, A review on the effect of silica to alumina ratio, alkaline solution to binder ratio, calcium oxide + ferric oxide, molar concentration of sodium hydroxide and sodium silicate to sodium hydroxide ratio on the compressive strength of geopolymer concrete. SILICON 14, 3147–3162 (2022). https://doi.org/10.1007/s12633-021-01130-3

S.M. Mustakim, S.K. Das, J. Mishra, A. Aftab, T.S. Alomayri, H.S. Assaedi, C.R. Kaze, Improvement in fresh, mechanical and microstructural properties of fly ash-blast furnace slag based geopolymer concrete by addition of nano and micro silica. SILICON 13, 2415–2428 (2021). https://doi.org/10.1007/s12633-020-00593-0

L. Srinivasamurthy, V.S. Chevali, Z. Zhang, M.A. Longhi, T.W. Loh, H. Wang, Mechanical property and microstructure development in alkali activated fly ash slag blends due to efflorescence. Constr. Build. Mater. 332, 127273 (2022). https://doi.org/10.1016/j.conbuildmat.2022.127273

L. Srinivasamurthy, V.S. Chevali, Z. Zhang, H. Wang, Phase changes under efflorescence in alkali activated materials with mixed activators. Constr. Build. Mater. 283, 122678 (2021). https://doi.org/10.1016/j.conbuildmat.2021.122678

R. Kumar, S.S. Mayengbam, Enhancement of the thermal durability of fly ash-based geopolymer paste by incorporating potassium feldspar. J. Inst. Eng. Ser. A 102, 175–183 (2021). https://doi.org/10.1007/s40030-020-00498-6

R.R. Bellum, M. Al Khazaleh, R.K. Pilla, S. Choudhary, C. Venkatesh, Effect of slag on strength, durability and microstructural characteristics of fly ash-based geopolymer concrete. J. Build. Pathol. Rehabil. 7, 1–15 (2022). https://doi.org/10.1007/s41024-022-00163-4

T. Mohanty, A. Kumar, P.K. Acharya, S.K. Patro, P. Saha, Performance of structural geopolymer concrete utilising ferrochrome ash and fly ash as source material. J. Inst. Eng. Ser. A 103, 1183–1194 (2022). https://doi.org/10.1007/s40030-022-00681-x

S. Jena, R. Panigrahi, P. Sahu, Mechanical and durability properties of fly ash geopolymer concrete with silica fume. J. Inst. Eng. Ser. A 100, 697–705 (2019). https://doi.org/10.1007/s40030-019-00400-z

M. Nuruddin, A. Malkawi, A. Fauzi, B. Mohammed, H.M. Al-Mattarneh, Geopolymer concrete for structural use: recent findings and limitations. IOP Conf. Ser. Mater. Sci. Eng. 133, 012021 (2016)

P. Venyite, E.C. Makone, R.C. Kaze, A. Nana, J.G.D. Nemaleu, E. Kamseu, U.C. Melo, C. Leonelli, Effect of combined metakaolin and basalt powder additions to laterite-based geopolymers activated by rice husk ash (RHA)/NaOH solution. SILICON 14, 1643–1662 (2022). https://doi.org/10.1007/s12633-021-00950-7

S. Lakshmikanth, M.C. Nataraja, Supreeth, performance of high-strength concrete using alccofine and GGBFS. J. Inst. Eng. Ser. A 103, 567–580 (2022). https://doi.org/10.1007/s40030-022-00635-3

F. Bencardino, L. Rizzuti, G. Spadea, R.N. Swamy, Stress–Strain behavior of steel fiber-reinforced concrete in compression. J. Mater. Civ. Eng. 20, 255–263 (2008)

B.W. Xu, H.S. Shi, Correlations among mechanical properties of steel fiber reinforced concrete. Constr. Build. Mater. 23, 3468–3474 (2009). https://doi.org/10.1016/j.conbuildmat.2009.08.017

Y. Haddaji, H. Hamdane, H. Majdoubi, S. Mansouri, D. Allaoui, M. El Bouchti, Y. Tamraoui, B. Manoun, M. Oumam, H. Hannache, Eco-friendly geopolymer composite based on non-heat-treated phosphate sludge reinforced with polypropylene fibers. SILICON 13, 2389–2400 (2021). https://doi.org/10.1007/s12633-020-00873-9

M. Abbass, G. Singh, Experimental investigation of engineered alkali-activated fibrous geopolymer concrete. J. Build. Pathol. Rehabil. 8, 1–15 (2023). https://doi.org/10.1007/s41024-022-00259-x

P.S. Song, S. Hwang, Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 18, 669–673 (2004)

C. Diagloes, Felipe, High performance fiber reinforced Geopolymer concrete for pavement, in: Second International Airports Conference: Planning, Infrastructure and Environment, Sao Paulo – Brazil (2006)

A. Aziz, Structural and physico-mechanical investigations of new acidic geopolymers based on natural moroccan pozzolan: a parametric study. SILICON (2022). https://doi.org/10.1007/s12633-022-02089-5

B. Susan, Performance of geopolymer reinforced with steel fiber, in: IIBC 10th Inorganic-Bonded Fiber Composite Conference (2006)

M.H. Al-Majidi, A. Lampropoulos, A.B. Cundy, Steel fibre reinforced geopolymer concrete (SFRGC) with improved microstructure and enhanced fibre-matrix interfacial properties. Constr. Build. Mater. 139, 286–307 (2017)

A.H. Choudhury, A.I. Laskar, Rehabilitation of substandard beam-column joint using geopolymer. Eng. Struct. 238, 112241 (2021). https://doi.org/10.1016/j.engstruct.2021.112241

C. Montes, E.N. Allouche, Evaluation of the potential of geopolymer mortar in the rehabilitation of buried infrastructure. Struct. Infrastruct. Eng. 8, 89–98 (2012). https://doi.org/10.1080/15732470903329314

S. Kumar, S. Rajendra, Experimental study on workability and strength parameters of fly ash based geopolymer concrete using M-sand. Int. J. Manag. Technol. Eng. 9, 338–347 (2020)

R.V. Rangnath, S. Mohammad, Some optimal values in geopolymer concrete incorporating fly ash. Indian Concr. J. 82, 26–35 (2008)

D. Hardjito, S.E. Wallah, D.M. Sumajouw, B.V. Rangan, Fly ash-based geopolymer concrete development and properties of low-calcium fly ash-based geopolymer concrete. Aust. J. Struct. Eng. 6, 77–86 (2005)

P. Ramadoss, K. Nagamani, Investigation on the tensile strength of high performance fiber reinforced concrete using statistical methods. Comput. Concr. 3, 389–400 (2006)

S.K.K.Y. Mohammadi, S.P. Singh, Properties of steel fibrous concrete containing mixed fibres in fresh and hardened state. Constr. Build. Mater. 22, 956–965 (2008)

N. Ganesan, P.V. Indira, Engineering properties of steel fibre reinforced geopolymer concrete. Adv. Concr. Constr. 1, 305–318 (2013)

IS 1199 (Part 1) : 2018, Fresh Concrete Methods of Sampling, Testing and Analysis Part 1 Sampling of Fresh Concrete (First Revision) (2018)

IS 3812–2003 (Part 1&2), Specification for Pulverized Fuel Ash (2003)

IS 1785–2 (1983), Plain Hard-Drawn Steel Wire for Prestressed Concrete, Part 2: As Drawn Wire (1983)

IS: 9103–1999, Concrete Admixtures Specifications (1999)

IS 1199: Part 2: 2018, Fresh Concrete Methods of Sampling, Testing and Analysis Part 2 Determination of Consistency of Fresh Concrete (First Revision) (BIS, India, n.d.)

M.C. Nataraja, A.P.Gupta, N. Dhang, Stress-strain curves for steel fiber-reinforced concrete in compression. Cem. Concr. Res. 21, 383–390 (1999)

M.C. Nataraja, A. P Gupta, N. Dhang, Toughness characterization of steel fiber reinforced concrete by JSCE approach. Cem. Concr. Res. 30, 593–597 (2000)

S.K. Nath, S. Maitra, S. Mukherjee, S. Kumar, Microstructural and morphological evolution of fly ash based geopolymers. Constr. Build. Mater. 111, 758–765 (2016). https://doi.org/10.1016/j.conbuildmat.2016.02.106

IS 516: Part 1: Sec 1: 2021, Hardened Concrete Methods of Test Part 1 Testing of Strength of Hardened Concrete Section 1 Compressive, Flexural and Split Tensile Strength (First Revision) (2021)

Acknowledgements

The authors would like to thank Bangalore Institute of Technology (BIT), Bangalore, India, for providing laboratory access for the conduction of necessary experiments.

Funding

The authors declare that no funds, grants, or other supports were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics Approval

Not applicable (as the results of studies do not involve any human or animal).

Consent to Participate

All the authors declare their consent to participate in this research article.

Consent for Publication

All the authors declare their consent for publication of the article on acceptance.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Mix Design

The wet density of geopolymer concrete = 2400 kg/m3.

The ratio of sodium silicate to sodium hydroxide solution = 2.5.

Total water content (chosen) = 130 l/m3 and the water content in sodium silicate = 33.53%.

(Na2SiO3/NaOH) solution = 2.5.

Calculation of Total Alkaline Solution for the Given Water Content

Total water present in combined solution = water present in NaOH + water in Na2SiO3.

i.e., 130 = ((1000 × Xg)/1640) + (2.5 × Xg × 0.3353), where Xg is the mass of NaOH solution.

Xg = 89.77 kg/m3, therefore Na2SiO3 = 224.425 kg/m3

Total solid particulate = 2400 − (89.77 + 224.425) = 2085.81 kg/m3

If 27% fly ash is used, then fly ash = 2085.81 × 0.27 = 563.17 kg/m3

Total aggregate excluding to fly ash = 2085.81 − 563.17 = 1522.64 kg/m3

The proportion of coarse aggregate to fine aggregate based on the least void content.

Coarse aggregate = 0.56 × 1522.64 = 852.68 kg/m3

Fine aggregate = 0.44 × 1522.64 = 669.96 kg/m3

Polycarboxyl ether-based superplasticizers used with a dosage of 1–2%.

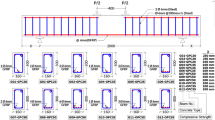

Appendix 2: Moment of Resistance and Post-tensioning Force

Moment of Resistance of Singly Reinforced GR Beam

Post-tensioning Force for GR Beam

The load balancing concept is applied to equate the moment of resistance of the beam with the post-tensioning force. Assuming zero tensile stress at the bottom of the beam

3 No -7 mm ϕ tendons were used,

Force applied on each tendon = \(\frac{P}{3}\) = 35 kN.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Srinivasamurthy, L., Nataraja, M.C. & Srinivasan, K. Investigation on Flexural Behavior of Conventionally Reinforced, Steel Fiber-Reinforced, and Post-tensioned Geopolymer Concrete Beams. J. Inst. Eng. India Ser. A 105, 129–150 (2024). https://doi.org/10.1007/s40030-023-00772-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40030-023-00772-3