Abstract

This study investigates the potential of a blended binder formulated from two industrial solid wastes viz. phosphogypsum and fly ash in combination with lime. Three mix proportions of phosphogypsum and fly ash were investigated, and the minimum lime contents required for activation were determined using the Eades and Grim pH test. The lime–fly ash–phosphogypsum blends were then cast into cubes, both in their paste form as well as mortar form, mixed with sand in the ratio of 1:3. They were cured for a period of seven days, and afterwards, their compressive strength was determined. Ordinary Portland cement and lime mortar blocks were also cast as control specimens for comparative evaluation of the strength. The optimal lime–fly ash–phosphogypsum blend was identified and used to construct a masonry prism, and the strengths of the masonry prisms were also evaluated. The optimal lime–fly ash–phosphogypsum blend mortar was also subjected to an X-ray diffraction analysis to determine the reaction products formed during hydration. The study revealed that 5% lime mixed with fly ash:phosphogypsum in the ratio of 3:1 was the optimal proportion which gave the maximum strength to the cubes. The optimal lime–fly ash–phosphogypsum blend mortar developed strength that was higher than conventional Portland cement and lime mortar. The optimal lime–fly ash–phosphogypsum blend mortar masonry prisms developed strength that was comparable to that of Portland cement mortar masonry. The X-ray diffraction analysis revealed the formation of calcium silicate hydrate minerals as well as ettringite and portlandite which were responsible for strength gain.

Similar content being viewed by others

Introduction

Shelter is one of the fundamental requirements of any human being which protects humans from the vagaries of the weather and provides privacy. The invention of cement was a turning point in the evolution of human civilization and has resulted in great progress in the developmental activities of the human nature. Although cement has been greatly helpful in achieving larger, stronger, and taller constructions, it became a source of heavy carbon dioxide generation and needs huge energy requirement (Lam 2018). Cement concrete is now, by far, the most utilized material in the world for construction, second only to water (Gagg 2014). With increasing developmental activity, the demand for cement does not show any reduction. The worldwide cement production was 4.1 Gt per annum in 2019 with China accounting for 55% of the production (Levi et al. 2020). In developing countries like India, there is a huge need for housing. India has taken up an ambitious project of housing for all by 2022, requiring an investment of 2 trillion US dollars with 70% of the need in the affordable housing segment (Klynveld Peat Marwick Goerdeler and National Real Estate Development Council 2014). In India, the cement prices have also spurted in recent times with renewed construction activity after a period of lull due to the COVID-19 pandemic. Thus, there is an urgent need to develop alternative binders to reduce the environmental impact of the use of cement and concrete as well as the cost of affordable housing construction. The most common technique to reduce the environmental footprint of cement is the industrial waste usage in the manufacture of cement clinkers thereby developing blended types of cements, like Portland pozzolana and Portland slag cement. However, alternative binders are key to reduce emissions during cement production process (Levi et al. 2020). There are different component alternatives for cement including sulfoaluminate cement, activated alkaline binders and geopolymers (Coppola et al. 2018). Carbonation of calcium silicates developed by Solidia Technologies is another alternative (Levi et al. 2020). In recent years, researchers attempted the utilization of solid wastes in the developmental process of alternative binders. The attempts in development of alternative binders are approached from two angles. Both involve the utilization of solid waste materials in the development of the binders, the difference being one approach adopts small quantities of cement as activator for the binder, whereas the second approach is completely devoid of cement in its composition. Hwang and Shahsavari (2019) investigated the optimization of a high calcium cementless fly ash (FA) binder with a low environmental footprint. Their optimized composition comprising of FA and calcium oxide with small quantities of sodium hydroxide, sodium metasilicate pentahydrate and nano silica developed 7-day strength of 16.18 MPa, which was comparable to that of conventional cement. Huang and Lin (2010) investigated the potential of cement made from phosphogypsum (PG), steel slag, ground granulated blast furnace slag (GGBS) and limestone. They found that the combination of 45% PG, 10% steel slag, 35% GGBS and 10% limestone was capable of developing a 28-day strength in excess of 40 MPa. Do et al. (2018) researched the development of a cementless binder for stabilization of marine sediments. Their optimal combination of binder made with FA, lime, gypsum and red mud resulted in the strength of the untreated marine dredged sediments increasing from less than 0.1 MPa to close to 7 MPa. Morsy et al. (2020) studied the performance of a green binder comprising of lime, FA, ceramic waste powder and anhydrous gypsum. The study revealed that a combination of 30% lime, 50% FA, 20% ceramic waste powder and 10% anhydrous gypsum developed a strength greater than 25 MPa at 28 days of curing. Kang et al. (2019) attempted to develop an eco-friendly construction material free of ordinary Portland cement (OPC). A combination of 61% GGBS, 26% hydrated lime, 6.5% silica fume and 6.5% rice husk ash developed a strength of more than 30 MPa at 7 days and 50 MPa at 28 days of curing. Huang and Lin (2011) investigated the development of a PG-GGBS-OPC binder, wherein the OPC content was limited to 4% of the binder paste. A combination of 40% PG, 56% GGBS and 4% OPC was capable of developing a strength greater than 50 MPa at 28 days of curing. Lam (2018) attempted to develop a super-sulphated cement using combinations of PG, GGBS and OPC. It was found that a combination of 30% PG, 60% GGBS and 10% OPC was capable of developing a strength of 50 MPa after 28 days of curing against a strength of 48 MPa developed by pure OPC. Bumanis et al. (2020) investigated the performance of a lightweight high-performance PG-based ternary system binder. Their ternary binder system consisting of PG, OPC and metakaolin in the proportions of 1, 0.4 and 0.4, respectively, admixed with superplasticizer and set retarder developed a strength of 50 MPa at 28 days of curing and 88 MPa at 35 days of curing. Mashifana et al. (2019) delved into a PG-based binder composite comprising of PG, lime, FA and basic oxygen furnace slag (BOF). A combination of 20% raw PG, 70% lime-FA in the ratio 1:2 and 10% BOF developed a strength of 7.4 MPa at an elevated temperature of 80 °C for 4 days. Based on the sift through literature, it can be seen that there have been attempts to develop binders which can potentially reduce the dependence on OPC. The use of industrial wastes in the development of alternative binders shows a lot of promise with FA, PG and GGBS being often used waste materials in this endeavour. Despite active research continuing in this field, there has not been much headway achieved in making them mainstream materials to replace OPC in common applications. There still remains a need to identify new composites that can achieve mainstream popularity to replace OPC. To begin with, this can be done by focussing on development of alternative binder composites for specific applications such as masonry, plastering and concreting. Thus, this investigation attempted to adopt two of the commonly used industrial wastes viz. PG and FA along with lime in the development of a binder without cement for use in the construction of low-cost houses. This investigation was carried out from January to April of 2018 at Tagore Engineering College, Chennai, India, and all self-elaborated data used in this work are from this period.

Materials and methods

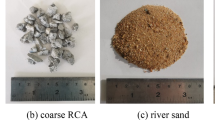

The various materials used in this investigation include PG, FA and lime which formed the core components of the binder and river sand for use in the preparation of the mortar.

Materials used in the investigation

PG is a by-product of the fertilizer industry generated during the manufacturing of phosphatic fertilizers from phosphate containing rocks using the wet acid method. The worldwide PG production is estimated to be in the range of 200–250 million tonnes per year (Saadaoui et al. 2017). The worldwide utilization of PG as building materials is around 15% (Rashad 2017; Chernysh et al. 2021). In India, the annual production of PG is 12 million tonnes of which around 40–45% of the waste is reused in the manufacture of building materials (Havanagi et al. 2018). That still leaves huge quantities in PG dumps leading to waste management problems. The PG used in the present investigation was obtained from Ennore, near Chennai, India. FA is the residual ash obtained from the burning of coal for the generation of power in thermal power plants. It is one of the four coal combustion products (Puppala 2016). FA is broadly categorized into Class C type which is calcareous and Class F type which is siliceous in nature. The former is self-cementing, whereas the latter is pozzolanic. The worldwide generated quantity of coal combustion products as of 2016 was 1221.9 million tonnes (Harris et al. 2019). The annual generation of FA in the first half of the financial year 2019–2020 in India was 129.1 million tonnes (Central Electricity Authority 2020). The FA generated in India has a utilization rate of 78.19% amounting to 100.94 million tonnes. The utilization statistics of FA in various avenues are shown in Fig. 1. The FA used in this investigation was class F, sourced from a local supplier. High-quality industrial-grade hydrated lime was used in the investigation. The industrial-grade lime was obtained from M/s. Shiyal Chemicals, Chennai. Table 1 lists the chemical composition of the materials used in this investigation.

Modes of utilization of FA (%) in first half of 2019–2020 in India (Central Electricity Authority 2020)

Experimental methodology

The experimental investigation began with the collection and preparation of materials. The PG collected from its source was wet. It was air-dried in the geotechnical laboratory, and clumps were pulverized. It was then sieved through a 75-micron sieve, and the fine fractions passing through the sieve were used in the investigation. A similar procedure was also followed for the preparation of FA as well. The lime was used without any specific preparatory processes. Following the preparation, three trial mixes were randomly selected for blending FA and PG as the base material for the alternative binder. The three combinations of FA:PG considered were 25:75, 50:50 and 75:25. To determine the lime required for activation of the binder, a pH test to determine the initial consumption of lime (ICL) was performed, according to the American Society of Testing and Materials (ASTM) code (ASTM 2019). The FA and PG samples were oven-dried at a temperature of 60 °C before testing. 25 g of a particular blend of FA:PG was placed in an airtight container. To this sample, 2% of lime by total dry weight of the blend was added in dry form and mixed thoroughly. Similarly, for a particular blend, multiple samples of 25 g each were prepared with increasing lime content up to 12%, in increments of 1%. To each of these mixtures, 100 ml of distilled water was added and stirred for a minimum of 30 s. The specimens were continued to be stirred for 30 s every 10 min for a duration of 1 h. Within 15 min of the end of the 1 h period, a calibrated pH metre was inserted into each of the containers to determine the pH of the solutions prepared. The ICL was fixed as the minimum lime content required to raise the pH of the solution to 12.4. The same procedure was repeated to determine the ICL values of the other two FA:PG blends as well. Although the test was originally proposed for determining the lime proportion required for modifying soil properties, this was extended to the solid wastes in the present study. In earlier studies, involving lime–FA–PG (LFP) combinations, the lime required for activation was determined based on strength tests (Shen et al. 2007) or compaction tests (Dutta and Kumar 2016). Following the determination of ICL values for the three trial mixes, the FA–PG blends were mixed with lime as determined from the pH tests to prepare a binder paste. The paste was prepared by dry mixing the calculated quantities of FA and PG to obtain a uniform dry mix while maintaining the FA:PG ratio. To this, the ICL content was added in dry form and again mixed to achieve a uniform mix. A water-binder ratio of 0.5 was used for preparing the wet mix. The mixing of the pastes was done manually using a trowel for a period of 10 min. According to the Bureau of Indian Standards (BIS) code, the binder paste was filled in mortar moulds of dimensions 70.6 mm × 70.6 mm × 70.6 mm (BIS 1988) in two layers and tamped uniformly using a tamping rod such that there is full compaction without segregation or laitance. The excess paste in the top layer was stricken off, and top surface was finished uniformly using a trowel. The moulds were then placed under damp sacks for 24 h. They were then demoulded and immersed in water for a period of 7 days for curing. The same three combinations were also used to prepare a mortar mix, wherein one part of the binder in the fixed proportions was mixed with three parts of well-graded river sand. The mortar cubes were also prepared following the same procedure described for paste cubes. At the end of the curing period, the cubes were tested for compressive strength without any packing. Three specimens of each combination were cast, and the average value was reported as the final result. Three specimens of 1:3 OPC mortar as well as lime mortar were also cast as control specimens to compare the performance of the blended paste as well as mortar cubes. Following the identification of the optimal combination of the blend, a brick masonry prism of size 680 mm × 280 mm × 120 mm was constructed using 1:3 OPC mortar, lime mortar and the optimal combination to compare the performance of the same when used in masonry construction. To test the strength of the masonry prism, it was loaded on to a compression testing machine and loaded until failure. Finally, a cost analysis was also performed to compare the cost economics of the alternative mortar in comparison with conventional mortars. Table 2 shows the various combinations tested in this study. CM and LM refer to OPC and lime mortar, respectively. The proportions of each material have been worked out as percentage of the final mix of 100%. LFP refers to the combination of lime, FA and PG mix with the numbers indicating the proportions of FA to PG blends.

Results and discussion

The results of the investigation have been discussed in the following sections.

Identification of lime content required for activation

The lime content required for activating the blend to set into a hardened paste was determined using a pH test as against the usual practice of strength tests or compaction tests. Fig. 2 shows the results of the pH test. The minimum lime content required to raise the pH to 12.4 was taken as the ICL requirement for a particular mix. For LFP13, when the lime content is increased from 2 to 3%, the pH increases from 10.31 to 12.49. For LFP11, the pH increases from 10.5 to 12.43 when the lime content increases from 3 to 4%. For LFP31, the pH increases from 11.27 to 12.43, when the lime content increases from 4 to 5%. For all three combinations, there is very marginal variation in pH, on further increase in lime content. Thus, from Fig. 2, the ICL for LFP13, LFP11 and LFP31 was 3%, 4% and 5%, respectively. With the increase in FA content, there is an increase in the lime content required for increasing the pH to 12.4. It is a well-known fact that lime stabilization requires a high pH for the pozzolanic reactions to proceed. The increased availability of the pozzolan has thus increased the requirement of the activator. Increased FA content results in more interaction between the pozzolan and the activator thereby increasing the requirement of the activator for enhanced pH of the mix. It can also be seen that this quick test can be used for the determination of lime content for activation.

Compressive strength of blend pastes

The compressive strengths of the pastes were determined according to the procedure in BIS code (BIS 1981). The mortar, as well as paste cubes, was cured for a period of 7 days following which they were tested for their compressive strengths. Figure 3 shows the compressive strength of all the paste cubes in comparison with the conventional OPC and lime mortars. OPC and lime paste cubes were not considered for comparison because they are usually adopted as mortars in combination with sand for masonry construction in practice. Results show that none of the combinations match up to the strength developed by 1:3 OPC mortar which developed a strength of 12.26 MPa after 7 days of curing. Strength as high as 30 MPa after 7 days of curing has been reported (Karim et al. 2015). LFP11P and LFP31P performed significantly better than lime mortar which developed a strength of 1.65 MPa at the end of 7 days of curing. LFP13P could develop only a strength of 0.24 MPa, whereas the other two combinations of LFP11P and LFP31P were able to develop significant strength of 6.64 MPa and 7.11 MPa, respectively. Lime mortar develops only 13.5% of the strength developed by OPC mortar. LFP13P, LFP11P and LFP31P were able to develop 1.9%, 54.1% and 58% of the strength of the OPC mortar, respectively. Thus, direct utilization of wastes in the paste form cannot give a comparable performance to that of conventional OPC mortar. The compositions of the different LFP combinations reveal that high proportions of PG were detrimental to the development of strength of the paste. With a reduction in PG content and an increase in FA content, the strength increased significantly. This was also evident in the study conducted by Shen et al. (2007). They found that strength was maximum when the PG content was between 23 and 34% (Shen et al. 2007), which is in agreement with the results in this study. However, the proportions of FA and PG were varied in very broad proportions, and hence, the optimal combination of FA and PG cannot be very accurately inferred from the present results. However, high proportions of PG in the mix are certainly not beneficial for strength gain.

Compressive strength of blend mortars

The blends were also tested in combination with sand as a mortar instead of pure pastes. For the preparation of blend mortars, one part of the blend and three parts of sand were used. Fig. 4 shows the strength of the blend mortars compared to conventional OPC and lime mortars. The trends of the strength gained in the blend mortar cubes are almost similar to that of the paste cubes with the exception that the mortar cubes perform much better than the paste cubes. The combination LFP31M performs significantly well enough to develop strength higher than OPC mortar. Similar to the paste cubes, LFP13M develops the least strength of all three blends at 0.71 MPa, whereas the blends LFP11M and LFP31M develop strengths of 8 MPa and 13.87 MPa, respectively. When prepared as blend mortars, LFP13M, LFP11M and LFP31M were capable of developing 5.8%, 65.2% and 113.1% of the strength developed by OPC mortar, respectively. The addition of sand in the mix has resulted in significant improvement in the performance of the binder. Taking a look at LFP31, its performance increases from 58% for the paste to 113.1% for the mortar, indicating that it has gained 13.1% more strength than the control OPC mortar specimen, due to the introduction of sand into the mix. Thus, three things are evident. The alternative blends perform significantly better in the mortar form rather than their pure paste form. This may be due to better hydration and packing of the mix when sand is incorporated into the mix. The second point is that even in the case of mortars when sand is incorporated into the mix, too much PG is not beneficial for the strength of the mix. The last point is that LFP31 is the most optimal combination for use as an alternative binder.

A comparative evaluation of the present study with earlier work

The development of strength of the paste, as well as mortar cubes in this study, was put in perspective with other similar studies conducted earlier. Three studies stood out in particular due to the similarities in the composition of the blend investigated. These investigations were done by Shen et al. (2007), Dutta and Kumar (2016) and Mashifana et al. (2018). The former two considered the LFP combination for use as a road base material, whereas the latter considered the combination for stabilizing expansive soils to be used as a road base. Table 3 gives the proportions of LFP used in the four studies for comparison of their respective strengths. All combinations compared were those of pastes since there was insufficient data related to mortar combinations for comparison.

Figure 5 shows the comparison of the strengths of the composite blends from the three studies. The strength tests on the blends in the present study, Shen et al. (2007) and Mashifana et al. (2018) were done on specimens with width to height ratio of 1, whereas Dutta and Kumar (2016) adopted a diameter to height ratio of 2. Generally, the strength of a cylindrical concrete specimen is taken as 80% of the strength of a concrete cube. However, other works like Dillon and Rankin (2013) report this relation to be 0.88 on an average for concrete with strength less than 35 MPa, whereas Kusumawardaningsih et al. (2015) report this to be 0.89 for ultra-high performance concrete. Since there is no big difference between the two values and the present study deals with alternative binder mortars whose strength does not exceed 35 MPa, the conservative value of 0.88 has been adopted to normalize the cylinder strength to cube strength. There is a major limitation in adopting this value which is the use of the value for a material for which it was not developed. Despite the shortcoming, the normalization is only for the sake of comparison and not for drawing any significant conclusions. It is clear from the figure that the compressive strengths developed by two of the LFP composites in the present study are higher than those reported in the earlier investigations. Shen et al. (2007) reported a strength of 2.75 MPa, whereas Dutta and Kumar (2016) reported a much lower strength of 0.58 MPa. Mashifana et al. (2018) reported a strength of 4.8 MPa, which is the highest of the three studies considered for comparison with the present study. But, it should be noted that their lime content of 20% was significantly higher than the ones used in the other investigations. The combinations reporting good strengths were LFP31P, LFP11P and LFP35, all of which had a PG content of 50% or lower. Thus, it can be stated that PG content beyond 50% may not give beneficial strength of LFP composites. On the other hand, too low PG content is also not beneficial. Dutta and Kumar (2016) reported a lower strength in their investigation, wherein their PG content was only 2%. As mentioned earlier, Shen et al. (2007) reported that the maximum strength of the LFP composites is obtained when the PG content is between 23 and 34%. The present study is in very good agreement with it as the maximum strength was obtained for the combination LFP31P, wherein the PG proportion was 23.81%.

Strength of masonry prisms

The performance of the optimal blend mortar was also studied in comparison with that of lime and OPC mortar to measure its specific performance for masonry construction. Figure 6 shows the compressive strength of the masonry prisms constructed using OPC mortar, lime mortar, optimal blend paste and optimal blend mortar. The strength of the masonry prism constructed using conventional burnt clay bricks and optimal blend mortar (LFP31MM) has developed the maximum strength of 1.225 MPa compared to a strength of 1.18 MPa developed by OPC mortar masonry (CMM). The strength of the LFP31MM was 4.17% higher than CMM and 38.89% higher than the strength developed by lime mortar masonry (LMM). The masonry constructed with optimal blend paste (LFP31PM) developed a strength of 0.98 MPa which was 0.1 MPa more than that of the LMM prism. The incorporation of sand in the paste resulted in an increase in the masonry strength by 11.11%. Thus, it can be seen that the optimal blend mortar was found to be effective as a mortar for the construction of masonry walls and provided a comparable performance to that of CMM.

Cost analysis of masonry

The material cost incurred to construct the masonry prisms was worked out based on the prevailing schedule of rates in Tamil Nadu, India. Labour cost was not considered because it is the same irrespective of the mortar adopted for the construction of the masonry prism. This cost analysis was done to compare the cost-effectiveness of the blended pastes and mortars to determine whether the blended mortar was capable of achieving low-cost construction. Table 4 shows the cost incurred for the construction of the masonry prisms and projected as cost per square metre area of masonry. From the table, it can be seen that in terms of absolute material cost incurred to construct the masonry wall, the blended paste, as well as blended mortar, is cheaper when compared to lime and OPC mortar. Taking the cost for OPC mortar masonry as a reference, the cost of construction of LMM was 34.48% higher. LFP31PM resulted in 31.04% cheaper construction, whereas LFP31MM was cheaper by 9.2%.

Figure 7 shows the cost to strength ratio of the different masonry prisms. Taking into account the strength developed by the masonry prisms, the blended paste, as well as mortar, resulted in masonry that cost ₹643.11 and ₹677.41 per MPa strength developed. CMM cost ₹777.1 per MPa strength developed, whereas LMM was even more costlier, ₹1393.41 per MPa strength developed. Thus, they were cheaper than CMM by 17.24% and 12.83%, respectively. The strength of the masonry gave a more realistic picture of the cost-effectiveness of the blended paste as well as mortar. Thus, it can be concluded that the alternative blended paste as well as mortars is cost effective and can play a vital role in providing affordable housing.

X-ray diffraction (XRD) of optimal blend

To understand the cause for the increase in strength of the blended paste and mortar, XRD tests were conducted on specimens of optimal blended paste and mortar. Figure 8 shows the XRD scatter pattern of the blended mortar. From the figure, it can be seen that peaks are corresponding to different phases of calcium silicate hydrate (CSH) at 2-theta angles of 15.9°, 23.01°, 29.45° and 32.32°. A peak of ettringite was also detected at a 2-theta angle of 9.29°. The introduction of sand into the paste to make the mortar was also detected in the form of quartz peaks at 2-theta angles of 21°, 26.71°, 39.62°, 40.96° and 68.33°. Formation of portlandite was also detected with peaks at 2-theta angles of 51.42° and 55.09°. Thus, the XRD test reveals that the formation of CSH minerals, ettringite and portlandite contributes to the hardening and strength gain of the binder mortar. The mechanism of strength gain in the alternative binder is the pozzolanic reaction between the lime and FA resulting in the formation of reaction products like CSH and ettringite accelerated by the addition of PG. PG accelerates the reaction between lime and FA. Ettringite further contributes to strength gain by filling the pore spaces. The crystalline nature of PG with regular sharp edges also contributes to the increased frictional interaction in the alternate binder.

The literature reveals supporting evidences for the proposed mechanism of strength gain in the alternative binder in different investigations. Peaks at 2-theta angles similar to the present study corresponding to CSH minerals, ettringite, quartz and portlandite have been reported by earlier researchers including Hajjaji and Mleza (2014), Dutta and Kumar (2016), Do et al. (2018) and Manh Do et al. (2019). Dutta and Kumar (2016) found CSH and ettringite being responsible for strength gain in lime–PG systems. PG has been found to accelerate development of strength in lime stabilized soil by James and Pandian (2014, 2016a, b). Frictional interaction of PG and ettringite’s contribution to strength through filling of pores have also been reported by Shen et al. (2007).

Environmental impact of alternative binders

The significance of alternative binders is their reduced environmental impact and sustainable nature. Alternative binders made of wastes have the potential to increase the reuse of solid wastes (Kang et al. 2019). The OPC-free mortar proposed in this study has the potential to increase the utilization of wastes like FA and PG, thereby reducing problems of dumping. This is especially useful for a waste like PG whose global utilization levels in building materials are only around 15% of the generation levels (Rashad 2017; Chernysh et al. 2021). Based on the development of strength of the binder mortar, it can be safely stated that this alternative blended mortar can have practical applications and eventually can replace OPC mortars. Moreover, the reduction in the use of OPC mortars can greatly reduce the carbon footprint and embodied energy required for its manufacture. However, it is paramount that such mortars are user-friendly and perform satisfactorily in field conditions and are durable. The performance of the mortar in masonry construction was evaluated in this study, but long-term durability performance still needs to be evaluated in the future investigations.

Conclusion

The present investigation attempted to develop an alternative binder by blending waste materials generated as by-products from industries to potentially replace OPC for use in masonry construction. There have been earlier works investigating this combination of LFP focussing on its application as a road base material. Moreover, previous investigations, adopted strength tests or compaction tests for identifying the optimal dosage of lime used in the binder. However, the present study differs from earlier ones in the facts that (1) it used a simple and quick method of identifying the lime content required as activator based on pH test for quick optimization of the various blends, and (2) it focussed on the utilization of the binder as a cost-effective alternative for OPC to be used in masonry construction. Based on the results of the investigation, the following points can be concluded.

-

1.

The Eades and Grim pH test was adopted for the determination of the lime content required for the various blends of the wastes. The lime content required for different blends for activation increased with an increase in the FA content of the blend. Thus, it can be concluded that the requirement of activator depends on the composition of the blend, especially the pozzolan.

-

2.

Both the pastes, and the mortars with high PG content, produced very low strengths. Thus, it can be concluded that high PG content in the blend is detrimental to the development of the strength of the blend irrespective of the presence or absence of sand.

-

3.

The maximum strength of the paste, as well as the mortar blends, was developed by the LFP31 combination. It can be stated that for the combinations considered in the present study, LFP31 with 5% lime was the most optimal combination.

-

4.

Comparing the strength of the pure paste blends with those of the mortar blends, it was found that mortar blends developed higher strengths. This was also true for the optimal blend paste and mortar used in the construction of masonry prisms. Thus, it can be stated that the use of solid waste blends with sand in the form of a mortar is recommended rather than the pure paste of the blend as a binder.

-

5.

The cost analysis of the masonry construction using conventional mortars as well as the optimal blend developed in the present study revealed that the waste blended paste was 31% cheaper than OPC masonry, whereas the waste blended mortar was 9% cheaper. However, on analysing the cost to strength ratio, it was found that the alternative blend paste and mortar were cheaper than OPC masonry by 17% and 13%, respectively. Thus, it can be concluded that the optimal blend binder is more cost-effective than conventional OPC and lime-based masonry.

-

6.

The XRD test on the optimal blend mortar revealed the formation of CSH minerals, ettringite and portlandite which was responsible for the development of strength, and the inherent mechanism responsible for the development of the strength of the blend mortar is very similar to the hydration reactions of OPC.

This investigation focussed on the strength development of the alternative solid waste-based binder for use in masonry construction. However, the durability aspect of the alternative binder can be evaluated to know its long-term performance in the future investigations. Moreover, the proportions of the solid wastes were varied broadly, which still leaves scope for optimizing the proportions for maximum strength of the binder.

References

ASTM (2019) D6276 Standard test method for using pH to estimate the soil-lime proportion requirement. United States

BIS (1981) IS 2250: preparation and use of masonry mortar

BIS (1988) IS 4031 Part 6: methods of physical tests for hydraulic cement part 6 determination of compressive strength of hydraulic cement other than masonry cement (First Revision)

Boral Industries Inc. (2021) Chemical Comparison of Flyash and Portland Cement. In: Flyash.com. https://flyash.com/wp-content/uploads/assets/Boral-Chemical-Comparison-2-1-21.pdf. Accessed 12 May 2021

Bumanis G, Zorica J, Bajare D (2020) Properties of foamed lightweight high-performance phosphogypsum-based ternary system binder. Appl Sci 10:6222

Central Electricity Authority (2020) Report on at coal/lignite based thermal power stations and its utilization in the country for first half of the year 2019-20. New Delhi, India

Central Pollution Control Board (2012) Guidelines for management and handling of phosphogypsum generated from phosphoric acid plants (Final Draft). New Delhi, India

Chernysh Y, Yakhnenko O, Chubur V, Roubík H (2021) Phosphogypsum recycling: a review of environmental issues, current trends, and prospects. Appl Sci 11:1–22. https://doi.org/10.3390/app11041575

Coppola L, Bellezze T, Belli A et al (2018) Binders alternative to Portland cement and waste management for sustainable construction—part 1. J Appl Biomater Funct Mater 16:186–202. https://doi.org/10.1177/2280800018782845

Dillon R, Rankin GIB (2013) Cube, cylinder, core and pull-off strength relationships. Proc Inst Civ Eng Struct Build 166:521–536. https://doi.org/10.1680/stbu.11.00075

Do TM, Kang G, Vu N, Sang KY (2018) Development of a new cementless binder for marine dredged soil stabilization: strength behavior, hydraulic resistance capacity, microstructural analysis, and environmental impact. Constr Build Mater 186:263–275. https://doi.org/10.1016/j.conbuildmat.2018.07.130

Dutta RK, Kumar V (2016) Suitability of flyash-lime-phosphogypsum composite in road pavements. Period Polytech Civ Eng 60:455–469. https://doi.org/10.3311/PPci.7800

Gagg CR (2014) Cement and concrete as an engineering material: an historic appraisal and case study analysis. Eng Fail Anal 40:114–140. https://doi.org/10.1016/j.engfailanal.2014.02.004

Klynveld Peat Marwick Goerdeler, National Real Estate Development Council (2014) Decoding housing for all by 2022. https://www.kpmg.com/IN/en/IssuesAndInsights/ArticlesPublications/Documents/Decoding-Housing-for-all-2022.pdf

Hajjaji M, Mleza Y (2014) Hydrated burnt clay–lime mixes: effects of curing time and lime addition. Appl Clay Sci. https://doi.org/10.1016/j.clay.2014.07.033

Harris D, Heidrich C, Feuerborn J (2019) Global aspects on coal combustion products. In: Coaltrans Conference on https://www.coaltrans.com/insights/article/global-aspects-on-coal-combustion-products

Havanagi V, Sinha AK, Parvathi GS (2018) Characterization of Phosphogypsum waste for Road construction. In: Proceedings of the Indian Geotechnical Conference, 13–15 December. Bengaluru, India, pp 1–5

Huang Y, Lin Z (2010) Investigation on phosphogypsum–steel slag–granulated blast-furnace slag–limestone cement. Constr Build Mater 24:1296–1301. https://doi.org/10.1016/j.conbuildmat.2009.12.006

Huang Y, Lin Z (2011) A binder of phosphogypsum-ground granulated blast furnace slag-ordinary portland cement. J Wuhan Univ Technol Sci Ed 26:548–551. https://doi.org/10.1007/s11595-011-0265-6

Hwang SH, Shahsavari R (2019) High calcium cementless fly ash binder with low environmental footprint: Optimum Taguchi design. J Am Ceram Soc 102:2203–2217. https://doi.org/10.1111/jace.15873

James J, Pandian PK (2014) Effect of Phosphogypsum on the Strength of Lime Stabilized Expansive Soil. Gradevinar 66:1109–1116. https://doi.org/10.14256/JCE.1097.2014

James J, Pandian PK (2016a) Plasticity, swell-shrink and microstructure of phosphogypsum admixed lime stabilized expansive soil. Adv Civ Eng 2016:1–10

James J, Pandian PK (2016b) Role of Phosphogypsum and ceramic dust in amending the early strength development of a lime stabilized expansive soil. Int J Sustain Constr Eng Technol 7:38–49

James J, Pandian PK, Switzer AS (2017) Egg Shell Ash as Auxiliary Addendum to Lime Stabilization of an Expansive Soil. J Solid Waste Technol Manag 43:15–25

Kang SH, Kwon YH, Hong SG et al (2019) Hydrated lime activation on byproducts for eco-friendly production of structural mortars. J Clean Prod 231:1389–1398. https://doi.org/10.1016/j.jclepro.2019.05.313

Karim MR, Zain MFM, Jamil M, Lai FC (2015) Development of a zero-cement binder using slag, fly ash, and rice husk ash with chemical activator. Adv Mater Sci Eng. https://doi.org/10.1155/2015/247065

Kusumawardaningsih Y, Fehling E, Ismail M (2015) UHPC compressive strength test specimens: Cylinder or cube? Procedia Eng 125:1076–1080. https://doi.org/10.1016/j.proeng.2015.11.165

Lam NN (2018) A study on super-sulfated cement using Dinh Vu phosphogypsum. IOP Conf Ser Earth Environ Sci. https://doi.org/10.1088/1755-1315/143/1/012016

Levi P, Vass T, Mandova H, Gouy A (2020) Cement. In: IEA. https://www.iea.org/reports/cement

Manh Do T, Kang GO, Sang KY (2019) Development of a new cementless binder for controlled low strength material (CLSM) using entirely by-products. Constr Build Mater 206:576–589. https://doi.org/10.1016/j.conbuildmat.2019.02.088

Mashifana TP, Okonta FN, Ntuli F (2018) Geotechnical properties and microstructure of lime-fly ash-phosphogypsum-stabilized soil. Adv Civ Eng. https://doi.org/10.1155/2018/3640868

Mashifana TP, Okonta FN, Ntuli F (2019) Development of low content phosphogypsum waste composites modified by lime-fly ash-basic oxygen furnace slag. Rev Rom Mater Rom J Mater 49:294–302

Morsy MS, Rashad AM, Shoukry H et al (2020) Development of lime-pozzolan green binder: The influence of anhydrous gypsum and high ambient temperature curing. J Build Eng 28:101026. https://doi.org/10.1016/j.jobe.2019.101026

Puppala AJ (2016) Advances in ground modification with chemical additives: from theory to practice. Transp Geotech 9:123–138. https://doi.org/10.1016/j.trgeo.2016.08.004

Rashad AM (2017) Phosphogypsum as a construction material. J Clean Prod 166:732–743. https://doi.org/10.1016/j.jclepro.2017.08.049

Saadaoui E, Ghazel N, Ben Romdhane C, Massoudi N (2017) Phosphogypsum: potential uses and problems–a review. Int J Environ Stud 74:558–567. https://doi.org/10.1080/00207233.2017.1330582

Shen W, Zhou M, Zhao Q (2007) Study on lime–fly ash–phosphogypsum binder. Constr Build Mater 21:1480–1485. https://doi.org/10.1016/j.conbuildmat.2006.07.010

Acknowledgements

The authors would like to extend their heartfelt gratitude to the managements of Sri Sivasubramaniya Nadar College of Engineering and Tagore Engineering College for providing the necessary facilities to carry out this research work.

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Data availability

The data will be made available upon request.

Additional information

Editorial responsibility: Lifeng Yin.

Rights and permissions

About this article

Cite this article

James, J., Arthi, C., Balaji, G. et al. Lime activated flyash-phosphogypsum blend as a low-cost alternative binder. Int. J. Environ. Sci. Technol. 19, 8969–8978 (2022). https://doi.org/10.1007/s13762-021-03618-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03618-2