Abstract

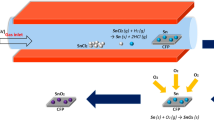

Transition metal oxides (TMOs), such as tin dioxide (SnO2)-based materials, are claimed to be one of the most interesting classes of solids, exhibiting varieties of properties, structures and applications. TMOs have been attracting growing research attention due to their characteristic properties such as plentiful active sites, the high theoretical capacity and diverse reaction mechanisms. Herein, the optimal condition for fabricating SnO2-carbon nanotube (SnO2/CNTs) nanohybrids using the atmospheric pressure chemical vapor deposition and thermal growth process has been described. As well as, the SnO2 thin film was exposed to the functionalized multiwalled carbon nanotubes (F-MWCNTs) via solution mixing for thermal growth process. The effect of essential parameters on optical and morphological properties of thin films was optimized. According to the results, the conditions in which the nanohybrid films had the best quality are as follows: 300 °C re-heating temperature, DMSO solvent, and 6 mg amount of FMWCNTs. Absorption and reflection modes of UV/Vis spectroscopy detected the peak changes of the fabricated films in each stage and confirmed their crystal structure. Furthermore, the crystal structure and atomic composition of the SnO2-carbon nanotubes films were analyzed to assess surface properties of the thin films by scanning electron microscopy and by X-ray diffraction (EDX), respectively. This new synthetic method suggested a facile means to produce SnO2/MWCNT thin films with the aim of using it to fabricate the gas sensors.

Similar content being viewed by others

References

N. Van Hieu, N.A.P. Duc, T. Trung, M.A. Tuan, N.D. Chien, Sens. Actuators B Chem. 144, 450 (2010)

N. Rani, K. Khurana, N. Jaggi, Appl. Nanosci. 11, 2291 (2021)

S. Das, V. Jayaraman, Prog. Mater. Sci. 66, 112 (2014)

Y.-L. Liu, H.-F. Yang, Y. Yang, Z.-M. Liu, G.-L. Shen, R.-Q. Yu, Thin Solid Films 497, 355 (2006)

P. Jayanthi, G. Saranya, J. Duraimurugan, P. Sengodan, S. Ravichandran, R. Usha, N. Bhuvaneshwari, J. Sol-Gel Sci. Technol. 108, 112 (2023)

S. M. Ingole, S. T. Navale, Y. H. Navale, D. K. Bandgar, F. J. Stadler, R. S. Mane, N. S. Ramgir, S. K. Gupta, D. K. Aswal, and V. B. Patil, J. Colloid Interface Sci. (2017).

G.D. Khuspe, R.D. Sakhare, S.T. Navale, M.A. Chougule, Y.D. Kolekar, R.N. Mulik, R.C. Pawar, C.S. Lee, V.B. Patil, Ceram. Int. 39, 8673 (2013)

S.B. Naghadeh, S. Vahdatifar, Y. Mortazavi, A.A. Khodadadi, A. Abbasi, Sens. Actuators B Chem. 223, 252 (2016)

M. Narjinary, P. Rana, A. Sen, M. Pal, Mater. Des. 115, 158 (2017)

Y. Zhao, J. Zhang, Y. Wang, Z. Chen, Nanoscale Res. Lett. 15, 40 (2020)

Y. Jia, L. He, Z. Guo, X. Chen, F. Meng, T. Luo, M. Li, J. Liu, J. Phys. Chem. C 113, 9581 (2009)

S.J. Young, Z.D. Lin, Microsyst. Technol. 24, 55 (2018)

Y.X. Liang, Y.J. Chen, T.H. Wang, Appl. Phys. Lett. 85, 666 (2004)

S. Majumdar, P. Nag, P.S. Devi, Mater. Chem. Phys. 147, 79 (2014)

S. Navazani, M. Hassanisadi, M.M. Eskandari, Z. Talaei, Synth. Met. 260, 116267 (2020)

M.D. Badry, M.A. Wahba, R.K. Khaled, S.K. El-Mahy, J. Electron. Mater. 49, 3191 (2020)

N. Sezer, M. Koç, Surfaces and Interfaces 14, 1 (2019)

A.G. Osorio, I.C.L. Silveira, V.L. Bueno, C.P. Bergmann, Appl. Surf. Sci. 255, 2485 (2008)

R. Sharma, A.K. Sharma, V. Sharma, Cogent Eng. 2, 1094017 (2015)

Y. Fu, N. Nabiollahi, T. Wang, S. Wang, Z. Hu, B. Carlberg, Y. Zhang, X. Wang, J. Liu, Nanotechnology 23, 45304 (2012)

M. Baro, P. Nayak, T.T. Baby, S. Ramaprabhu, J. Mater. Chem. A 1, 482 (2013)

S. Claramunt, O. Monereo, M. Boix, R. Leghrib, J.D. Prades, A. Cornet, P. Merino, C. Merino, A. Cirera, Sens. Actuators B Chem. 187, 401 (2013)

S.-K. Lee, D. Chang, S.W. Kim, J. Hazard. Mater. 268, 110 (2014)

D. Jung, M. Han, G.S. Lee, Carbon N. Y. 78, 156 (2014)

H.E. Unalan, P. Hiralal, D. Kuo, B. Parekh, G. Amaratunga, M. Chhowalla, J. Mater. Chem. 18, 5909 (2008)

C.P. Deck, K. Vecchio, Carbon N. Y. 44, 267 (2006)

K.P. De-Jong, J.W. Geus, Catal. Rev. 42, 481 (2000)

Acknowledgements

This work was done in the Payame Noor University, Mashhad, Iran.

Author information

Authors and Affiliations

Contributions

Somayyeh Ziaei carried out the experiments, involved in data collection, performed the analytic calculations, involved in sample analysis, involved in writing—original draft, and involved in data interpretation. Zarrin Es’haghi involved in conceptualization, supervised the project, verified the analytical methods, contributed to the final version of the manuscript, and edited the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ziaei, S., Es’haghi, Z. Combination of chemical vapor deposition and thermal growth methods for facile synthesis of tin oxide-doped multiwalled carbon nanotubes. J IRAN CHEM SOC 21, 1403–1411 (2024). https://doi.org/10.1007/s13738-024-03007-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-024-03007-9