Abstract

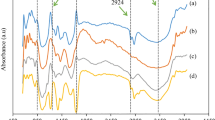

Cellulose acetate was obtained from the coir fiber submitted to the treatment with the IL. The coir fiber was initially subjected to treatment with the n-butylammonium acetate IL (CFIL) and subsequent bleaching (CFILB). By analyzing the CFILB, it was possible to observe a delignification of 6.10% in relation to the natural material and an 8.1% increase in the concentration of cellulose. The results from SEM, XRD, and FTIR-ART confirm the modifications in the fiber. After characterizing the treated coir fiber and obtaining the cellulose acetate, analyses by NMR confirmed its regeneration with a degree of substitution at 2.92. FTIR analyses corroborate with the obtained data, verifying the presence of the main adsorption bands. The XRD analysis of cellulose acetate shows peaks at 8.5° regarding the randomness after the acetylation of cellulose, as well as peaks between 18° and 22.5° regarding the packing of carbon atoms due to the Van der Waals forces, which confirm the production of cellulose acetate. The thermal analysis shows that decomposition events occurred in two stages, indicating the thermal decomposition of the remaining cellulose, which did not undergo acetylation, and attribution to its thermal degradation.

Similar content being viewed by others

References

Candido RG, Godoy GG, Gonçalves AR (2017) Characterization and application of cellulose acetate synthesized from sugarcane bagasse. Carbohydr Polym 167:280–289

Ayeni AO, Daramola MO, Sekoai PT, Adeeyo O, Garba MJ, Awosusi AA (2018) Statistical modelling and optimization of alkaline peroxide oxidation pretreatment process on rice husk cellulosic biomass to enhance enzymatic convertibility and fermentation to ethanol. Cellulose 25:2487–2504

Demirel F, Germec M, Coban HB, Turhan I (2018) Optimization of dilute acid pretreatment of barley husk and oat husk and determination of their chemical composition. Cellulose 25:6377–6393

Moura HOMA, Campos LMA, Silva VL, Andrade JCF, Assumpção SMN, Pontes LAM, Carvalho LS (2018) Investigating acid/peroxide-alkali pretreatment of sugarcane bagasse to isolate high accessibility cellulose applied in acetylation reactions. Cellulose 25:5669–5685

Andrade Neto JC, Cabral AS, Oliveira LRD, Torres RB, Morandim-Giannetti AA (2016) Synthesis and characterization of new low-cost ILs based on butylammonium cation and application to lignocellulose hydrolysis. Carbohydr Polym 143:279–287

Jonoobi M, Oladi R, Davoudpour Y, Oksman K, Dufresne A, Hamzeh Y, Davoodi R (2015) Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: a review. Cellulose 22:935–969

Bai YY, Xiao LP, Sun RC (2014) Efficient hydrolyzation of cellulose in ionic liquid by novel sulfonated biomass-based catalysts. Cellulose 21:2327–2336

Venkateswar RL, Goli JK, Gentela J, Koti S (2016) Bioconversion of lignocellulosic biomass to xylitol: an overview. Bioresour Technol 213:299–310

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Ichiura H, Hirose Y, Masumoto M, Ohtani Y (2017) Ionic liquid treatment for increasing the wet strength of cellulose paper. Cellulose 24:3469–3477

Pang Z, Dong C, Pan X (2016) Enhanced deconstruction and dissolution of lignocellulosic biomass in ionic liquid at high water content by lithium chloride. Cellulose 23:323–338

Boukhriss A, Gmouh S, Hannach H, Roblin JP, Cherkaoui O, Boyer D (2016) Treatment of cotton fabrics by ionic liquid with PF6 − anion for enhancing their flame retardancy and water repellency. Cellulose 23:3355–3364

Nemr AE, RagaB S, Sikaily AE (2017) Rapid synthesis of cellulose triacetate from cotton cellulose and its effect on specific surface area and particle size distribution. Iran Polym J 26:261–272

Ribeiro WCO, Lima ACS, Morandim-Giannetti AA (2018) Optimizing treatment condition of coir fiber with ionic liquid and subsequent enzymatic hydrolysis for future bioethanol production. Cellulose 25:527–536

Goswami M, Das AM (2019) Synthesis and characterization of a biodegradable cellulose acetate montmorillonite composite for effective adsorption of Eosin Y. Carbohydr Polym 206:863–872

Cai J, Zhou R, Li T, He J, Wang G, Wang H, Xiong H (2018) Bamboo cellulose-derived cellulose acetate for electrospun nanofibers: synthesis, characterization and kinetics. Cellulose 25:391–398

Das AM, Ali AA, Hazarika MP (2014) Synthesis and characterization of cellulose acetate from rice husk: eco-friendly condition. Carbohydr Polym 112:342–349

Nabili A, Fattoum A, BrochierSalon MC, Bras J, Elaloui E (2017) Synthesis of cellulose triacetate-I from microfibrillated date seeds cellulose (Phoenix dactylifera L.). Iran Polym J 26:137–147

Kajjout M, Lemmouchi Y, Jama C, Rolando C, Villasmunta F, Heinrich F, Mazzah A (2019) Grafting of amine functions on cellulose acetate fibers by plasma processing. React Funct Polym 134:40–48

Hayakawa D, Gouda H, Hirono S, Ueda K (2019) DFT study of the influence of acetyl groups of cellulose acetate on its intrinsic birefringence and wavelength dependence. Carbohydr Polym 207:122–130

Jatoi AW, Kim IS, Ni QQ (2019) Cellulose acetate nanofibers embedded with AgNPs anchored TiO2 nanoparticles for long term excellent antibacterial applications. Carbohydr Polym 207:640–649

Chen J, Zhan Y, Wang Y, Han D, Tao B, Luo Z, Ma S, Wang Q, Li X, Fan L, Li C, Deng H, Cao F (2018) Chitosan/silk fibroin modified nanofibrous patches with mesenchymal stem cells prevent heart remodeling post-myocardial infarction in rats. Acta Biomater 80:154–168

Asai H, Kato S, Nakane K (2019) Characteristic behavior of a cellulose acetate fiber cross-linked with amorphous TiO2. Solid State Sci 88:67–73

Xin S, Zeng Z, Zhou X, Luo W, Shi X, Wang Q, Deng H, Du Y (2017) Recyclable Saccharomyces cerevisiae loaded nanofibrous mats with sandwich structure constructing via bio-electrospraying for heavy metal removal. J Hazard Mater 324:365–372

Cheng G, Davoudi Z, Xing X, Yu X, Cheng X, Li Z, Deng H, Wang Q (2018) Advanced silk fibroin biomaterials for cartilage regeneration. ACS Biomater Sci Eng 4:2704–2715

Cheng G, Chen J, Wang Q, Yang X, Cheng Y, Li Z, Tu H, Deng H, Li Z (2018) Promoting osteogenic differentiation in pre-osteoblasts and reducing tibial fracture healing time using functional nanofibers. Nano Res 11:3658–3677

Peredo K, Escobar D, Vega-Lara J, Berg A, Pereira M (2016) Thermochemical properties of cellulose acetate blends with acetosolv and sawdust lignin: a comparative study. Macromol Biol J Int 83:403–409

Daud WRW, Djuned FM (2015) Cellulose acetate from oil palm empty fruit bunch via a one-step heterogeneous acetylation. Carbohydr Polym 132:252–260

Bendaoud A, Chalamet Y (2014) Plasticizing effect of ionic liquid on cellulose acetate obtained by melt processing. Carbohydr Polym 108:75–82

Morandim-Giannetti AA, Albuquerque TS, Carvalho RKC, Araújo RMS, Magnabosco R (2013) Study of “napier grass” delignification for production of cellulosic derivatives. Carbohydr Polym 92:849–855

Wise LEM (1946) Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicellulose. Paper Trade J 122:35–43

Technical Association of the Pulp and Paper Industry—TAPPI (2009) TAPPI T203 cm-99: Alpha-, beta- and gamma-cellulose in pulp. Atlanta

Technical Association of the Pulp and Paper Industry—TAPPI (2002) TAPPI T222 om-22: Acid-insoluble lignin in wood and pulp. Atlanta

Kambli ND, Mageshwaran V, Patil PG, Saxena S, Deshmukh RR (2017) Synthesis and characterization of microcrystalline cellulose powder from corn husk fibres using bio-chemical route. Cellulose 24:5355–5369

Naduparambath S, Purushothaman E (2016) Sago seed shell: determination of the composition and isolation of microcrystalline cellulose (MCC). Cellulose 23:1803–1812

Meireles CS, Rodrigues Filho G, Ferreira MF Jr, Cerqueira DA, Assunção RMN, Ribeiro EAM, Poletto P, Zeni M (2010) Characterization of asymmetric membranes of cellulose acetate from biomass: newspaper and mango seed. Carbohydr Polym 80:954–961

Rodrigues Filho G, Monteiro DS, Meireles CS, Assunção RMN, Cerqueira DA, Barud HS, Ribeiro SJ, Messadeq Y (2008) Synthesis and characterization of cellulose acetate produced from recycled newspaper. Carbohydr Polym 73:74–82

Yuan W, Wu K, Liu N, Zhang Y, Wang H (2018) Cellulose acetate fibers with improved mechanical strength prepared with aqueous NMMO as solvent. Cellulose 25:6395–6404

Pavia DL, Lampman GM, Kriz GS (2014) Introduction to spectroscopy, 5th edn. Cengage Learning, Washington

Barud HS, AraújoJúnior AM, Santos DB, Assunção RMN, Meireles CS, Cerqueira DA, Rodrigues Filho G, Ribeiro CA, Messaddeq Y, Ribeiro SJL (2008) Thermal behavior of cellulose acetate produced from homogeneous acetylation of bacterial cellulose. Thermochim Acta 471:61–69

Acknowledgements

This work has been supported by the Fundação Educacional Inaciana Padre Sabóia de Medeiros (FEI) and FAPESP granted scholarship #2017/05485-3. We thank Dr. Nivaldo Boralle for the NMR measurements and LMA-IQ UNESP-Araraquara for making the high-resolution electronic scanning microscope available.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Andrade Neto, J.C., de Almeida, A.C., dos Santos Machado, C. et al. Attainment of cellulose acetate from coir fiber submitted to pretreatment with IL n-butylammonium acetate. Iran Polym J 28, 425–433 (2019). https://doi.org/10.1007/s13726-019-00711-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-019-00711-9