Abstract

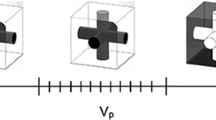

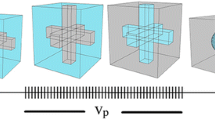

Modeling of polymeric blends has attracted considerable attention due to simplification of blending processes, rapidity in usage and its inexpensive cost. So far, a great deal of effort has been made to seek new models with embodied correct assumptions and application of mathematical calculation process. In this work, direct and independent approximation model (DIA) including a consistency parameter, F(D), is proposed to predict the modulus of polymeric blends. Using F(D), two entirely different models are unified; one implies droplet-matrix structure and the other characterizes the modulus of co-continuous structure. Furthermore, a fraction of interconnected dispersed droplets (co-continuous sector) after percolation threshold is introduced by parameter R(D), which is also based on percolation theory. However, both introduced parameters are mathematically evaluated, and unlike the other proposed models they can simplify the calculation procedure significantly by preventing complicated geometrical shapes and parameters. Furthermore, as another advantage, any model which expresses the mechanical properties of co-continuous and/or droplet-matrix structure could be used as basis of DIA model. Considering pre-indicated volume fractions, a blend of polyamide and polyolefin elastomer was designed to compare the experimental data with DIA model predictions. Also, some other experimental data from other related research findings were used. The coincidence of the experimental data with the corresponding predictions of DIA model shows its high accuracy and validity.

Similar content being viewed by others

References

Galloway JA, Macosko CW (2004) Comparison of methods for the detection of co-continuity in poly(ethylene oxide)/polystyrene blends. Polym Eng Sci 44:714–727

Veenstra H, Verkooijen PCJ, Lent BJJV, Dam JV, Boer APD, Nijhof APHJ (2000) On the mechanical properties of co-continuous polymer blends: experimental and modeling. Polymer 41:1817–1826

Okamoto S, Ishida H (2001) Nondestructive evaluation of the three dimensional morphology of polyethylene/polystyrene blends by thermal conductivity. Macromolecules 34:7392–7402

Mortazavi S, Ghasemi I, Oromiehie A (2013) Effect of phase inversion on the physical and mechanical properties of low density polyethylene/thermoplastic starch. Polym Test 32:482–491

Kolarik J (1997) Three-dimensional models for predicting the modulus and yield strength of polymer blends, foams, and particulate composites. Polym Compos 18:433–441

Wang JF, Carson JK, Willix J, North MF, Cleland DJ (2010) A symmetric and interconnected skeleton structural (SISS) model for predicting thermal and electrical conductivity and Young’s modulus of porous foams. Acta Mater 56:5138–5146

Nijhof AHJ (1998) On the modelling of the elastic properties of polymer blends. LTM-Report 1167, Technical University of Delft

Wang J, Carson JK, North MF, Cleland DJ (2010) A knotted and interconnected skeleton structural model for predicting Young’s modulus of binary phase polymer blends. Polym Eng Sci 50:643–651

Zhao X, Deng S, Huang Y, Liu H, Hu H (2011) Simulation of morphologies and mechanical properties of A/B polymer blend film. Chin J Chem Eng 19:549–557

Deng S, Zhao X, Huang Y, Han X, Liu H, Hu Y (2011) Deformation and fracture of polystyrene/polypropylene blends: a simulation study. Polymer 56:5681–5694

Yousef BF, Mourad AI, Halil-Alnaqbi A (2011) Prediction of the mechanical properties of PE/PP blends using artificial neural network. Procedia Eng 10:2713–2718

Stauffer D, Aharony A (1992) Introduction to percolation theory, vol Chapter 4, 2nd edn. Taylor and Francis, London

Cliquet G, Guillo P (2013) Retail network spatial expansion: an application of percolation theory to hard discounters. Retail Consum Serv 20:173–181

Gabl M, Memmel N, Bertel E (2005) Analysis of compacted and sintered metal powders by temperature-dependent resistivity measurements. Appl Phys Lett 86:042114

Axelos MAV, Kolb M (1990) Crosslinked biopolymers: experimental evidence for scalar percolation theory. Phys Rev Lett 64:1457–1460

Krache R, Debbah I (2011) Some mechanical and thermal properties of PC/ABS blends. Mater Sci Appl 2:404–410

Broz ME, Vande Hart DL, Washburn NR (2003) Structure and mechanical properties of poly(d, l-lactic acid)/poly(ε-caprolactone) blends. Biomaterials 24:4181–4190

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharifzadeh, E., Ghasemi, I., Karrabi, M. et al. A new approach in modeling of mechanical properties of binary phase polymeric blends. Iran Polym J 23, 525–530 (2014). https://doi.org/10.1007/s13726-014-0247-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-014-0247-6