Abstract

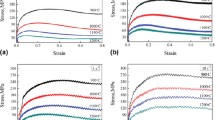

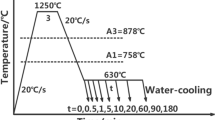

Flow behavior and microstructure characteristics of a Mo–V–Ti micro-alloyed high-strength steel were investigated through hot compression tests with two procedures. In group 1, the specimens were quenched after deformation at temperature range of 800–1100 °C, with strain rate of 10/s. Initiation of dynamic transformation (DT) and dynamic recrystallization (DRX) were confirmed by the evolution characteristics of work hardening rate (θ) during deformation. Critical stresses of both DT and DRX decreased with the increase in deformation temperature. The critical strain for DRX also decreased with the increase in temperature, while the critical strain of DT was less temperature dependent. In group 2, with different holding times at 630 °C after 3-pass deformation, complex precipitates were acquired from all the specimens. For the specimen that was water quenched after deformation, the particles were as fine as 20 nm. For the specimens that were held at 630 °C for 30–120 min, the particles were around 100–200 nm. Mo content in the precipitates decreased with holding time at 630 °C. V content in the particles is much less than Ti content because the Gibbs free energy of TiC is less than that of VC at the same temperature.

Similar content being viewed by others

References

T. Gladman, Precipitation hardening in metals. Mater. Sci. Technol. 15(1), 30–36 (1999)

Z. Ning, Q. Cai, B. Xie et al., The effect of deformation-induced-ferrite-transformation on nanometre-sized carbides in Ti–Mo ferritic steel. Mater. Sci. Technol. 33(10), 1215–1223 (2017)

D.-B. Park, M.-Y. Huh, J.-H. Shim et al., Strengthening mechanism of hot rolled Ti and Nb microalloyed HSLA steels containing Mo and W with various coiling temperature. Mater. Sci. Eng. A 560, 528–534 (2013)

J. Dong, X. Zhou, Y. Liu et al., Carbide precipitation in Nb–V–Ti microalloyed ultra-high strength steel during tempering. Mater. Sci. Eng. A 683, 215–226 (2017)

S.S. Xu, Y. Zhao, X. Tong et al., Independence of work hardening and precipitation strengthening in a nanocluster strengthened steel. J. Alloys Compd. 712, 573–578 (2017)

T. Gladman, Structure-property relationships in high-strength microalloyed steel, in Proc. of Symp. on Microalloying 75, Union Carbide Corp., 1976

K. Seto, Y. Funakawa, K.S. Hot, Rolled high strength steels for suspension and chassis parts “NANOHITEN” and “BHT” steel. JFE Tech. Rep. 10, 19–25 (2007)

Y. Funakawa, T. Shiozaki, K. Tomita et al., Development of high strength hot-rolled sheet steel consisting of ferrite and nanometer-sized carbides. ISIJ Int. 44(11), 1945–1951 (2004)

C.-Y. Chen, J.-R. Yang, C.-C. Chen et al., Microstructural characterization and strengthening behavior of nanometer sized carbides in Ti–Mo microalloyed steels during continuous cooling process. Mater. Charact. 114, 18–29 (2016)

J.H. Jang, Y.U. Heo, C.H. Lee et al., Interphase precipitation in Ti–Nb and Ti–Nb–Mo bearing steel. Mater. Sci. Technol. 29(3), 309–313 (2013)

Y.F. Shen, C.M. Wang, X. Sun, A micro-alloyed ferritic steel strengthened by nanoscale precipitates. Mater. Sci. Eng. A 528(28), 8150–8156 (2011)

H.-W. Yen, P.-Y. Chen, C.-Y. Huang et al., Interphase precipitation of nanometer-sized carbides in a titanium–molybdenum-bearing low-carbon steel. Acta Mater. 59(16), 6264–6274 (2011)

H.-L. Yi, Y. Xu, M.-X. Sun et al., Influence of finishing cooling temperature and holding time on nanometer-size carbide of Nb–Ti microalloyed steel. J. Iron Steel Res. Int. 21(4), 433–438 (2014)

W. Zhou, H. Guo, Z. Xie et al., High strength low-carbon alloyed steel with good ductility by combining the retained austenite and nano-sized precipitates. Mater. Sci. Eng. A 587, 365–371 (2013)

H.-L. Yi, Z.-Y. Liu, G.-D. Wang et al., Development of Ti-microalloyed 600 MPa hot rolled high strength steel. J. Iron Steel Res. Int. 17(12), 54–58 (2010)

Z. Wang, H. Zhang, C. Guo et al., Evolution of (Ti, Mo)C particles in austenite of a Ti–Mo-bearing steel. Mater. Des. 109(Supplement C), 361–366 (2016)

C.Y. Chen, H.W. Yen, F.H. Kao et al., Precipitation hardening of high-strength low-alloy steels by nanometer-sized carbides. Mater. Sci. Eng. A 499(1–2), 162–166 (2009)

K. Zhang, Z.-D. Li, X.-J. Sun et al., Development of Ti–V–Mo complex microalloyed hot-rolled 900-MPa-grade high-strength steel. Acta Metall. Sin. (Engl. Lett.) 28(5), 641–648 (2015)

C. Ghosh, V.V. Basabe, J.J.J.S.R.I. Jonas, Determination of the critical strains for the initiation of dynamic transformation and dynamic recrystallization in four steels of increasing carbon contents. Steel Res. Int. 84(5), 490–494 (2013)

E.I. Poliak, J.J. Jonas, A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization. Acta Mater. 44(1), 127–136 (1996)

C. Aranas Jr., T. Nguyen-Minh, R. Grewal et al., Flow softening-based formation of Widmanstätten ferrite in a 0.06% C steel deformed above the Ae3. ISIJ Int. 55(1), 300–307 (2015)

C. Ghosh, V.V. Basabe, J.J. Jonas et al., The dynamic transformation of deformed austenite at temperatures above the Ae3. Acta Mater. 61(7), 2348–2362 (2013)

J. Wang, P.D. Hodgson, I. Bikmukhametov et al., Effects of hot-deformation on grain boundary precipitation and segregation in Ti–Mo microalloyed steels. Mater. Des. 141, 48–56 (2018)

T.N. Baker, Processes, microstructure and properties of vanadium microalloyed steels. Mater. Sci. Technol. 25(9), 1083–1107 (2009)

J.H. Jang, C.-H. Lee, Y.-U. Heo et al., Stability of (Ti, M)C (M = Nb, V, Mo and W) carbide in steels using first-principles calculations. Acta Mater. 60(1), 208–217 (2012)

S. Jiang, H. Wang, Y. Wu et al., Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 544(7651), 460–464 (2017)

S. Dhara, R.K.W. Marceau, K. Wood et al., Precipitation and clustering in a Ti–Mo steel investigated using atom probe tomography and small-angle neutron scattering. Mater. Sci. Eng. A 718, 74–86 (2018)

S. Mukherjee, I.B. Timokhina, C. Zhu et al., Three-dimensional atom probe microscopy study of interphase precipitation and nanoclusters in thermomechanically treated titanium–molybdenum steels. Acta Mater. 61(7), 2521–2530 (2013)

P. Gong, X.G. Liu, A. Rijkenberg et al., The effect of molybdenum on interphase precipitation and microstructures in microalloyed steels containing titanium and vanadium. Acta Mater. 161, 374–387 (2018)

X.H. Wang, L. Cheng, M. Zhang et al., Reaction synthesis of (Ti, V)C carbide reinforced Fe based surface composite coating by laser cladding. Surf. Eng. 25(3), 211–217 (2009)

L.K. Liang, Thermodynamic analysis of preparation of metallic vanadium (V), vanadium carbide (VC) and vanadium nitride (VN). Iron Steel Vanadium Titan. 20(3), 43–46 (1999)

X.H. Wang, M. Zhang, B.S. Du et al., Microstructure and wear properties of in situ multiple carbides reinforced Fe based surface composite coating produced by laser cladding. Mater. Sci. Technol. 26(8), 935–939 (2010)

Acknowledgements

This work was financially supported by Shandong Provincial Natural Science Foundation, China (Grant No. ZR2014YL003), the National Natural Science Foundation of China (Grant Nos. 11404192 and 11605106), the Key Research and Development Project of Shandong Province, China (Grant No. 2017GSF220004), and the Shandong Province Special Grant for High-Level Overseas Talents and the research fund of Shandong Academy of Sciences (Grant Nos. 2017QN001, 2019GHPY11, and KJHZ201805).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, W., Ding, N., Liu, L. et al. Flow Behavior and Microstructure of a Mo–V–Ti Micro-Alloyed High-Strength Steel. Metallogr. Microstruct. Anal. 9, 252–260 (2020). https://doi.org/10.1007/s13632-020-00627-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-020-00627-4