Abstract

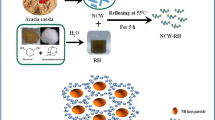

The surface modification of nanocellulose whiskers is vital for improving the compatibility between hydrophilic nanocellulose whiskers (NCW) and hydrophobic natural rubber (NR). In this study, we surface-modified Acacia caesia-derived nanocellulose whiskers using an eco-friendly ball milling method with sodium isopropyl xanthate, a vulcanization accelerator. The resulting sodium isopropyl xanthate (SX)-modified nanocellulose whiskers were comprehensively characterized using various analyses. Incorporating 2 parts per hundred rubber (phr) of SX-modified NCW significantly enhanced tensile strength by 27% and tear strength by 57% compared to unfilled NR gum. Notably, the NR-NCW-SX-2 phr composite exhibited a 21% reduction in swelling index and a 10% decrease in nitrogen gas permeability relative to NR gum. Biodegradability increased with higher filler loadings. High-resolution TEM analysis revealed effective alignment of modified nanocellulose whiskers along rubber particle boundaries, forming a segregated network configuration. In summary, our study elucidates the impact of NCW-SX on NR latex, offering intriguing prospects for applications such as gloves, catheters, swim caps, and related products.

Graphical abstract

Similar content being viewed by others

Data availability

All of the data sets that were included and/or examined in the present study can be obtained from the corresponding author upon request.

References

Julkapli NM, Bagheri S (2017) Progress on nanocrystalline cellulose biocomposites. React Funct Polym 112:9–21. https://doi.org/10.1016/j.reactfunctpolym.2016.12.013

Sinclair A, Zhou X, Tangpong S et al (2019) High-performance styrene-butadiene rubber nanocomposites reinforced by surface-modified cellulose nanofibers. ACS Omega 4:13189–13199. https://doi.org/10.1021/acsomega.9b01313

Thomas SK, Begum PMS, Midhun Dominic CD et al (2021) Isolation and characterization of cellulose nanowhiskers from Acacia caesia plant. J Appl Polym Sci 138:50213. https://doi.org/10.1002/app.50213

Bangar SP, Harussani MM, Ilyas RA et al (2022) Surface modifications of cellulose nanocrystals: processes, properties, and applications. Food Hydrocoll 130:107689. https://doi.org/10.1016/j.foodhyd.2022.107689

Jailudin NAH, Mohd Amin KN (2020) Effect of curing temperature on cellulose nanocrystal reinforced natural rubber latex. J Chem Eng Ind Biotechnol 6:20–25. https://doi.org/10.15282/jceib.v6i1.4875

Thomas SK, Begum PMS, Dileep P et al (2023) Composites of resorcinol and hexamethylenetetramine modified nanocellulose whiskers as potential biofiller in natural rubber latex: synthesis, characterization and property evaluation. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-023-03850-5

Taib MNAM, Yehye WA, Julkapli NM, Hamid SBOAA (2018) Influence of hydrophobicity of acetylated nanocellulose on the mechanical performance of nitrile butadiene rubber (NBR) composites. Fibers Polym 19:383–392. https://doi.org/10.1007/s12221-018-7591-z

Fukui S, Saito T, Ito T et al (2018) (2018) Counterion design of TEMPO-nanocellulose used as filler to improve properties of hydrogenated acrylonitrile-butadiene matrix. Int Conf Nanotechnol Renew Mater 2:769–771

Singh S, Dhakar GL, Kapgate BP et al (2020) Synthesis and chemical modification of crystalline nanocellulose to reinforce natural rubber composites. Polym Adv Technol 31:3059–3069. https://doi.org/10.1002/pat.5030

Zhu G, Dufresne A (2022) Synergistic reinforcing and cross-linking effect of thiol-ene-modified cellulose nanofibrils on natural rubber. Carbohydr Polym 278:118954. https://doi.org/10.1016/j.carbpol.2021.118954

Dearmitt C, Rothon R (2016) Polymers and polymeric composites: a reference series. Polym Polym Compos A Ref Ser. https://doi.org/10.1007/978-3-642-37179-0

Dileep P, Jacob S, Chandra CSJ et al (2022) Functionalized nanosilica for vulcanization efficiency and mechanical properties of natural rubber composites. Silicon 14:4411–4422. https://doi.org/10.1007/s12633-021-01281-3

Zhu K, Liu Y, Wang H et al (2021) Xanthate-modified silica as a novel multifunctional additive for properties improvement of natural rubber. Compos Sci Technol 203:108567. https://doi.org/10.1016/j.compscitech.2020.108567

Liu Y, Wang H, Guo X et al (2021) Xanthate-modified nanoTiO 2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber. 10(1):478–487

Li K, You J, Liu Y et al (2020) Functionalized starch as a novel eco-friendly vulcanization accelerator enhancing mechanical properties of natural rubber. Carbohydr Polym 231:115705. https://doi.org/10.1016/j.carbpol.2019.115705

Ling Z, Wang T, Makarem M et al (2019) Effects of ball milling on the structure of cotton cellulose. Cellulose 26:305–328. https://doi.org/10.1007/s10570-018-02230-x

Kumar M, Xiong X, Wan Z et al (2020) Ball milling as a mechanochemical technology for fabrication of novel biochar nanomaterials. Bioresour Technol 312:123613. https://doi.org/10.1016/j.biortech.2020.123613

Zhixiao C, Miaomiao Q, Chang LIU et al (2021) Surface modification of rice husk ash by ethanol-assisted milling to reinforce the properties of natural rubber/butadiene rubber composites. 37:757–762

Hwang WG, Wei KH, Wu CM (2004) Preparation and mechanical properties of nitrile butadiene rubber/silicate nanocomposites. Polymer (Guildf) 45:5729–5734. https://doi.org/10.1016/j.polymer.2004.05.040

Abraham E, Elbi PA, Deepa B et al (2012) X-ray diffraction and biodegradation analysis of green composites of natural rubber/nanocellulose. Polym Degrad Stab 97:2378–2387. https://doi.org/10.1016/j.polymdegradstab.2012.07.028

Chen W, Yu H, Liu Y et al (2011) Isolation and characterization of cellulose nanofibers from four plant cellulose fibers using a chemical-ultrasonic process. Cellulose 18:433–442. https://doi.org/10.1007/s10570-011-9497-z

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Dalev P, Staromanova E, Dalev D et al (2001) Biodegradation of chemically modified gelatin films in a simulated natural environment. Biotechnol Biotechnol Equip 15:116–123. https://doi.org/10.1080/13102818.2001.10819142

Kalita NK, Nagar MK, Mudenur C et al (2019) Biodegradation of modified poly(lactic acid) based biocomposite films under thermophilic composting conditions. Polym Test 76:522–536. https://doi.org/10.1016/j.polymertesting.2019.02.021

Stenstad P, Andresen M, Tanem BS, Stenius P (2008) Chemical surface modifications of microfibrillated cellulose. Cellulose 15:35–45. https://doi.org/10.1007/s10570-007-9143-y

Larsson PT, Wickholm K, Iversen T (1997) A CP/MAS 13C NMR investigation of molecular ordering in celluloses. Carbohydr Res 302:19–25. https://doi.org/10.1016/S0008-6215(97)00130-4

Thiripura Sundari M, Ramesh A (2012) Isolation and characterization of cellulose nanofibers from the aquatic weed water hyacinth - Eichhornia crassipes. Carbohydr Polym 87:1701–1705. https://doi.org/10.1016/j.carbpol.2011.09.076

Neenu KV, Midhun Dominic CD, Begum PMS et al (2022) Effect of oxalic acid and sulphuric acid hydrolysis on the preparation and properties of pineapple pomace derived cellulose nanofibers and nanopapers. Int J Biol Macromol 209:1745–1759. https://doi.org/10.1016/j.ijbiomac.2022.04.138

Peng H, Wu D, Abdalla M et al (2017) Study of the effect of sodium sulfide as a selective depressor in the separation of chalcopyrite and molybdenite. Minerals 7:51. https://doi.org/10.3390/min7040051

Tang L, Huang B, Yang N et al (2013) Organic solvent-free and efficient manufacture of functionalized cellulose nanocrystals via one-pot tandem reactions. Green Chem 15:2369. https://doi.org/10.1039/c3gc40965a

Reddy KO, Zhang J, Zhang J, Rajulu AV (2014) Preparation and properties of self-reinforced cellulose composite films from Agave microfibrils using an ionic liquid. Carbohydr Polym 114:537–545. https://doi.org/10.1016/j.carbpol.2014.08.054

Somseemee O, Sae-Oui P, Siriwong C (2021) Reinforcement of surface-modified cellulose nanofibrils extracted from Napier grass stem in natural rubber composites. Ind Crops Prod 171:113881. https://doi.org/10.1016/j.indcrop.2021.113881

Prerna Khawas SCD (2016) Isolation and characterization of cellulose nanofibers from culinarybanana peel using high-intensity ultrasonication combined with chemical treatment chemical treatment and ultrasonication. Carbohydr Polym 137:608–616. https://doi.org/10.1016/j.carbpol.2015.11.020

Deepa B, Abraham E, Cordeiro N et al (2015) Utilization of various lignocellulosic biomass for the production of nanocellulose: a comparative study. Cellulose 22:1075–1090. https://doi.org/10.1007/s10570-015-0554-x

Zheng C, Chen W, Ye X (2012) Study on Au nanoparticles, TiO2 nanoclusters, and SiO 2 nanoshells coated multi-wall carbon nanotubes/silica gel-glass. Opt Mater (Amst) 34:1042–1047. https://doi.org/10.1016/j.optmat.2011.12.017

Hashim KKM, Manoj E, Kurup MRP (2021) A novel manganese(II) bisthiocarbohydrazone complex: crystal structures, Hirshfeld surface analysis, DFT and molecular docking study with SARS-CoV-2. J Mol Struct 1246:131125. https://doi.org/10.1016/j.molstruc.2021.131125

Fiorote JA, Freire AP, de Rodrigues DS et al (2019) Preparation of composites from natural rubber and oil palm empty fruit bunch cellulose: effect of cellulose morphology on properties. BioResources 14:3168–3181. https://doi.org/10.15376/biores.14.2.3168-3181

Hu J, Wu H, Liang S et al (2023) Effects of the surface chemical groups of cellulose nanocrystals on the vulcanization and mechanical properties of natural rubber/cellulose nanocrystals nanocomposites. Int J Biol Macromol 230:123168. https://doi.org/10.1016/j.ijbiomac.2023.123168

Gao TM, Huang MF, Xie RH, Chen HL (2013) Preparation and characterization of nano-crystalline cellulose/natural rubber(NCC/NR) composites. Adv Mater Res 712–715:111–114. https://doi.org/10.4028/www.scientific.net/AMR.712-715.111

Lorwanishpaisarn N, Sae-Oui P, Amnuaypanich S, Siriwong C (2023) Fabrication of untreated and silane-treated carboxylated cellulose nanocrystals and their reinforcement in natural rubber biocomposites. Sci Rep 13:1–14. https://doi.org/10.1038/s41598-023-29531-x

Shafik ES (2021) Natural rubber biocomposites based on nanocrystalline and modified nanocrystalline cellulose: curing, mechanical, thermal and electrical properties. J Polym Res 28:1–9. https://doi.org/10.1007/s10965-021-02750-4

Noguchi T, Niihara K, Kurashima A et al (2021) Cellulose nanofiber-reinforced rubber composites prepared by TEMPO-functionalization and elastic kneading. Compos Sci Technol 210:108815. https://doi.org/10.1016/j.compscitech.2021.108815

Sharma SK, Sharma PR, Lin S et al (2020) Reinforcement of natural rubber latex using jute carboxycellulose nanofibers extracted using nitro-oxidation method. Nanomaterials 10:706. https://doi.org/10.3390/nano10040706

Jiang W, Gu J (2020) Nanocrystalline cellulose isolated from different renewable sources to fabricate natural rubber composites with outstanding mechanical properties. Cellulose 27:5801–5813. https://doi.org/10.1007/s10570-020-03209-3

Somseemee O, Saeoui P, Schevenels FT, Siriwong C (2022) Enhanced interfacial interaction between modified cellulose nanocrystals and epoxidized natural rubber via ultraviolet irradiation. Sci Rep 12:6682. https://doi.org/10.1038/s41598-022-10558-5

Zhang W, Zhang X, Liang M, Lu C (2008) Mechanochemical preparation of surface-acetylated cellulose powder to enhance mechanical properties of cellulose-filler-reinforced NR vulcanizates. Compos Sci Technol 68:2479–2484. https://doi.org/10.1016/j.compscitech.2008.05.005

Li Y, Sun H, Zhang Y et al (2019) The three-dimensional heterostructure synthesis of ZnO/cellulosic fibers and its application for rubber composites. Compos Sci Technol 177:10–17. https://doi.org/10.1016/j.compscitech.2019.04.012

Jiang W, Cheng Z, Wang J, Gu J (2022) Modified nanocrystalline cellulose partially replaced carbon black to reinforce natural rubber composites. J Appl Polym Sci 139:1–9. https://doi.org/10.1002/app.52057

Parambath Kanoth B, Claudino M, Johansson M et al (2015) Biocomposites from natural rubber: synergistic effects of functionalized cellulose nanocrystals as both reinforcing and cross-linking agents via free-radical thiol-ene chemistry. ACS Appl Mater Interfaces 7:16303–16310. https://doi.org/10.1021/acsami.5b03115

Xu SH, Gu J, Luo YF, Jia DM (2012) Effects of partial replacement of silica with surface modified nanocrystalline cellulose on properties of natural rubber nanocomposites. Express Polym Lett 6:14–25. https://doi.org/10.3144/expresspolymlett.2012.3

Zhang C, Zhai T, Sabo R et al (2014) Reinforcing natural rubber with cellulose nanofibrils extracted from bleached eucalyptus kraft pulp. J Biobased Mater Bioenergy 8:317–324. https://doi.org/10.1166/jbmb.2014.1441

Silva MJ, Sanches AO, Medeiros ES et al (2014) Nanocomposites of natural rubber and polyaniline-modified cellulose nanofibrils. J Therm Anal Calorim 117:387–392. https://doi.org/10.1007/s10973-014-3719-1

Agrebi F, Ghorbel N, Bresson S et al (2019) Study of nanocomposites based on cellulose nanoparticles and natural rubber latex by ATR/FTIR spectroscopy: The impact of reinforcement. Polym Compos 40:2076–2087. https://doi.org/10.1002/pc.24989

Supanakorn G, Taokaew S, Phisalaphong M (2021) Ternary composite films of natural rubber, cellulose microfiber, and carboxymethyl cellulose for excellent mechanical properties, biodegradability and chemical resistance. Cellulose 4. https://doi.org/10.1007/s10570-021-04082-4

Dominic M, Joseph R, Sabura BP et al (2020) Green tire technology: effect of rice husk derived nanocellulose (RHNC) in replacing carbon black (CB) in natural rubber (NR) compounding. Carbohydr Polym 230:115620. https://doi.org/10.1016/j.carbpol.2019.115620

Zhan Y, Lago E, Santillo C et al (2020) An anisotropic layer-by-layer carbon nanotube/boron nitride/rubber composite and its application in electromagnetic shielding. Nanoscale 12:7782–7791. https://doi.org/10.1039/c9nr10672c

Blanchard R, Ogunsona EO, Hojabr S et al (2020) Synergistic cross-linking and reinforcing enhancement of rubber latex with cellulose nanocrystals for glove applications. ACS Appl Polym Mater 2:887–898. https://doi.org/10.1021/acsapm.9b01117

Abraham E, Deepa B, Pothan LA et al (2013) Physicomechanical properties of nanocomposites based on cellulose nanofibre and natural rubber latex. Cellulose 20:417–427. https://doi.org/10.1007/s10570-012-9830-1

Joseph S, Sreekumar PA, Kenny JM, Puglia D, Thomas S, Joseph K Dynamic mechanical analysis of oil palm microfibril- reinforced acrylonitrile butadiene rubber composites. Polym Compos 16:101–113. https://doi.org/10.1002/pc.20791

Gheith MH, Aziz MA, Ghori W et al (2019) Flexural, thermal and dynamic mechanical properties of date palm fibres reinforced epoxy composites. J Mater Res Technol 8:853–860. https://doi.org/10.1016/j.jmrt.2018.06.013

Chee SS, Jawaid M, Sultan MTH et al (2019) Thermomechanical and dynamic mechanical properties of bamboo/woven kenaf mat reinforced epoxy hybrid composites. Compos Part B Eng 163:165–174. https://doi.org/10.1016/j.compositesb.2018.11.039

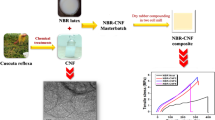

Dominic CDM, Joseph R, Begum PMS et al (2020) Cellulose nanofibers isolated from the Cuscuta reflexa plant as a green reinforcement of natural rubber. Polymers (Basel) 12:814. https://doi.org/10.3390/polym12040814

Visakh PM, Thomas S, Oksman K, Mathew AP (2012) Crosslinked natural rubber nanocomposites reinforced with cellulose whiskers isolated from bamboo waste: processing and mechanical/thermal properties. Compos Part A Appl Sci Manuf 43:735–741. https://doi.org/10.1016/j.compositesa.2011.12.015

Abraham E, Thomas MS, John C et al (2013) Green nanocomposites of natural rubber/nanocellulose: membrane transport, rheological and thermal degradation characterisations. Ind Crops Prod 51:415–424. https://doi.org/10.1016/j.indcrop.2013.09.022

Bendahou A, Kaddami H, Dufresne A (2010) Investigation on the effect of cellulosic nanoparticles’ morphology on the properties of natural rubber based nanocomposites. Eur Polym J 46:609–620. https://doi.org/10.1016/j.eurpolymj.2009.12.025

Siqueira G, Bras J, Dufresne A (2010) Cellulosic bionanocomposites: a review of preparation, properties and applications. Polymers (Basel) 2:728–765. https://doi.org/10.3390/polym2040728

Potivara K, Phisalaphong M (2019) Development and characterization of bacterial cellulose reinforced with natural rubber. Materials (Basel) 12. https://doi.org/10.3390/ma12142323

Abraham J, Maria HJ, George SC et al (2015) Transport characteristics of organic solvents through carbon nanotube filled styrene butadiene rubber nanocomposites: the influence of rubber-filler interaction, the degree of reinforcement and morphology. Phys Chem Chem Phys 17:11217–11228. https://doi.org/10.1039/c5cp00719d

Bras J, Hassan ML, Bruzesse C et al (2010) Mechanical, barrier, and biodegradability properties of bagasse cellulose whiskers reinforced natural rubber nanocomposites. Ind Crops Prod 32:627–633. https://doi.org/10.1016/j.indcrop.2010.07.018

Stelescu MD, Manaila E, Craciun G, Chirila C (2017) Development and characterization of polymer eco-composites based on natural rubber reinforced with natural fibers. Materials (Basel) 10:1–20. https://doi.org/10.3390/ma10070787

Phomrak S, Phisalaphong M (2017) Reinforcement of natural rubber with bacterial cellulose via a latex aqueous microdispersion process. J Nanomater 2017. https://doi.org/10.1155/2017/4739793

Stephen R, Ranganathaiah C, Varghese S et al (2006) Gas transport through nano and micro composites of natural rubber (NR) and their blends with carboxylated styrene butadiene rubber (XSBR) latex membranes. Polymer (Guildf) 47:858–870. https://doi.org/10.1016/j.polymer.2005.12.020

Acknowledgements

Seena K. Thomas would like to acknowledge CSIR for the fellowship given for doing this work. The authors acknowledge Rubber Park India (P) Ltd., Airapuram; STIC, CUSAT; PSRT, CUSAT; and DOP, CUSAT, also for helping to do analysis in time. The authors also would like to acknowledge IUCND, CUSAT, and Anugop B. and Vijoy K.V. at International School of Photonics, CUSAT, for material characterization.

Author information

Authors and Affiliations

Contributions

Seena K. Thomas: conceptualization, methodology, visualization, and writing original draft; P. M. Sabura Begum: supervision; Neenu K. V.: investigation; Dhanyasree P.: data curation; Dileep P.: formal analysis and resources; Lakshmipriya Ravindran: investigation; Chomsri Siriwong: methodology, writing, reviewing, and editing; Yongxin Duan: writing, reviewing, and editing, Michael Badawi: resources, funding acquisition, writing, reviewing, and editing; Midhun Dominic C. D.: writing, reviewing, and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Declaration of generative AI and AI-assisted technologies in the writing process

During the preparation of this work the corresponding author (Midhun Dominic C D) used [ChatGpt] in order to improve the language and readability. After using this tool/service, the author reviewed and edited the content as needed and takes full responsibility for the content of the publication.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thomas, S.K., Begum, P.S., Neenu, K. et al. Tailoring natural rubber composites via surface-modified nanocellulose whiskers with sodium isopropyl xanthate: characterization and performance analysis. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05647-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05647-6