Abstract

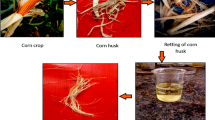

This study investigates the synergistic effects of incorporating heat-treated rice husk Si3N4 bioceramic and corn husk fibers in high-content cellulosic corn husk fiber-polyester composites (E0 to E4). Mechanical, flammability, and fatigue properties are comprehensively analyzed. Tensile strength and modulus exhibit significant improvements, showcasing Si3N4’s positive impact. Flexural properties demonstrate synergies between Si3N4 and corn husk fibers. SEM analysis validates reinforcing mechanisms, emphasizing improved matrix adhesion and toughened matrices. Impact strength, hardness, wear resistance, and flame resistance all show positive trends, highlighting Si3N4’s pivotal role in enhancing these properties. Tensile creep analysis indicates Si3N4’s influence in minimizing deformation over time. Fatigue performance reflects the synergistic effects of corn husk fibers and Si3N4. Overall, these composites demonstrate enhanced mechanical strength, durability, and flame resistance, suggesting their potential for diverse applications requiring superior material properties. The study provides valuable insights into the multifaceted improvements achievable through the strategic combination of heat-treated Si3N4 and natural fiber in composite materials, offering a promising avenue for advanced material development with applications in drones, automotives, aviation, and radomes.

Similar content being viewed by others

Data availability

All data are in manuscript.

References

Islam MR, Beg MDH (2019) Thermo-mechanical properties of glass fiber and functionalized multi-walled carbon nanotubes filled polyester composites. Polym Compos 40:E1235–E1242. https://doi.org/10.1002/pc.24954

Islam MR, Beg MDH (2018) Dispersion characteristics of hydroxyl and carboxyl-functionalized multi-walled carbon nanotubes in polyester nanocomposites. J Polym Eng 38(8):759–765

Faiza W, Firouzi A, Islam MR, Sumdani G, Taher A (2021) Degradation analysis of epoxy resin composites reinforced with bioprotein: effects of hydrolysis using papain and bromelain. Polym Compos 42:2717–2727. https://doi.org/10.1002/pc.26007

Bijlwan PP, Prasad L, Sharma A, Kumar S (2023) Taguchi optimized sliding wear behavior and hardness of novel Grewia optiva/basalt fiber reinforced hybrid polyester composites. J Appl Polym Sci 140(30):e54106. https://doi.org/10.1002/app.54106

Hanny A, Islam MR, Sumdani MG, Rashidi NM (2019) The effects of sintering on the properties of epoxy composites reinforced with chicken bone-based hydroxyapatites. Polym Testing 78:105987

Maou S, Meftah Y, Bouchamia I, Benyaghla A (2023) Alkali-treated date palm fiber-reinforced unsaturated polyester composites: thermo-mechanical performances and structural applications. Iran Polym J 32(12):1581–1593. https://doi.org/10.1007/s13726-023-01224-2

Jamaluddin JF, Firouzi A, Islam MR et al (2020) Effects of luffa and glass fibers in polyurethane-based ternary sandwich composites for building materials. SN Appl Sci 2:1207. https://doi.org/10.1007/s42452-020-3037-0

Hani F, Firouzi A, Islam MR, Sumdani MG (2021) Mechanical and thermal properties of fishbone-based epoxy composites: the effects of thermal treatment. Polym Compos 42:1224–1234. https://doi.org/10.1002/pc.25895

Sari NH, Suteja S (2020) Corn husk fibers reinforced polyester composites: tensile strength properties, water absorption behavior, and morphology. In IOP conference series: materials science and engineering (Vol. 722, No. 1, p. 012035). IOP Publishing. https://doi.org/10.1088/1757-899X/722/1/012035

Dharmalingam S, Sasikumar T (2023) Mechanical, wear, and flammability properties of silanized cow dung biosilica-dispersed corn husk fiber-reinforced epoxy composites. Biomass Convers Biorefinery 1–11. https://doi.org/10.1007/s13399-023-05082-z

Alomaja JA, Jimoh AA, Joseph OP, Wilson UN (2023) Flexural and tensile properties of chemically treated guinea corn husk-cow hair hybrid fiber reinforced cement composite. Mater Today: Proceedings. https://doi.org/10.1016/j.matpr.2023.03.121

Daniel A, Islam MR, Sumdani MG, Firouzi A (2021) Influence of hydration on the mechanical, structural, thermal, and morphological properties of cement filled epoxy composites. J Vinyl Addit Technol 27:119–126. https://doi.org/10.1002/vnl.21789

Islam MR, Beg MDH (2019) Thermo-mechanical properties of glass fiber and functionalized multi-walled carbon nanotubes filled polyester composites. Polym Compos 40(S2):E1235–E1242. https://doi.org/10.1002/pc.24954

Raja T, Devarajan Y (2023) Mechanical and thermal stability of Millettia pinnata fibre-reinforced ZrO2 nanofiller particulates polyester composite—an experimental study. Biomass Convers Biorefinery 1–8. https://doi.org/10.1007/s13399-023-04837-y

Velmurugan G, Shankar VS, Rahiman MK, Prathiba R, Dhilipnithish LR, Khan FA (2023) Effectiveness of silica addition on the mechanical properties of jute/polyester based natural composite. Mater Today: Proceedings 72:2075–2081. https://doi.org/10.1016/j.matpr.2022.08.138

Bhuvaneswari V, Balaji D, Jeyakumar R, Srinivasan N, Rajeshkumar L (2023) Effect of limestone powder as bioceramic reinforcement on mechanical and tribological properties of aluminium matrix composites. Mater Today: Proceedings. https://doi.org/10.1016/j.matpr.2022.12.154

Venkatesh R, Sakthivel P, Selvakumar G, Krishnan AM, Purushothaman P, Priya CB (2023) Mechanical and thermal properties of a waste fly ash-bonded Al-10 Mg alloy composite improved by bioceramic silicon nanoparticles. Biomass Convers Biorefinery 1–12. https://doi.org/10.1007/s13399-023-04588-w

Chandrashekhar KG, Laxmaiah G, P RK, Ramesh B (2023) Load-bearing characteristics of a hybrid si3n4-epoxy composite. Biomass Convers Biorefinery 1–9. https://doi.org/10.1007/s13399-023-04577-z

Dwivedi, S. P., Selvaprakash, S., Sharma, S., Kumari, S., Saxena, K. K., Goyal, R., ... &Djavanroodi, F. (2023). Evaluation of various properties for spent alumina catalyst and Si3N4 reinforced with PET-based polymer composite. Mech Adv Mater Struct 1–11. https://doi.org/10.1080/15376494.2023.2249888

de Andrade, R., Paim, T. C., Bertaco, I., Naasani, L. S., Buchner, S., Kovářík, T., ... & Wink, M. R. (2023). Hierarchically porous bioceramics based on geopolymer-hydroxyapatite composite as a novel biomaterial: structure, mechanical properties and biocompatibility evaluation. Appl Mater Today 33:101875. https://doi.org/10.1016/j.apmt.2023.101875

Yelten A, Yilmaz S (2019) A novel approach on the synthesis and characterization of bioceramic composites. Ceram Int 45(12):15375–15384. https://doi.org/10.1016/j.ceramint.2019.05.031

Drupitha MP, Misra M, Mohanty AK (2023) Recent advances on value-added biocarbon preparation by the pyrolysis of renewable and waste biomass, their structure and properties: a move toward an ecofriendly alternative to carbon black. Environ Sci: Advances. https://doi.org/10.1039/D3VA00107E

Islam MR, Beg MDH (2018) Dispersion characteristics of hydroxyl and carboxyl-functionalized multi-walled carbon nanotubes in polyester nanocomposites. J Polym Eng 38(8):759–765. https://doi.org/10.1515/polyeng-2017-0363

Sundarababu J, Anandan SS, Griskevicius P (2021) Evaluation of mechanical properties of biodegradable coconut shell/rice husk powder polymer composites for light weight applications. Mater Today: Proceedings 39:1241–1247. https://doi.org/10.1016/j.matpr.2020.04.095

Sajin JB, Aurtherson PB, Binoj JS, Manikandan N, Saravanan MS, Haarison TM (2021) Influence of fiber length on mechanical properties and microstructural analysis of jute fiber reinforced polymer composites. Mater Today: Proceedings 39:398–402. https://doi.org/10.1016/j.matpr.2020.07.623

Bourchak M, Ajaj RM, Khalid M, Juhany K (2023) Development of light weight sustainable pineapple/kevlar hybridized fiber and peanut husk cellulose toughened vinyl ester biocomposite for unmanned aerial vehicle applications. J Vinyl Addit Technol 1. https://doi.org/10.1002/vnl.21990

Naveen J, Jawaid M, Zainudin ES, Sultan MTH, Yahaya R (2019) Mechanical and moisture diffusion behaviour of hybrid Kevlar/Cocos nucifera sheath reinforced epoxy composites. J Mater Res Technol 8:1308. https://doi.org/10.1016/j.jmrt.2018.07.023

Prabhu P, Jayabalakrishnan D, Balaji V, Bhaskar K (2022) Mechanical, tribology, dielectric, thermal conductivity, and water absorption behaviour of Caryota urens woven fibre-reinforced coconut husk biochar toughened wood-plastic composite. Bio- mass ConvBioref. https://doi.org/10.1007/s13399-021-02177-3

Inbakumar JP, Ramesh S (2018) Mechanical, wear and thermal behaviour of hemp fibre/egg shell particle reinforced epoxy resin bio composite. Trans Can SocMech Eng 42(3):280–285. https://doi.org/10.1139/tcsme-2017-0079

ArunPrakash VR, Jayaseelan V, Mothilal T et al (2020) Effect of silicon coupling grafted ferric oxide and e-glass fibre in thermal stability, wear and tensile fatigue behaviour of epoxy hybrid composite. Silicon 12:2533–2544. https://doi.org/10.1007/s12633-019-00347-7

Suriani MJ, Radzi FSM, Ilyas RA, Petru M, Sapuan SM, Ruzaidi CM (2021) Flammability, tensile, and morphological properties of oil palm empty fruit bunches fiber/pet yarn-reinforced epoxy fire retardant hybrid polymer composites. Polymers 13:1282. https://doi.org/10.3390/polym13081282

Omanovic-Miklicanin E, Badnjevic A, Kazlagic A, Hajlovac M (2020) Nanocomposites: a brief review. Health Technol 10:51–59. https://doi.org/10.1007/s12553-019-00380-x

Rajadurai A (2016) Thermo-mechanical characterization of siliconized E-glass fiber/hematite particles reinforced epoxy resin hybrid composite. Appl Surf Sci 384:99–106

Xiang G, Yin D, Meng R, Lu S (2020) Creep model for natural fiber polymer composites (NFPCs) based on variable order fractional derivatives: simulation and parameter study. J ApplPolym Sci 137:48796. https://doi.org/10.1002/app.48796

AsimShahzad Post-impact fatigue properties of hemp and glass fibre composites, biocomposites: properties, performance and applications ISBN: 978–1–53612–120–9

Todkar SS, Patil SA (2019) Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites. Compos B Eng 174:106927. https://doi.org/10.1016/j.compositesb.2019.106927

Prakash VA, Viswanthan R (2019) Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos A Appl Sci Manuf 1(118):317–326

Alshahrani H, Arun Prakash V (2024) Characterisation of microcrystalline cellulose from waste green pea pod sheath and its sunn hemp fibre-polyester composite: A step towards greener manufacturing. Physiologia Plantarum 176(1):e14166. https://doi.org/10.1111/ppl.14166

Khan MKA, Faisal M, Arun Prakash VR (2024) Effect of silane coupling grafted polyethylene terephthalate foam and areca fruit fiber reinforced chitin modified vinyl ester prosthetic composite on thermal and water accelerated aging conditions. Polym Compos 1–14. https://doi.org/10.1002/pc.28114

Alshahrani H, Arun Prakash VR (2023) Load bearing investigations on novel acrylonitrile butadiene styrene-carbon quantum dots 3D printed core/bamboo fiber polyester sandwich composite for structural applications. Polym Compos 1–13. https://doi.org/10.1002/pc.27972

Alshahrani H, Prakash VA (2023) Development of highly flexible electromagnetic interference shielding composites for electronic applications using Cobalt/Hevea brasiliensis seed husk carbon dots/Bamboo microfibre-polyvinyl alcohol. Ind Crops Prod 191:115967

Funding

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through a Large Group Research Project under grant number: RGP 2/177/44.

Author information

Authors and Affiliations

Contributions

Mohan Das Gandhi A.G.—research idea creation and execution. Sivaraman R.—testing and other support. Nagabooshnam N. and Rajesh Verma R—testing.

Corresponding author

Ethics declarations

Ethical approval

NA

Competing interests

The authors declare is no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Das Gandhi, A.G.M., Sivaraman, R., Nagabooshnam, N. et al. Characterization of heat-treated rice husk Si3N4 bioceramic on cellulosic corn husk fiber-polyester composite. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05390-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05390-y